1/6ページ

ダウンロード(849Kb)

最高の柔軟性とコントロール

マルチパラメータ変換器は、純水とプロセスアプリケーションの pH/ORP、光学式 DO、アンペロメトリック O2(DO および O2 ガス)、導電率、比抵抗、溶存酸素、流量、濁度の測定を行う 1、2、または 4本のインラインセンサを同時にモニタリングできます。

このカタログについて

| ドキュメント名 | マルチパラメータプロセス分析変換器『M800』カタログ |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 849Kb |

| 取り扱い企業 | メトラー・トレド株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

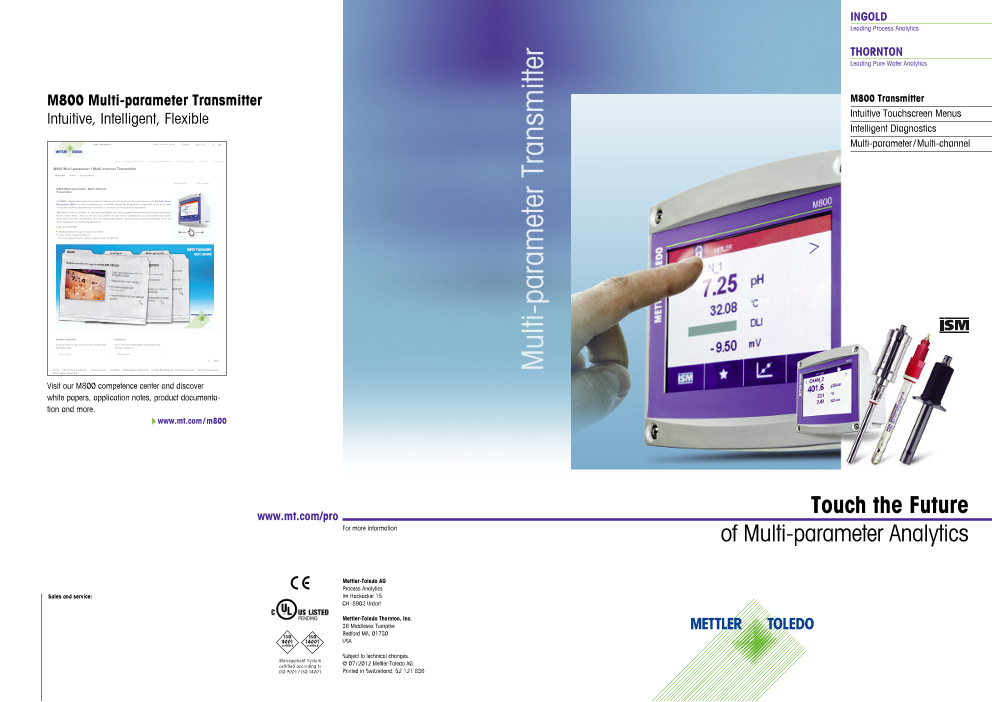

INGOLD

Leading Process Analytics

THORNTON

Leading Pure Water Analytics

M800 Multi-parameter Transmitter M800 Transmitter

Intuitive, Intelligent, Flexible Intuitive Touchscreen Menus

Intelligent Diagnostics

Login / Registration Other Countries / Areas English Search for... Go Multi-parameter /Multi-channel

Home Products & Solutions Industries & Workplaces Services & Support About Us Contact Us

M800 Multi-parameter / Multi-channel Transmitter

Overview Details Documentation

Request Info Get a Quote

M800 Multi-parameter / Multi-channel

Transmitter

The M800 multiparameter transmitter provides simultaneous monitoring of up to four in-line sensors with Intelligent Sensor

Management (ISM) technology for measurement of pH/ORP, optical DO, amperometric oxygen (DO as well as O2 gas),

conductivity, resistivity, dissolved ozone and flow, in pure water as well as process applications.

ISM features Plug and Measure for fast sensor installation and start up, predictive maintenance information and dynamic

sensor lifetime status. Thanks to iMonitor, the condition of each sensor is determined at a glance allowing preventive

action before processes are affected. The color touchscreen provides intuitive operation, with user selectable control and

alarm management for challenging applications.

Features and Benefits:

Simple operation through intuitive user interface

Lower cost of measurement point

Predictive diagnostics and improved maintenance management

Request a Quotation Contact Us

If you are ready to buy or need a quote, request more If you need more details about our products and

information here. services, contact us.

Get a Quote Request Info

| More

Home Find Products & Solutions Process Analytics Transmitter Multiparameter Transmitter Process Multiparameter Transmitters (Ingold) M800 Multi-parameter /

Multi-channel Transmitter

Visit our M800 competence center and discover

white papers, application notes, product documenta-

tion and more.

4www.mt.com/m800

www.mt.com/pro Touch the Future

For more information of Multi-parameter Analytics

Mettler-Toledo AG

Process Analytics

Sales and service: Im Hackacker 15

CH-8902 Urdorf

Mettler-Toledo Thornton, Inc.

36 Middlesex Turnpike

Bedford MA, 01730

ISO ISO

9001 14001 USA

certified certified

Subject to technical changes.

Management System

certified according to © 07/2012 Mettler-Toledo AG.

ISO 9001 / ISO 14001 Printed in Switzerland. 52 121 836

Multi-parameter Transmitter

Page2

M800 Multi-parameter Transmitter

Intuitive, Intelligent, Flexible

Improved productivity, lower operating costs and reliable processes. High-

performance process analytical systems help you accomplish all of this.

With the M800 multi-parameter, multi-channel transmitter, intuitive opera-

tion saves time, predictive maintenance ensures reliability and reduces

maintenance, and multi-channel installation reduces cost per measurement.

Convenience meets performance solved oxygen and conductivity

You need assurance that your mean that one transmitter family

processes are running to specifica- can cover all your process meas-

tion. The M800 transmitter is the urement needs.

ideal combination of convenience

and performance in a cost-effective Intelligent Sensor Management

multi-parameter instrument. (ISM)

ISM enables you to take full advan- Intuitive Touchscreen Operation

The M800 is focused on providing tage of digital sensor-transmitter The large, button-free front panel provides intuitive

reliable and accurate measure- communication for excellent signal and simple operation, clear and tailorable informa-

ments, convenient operation, stability, fast sensor commissioning tion, and fast access to any menu or function.

at-a-glance diagnostics, and and predictive maintenance.

system flexibility and security. For details about the ISM technology

Its multi-parameter capabilities for see page 7. Intelligent Diagnostics

pH, amperometric and optical dis- The unique iMonitor offers predictive diagnostics

using traffic light color coding to warn you of sensor

problems and tells you how to rectify them – before

performance is affected.

Flexible and Secure

Multi-parameter, multi-channel capabilities mean that

one transmitter family can be utilized throughout

your facility. User management and internal logbook

features provide excellent security and reduce human

error.

Actual size

2 3

M800 Multi-parameter Transmitter

Page3

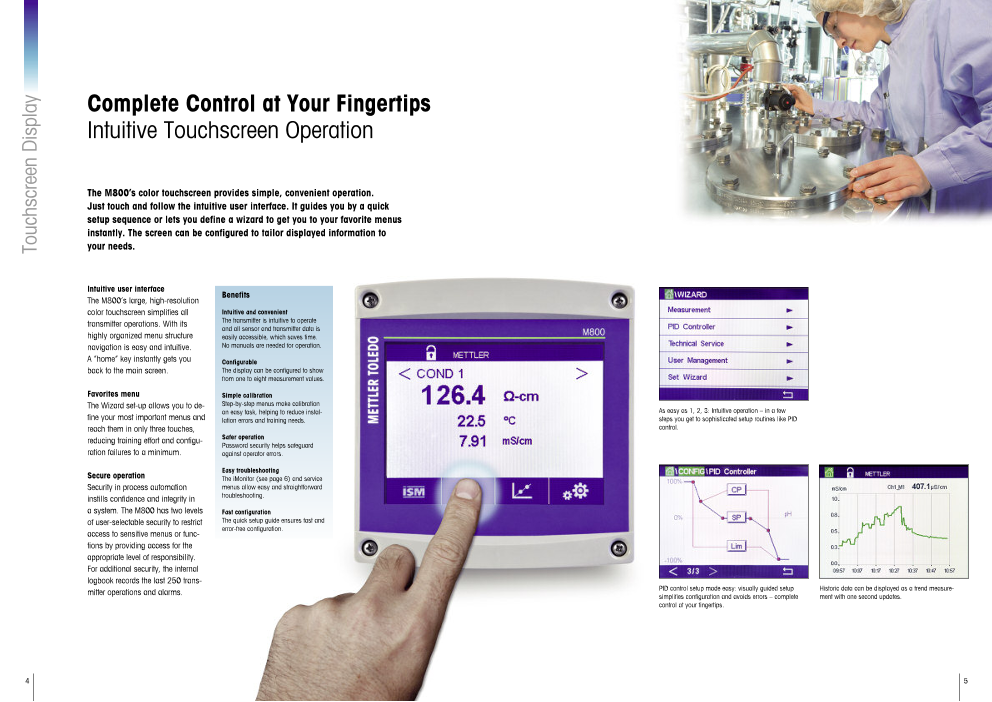

Complete Control at Your Fingertips

Intuitive Touchscreen Operation

The M800’s color touchscreen provides simple, convenient operation.

Just touch and follow the intuitive user interface. It guides you by a quick

setup sequence or lets you define a wizard to get you to your favorite menus

instantly. The screen can be configured to tailor displayed information to

your needs.

Intuitive user interface

Benefits

The M800’s large, high-resolution

color touchscreen simplifies all Intuitive and convenient

transmitter operations. With its The transmitter is intuitive to operate

and all sensor and transmitter data is

highly organized menu structure easily accessible, which saves time.

navigation is easy and intuitive. No manuals are needed for operation.

A “home” key instantly gets you Configurable

back to the main screen. The display can be configured to show

from one to eight measurement values.

Favorites menu Simple calibration

The Wizard set-up allows you to de- Step-by-step menus make calibration

an easy task, helping to reduce instal- As easy as 1, 2, 3: Intuitive operation – in a few

fine your most important menus and lation errors and training needs. steps you get to sophisticated setup routines like PID

reach them in only three touches, control.

reducing training effort and configu- Safer operation

Password security helps safeguard

ration failures to a minimum. against operator errors.

Easy troubleshooting

Secure operation The iMonitor (see page 6) and service

Security in process automation menus allow easy and straightforward

instills confidence and integrity in troubleshooting.

a system. The M800 has two levels Fast configuration

of user-selectable security to restrict The quick setup guide ensures fast and

error-free configuration.

access to sensitive menus or func-

tions by providing access for the

appropriate level of responsibility.

For additional security, the internal

logbook records the last 250 trans-

mitter operations and alarms. PID control setup made easy: visually guided setup Historic data can be displayed as a trend measure-simplifies configuration and avoids errors – complete ment with one second updates.

control at your fingertips.

4 5

Touchscreen Display

Page4

iMonitor: Intelligent Diagnostics

Ensure High Process Reliability

Most scheduled maintenance is unnecessary and doesn’t always prevent

unplanned shutdowns due to failed sensors. With its unique iMonitor

predictive diagnostics functionality, based on METTLER TOLEDO’s ISM

technology, the M800 tells you not only what is wrong with a sensor but

how to fix it – before a problem arises.

Reduce maintenance Dynamic Lifetime Indicator

Benefits (DLI) ISM at a glanceWhy schedule maintenance when it DLI DynamiAc Lifetime Indicator esti-

Dynamic Lifetime Indicator

is not required? A great deal of time Reduced maintenance costs through mates in real-time the remaining Intelligent

is spent maintaining plant equip- ISM lifetime of the sensor. • Digital sensor technology offers

Real-time measurement sensor data easy handling and enhanced sensor

ment, but over 60% of mainte- are included in proprietary algorithms Time to Maintenance (TTM) performance.

nance work is unnecessary. leading to online predictive mainte-

nance information. iMonitor provides TTM The sensor also indicates

• Sensors can be pre-calibrated and

Time to Maintenance when you will have to perform stored for later use.

an at-a-glance overview of all sensors’ the next maintenance. • Electronic documentation of calibra-

Predictive diagnostics with health status and allows the user to tion and maintenance for regulatory

iMonitor • avoid unexpected process downtime Adaptive Calibration Timer compliance.

• estimate measurement accuracy, (ACT)

iMonitor constantly checks the predict failure and plan maintenance ACT Based on the above algorithm Predictive

Adaptive Calibration Timer

condition of all connected sensors. schedules more efficiently the sensor predicts the time • Avoid unscheduled maintenance with

• convert to a new revolutionary main-

Should a sensor need cleaning, when the next calibration will

real-time diagnostics.

tenance management which will sig- be needed. • Unique software provides instant

calibrating or replacement, an nificantly reduce maintenance costs. evaluation of sensor condition.

alarm is triggered and iMonitor tells CIP/SIPM C ounter

At-a-glance warnings 00/NN CIP and SIP cycles are Adaptive

you what is wrong and indicates Flashing red bar provides instant notice CIP interpreted with a proprietary, • Flexible system integration via trans-CIP/SIP Counter

how to rectify it. of sensor issues. patented algorithm. mitters, converters or Ethernet allows

integration of diagnostic information.

Predictive indicator for problems • Digital technology permits temporary,

Use of traffic light color coding Clear information on how and when to remote and wireless solutions.

provides continuous notification of restore sensor condition.

Tailorable

sensor health: Complete overview • Industry specific solutions tailored to

All sensors monitored in real-time and respective needs, from Biopharma to

displayed on iMonitor for at-a-glance Chemical to Food and Beverage.

maintenance required overview.

maintenance required

soon

good to go

Learn more about ISM

www.mt.com/ISM

6 7

Predictive Diagnostics

Page5

Powerful Flexibility

More Parameters, More Channels

Having a variety of different transmitter models at your facility means

increased system complexity, additional training for operators and

maintenance engineers, larger inventory and greater risk of human error.

The multi-parameter, multi-channel M800 transmitter with its user

management and logbook features answers all these concerns while

reducing cost per measurement point.

Multi-parameter

Benefits

The advantages of one transmitter

model that can analyze pH, ORP, Lower inventory

conductivity / resistivity, dissolved Multi-parameter Measurement System One transmitter model for all processes

and parameters.

oxygen, dissolved ozone and flow

with more parameters to follow, are Versatility

One transmitter can measure up to four

obvious: greater flexibility, less different parameters plus flow.

complexity, and less training and Flow

inventory. Order only one model of Low cost per measurement

Flow Multiple sensors on one transmitter

transmitter for your process analyt- reduces cost per measurement point

ics needs. and saves space.

Simpler handling for fabricators

Multi-channel Transmitter configurations can be

Two- and four-channel M800 trans- downloaded to a PC and uploaded to

other M800 transmitters. This simpli-

mitters reduce the cost per measure- fies handling and reduces commis-

ment point by providing multiple sioning errors significantly.

measurements from a single trans-

pH/ORP On-site upgrades

mitter. Combined with the multi-pa- USB interface provides easy upgrading

rameter capabilities, you can mix as new parameters and features are in-

Conductivity troduced.and match parameters for flexible

measurement configuration. Universal power supply

One version for all standard power

systems simplifies specifications and

reduces inventory.

DO2 /O3

TOC

Coming in 2011

8 9

Flexible and Powerful

Page6

Optimized Process Analytics Solutions

To Meet Specific Industry Needs

The M800 multi-parameter transmitter offers tailored solutions for ultrapure

water and process applications in a wide range of industries. The combination

of convenient multi-channel/multi-parameter measurement, best-in-class

measurement performance and predictive diagnostics functionality of ISM

sensors enable cost-effective UPW measurement as well as low maintenance

ISM solutions for enhanced process reliability in production processes.

Multi-parameter for high purity water applications Flexible ISM solutions for process applications

Water purity and the elimination of urement and control capabilities. Production processes in pharma- The M800 multi-channel transmitter

M800 for high purity water M800 for production processes

potential contaminants are critical in Simplicity in operation minimizes ceutical or biotechnology plants allows redundant measurements

water make-up applications. system complexity – measurement 2 Models require high process reliability and with full access to all ISM diagnos- 2 Models

Reclaim and reuse of contaminated from one multi-parameter instrument • M800, 2 channel, + 2� flow traceable documentation in both tics to ensure high uptime and low • M800, 2 channel

• M800, 4 channel, + 2� flow • M800, 4 channel

waters must include rapid system family with ISM is key! upstream and downstream opera- maintenance.

monitoring and control. Water sys- Covers all UPW parameters with full tions. In breweries, a 24/7 filler line Covers all process parameters with

mix & match flexibility full mix & match flexibility

tem fabricators are challenged to • Conductivity or Resistivity operation puts very demanding • pH/ORP

build sophisticated, efficient and • pH/ORP requirements on oxygen measure- • Amperometric and optical Dissolved

effective water systems with meas- • Dissolved Oxygen ment to control product quality. Oxygen

• Dissolved Ozone • Conductivity

• Flow • CO2 (coming in 2011)

• TOC (coming in 2011)

Microelectronics Pharmaceutical Waters Power Generation Pharmaceutical Industry Brewing

Multi-parameter M800 transmitter and ISM Verification, calibration and certification Multi-parameter measurements with con- With the M800, sensors can be pre-cali- The M800 transmitter offers the opportunity

sensors manage a complete UPW system following system SOPs are simplified venient temperature compensation algo- brated and diagnosed before the next of determining optical DO and implement-

to ensure highly accurate measurement with pre-calibrated ISM sensors and the rithms for ISM sensors ensure efficient fermentation batch. In addition, the M800 ing cost-effective redundant measurement

and control. certified M800. plant water management. enables cost-effective redundant measure- points. Predictive diagnostics with ISM

ments for all parameters needed. help to avoid unplanned maintenance

shutdowns.

10 11

Industry Specific M800 Solutions