1/22ページ

ダウンロード(2Mb)

各種評価試験レポート付き

Formlabsが2023年5月2日に発売したUL 94 V-0認証取得済みの難燃性材料 Flame Retardantレジンのデータシートです。本資料では、自動車や鉄道車両、ドローンなどを含む航空機の内装部品(試作~量産)、電子機器の筐体やコネクタ(試作~量産)、高温環境や発火源のある環境で使用する治工具製作に向けて開発された本材料の詳細情報をご確認いただけます。

関連メディア

このカタログについて

| ドキュメント名 | UL 94 V-0認証取得済み:Flame Retardant(難燃性)レジンデータシート |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 2Mb |

| 登録カテゴリ | |

| 取り扱い企業 | Formlabs株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

SPECIALTY RESIN

Flame Retardant(難燃性レジン)

精度と表面品質、耐熱性に優れたUL 94 V-0の認定取得済の難燃性材料

剛性、耐クリープ性、機能性に優れた難燃樹脂部品を簡単かつ短時間でプリントいただけます。

Flame Retardantレジンは、自己消火性を備えハロゲンフリーで、優良なFST(炎、煙、毒性)

評価、2.9GPaの引張弾性率、0.45MPaで112℃の荷重たわみ温度(HDT)を有しています。

高温環境や製造現場など過酷な環境で使用する治工具や設備機器の交換部品に

航空機、自動車、鉄道車両など 消費者向け電子機器または医療機器の筐体や

優れた表面品質が求められ る 内部部品に

内装部品に

V1 FLFRGR01 * 一部の国・地域ではご使用いただけない場合があります

初版 2023年4月13日 本紙記載の情報は弊社が知り得る限りの情報において正確なものですが、Formlabs, Inc.はその

使用によって得られる結果については明示または黙示を問わず、いかなる保証もすることは

修正 01 2023年4月13日 できません。

Page2

材料特性 Flame Retardant Resin

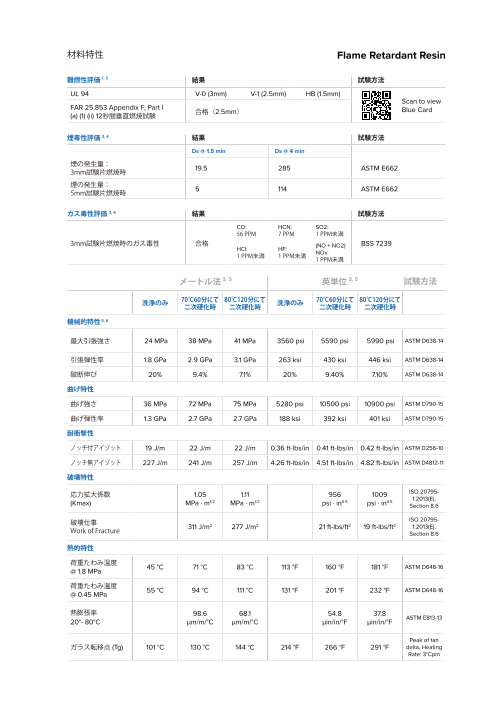

難燃性評価 1, 2 結果 試験方法

UL 94 V-0 (3mm) V-1 (2.5mm) HB (1.5mm)

Scan to view

FAR 25.853 Appendix F, Part I Blue Card

(a) (1) (ii) 12秒間垂直燃焼試験 合格(2.5mm)

煙毒性評価 3, 4 結果 試験方法

Ds @ 1.5 min Ds @ 4 min

煙の発生量:

3mm試験片燃焼時 19.5 285 ASTM E662

煙の発生量:

5mm試験片燃焼時 5 114 ASTM E662

ガス毒性評価 3, 4 結果 試験方法

CO: HCN: SO2:

56 PPM 7 PPM 1 PPM未満

3mm試験片燃焼時のガス毒性 合格 BSS 7239

HCl: HF: (NO + NO2)

1 PPM未満 1 PPM未満 NOx:

1 PPM未満

メートル法 3, 5 英単位 3, 5 試験方法

洗浄のみ 70℃60分にて 80℃120分にて

二次硬化時 洗浄のみ 70℃60分にて 80℃120分にて

二次硬化時 二次硬化時 二次硬化時

機械的特性 5, 6

最大引張強さ 24 MPa 38 MPa 41 MPa 3560 psi 5590 psi 5990 psi ASTM D638-14

引張弾性率 1.8 GPa 2.9 GPa 3.1 GPa 263 ksi 430 ksi 446 ksi ASTM D638-14

破断伸び 20% 9.4% 7.1% 20% 9.40% 7.10% ASTM D638-14

曲げ特性

曲げ強さ 36 MPa 72 MPa 75 MPa 5280 psi 10500 psi 10900 psi ASTM D790-15

曲げ弾性率 1.3 GPa 2.7 GPa 2.7 GPa 188 ksi 392 ksi 401 ksi ASTM D790-15

耐衝撃性

ノッチ付アイゾット 19 J/m 22 J/m 22 J/m 0.36 ft-lbs/in 0.41 ft-lbs/in 0.42 ft-lbs/in ASTM D256-10

ノッチ無アイゾット 227 J/m 241 J/m 257 J/m 4.26 ft-lbs/in 4.51 ft-lbs/in 4.82 ft-lbs/in ASTM D4812-11

破壊特性

応力拡大係数 1.05 1.11 956 1009 ISO 20795-

(Kmax) MPa · m1/2 MPa · m1/2 psi · in0.5 psi · in0.5 1:2013(E),

Section 8.6

破壊仕事 ISO 20795-

Work of Fracture 311 J/m2 277 J/m2 21 ft-lbs/ft2 19 ft-lbs/ft2 1:2013(E),

Section 8.6

熱的特性

荷重たわみ温度

@ 1.8 MPa 45 °C 71 °C 83 °C 113 °F 160 °F 181 °F ASTM D648-16

荷重たわみ温度

@ 0.45 MPa 55 °C 94 °C 111 °C 131 °F 201 °F 232 °F ASTM D648-16

熱膨張率 98.6 68.1 54.8 37.8

20°- 80°C μm/m/°C μm/m/°C μin/in/°F μin/in/°F ASTM E813-13

Peak of tan

ガラス転移点 (Tg) 101 °C 130 °C 144 °C 214 °F 266 °F 291 °F delta, Heating

Rate: 3°Cpm

Page3

材料特性 Flame Retardant Resin

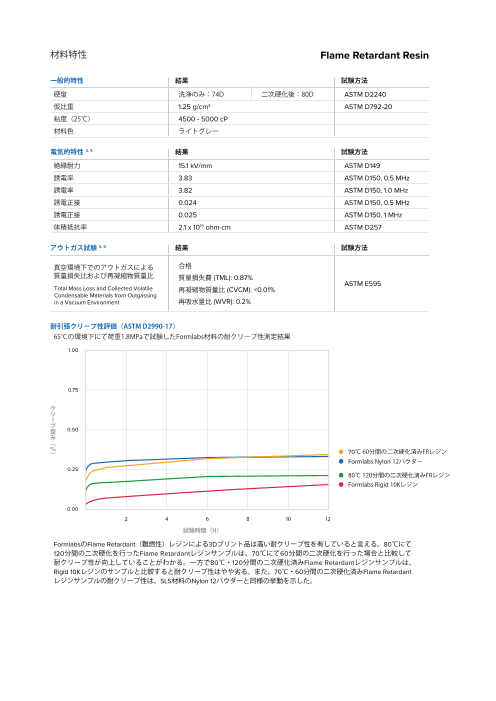

一般的特性 結果 試験方法

硬度 洗浄のみ:74D 二次硬化後:80D ASTM D2240

仮比重 1.25 g/cm3 ASTM D792-20

粘度(25℃) 4500 - 5000 cP

材料色 ライトグレー

電気的特性 3, 5 結果 試験方法

絶縁耐力 15.1 kV/mm ASTM D149

誘電率 3.83 ASTM D150, 0.5 MHz

誘電率 3.82 ASTM D150, 1.0 MHz

誘電正接 0.024 ASTM D150, 0.5 MHz

誘電正接 0.025 ASTM D150, 1 MHz

体積抵抗率 2.1 x 1015 ohm-cm ASTM D257

アウトガス試験 3, 5 結果 試験方法

真空環境下でのアウトガスによる 合格

質量損失比および再凝縮物質量比 質量損失費 (TML): 0.87%

ASTM E595

Total Mass Loss and Collected Volatile 再凝縮物質量比 (CVCM): <0.01%

Condensable Materials from Outgassing

in a Vacuum Environment 再吸水量比 (WVR): 0.2%

耐引張クリープ性評価(ASTM D2990-17)

65℃の環境下にて荷重1.8MPaで試験したFormlabs材料の耐クリープ性測定結果

1.00

0.75

ク

リ

ー

プ

歪 0.50

み

(

%

) 70℃ 60分間の二次硬化済みFRレジン

Formlabs Nylon 12パウダー

0.25

80℃ 120分間の二次硬化済みFRレジン

Formlabs Rigid 10Kレジン

0.00

2 4 6 8 10 12

試験時間(H)

FormlabsのFlame Retardant(難燃性)レジンによる3Dプリント品は高い耐クリープ性を有していると言える。80℃にて

120分間の二次硬化を行ったFlame Retardantレジンサンプルは、70℃にて60分間の二次硬化を行った場合と比較して

耐クリープ性が向上していることがわかる。一方で80℃・120分間の二次硬化済みFlame Retardantレジンサンプルは、

Rigid 10Kレジンのサンプルと比較すると耐クリープ性はやや劣る。また、70℃・60分間の二次硬化済みFlame Retardan t

レジンサンプルの耐クリープ性は、SLS材料のNylon 12パウダーと同様の挙動を示した。

Page4

耐薬品性 3 Flame Retardant Resin

プリントおよび二次硬化後の10 x 10 x 10mmの立方体を、各溶媒に24時間浸漬した際の質量増加率

洗浄剤 24時間後の質量増加率

アセトン 2.1

漂白剤(次亜塩素酸ナトリウム約5%) 0.3

Windex Powerized Formula(ガラス・表面クリーナー) 0.3

過酸化水素(30%) 1

石鹸水 0.2

TPM(トリプロピレングリコールモノメチルエーテル) 0.1

蒸留水 0.2

高濃度溶剤・酸およびアルコール

塩酸(10%) 0.1未満

次亜塩素酸ナトリウム水溶液 0.1未満

水酸化ナトリウム水溶液(0.025% pH = 10) 0.3

塩水(塩化ナトリウム 3.5%) 0.2

IPA(イソプロピルアルコール) 0.2

過酸化水素水(3%) 0.2

酢酸ブチル 0.4

濃硫酸(30%) 溶解

工業用燃料

ガソリン(ISO 1817、Liquid C) 0.1未満

トランスミッションオイル(Havoline Synthetic ATF) 0.1未満

エンジンオイル(Havoline SAE 5W-30) 0.1未満

ブレーキオイル(Castrol DOT-4) 0.1未満

ディーゼルオイル(Chevron#2) 0.1未満

パワーステアリングオイル 0.1未満

スカイドロール 5 0.1未満

油圧作動油 0.1未満

ジエチレングリコールモノメチルエーテル 0.3

重質鉱物 0.1未満

軽質鉱物 0.1未満

1 UL難燃性試験棒は、Form 3+/Form 3にて50μmの 2 FAR 25.853 Appendix F Part I (a)の 3 二次硬化サンプルのデータは、別途記載がない

積層ピッチでFlame Retardantレジンにてプリント 試験棒はForm 3Lにて積層ピッチ 限りはForm3+にて積層ピッチ100μmでFlame

したものをForm Washにて(a)99%以上のイソプロ 100μmでFlame Retardantレジンで Retardantレジンでプリントした後、Form Wash

ピルアルコール(IPA)で10分間、(b)99%以上の プリントした後、Form Wash Lにて にて純度99%以上のイソプロピルアルコール

トリプロピレングリコールモノメチルエーテル(TPM) 純度99%以上のイソプロピルアルコ (IPA)で10分間洗浄し、Form Cureにて70℃

で15分間洗浄した後に軽く水ですすぎ、Form Cure ール(IPA)で10分間洗浄し、Form で60分間二次硬化を行ったものから取得された

にて70℃で60分間二次硬化を行ったものです。 Cure Lにて70℃で60分間二次硬化を ものです。

本評価は、Form 3、Form 3+、Form 3B、Form 3B+、 行ったものです。

Form 3L、Form 3BLのすべてのプリンタにてモデルの

向きや積層ピッチに関わらず同様の結果が得られます。

4 5mm厚のサンプルは、ASTM E 662の火炎モードで 5 材料特性はモデル形状、プリントの 6 引張試験片のデータは、Form 3+にて積層ピッ

4分間の発煙濃度(Ds)が200という合格基準に準拠 向きなどの造形設定、温度および チ100μmでFlame Retardantレジンでプリント

したスモークテストに合格しています。さらにユー 消毒や滅菌処理により変動する場合 した後、Form Washにて純度99%以上のイソ

ザー様はご自身の設計に基づいて厚み3~5mmのサン があります。 プロピルアルコール(IPA)で10分間洗浄し、

プルにて試験を実施いただけます。また、サンプルは Form Cureにて70℃で60分間、または80℃で

厚み3mmにてガス毒性試験に合格しています。 120分間二次硬化を行ったType Iの引張試験片

で測定したものです。

Page7

FAR 25.853 VERTICAL

FLAMMABILITY TESTING (12 SEC.)

FOR

FORMLABS

ON

2.5 MM

VTEC #100-7544-1

TESTED: MARCH 29, 2023

Page8

V T E C L a b o r a t o r i e s I n c .

March 29, 2023

Client: Formlabs

35 Medford Street

Somerville, MA 02143

I. SCOPE:

This report contains the reference to the test method, sample description, and test results.

II. TEST METHOD:

This test was conducted in accordance with the FAR 25.853, Appendix F, Part 25 Vertical

Flammability (12 sec.) specification.

III. PASSING CRITERIA:

Fabrics, tested in both the weft and warp directions, must have an average burn length not

exceeding 6 inches, an average after flame time not exceeding 15 seconds, and any dripping may

not continue to flame for more than an average of 3 seconds after falling.

Disclaimer: This is a factual report of the results obtained from the laboratory test of sample products. The results may be applied only to the

products tested and should not be construed as applicable to other similar products of the manufacturer. The report is not a recommendation or

disapprobation by VTEC Laboratories, Inc. of the material tested. While this report may be used for obtaining product acceptance, it may not be

used in advertising.

Notice: VTEC Laboratories Inc. will not be liable for any loss or damage resulting from the use of the data in this report, in excess of the

invoice. This report pertains to the sample tested only. Such report shall not be interpreted to be a warranty, either expressed or implied as to the

suitability or fitness of said sample for such uses or applications, as the party contracting for the report may apply such sample.

212 Manida Street , Bronx, New Y ork 10474 · Te l 718 -542-8248 · Fax 718-542-8759

Page9

VTEC #100-7544-1 FORMLABS FAR 25.853 VERTICAL (12 Sec.)

III. SAMPLE DESCRIPTION:

1) Manufacturer: Formlabs

2) Product Description: 2.5 mm

3) Color: Grey

4) Number of Specimens: 3

5) Specimen Dimensions: 3 x 13 inches

6) Material Description: By Manufacturer

7) Date of Selection: March 2023

8) Purpose of Test: Showing compliance with 25.853 Vertical (12 sec.)

Flammability Test

9) Sample Mounting Method: Vertically in a metal frame with the two long edges

and the upper edge secured

10) Conditioning: 70°F and 50% RH for 24 hours

IV TEST RESULTS:

Flame Application Time: 12 Seconds

Sample 1 Sample 2 Sample 3 Average

After Flame Time (sec.) 2.00 0.00 0.00 0.67

Burn Length (in.) 0.19 0.13 0.18 0.17

Dripping Flaming Time (sec.) 0.00 0.00 0.00 0.00

Based upon the results shown above, the material met the passing criteria per the FAR 25.853

(12 sec.) vertical flammability specification.

________________ __________________

Neil Schultz Amirudin Rahim

Executive Director Technical Director

3

Page10

ASTM E662 TESTING

FOR

FORMLABS

ON

FR RESIN V1 3MM

VTEC #100-7571-2

TESTED: APRIL 12, 2023

Page11

V T E C L a b o r a t o r i e s I n c .

April 12, 2023

Client: Formlabs

35 Medford Street

Somerville, MA 02143

I. SCOPE:

This report contains the reference to the test method, purpose, limitations, description of

materials, operating data, and test results.

II. TEST METHOD:

The test was conducted in accordance with ASTM Designation E-662, "Standard Test Method

for Specific Optical Density of Smoke Generated by Solid Material".

III. PURPOSE:

The purpose of the test is to measure the smoke generated by solid materials and assemblies in

thickness up to and including one inch. The test is based on the attenuation of a light beam by

smoke accumulating within a closed chamber. Both non-flaming and flaming exposures are

conducted. Results are expressed in terms of specific optical density, which is derived from

measuring optical density (absorbance).

IV. DISCLAIMER:

This is a factual report of the results obtained from the laboratory tests of sample products. The

results may be applied only to the products tested and should not be construed as applicable to

other similar products of the manufacturer. The report is not a recommendation or a

disapprobation by VTEC Laboratories Inc. of the material tested. While this report may be used

for obtaining product acceptance, it may not be used in advertising.

NOTICE: VTEC Laboratories Inc. will not be liable for any loss or damage resulting from the use of the data in this report, in

excess of the invoice. This report pertains to the sample tested only. Such report shall not be interpreted to be a warranty, either

expressed or implied as to the suitability of fitness of said sample for such uses or applications, as the party contracting for the

report may apply such sample.

Page12

VTEC #100-7571-2 FORMLABS ASTM E662

TEST DATA: LIGHT TRANSMITTANCE

TEST: NON-FLAMING FLAMING

Time (min.) Test #1 Test #2 Test#3 Test#4 Test#5 Test#6

0.0 100.00% 100.00% 100.00% 100.00% 100.00% 100.00%

0.5 99.94% 99.94% 100.00% 100.00% 102.37% 97.45%

1.0 100.00% 102.43% 97.69% 100.00% 90.22% 87.73%

1.5 100.00% 99.94% 97.74% 95.63% 59.38% 63.49%

2.0 100.00% 102.43% 97.69% 73.33% 10.01% 24.70%

2.5 95.75% 100.24% 97.69% 37.25% 1.23% 5.38%

3.0 85.42% 95.14% 93.00% 8.04% 0.26% 1.48%

3.5 63.49% 80.90% 78.58% 0.98% 0.98% 0.26%

4.0 47.63% 64.41% 61.96% 0.26% 1.23% 1.04%

4.5 29.67% 49.09% 46.84% 0.98% 1.48% 0.98%

5.0 20.87% 37.08% 33.77% 0.95% 1.24% 1.23%

5.5 13.17% 25.48% 25.70% 1.23% 0.98% 0.98%

6.0 7.70% 18.07% 17.66% 0.98% 1.48% 0.75%

6.5 6.60% 12.54% 12.86% 1.48% 1.48% 0.98%

7.0 6.32% 9.80% 10.41% 1.48% 0.98% 1.06%

7.5 3.68% 7.85% 7.86% 1.48% 0.75% 0.32%

8.0 3.19% 5.96% 6.45% 0.98% 0.75% 0.98%

8.5 2.70% 4.76% 5.50% 1.78% 0.86% 0.78%

9.0 2.21% 4.06% 4.58% 0.75% 0.75% 0.98%

9.5 2.21% 3.48% 4.57% 1.47% 0.98% 0.26%

10.0 1.55% 3.01% 3.87% 0.98% 0.75% 0.75%

10.5 2.35% 2.87% 5.01% 0.98% 0.98% 0.73%

11.0 1.62% 2.64% 3.12% 0.75% 0.50% 0.50%

11.5 1.48% 2.55% 3.12% 0.75% 0.50% 0.26%

12.0 1.59% 1.69% 2.64% 0.75% 0.34% 0.26%

12.5 1.23% 2.18% 2.64% 0.98% 0.35% 0.26%

13.0 1.96% 2.15% 2.80% 0.98% 0.71% 0.11%

13.5 1.25% 1.83% 2.15% 0.75% 0.20% 0.26%

14.0 1.28% 1.91% 2.64% 0.75% 0.25% 0.26%

14.5 0.83% 2.39% 2.52% 0.50% 0.26% 0.26%

15.0 1.23% 2.41% 1.86% 0.26% 0.86% 0.49%

15.5 0.81% 2.16% 2.15% 0.74% 0.03% 0.75%

16.0 1.48% 2.64% 2.15% 0.24% 0.72% 0.75%

16.5 0.98% 2.83% 2.41% 0.27% 0.77% 0.98%

17.0 1.48% 3.17% 2.15% 0.27% 0.98% 0.98%

17.5 1.49% 2.17% 2.15% 0.27% 0.65% 0.98%

18.0 1.07% 3.11% 2.64% 0.26% 0.82% 2.21%

18.5 1.96% 3.26% 3.31% 0.24% 0.98% 1.15%

19.0 1.39% 3.14% 2.16% 0.21% 0.69% 1.62%

19.5 1.96% 3.81% 2.99% 0.29% 1.71% 1.96%

20.0 2.21% 3.35% 3.35% 0.26% 1.48% 2.35%

3

Page13

VTEC #100-7571-2 FORMLABS ASTM E662

DATE: 4/12/2023

PROJECT #: 100-7571-2

SUPPLIER: Formlabs

CONDITIONING: 140°F for 24 hours.

TEST ROOM TEMP: 76 ± 5°F

RELATIVE HUMIDITY: 50 ± 10 %

CHAMBER WALL TEMP: 95 ± 4°F

SPECIMEN MOUNTING: Standard

SPECIAL PREPARATION: None

SPECIMEN COMPOSITION: Homogeneous

SPECIMEN COLOR: Grey

SPECIMEN DESCRIPTION: FR Resin v1 3mm

NON-FLAMING FLAMING

SAMPLE #: 1 2 3 4 5 6

Thickness (in): 0.1165 0.1165 0.1165 0.1165 0.1165 0.1165

Weight (g): 21.86 21.71 22.09 21.79 21.52 21.82

Tmin (%): 0.81% 1.69% 1.86% 0.21% 0.03% 0.11%

Dm (20.0 min.): 276.22 233.91 228.50 354.41 464.30 390.87

T (clear): 91.80% 79.54% 76.97% 54.45% 54.50% 58.63%

Dc (clear): 4.91 13.12 15.00 34.84 34.79 30.61

Dm (corr): 271.31 220.78 213.50 319.57 429.51 360.27

Ds (1.5 min.): 0.00 0.03 1.31 2.56 29.88 26.05

Ds (4.0 min.): 42.52 25.22 27.44 342.30 251.98 261.81

Color of smoke: Grey Grey Grey Grey Grey Grey

OBSERVATIONS: During the flaming mode, the samples ignited at 0m06s and burned until

8m57s.

OPTICAL DENSITY TEST RESULT SUMMARY

NON-FLAMING FLAMING

Ds @ 1.5 min. (average): 0.4 19.5

Ds @ 4.0 min. (average): 31.7 285.4

Dm (average): 246.2 403.2

Dm(corr) (average): 235.2 369.8

_______________ _______________

Neil Schultz Amirudin Rahim

Executive Director Technical Director

4

Page14

VTEC #100-7571-2 FORMLABS ASTM E662

DATE: 4/12/2023

PROJECT #: 100-7571-2

SUPPLIER: Formlabs

CONDITIONING: 140°F for 24 hours.

TEST ROOM TEMP: 76 ± 5°F

RELATIVE HUMIDITY: 50 ± 10 %

CHAMBER WALL TEMP: 95 ± 4°F

SPECIMEN MOUNTING: Standard

SPECIAL PREPARATION: None

SPECIMEN COMPOSITION: Homogeneous

SPECIMEN COLOR: Grey

SPECIMEN DESCRIPTION: FR Resin v1 3mm ASTM E662 TESTING

FOR

FORMLABS

ON

FR RESIN V1 5MM

NON-FLAMING FLAMING VTEC #100-7571-1

SAMPLE #: 1 2 3 4 5 6 TESTED: APRIL 12, 2023

Thickness (in): 0.1165 0.1165 0.1165 0.1165 0.1165 0.1165

Weight (g): 21.86 21.71 22.09 21.79 21.52 21.82

Tmin (%): 0.81% 1.69% 1.86% 0.21% 0.03% 0.11%

Dm (20.0 min.): 276.22 233.91 228.50 354.41 464.30 390.87

T (clear): 91.80% 79.54% 76.97% 54.45% 54.50% 58.63%

Dc (clear): 4.91 13.12 15.00 34.84 34.79 30.61

Dm (corr): 271.31 220.78 213.50 319.57 429.51 360.27

Ds (1.5 min.): 0.00 0.03 1.31 2.56 29.88 26.05

Ds (4.0 min.): 42.52 25.22 27.44 342.30 251.98 261.81

Color of smoke: Grey Grey Grey Grey Grey Grey

OBSERVATIONS: During the flaming mode, the samples ignited at 0m06s and burned until

8m57s.

OPTICAL DENSITY TEST RESULT SUMMARY

NON-FLAMING FLAMING

Ds @ 1.5 min. (average): 0.4 19.5

Ds @ 4.0 min. (average): 31.7 285.4

Dm (average): 246.2 403.2

Dm(corr) (average): 235.2 369.8

_______________ _______________

Neil Schultz Amirudin Rahim

Executive Director Technical Director

4

Page15

V T E C L a b o r a t o r i e s I n c .

April 12, 2023

Client: Formlabs

35 Medford Street

Somerville, MA 02143

I. SCOPE:

This report contains the reference to the test method, purpose, limitations, description of

materials, operating data, and test results.

II. TEST METHOD:

The test was conducted in accordance with ASTM Designation E-662, "Standard Test Method

for Specific Optical Density of Smoke Generated by Solid Material".

III. PURPOSE:

The purpose of the test is to measure the smoke generated by solid materials and assemblies in

thickness up to and including one inch. The test is based on the attenuation of a light beam by

smoke accumulating within a closed chamber. Both non-flaming and flaming exposures are

conducted. Results are expressed in terms of specific optical density, which is derived from

measuring optical density (absorbance).

IV. DISCLAIMER:

This is a factual report of the results obtained from the laboratory tests of sample products. The

results may be applied only to the products tested and should not be construed as applicable to

other similar products of the manufacturer. The report is not a recommendation or a

disapprobation by VTEC Laboratories Inc. of the material tested. While this report may be used

for obtaining product acceptance, it may not be used in advertising.

NOTICE: VTEC Laboratories Inc. will not be liable for any loss or damage resulting from the use of the data in this report, in

excess of the invoice. This report pertains to the sample tested only. Such report shall not be interpreted to be a warranty, either

expressed or implied as to the suitability of fitness of said sample for such uses or applications, as the party contracting for the

report may apply such sample.

Page16

VTEC #100-7571-1 FORMLABS ASTM E662

TEST DATA: LIGHT TRANSMITTANCE

TEST: NON-FLAMING FLAMING

Time (min.) Test #1 Test #2 Test#3 Test#4 Test#5 Test#6

0.0 100.00% 100.00% 100.00% 100.00% 100.00% 100.00%

0.5 100.00% 97.73% 99.28% 97.79% 97.69% 100.00%

1.0 100.00% 97.73% 97.73% 95.36% 97.69% 98.84%

1.5 100.00% 97.68% 97.68% 88.73% 95.07% 91.14%

2.0 100.00% 97.68% 97.68% 72.65% 77.81% 78.98%

2.5 100.00% 97.68% 95.57% 51.09% 60.19% 62.88%

3.0 98.17% 97.68% 95.57% 36.53% 36.75% 41.75%

3.5 97.68% 95.57% 93.30% 23.51% 21.10% 26.86%

4.0 95.57% 93.30% 93.25% 13.43% 12.26% 15.78%

4.5 88.99% 86.72% 86.72% 9.99% 7.03% 7.90%

5.0 78.03% 75.54% 75.48% 6.20% 4.00% 5.00%

5.5 64.53% 62.26% 60.54% 3.20% 3.27% 2.80%

6.0 47.70% 49.06% 47.92% 2.29% 1.27% 0.94%

6.5 37.04% 37.48% 38.14% 1.04% 1.01% 0.24%

7.0 26.07% 27.52% 29.95% 0.70% 0.55% 0.51%

7.5 18.42% 19.17% 23.77% 0.24% 0.71% 0.24%

8.0 13.55% 13.76% 18.42% 0.67% 0.26% 0.19%

8.5 10.45% 11.10% 14.39% 0.24% 0.27% 0.16%

9.0 7.26% 8.67% 11.54% 0.92% 0.77% 0.24%

9.5 6.45% 7.33% 9.77% 1.10% 0.26% 0.47%

10.0 5.78% 6.85% 7.82% 0.96% 0.26% 0.72%

10.5 5.12% 5.79% 6.67% 1.38% 0.46% 0.94%

11.0 4.72% 6.45% 6.12% 1.38% 0.26% 0.94%

11.5 4.79% 5.33% 4.45% 1.38% 0.51% 0.94%

12.0 4.23% 4.83% 4.23% 1.25% 0.77% 0.94%

12.5 4.23% 5.12% 4.00% 1.38% 0.33% 0.93%

13.0 4.57% 5.03% 3.55% 1.38% 0.91% 0.93%

13.5 4.23% 4.23% 3.60% 1.38% 0.74% 0.94%

14.0 4.32% 4.23% 3.12% 0.92% 0.77% 0.71%

14.5 3.62% 4.01% 2.91% 1.37% 0.51% 0.71%

15.0 3.79% 3.53% 3.00% 1.15% 0.73% 0.90%

15.5 4.01% 3.55% 2.71% 1.15% 0.50% 1.13%

16.0 3.79% 3.13% 2.00% 0.91% 0.75% 0.47%

16.5 4.23% 2.91% 2.47% 1.00% 0.26% 0.71%

17.0 3.97% 2.46% 2.65% 1.15% 0.26% 0.71%

17.5 3.88% 2.46% 2.91% 1.15% 0.77% 0.38%

18.0 3.77% 3.55% 3.13% 1.19% 0.16% 0.24%

18.5 4.01% 2.99% 3.55% 1.13% 0.26% 0.31%

19.0 4.01% 2.09% 2.87% 1.16% 0.96% 0.40%

19.5 3.55% 2.46% 3.35% 1.38% 0.77% 0.21%

20.0 3.60% 2.23% 3.12% 0.92% 0.26% 0.50%

3

Page17

VTEC #100-7571-1 FORMLABS ASTM E662

DATE: 4/12/2023

PROJECT #: 100-7571-1

SUPPLIER: Formlabs

CONDITIONING: 140°F for 24 hours.

TEST ROOM TEMP: 76 ± 5°F

RELATIVE HUMIDITY: 50 ± 10 %

CHAMBER WALL TEMP: 95 ± 4°F

SPECIMEN MOUNTING: Standard

SPECIAL PREPARATION: None

SPECIMEN COMPOSITION: Homogeneous

SPECIMEN COLOR: Grey

SPECIMEN DESCRIPTION: FR Resin v1 5mm

NON-FLAMING FLAMING

SAMPLE #: 1 2 3 4 5 6

Thickness (in): 0.1970 0.1970 0.1970 0.1950 0.1965 0.1965

Weight (g): 36.43 36.44 36.30 36.34 36.19 36.71

Tmin (%): 3.55% 2.09% 2.00% 0.24% 0.16% 0.16%

Dm (20.0 min.): 191.32 221.69 224.33 346.33 368.31 370.38

T (clear): 88.77% 93.25% 88.77% 74.97% 84.48% 78.92%

Dc (clear): 6.83 4.01 6.83 16.51 9.67 13.57

Dm (corr): 184.49 217.68 217.50 329.82 358.64 356.81

Ds (1.5 min.): 0.00 1.35 1.35 6.85 2.90 5.32

Ds (4.0 min.): 2.60 3.97 4.01 115.11 120.33 105.85

Color of smoke: Grey Grey Grey Grey Grey Grey

OBSERVATIONS: During the flaming mode, the samples ignited at 0m33s and burned until

11m44s.

OPTICAL DENSITY TEST RESULT SUMMARY

NON-FLAMING FLAMING

Ds @ 1.5 min. (average): 0.9 5.0

Ds @ 4.0 min. (average): 3.5 113.8

Dm (average): 212.4 361.7

Dm(corr) (average): 206.6 348.4

_______________ _______________

Neil Schultz Amirudin Rahim

Executive Director Technical Director

4

Page18

BSS 7239

TOXIC GAS TESTING

FOR

FORMLABS

ON

FR RESIN V1 3MM

VTEC #100-7571-3

TESTED: APRIL 12, 2023

Page19

V T E C L a b o r a t o r i e s I n c .

April 12, 2023

Client: Formlabs

35 Medford Street

Somerville, MA 02143

Subject:

Measure amount of toxic gas generation per BSS 7239 specification.

Test Description:

The gas analysis was made after 4 minutes of exposure to 2.5 w/cm² in the flaming mode. Toxic

gas was analyzed in accordance to BSS 7239 specification.

Disclaimer:

This test result alone does not assess the fire hazard of the material, or a product made from this

material, under actual fire conditions. Consequently, the results of this test alone are not to be

quoted in support of claims with respect to the fire hazard of the material or product under

actual fire conditions. The results when used alone are only to be used for research and

development, quality control and material specifications.

NOTICE: VTEC Laboratories Inc. will not be liable for any loss or damage resulting from the use of the data in this report, in excess of the

invoice. This report pertains to the sample tested only. Such report shall not be interpreted to be a warranty, either expressed or implied as to the

suitability of fitness of said sample for such uses or applications, as the party contracting for the report may apply such sample.

212 Manida Street , Bronx, New York 10474 · Tel 718 -542-8248 · Fax 718-542-8759

Page20

VTEC #100-7571-3 FORMLABS BSS 7239

Material Tested:

DATE: 4/12/2023

VTEC #: 100-7571-3

PRODUCT DESCRIPTION: FR Resin v1 3mm

SUPPLIER: Formlabs

COLOR: Grey

SPECIMEN COMPOSITION: Homogeneous

AVERAGE THICKNESS: 0.1165 in.

Results:

SPECIMEN #1 SPECIMEN #2

Weight (g) 21.5 21.8

CORRECTED CORRECTED AVERAGE STD. DEVIATION

GAS PPM PPM PPM PPM

CO 50 63 56 9

HCN 6 8 7 2

SO2 <1 <1 <1 <1

HCl <1 <1 <1 <1

HF <1 <1 <1 <1

(NO+NO2) NOX <1 <1 <1 <1

_________________ __________________

Neil Schultz Amirudin Rahim

Executive Director Technical Director

3