1/6ページ

ダウンロード(726Kb)

TVS Diodes Datasheet

このカタログについて

| ドキュメント名 | Surface Mount SLD8S Series |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 726Kb |

| 取り扱い企業 | マウザー・エレクトロニクス (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

TVS Diodes Datasheet

SLD8S Series

Surface Mount

RoHS Pb e3

Description

The SLD8S Series TVS Diode is housed in a SMTO-263 package

with lead modifications. It is designed to protect sensitive

electronics against lightning and inductive load switching voltage

transient events for severe Automotive Load Dump applications.

Features & Benefits

■ AEC-Q101 qualified ■ Excellent clamping capability

■ S MTO-263 package, and foot ■ Low incremental surge

print is compatible to industrial resistance

popular DO-218AB package ■ UL Recognized compound

■ Meet ISO7637-2 5a/5b meeting flammability rating V-0

protection and ISO16750 load ■ Meets MSL level 1, per

dump test (refer to APP note J-STD-020, LF maximun peak

for details)

Agency Approvals of 260°C

■ VBR @ TJ= VBR@25°C x (1+αT ■ For surface mounted

x (T - 25))(αT:Temperature

Agency Agency File Number J applications to optimize board

Coefficient, typical value is space

E230531 0.1%

■ Low profile package

■ G lass passivated chip junction

in modified TO-263 package ■ High temperature to reflow

soldering guaranteed:

Maximum Ratings and Thermal Characteristics ■ ESD protection of data lines in 260°C/10sec at terminals

(T =25OC unless otherwise noted) accordance with IEC 61000-4-

A 2, 30kV(Air), 30kV(Contact) ■ Matte tin lead–free plated

■ EFT protection of data lines in ■ Halogen free and RoHS

Parameter Symbol Value Unit accordance with IEC 61000- compliant

Peak Pulse Power Dissipation 4-4 ■ Pb-free E3 means 2nd level

1. 10ms x 150ms test waveform 2200 W

■ F ast response time: typically interconnect is Pb-free and

PPPM

less than 1.0ps from 0 Volts to the terminal finish material is

2. 10/1000 test waveform 7000 W

BV min tin (Sn) (IPC/JEDEC J-STD-

Power dissipation on infinite heatsink at 609A.01)

TC = 25 °C PD 8.0 W

Maximum Instantaneous Forward Voltage

at 100A for Unidirectional only VF 1.8 V

Applications

Peak forward surge current 8.3m single

half sine-wave IFSM 1000 A

Designed to protect sensitive electronics from:

Operating Junction and Storage T , T -55 to 175 °C ■ Inductive Load Switching

Temperature Range J STG

■ Alternator Load Dump

Typical Thermal Resistance Junction to

case RƟJC 0.9 °C/W

Functional Diagram

Bi-directional

Cathode Anode

Uni-directional

© 2021 Littelfuse, Inc.

1 Specifications are subject to change without notice.

Revised: JC.09/24/21

Page2

TVS Diodes Datasheet

SLD8S Series

Surface Mount

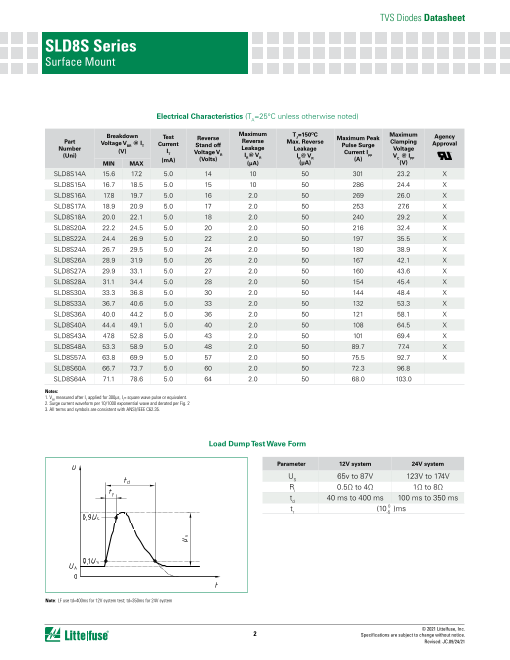

Electrical Characteristics (TA=25°C unless otherwise noted)

Breakdown Test Maximum TJ=150OC Maximum

Reverse Maximum Peak Agency

Part Voltage VBR @ IT Current Reverse Max. Reverse Clamping

Stand off Pulse Surge Approval

Number (V) I Leakage Leakage Voltage

T Voltage VR I @ V Current Ipp (Uni) I @ V V @ I

(mA) (Volts) R R R R (A) C PP

MIN MAX (µA) (µA) (V)

SLD8S14A 15.6 17.2 5.0 14 10 50 301 23.2 X

SLD8S15A 16.7 18.5 5.0 15 10 50 286 24.4 X

SLD8S16A 17.8 19.7 5.0 16 2.0 50 269 26.0 X

SLD8S17A 18.9 20.9 5.0 17 2.0 50 253 27.6 X

SLD8S18A 20.0 22.1 5.0 18 2.0 50 240 29.2 X

SLD8S20A 22.2 24.5 5.0 20 2.0 50 216 32.4 X

SLD8S22A 24.4 26.9 5.0 22 2.0 50 197 35.5 X

SLD8S24A 26.7 29.5 5.0 24 2.0 50 180 38.9 X

SLD8S26A 28.9 31.9 5.0 26 2.0 50 167 42.1 X

SLD8S27A 29.9 33.1 5.0 27 2.0 50 160 43.6 X

SLD8S28A 31.1 34.4 5.0 28 2.0 50 154 45.4 X

SLD8S30A 33.3 36.8 5.0 30 2.0 50 144 48.4 X

SLD8S33A 36.7 40.6 5.0 33 2.0 50 132 53.3 X

SLD8S36A 40.0 44.2 5.0 36 2.0 50 121 58.1 X

SLD8S40A 44.4 49.1 5.0 40 2.0 50 108 64.5 X

SLD8S43A 47.8 52.8 5.0 43 2.0 50 101 69.4 X

SLD8S48A 53.3 58.9 5.0 48 2.0 50 89.7 77.4 X

SLD8S57A 63.8 69.9 5.0 57 2.0 50 75.5 92.7 X

SLD8S60A 66.7 73.7 5.0 60 2.0 50 72.3 96.8

SLD8S64A 71.1 78.6 5.0 64 2.0 50 68.0 103.0

Notes:

1. VBR measured after IT applied for 300µs, IT= square wave pulse or equivalent.

2. Surge current waveform per 10/1000 exponential wave and derated per Fig. 2

3. All terms and symbols are consistent with ANSI/IEEE C62.35.

Load Dump Test Wave Form

Parameter 12V system 24V system

US 65v to 87V 123V to 174V

Ri 0.5Ω to 4Ω 1Ω to 8Ω

td 40 ms to 400 ms 100 ms to 350 ms

tr (10 0

-5 )ms

Note: LF use td=400ms for 12V system test; td=350ms for 24V system

© 2021 Littelfuse, Inc.

2 Specifications are subject to change without notice.

Revised: JC.09/24/21

Page3

TVS Diodes Datasheet

SLD8S Series

Surface Mount

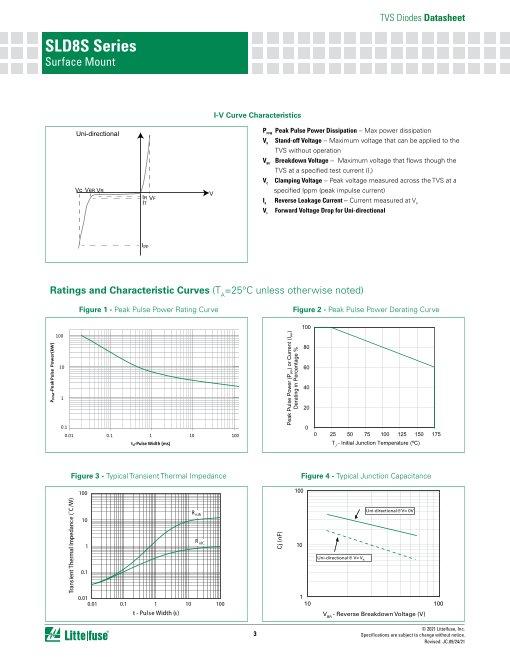

I-V Curve Characteristics

Uni-directional PPPM Peak Pulse Power Dissipation -- Max power dissipation

VR Stand-off Voltage -- Maximum voltage that can be applied to the

TVS without operation

VBR Breakdown Voltage -- Maximum voltage that flows though the

TVS at a specified test current (IT)

VC Clamping Voltage -- Peak voltage measured across the TVS at a

Vc VBR VR V specified Ippm (peak impulse current)

IR VF

IT IR Reverse Leakage Current -- Current measured at VR

VF Forward Voltage Drop for Uni-directional

Ipp

Ratings and Characteristic Curves (TA=25°C unless otherwise noted)

Figure 1 - Peak Pulse Power Rating Curve Figure 2 - Peak Pulse Power Derating Curve

100

100

80

10 60

40

1

20

0.1 0

0.01 0.1 1 10 100 0 25 50 75 100 125 150 175

td-Pulse Width (ms) TJ - Initial Junction Temperature (ºC)

Figure 3 - Typical Transient Thermal Impedance Figure 4 - Typical Junction Capacitance

100 100

R Uni-directional@V= 0V

θJA

10

R θJC

1 10

Uni-directional@ V= VR

0.1

0.01 1

0.01 0.1 1 10 100 10 100

t - Pulse Width (s) VBR - Reverse Breakdown Voltage (V)

© 2021 Littelfuse, Inc.

3 Specifications are subject to change without notice.

Revised: JC.09/24/21

PPPM-Peak Pulse Power(kW)

Transient Thermal Impedance (°C/W)

Cj (nF)

Peak Pulse Power (PPP) or Current (IPP)

Derating in Percentage %

Page4

TVS Diodes Datasheet

SLD8S Series

Surface Mount

Figure 5 - Typical SOA Chart

0.50 ISO7637 5A 12V Test System 0.50 ISO7637 5A 12V Test System

0.75 0.75

SLD8S14A SLD8S20A

SLD8S15A SLD8S24A

1.00 1.00

1.25 1.25

Td:400ms

Td:400ms

1.50 1.50

1.75 1.75

65 70 75 80 85 65 70 75 80 85

Vs(volt) Vs(volt)

1.5 ISO7637 5A 24V Test System

2.0

SLD8S30A

SLD8S36A

2.5

3.0

Td:350ms

3.5

4.0

123 133 143 153 163 173

Vs(volt)

Note: SOA (Safe Operation Area) refer to the area which below the curve line and refer to APP note for details.

Soldering Parameters

Reflow Condition Pb – Free assembly

- Temperature Min (Ts(min)) 150°C tP

Pre Heat - Temperature Max (T TP

s(max)) 200°C

- Time (min to max) (ts) 60 – 180 secs Ramp-up

Average ramp up rate (Liquidus Temp) (T ) to TL

L

peak 5°C/second max t

T L

S(max)

TS(max) to TL - Ramp-up Rate 5°C/second max Ramp-down

Preheat

- Temperature (TL) (Liquidus) 217°C

Reflow T

- Time ( min to max) (TS) 60 – 150 seconds S(min)

tS

Peak Temperature (T ) 260+0/-5

P °C

Time within 5°C of actual peak Temperature (tp) 20 – 40 seconds 25

time to peak temperature

Ramp-down Rate 5°C/second max Time

Time 25°C to peak Temperature (TP) 8 minutes Max.

Do not exceed 260°C

© 2021 Littelfuse, Inc.

4 Specifications are subject to change without notice.

Revised: JC.09/24/21

Ri(ohm) Ri(ohm)

Temperature

Ri(ohm)

Page5

TVS Diodes Datasheet

SLD8S Series

Surface Mount

Physical Specifications Environmental Specifications

Terminal Finish 100% Matte Tin-plated High Temp. Storage JESD22-A103

UL Recognized compound meeting HTRB JESD22-A108

Body Material

flammability rating V-0

Temperature Cycling JESD22-A104

Lead Material Copper Alloy MSL JEDEC-J-STD-020, LEVEL 1

H3TRB JESD22-A101

RSH JESD22-A111

Dimensions

F

B

G

Inches Millimeters

Dimensions

Min Max Min Max

H A 0.568 0.600 14.44 15.24

A

B 0.380 0.420 9.65 10.67

E C 0.098 0.114 2.50 2.90

D

J D 0.169 0.189 4.30 4.80

U E 0.102 0.118 2.60 3.00

C I

TOP VIEW SIDE VIEW F 0.178 0.188 4.52 4.78

G 0.045 0.060 1.14 1.52

AREA: 0.11 IN2 0.413

0.085 (10.50) H 0.360 0.370 9.14 9.40

(2.16)

I 0.106 0.122 2.69 3.09

0.331 J 0.069 0.089 1.75 2.25

0.276 (8.41) 0.276

(7.01) (7.01) M 0.284 0.300 7.22 7.62

0.601

(15.27) U 0 0.010 0 0.25

0.032 0.350

(0.81) (8.89)

0.091

(2.30)

M

0.320

(8.13) 0.118

(3.00)

BOTTOM VIEW RECOMMEND SOLDERING

PAD OUTLINE

Part Numbering System Part Marking System

SLD 8 S XX A

5% Voltage Tolerance

SLD8SXXX

Voltage YMXXX

SMTO-263 package

Power Dissipation

Series Code

© 2021 Littelfuse, Inc.

5 Specifications are subject to change without notice.

Revised: JC.09/24/21

Littelfuse Logo

Cathode Band

F

Y: Year Code

M: Month Code

XXX:Lot Code

Date Code Marking

Page6

TVS Diodes Datasheet

SLD8S Series

Surface Mount

Packaging

Part Number Component Package Quantity Packaging Option

SLD8SxxA SMTO-263 500 Embossed Carrier

SMTO-263 Embossed Carrier Reel Pack (RP) Specifications

Meets all EIA-481-2 Standards

0.63 0.157

(16.0) (4.0)

0.059 DIA

(1.5)

0.945 0.827

(24.0) *

(21.0)

* Cover tape

12.99

0.512 (13.0) Arbor (330.0)

Hole Dia. Dimensions

are in inches

(and millimeters).

1.01

(25.7)

Direction of Feed

Disclaimer Notice - Information furnished is believed to be accurate and reliable. However, users should independently evaluate the suitability of and test each product selected for their own applications. Littelfuse products are

not designed for, and may not be used in, all applications. Read complete Disclaimer Notice at http://www.littelfuse.com/disclaimer-electronics.

© 2021 Littelfuse, Inc.

6 Specifications are subject to change without notice.

Revised: JC.09/24/21