1/17ページ

ダウンロード(9.8Mb)

このカタログについて

| ドキュメント名 | Surface Mount Hybrid Aluminum Polymer Capacitors A780 125°C |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 9.8Mb |

| 取り扱い企業 | マウザー・エレクトロニクス (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

Overview、Applications、Benefits

Surface Mount Hybrid Aluminum Polymer Capacitors

A780 125°C

Overview Applications

KEMET’s A780 is a surface mount conductive KEMET’s A780 is a series of high-performance surface

polymer hybrid capacitor with outstanding electrical mount hybrid capacitors. Due to its mechanical

performance. The A780 winding is housed in a robustness, the A780 is suitable for use in mobile,

cylindrical aluminum can with a high/quality rubber automotive and aircraft installations with extremely high

deck. Low ESR is conditioned by a highly conductive demands and operation up to +125°C.

polymer (PEDOT/PSS). The polymer system creates

an electrical pathway between the anodic oxide layer

and the cathode through a mechanical separator

- paper. The A780 winding is impregnated with

liquid electrolyte that translates to the self-healing

features of the capacitor. Thanks to its mechanical

robustness, the A780 is suitable for use in mobile,

automotive and aircraft installations with operation up

to +125°C.

Benefits

• Surface mount form factor • Self-healing behaviours

• High ripple current for smaller case sizes • Outstanding electrical performance

and higher voltages • AEC-Q200 compliance

• High temperature; 125°C/3,000 hours • RoHS compliant

• Low leakage current • Halogen-Free

• High vibration resistance up to 30g

Standard Anti-Vibration

Built Into Tomorrow

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard A4098_A780 • 9/25/2020 1

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Page2

Part Number System、Ordering Options Table

Surface Mount Hybrid Aluminum Polymer Capacitors

A780 125°C

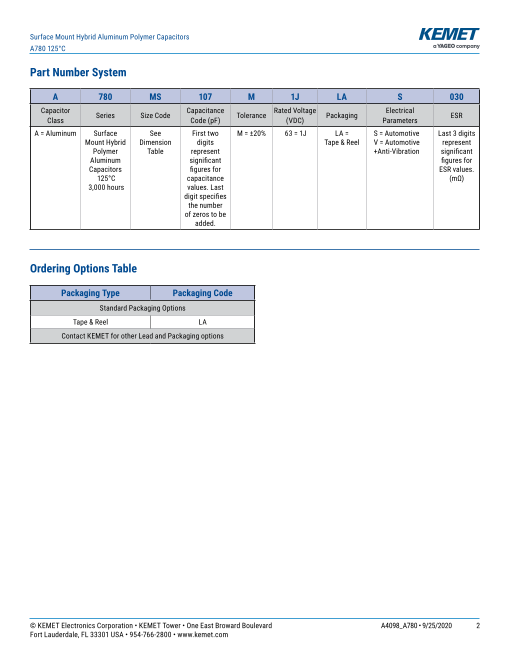

Part Number System

A 780 MS 107 M 1J LA S 030

Capacitor Capacitance Rated Voltage Electrical

Series Size Code Tolerance Packaging ESR

Class Code (pF) (VDC) Parameters

A = Aluminum Surface See First two M = ±20% 63 = 1J LA = S = Automotive Last 3 digits

Mount Hybrid Dimension digits Tape & Reel V = Automotive represent

Polymer Table represent +Anti-Vibration significant

Aluminum significant figures for

Capacitors figures for ESR values.

125°C capacitance (mΩ)

3,000 hours values. Last

digit specifies

the number

of zeros to be

added.

Ordering Options Table

Packaging Type Packaging Code

Standard Packaging Options

Tape & Reel LA

Contact KEMET for other Lead and Packaging options

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard A4098_A780 • 9/25/2020 2

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Page3

Dimensions – Millimeters

Surface Mount Hybrid Aluminum Polymer Capacitors

A780 125°C

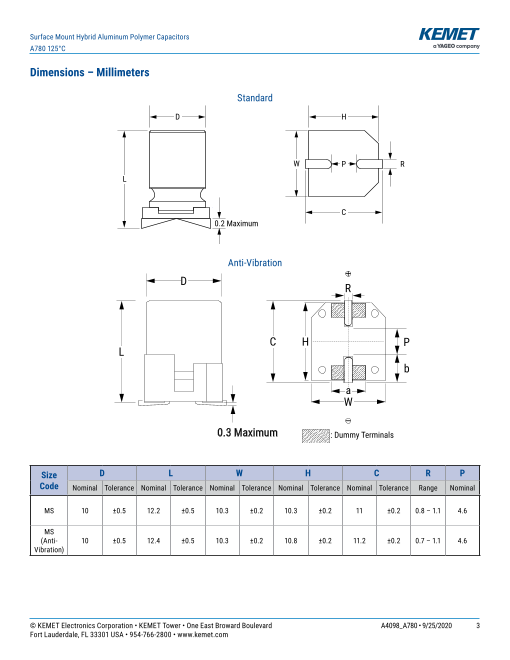

Dimensions – Millimeters

Standard

D H

W P R

L

C

0.2 Maximum

Anti-Vibration

Size D L W H C R P

Code Nominal Tolerance Nominal Tolerance Nominal Tolerance Nominal Tolerance Nominal Tolerance Range Nominal

MS 10 ±0.5 12.2 ±0.5 10.3 ±0.2 10.3 ±0.2 11 ±0.2 0.8 – 1.1 4.6

MS

(Anti- 10 ±0.5 12.4 ±0.5 10.3 ±0.2 10.8 ±0.2 11.2 ±0.2 0.7 – 1.1 4.6

Vibration)

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard A4098_A780 • 9/25/2020 3

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Page4

Environmental Compliance、Performance Characteristics 、Compensation Factor of Ripple Current (RC) vs. Frequency

Surface Mount Hybrid Aluminum Polymer Capacitors

A780 125°C

Environmental Compliance

As an environmentally conscious company, KEMET is working continuously with improvements concerning the environmental

effects of both our capacitors and their production. In Europe (RoHS Directive) and in some other geographical areas like China,

legislation has been put in place to prevent the use of some hazardous materials, such as lead (Pb), in electronic equipment.

All products in this catalogue are produced to help our customers’ obligations to guarantee their products and fulfil these

legislative requirements. The only material of concern in our products has been lead (Pb), which has been removed from all

designs to fulfil the requirement of containing less than 0.1% of lead in any homogeneous material. KEMET will closely follow

any changes in legislation worldwide and makes any necessary changes in its products, whenever needed. Some customer

segments such as medical, military and automotive electronics may still require the use of lead in electrode coatings. To clarify

the situation and distinguish products from each other, a special symbol is used on the packaging labels for RoHS compatible

capacitors.

Due to customer requirements, there may appear additional markings such as LF = Lead-free or LFW = Lead-free wires

on the label.

Performance Characteristics

Item Performance Characteristics

Capacitance Range 56 – 100 µF

Rated Voltage 63 VDC

Operating Temperature −55°C to +125°C

Capacitance Tolerance ±20% at 120 Hz/20°C

Life Test 3,000 hours at rated temperature (See conditions in Test Method and Performance)

I = 0.01 CV

Leakage Current

C = Rated capacitance (µF), V = Rated voltage (VDC), Voltage applied for 2 minutes at 20°C.

Compensation Factor of Ripple Current (RC) vs. Frequency

Frequency 100 Hz 400 Hz 1 kHz 10 kHz 100 kHz

Coefficient 0.19 0.35 0.45 0.80 1.00

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard A4098_A780 • 9/25/2020 4

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Page5

Test Method & Performance

Surface Mount Hybrid Aluminum Polymer Capacitors

A780 125°C

Test Method & Performance

Conditions Endurance Life Test High Temperature Storage Test

Temperature +125°C +125°C

Test Duration 3,000 hours 1,000 hours

Ripple Current Rated ripple applied No ripple current applied

Voltage Rated voltage No voltage applied

Performance The following specifications will be satisfied when the capacitor is restored to 20°C.

Capacitance Change Within ±20% of the initial value

Dissipation Factor Does not exceed 200% of the specified value

ESR Does not exceed 200% of the specified value

Leakage Current Does not exceed 200% of the specified value

Damp Heat The following specifications will be satisfied when the capacitor is restored to 20°C

after application of rated voltage for 2,500 hours at 85°C, 85% RH.

Capacitance Change Within ±20% of the initial value

Dissipation Factor Does not exceed 200% of the specified value

ESR Does not exceed 200% of the specified value

Leakage Current Does not exceed 200% of the specified value

Surge Voltage The following specifications will be satisfied when the capacitor is subjected to 1,000 cycles,

(Rated Voltage x each consisting of charge with the surge voltages specified at 105°C for 30 seconds through a

1.15(V)) protective resistor (Rc = 1 kΩ) and discharge for 5 minutes, 30 seconds.

Capacitance Change Within ±20% of the initial value

Dissipation Factor Does not exceed 150% of the specified value

ESR Does not exceed 150% of the specified value

Leakage Current Does not exceed 200% of the specified value

Resistance to

Soldering Heat Measurement for solder temperature profile at capacitor top and terminal.

Capacitance Change Within ±10% of the initial value

Dissipation Factor Does not exceed 150% of the specified value

ESR Does not exceed 150% of the specified value

Leakage Current Does not exceed 200% of the specified value

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard A4098_A780 • 9/25/2020 5

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Page6

Test Method & Performance – Anti-Vibration Version、Shelf Life & Re-Ageing

Surface Mount Hybrid Aluminum Polymer Capacitors

A780 125°C

Test Method & Performance – Anti-Vibration Version

Anti-Vibration Version

Vibration Test Specifications 1.5 mm displacement amplitude or 30 g maximum acceleration. Vibration applied

for three 4-hour sessions at 10 – 2,000 Hz (capacitor on PCB).

Capacitance Change Within ±20% of the initial value

Dissipation Factor Does not exceed 150% of the specified value

ESR Does not exceed 150% of the specified value

Leakage Current Does not exceed 200% the specified value

Shelf Life & Re-Ageing

Shelf Life

Solderability is 12 months

The capacitance, ESR and impedance of a capacitor will not change significantly after extended storage periods, however the

leakage current will slowly increase.

• This series should not be stored in high temperatures or where there is a high level of humidity.

• The suitable storage condition is +5 to +35°C and less than 75% in relative humidity.

• Do not store in damp conditions such as water, saltwater spray or oil spray.

• Do not store in an environment full of hazardous gas (hydrogen sulphide, sulphurous acid gas, nitrous acid, chlorine gas,

ammonium, etc.)

•Do not store under exposure to ozone, ultraviolet rays or radiation.

If a capacitor has been stored for more than 12 months under these conditions and it shows increased leakage current,

then a treatment by voltage application is recommended. The Capacitor should be soldered within 7 days after unpack.

MSL Rating 2A

Re-age Procedure

Apply the rated DC voltage to the capacitor at 125°C for a period of 120 minutes through a 1 kΩ series resistor.

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard A4098_A780 • 9/25/2020 6

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Page7

Table 1 – Ratings & Part Number Reference 、Installing

Surface Mount Hybrid Aluminum Polymer Capacitors

A780 125°C

Table 1 – Ratings & Part Number Reference

Rated Surge Rated ESR Dissipation Ripple Ripple Ripple

Voltage Voltage Capacitance Factor Current1 Current Current Leakage Case Case

Maximum2 Maximum2 Current Size KEMET Part Number Size

100 kHz 100 kHz 20°C

(VDC) (VDC) 120 Hz 20°C 20°C 120 Hz 20°C 125°C 100 kHz 100 kHz 2 minute D x L Represents Part Anti-Vibration D x L (mm)

(µF) 105°C (mA) 125°C (mA) (mm) Number Options Version Anti-

(mΩ) (mA) (µA) Vibration

63 72.45 56 30 0.08 1,500 5,500 3,700 35.3 10 × 12.2 A780MS566M1JLAS030 A780MS566M1JLAV030 10 × 12.4

63 72.45 100 30 0.08 1,500 5,500 3,700 63.0 10 × 12.2 A780MS107M1JLAS030 A780MS107M1JLAV030 10 × 12.4

1 Capacitor mounted on PCB, Lop: 3,000 hours

2 Capacitor mounted with low thermal resistance path (heat-sink), Lop: 2,000 hours

KEMET technology allows to achieve enhanced ripple performance by adding a heat sink solution. This component acts as a dissipator of generated

heat, granting effective cooling of the capacitor system. (Contact KEMET Aluminium Innovation Center for details and recommendations)

Installing

Hybrid Polymer Aluminum Capacitors are prone to a change in leakage current due to thermal stress during soldering. The

leakage current may increase after soldering or reflow soldering. Therefore, verify the suitability for use in circuits sensitive

to leakage current.

A general principle is that lower temperature operation results in a longer, useful life of the capacitor. For this reason, it

should be ensured that electrolytic capacitors are placed away from heat-emitting components. Adequate space should be

allowed between components for cooling air to circulate, especially when high ripple current loads are applied. In any case,

the maximum rated temperature must not be exceeded.

• Do not deform the case of capacitors or use capacitors with a deformed case.

• Verify that the connections of the capacitors are able to insert on the board without excessive mechanical force.

Excessive force during insertion, as well as after soldering may cause terminal damage and affect the

electrical performance.

• Ensure electrical insulation between the capacitor case, negative terminal, positive terminal and PCB.

• If the capacitors require mounting through additional means, the recommended mounting accessories shall be used.

• Verify the correct polarization of the capacitor on the board.

KEMET recommends, to ensure that the voltage across each capacitor does not exceed its rated voltage.

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard A4098_A780 • 9/25/2020 7

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Page8

Temperature Stability Characteristics、Expected Life Calculation Chart

Surface Mount Hybrid Aluminum Polymer Capacitors

A780 125°C

Temperature Stability Characteristics

Hybrid Polymer Aluminum Capacitors allow high ripple currents for smaller case sizes and higher voltage comparing with

standard electrolytics. The presence of conductive polymer and electrolyte allows for higher temperature robustness and a

more stable product performance.

Temperature Stability Characteristics

Hybrid Versus Electrolytic Ripple Test

45

40

35

30

25

20

15 Hybrid

10 Electrolytic

5

0

0 500 1,000 1,500 2,000 2,500

Time/s

DC Life Formula

Expected DC operational life (Lop, in k hours) can be calculated in accordance to the following equation:

Lop=27×2((85-T)/15)

Where:

Lop: Life at maximum permissible operating temperature with rated operating voltage applied (k hour).

T: Ambient operating temperature (ºC). Recommended to use the formula for the range 85ºC to 125ºC.

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard A4098_A780 • 9/25/2020 8

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Temperature/ oC

Page9

Stability of ESR across Frequency Range、Landing Pad – Millimeters

Surface Mount Hybrid Aluminum Polymer Capacitors

A780 125°C

Operational Life

Operational life (Lop1) of a Polymer Hybrid V-Chip mounted on a Printed Circuit Board (PCB) at temperature Ta and ripple

current IAC applied can be converted from the diagram:

PCB (I (1)

RAC = 1.5 A)

1.4

1.2

1

0.8

0.6

0.4

0.2

0

50 75 100 125 150

T (°

a C)

Operational life (Lop2), when using a low thermal resistance path, at terminal temperature Tt and ripple current IAC applied,

can be converted from the diagram:

Heat Sink ( I (2)

RAC = 3.7 A)

1.4

1.2

1

0.8

0.6

0.4

0.2

0

75 100 125 150

TT (°C)

I (1)

RAC and I (2)

RAC correspond to maximum Ripple Current specified for each case and should be consulted in Table 1 of

datasheet A780 series. The dashed lines correspond to the maximum ripple current allowed for each case. As an example,

135°C on terminal does not allow to apply Ripple Current more than corresponds to IAC/I (2)

RAC =0.8.

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard A4098_A780 • 9/25/2020 9

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

I (2) °

AC/IRAC (125 C)

I (1) °

AC/IRAC (125 C)

Page10

Marking、Construction

Surface Mount Hybrid Aluminum Polymer Capacitors

A780 125°C

Electrical Parameters across Frequency Range

Due to the conductive polymer and electrolyte, Hybrid Aluminum Polymer Capacitors feature higher conductivity. Therefore,

ESR and Impedance of these capacitors are significantly lower than that of a standard electrolytic capacitor at higher

frequencies. This allows an Hybrid Aluminum Polymer capacitor to replace several standard electrolytic capacitors, reducing

the number of components and maximizing board space.

ESR Versus Frequency Impedance Versus Frequency

10,000

100,000

Hybrid

1,000 10,000

Electrolytic

100 1,000

10 Hybrid 100

Electrolytic 10

1

3.E+01 3.E+02 3.E+03 3.E+04 3.E+05 1

Frequency/Hz 10 100 1,000 10,000 100,000 1,000,000

Frequency (Hz)

Landing Pad – Millimeters

Diameter A B C

10 4.5 4.4 2.2

C 10

(Anti-Vibration) 4.5 4.4 4.6

Units in mm

B A B

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard A4098_A780 • 9/25/2020 10

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

ESR/mΩ

Impedance (mΩ)

Page11

Surface Mount Hybrid Aluminum Polymer Capacitors

A780 125°C

Marking

Date Code*

1st Digits = Rated Voltage

Letter = Year Code T = 2020

st

Trademark Series Final Digits = Week of the Year 01 = 1 week of the Year to

52 = 52nd week of the Year

Date Code* Year Code

(Last 3 Digits)

T 2020

Rated Capacitance (µF) U 2021

Voltage

(VDC) V 2022

W 2023

X 2024

Y 2025

Z 2026

Construction

Aluminum Can

Liquid Electrolyte Detailed Cross Section

Lead Rubber Seal

Terminal Tabs Terminal Tab

Rubber Seal Margin

Aluminum Can

Paper Spacer with

Conductive Polymer

(First Layer)

Paper Spacer with Lead (+)

Conductive Polymer

(Third Layer)

Anode Aluminum Foil,

Etched, Covered with Cathode Aluminum

Aluminum Oxide Foil, Etched Lead (−)

(Second Layer) (Fourth Layer)

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard A4098_A780 • 9/25/2020 11

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Page12

Re-Flow Soldering

Surface Mount Hybrid Aluminum Polymer Capacitors

A780 125°C

Re-Flow Soldering

The soldering conditions should be within the specified conditions below:

• Do not dip the capacitors body into the melted solder.

• Flux should only be applied to the capacitors terminals.

• Vapour heat transfer systems are not recommended. The system should be thermal, such as infra-red radiation or hot

blast.

• Observe the soldering conditions as shown below.

• Do not exceed these limits and avoid repeated reflowing.

Time Period Preheating T1 T2 T3

Φ < 8 Φ ≥ 8

Temperature (°C) 150 – 180 ≥ 200 ≤ 230 ≤ 260 ≤ 240

Time (seconds) 60 – 180 ≤ 50 ≤ 40 ≤ 40

Reflow can be performed per the above parameters up to 2x

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard A4098_A780 • 9/25/2020 12

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Page13

Lead Taping & Packaging、Taping for Automatic Insertion Machines

Surface Mount Hybrid Aluminum Polymer Capacitors

A780 125°C

Lead Taping & Packaging

Reel

Size Code Diameter (mm) Length (mm) A B Reel Quantity Box Quantity

±0.5 ±0.2

MS 10 12.2 26 30 400 2,400

MS (Anti-Vibration) 10 12.4 26 30 400 2,400

Taping for Automatic Insertion Machines

D x L W P F B1 B0 T2

Size Code

Tolerance ±0.3 ±0.1 ±0.1 ±0.2 ±0.2 ±0.2

MS 10 x 12.2 24.0 16.0 11.5 10.7 10.7 13.1

MS (Anti-Vbration) 10 x 12.4 24.0 16.0 11.5 11.2 10.7 12.7

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard A4098_A780 • 9/25/2020 13

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Page14

Construction Data

Surface Mount Hybrid Aluminum Polymer Capacitors

A780 125°C

Construction Data

The manufacturing process begins with the anode foil being

electrochemically etched to increase the surface area and Polymerization

then ‘formed’ to produce the aluminum oxide layer. Both the

anode and cathode foils are then interleaved with absorbent Slitting

paper and wound into a cylinder. During the winding process,

aluminum tabs are attached to each foil to provide the Winding

electrical contact.

Welding

The deck, complete with terminals, is attached to the tabs

and then folded down to rest on top of the winding. The Chemical Treatment

complete winding is impregnated with a conductive polymer

electrolyte before being housed in a suitable container, Forming

usually an aluminum can, and sealed. Throughout the

process, all materials inside the housing must be maintained Assembling

at the highest purity and be compatible with the electrolyte.

Marking

Each capacitor is aged and tested before being packed.

The purpose of aging is to repair any damage in the oxide Aging

layer and thus reduce the leakage current to a very low level.

Aging is normally carried out at the rated temperature of the V-chip formin g and

capacitor and is accomplished by applying voltage to the marking

device while carefully controlling the supply current. The

process may take several hours to complete. Damage to the Inspection

oxide layer can occur due to a variety of reasons:

Packing

• Slitting of the anode foil after forming

• Attaching the tabs to the anode foil

• Minor mechanical damage caused during winding

Floor Terminal

Lead line

Rubber

Case

Anode foil

Cathode foil

Separator

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard A4098_A780 • 9/25/2020 14

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Page15

Product Safety

Surface Mount Hybrid Aluminum Polymer Capacitors

A780 125°C

Product Safety

THESE NOTES SHOULD BE READ IN CONJUNCTION WITH THE PRODUCT DATA SHEET. FAILURE TO OBSERVE THE RATINGS

AND THE INFORMATION ON THIS SHEET MAY RESULT IN A SAFETY HAZARD.

Warning

When potential lethal voltages e.g. 30 VAC (RMS) or 60 VDC are applied to the terminals of this product, the use of a

hazard warning label is recommended.

1. Electrolyte

Hybrid aluminum polymer electrolytic capacitors contain polymer and electrolyte, which can be hazardous.

1.1 Safety Precautions

In the event of gas venting, avoid contact and inhalation. Wash the affected area with hot water. Use rubber gloves to avoid

skin contact. Any contact with the eyes should be liberally irrigated with water and medical advice sought.

2. Intrinsic Properties

2.1 Operating

DC capacitors are polar devices and will operate safely only if correctly connected. Reversing the connections will result

in high leakage currents which could subsequently cause short circuit failure and possibly explosion and fire. Correctly

polarized operation may result in the above failure modes if:

• The surge voltage is exceeded

• The ambient temperature is too high

• Excessive ripple currents are applied

2.2 Non-Operating

Excessive torque or soldering heat may affect the performance of the capacitor or damage the sealing. Electric shock may

result if capacitors are not discharged.

3. Disposal

Aluminum electrolytic capacitors are consignable waste under the Special Waste Regulations 1996 (Statutory Instrument

1996 No 972), which complies with the EC Hazardous Waste Directive – Directive 91/689/EEC. The electrolyte should

therefore be treated as a hazardous waste and advice should be sought from the local office of the Environmental Agency

regarding its disposal.

Due to the construction of an aluminum electrolytic capacitors, high temperature incineration may cause the component to

explode due to build-up of internal pressure. In addition, incineration may also cause the emission of noxious fumes.

KEMET strongly recommends that if there are any doubts regarding the disposal of conductive polymer aluminum solid

electrolytic capacitors, that advice be sought from the local regulating authority.

In addition, KEMET would like to request that users of aluminum electrolytic capacitors respect the needs of the environment

and, wherever possible, recover as much of the materials as possible, i.e., aluminum.

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard A4098_A780 • 9/25/2020 15

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Page16

Surface Mount Hybrid Aluminum Polymer Capacitors

A780 125°C

Product Safety cont.

4. Unsafe Use

Most failures are of a passive nature and do not represent a safety hazard. A hazard may, however, arise if this failure causes

a dangerous malfunction of the equipment in which the capacitor is employed. Circuits should be designed to fail safe under

the normal modes of failure.

The usual failure mode is an increase in leakage current or short circuit. Other possible modes are decrease of capacitance,

increase in dissipation factor (and impedance) or an open circuit. Capacitors should be used in a well-ventilated enclosure or

cabinet.

5. Mounting

Care should be taken when mounting by clamp, that any safety vent in the can is not covered.

6. Fumigation

In many countries throughout the world it is now common practice to fumigate shipments of products in order to control

insect infestation, particularly when wooden packaging is used. Currently, methyl bromide is widely used as a fumigant,

which can penetrate cardboard packing and polymer bags and, therefore, come into direct contact with equipment or

components contained within.

If aluminum electrolytic capacitors become exposed to methyl bromide, then corrosion may occur, depending upon the

concentration and exposure time to the chemical.

This failure mode can affect all types of KEMET aluminum electrolytic capacitors. Methyl bromide can penetrate the seals of

aluminum electrolytic capacitors and cause internal corrosion of the anode connection, resulting in the component becoming

open circuit. The rate of corrosion will depend upon the level of exposure to methyl bromide as well as the subsequent

operating conditions, such as voltage and temperature. It may take months or, in some cases, several years before the

component becomes open circuit.

7. Dielectric Absorption

A phenomenon known as the dielectric absorption can cause aluminum electrolytic capacitors to recharge themselves. The

phenomenon is well known but impossible to predict with any great accuracy, so potentially any electrolytic product could be

affected. Thus, a capacitor that has been charged and then completely discharged, will appear to recharge itself if left open

circuit; this will manifest itself as a small voltage across the terminals of the capacitor. Generally, the voltages seen are less

than 20 VDC, however, higher voltages have on occasion been reported.

In order to avoid any problems caused by this voltage, KEMET recommends that capacitors be discharged before connecting

to the terminals.

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard A4098_A780 • 9/25/2020 16

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

Page17

KEMET Electronics Corporation Sales Offices、Disclaimer

Surface Mount Hybrid Aluminum Polymer Capacitors

A780 125°C

KEMET Electronics Corporation Sales Offi ces

For a complete list of our global sales offi ces, please visit www.kemet.com/sales.

Disclaimer

All product specifi cations, statements, information and data (collectively, the “Information”) in this datasheet are subject to change. The customer is responsible for

checking and verifying the extent to which the Information contained in this publication is applicable to an order at the time the order is placed. All Information given

herein is believed to be accurate and reliable, but it is presented without guarantee, warranty, or responsibility of any kind, expressed or implied.

Statements of suitability for certain applications are based on KEMET Electronics Corporation’s (“KEMET”) knowledge of typical operating conditions for such

applications, but are not intended to constitute – and KEMET specifi cally disclaims – any warranty concerning suitability for a specifi c customer application or use.

The Information is intended for use only by customers who have the requisite experience and capability to determine the correct products for their application. Any

technical advice inferred from this Information or otherwise provided by KEMET with reference to the use of KEMET’s products is given gratis, and KEMET assumes

no obligation or liability for the advice given or results obtained.

Although KEMET designs and manufactures its products to the most stringent quality and safety standards, given the current state of the art, isolated component

failures may still occur. Accordingly, customer applications which require a high degree of reliability or safety should employ suitable designs or other safeguards

(such as installation of protective circuitry or redundancies) in order to ensure that the failure of an electrical component does not result in a risk of personal injury

or property damage.

Although all product–related warnings, cautions and notes must be observed, the customer should not assume that all safety measures are indicted or that other

measures may not be required.

KEMET is a registered trademark of KEMET Electronics Corporation.

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard A4098_A780 • 9/25/2020 17

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com