1/16ページ

ダウンロード(1.3Mb)

TiMOTIONのMA1シリーズリニアアクチュエーターは、耐久性、長寿命が必要な用途に適しています。大型機械、産業用機械、オフロード車などの使用に適しています。

IP66ダイナミックレベルを必要とする用途で使う事ができます。オプション品として、AC電源、ボールスクリューまたはACMEスピンドル、機械式または電磁式ブレーキ、負荷制限クラッチまたは制限スイッチがあります。

【主な特長】

スピンドル:ACMEまたはボールスクリュー

最大負荷:4,500N (Push/Pull)

速度(定格負荷時):14.3mm/sec(ボールスクリュー、DCモーター、2,500N仕様)

取付寸法:≥ストローク+160mm(POTなし)

IP等級:IP69K

認証:UL73、EMC

ストローク:20~1000mm (ACME)、50~800mm (ボールスクリュー )

オプション:過負荷クラッチ、ホールセンサー、POT、手動クランク機能

入力電圧:12 / 24 / 36V DC;110 / 220V AC

色:黒

使用温度範囲:-30°C~+65°C

機械式または電磁ブレーキ

過酷な使用(Duty cycle 25%)、腐食耐性

このカタログについて

| ドキュメント名 | 電動リニアアクチュエータ【MA1】 |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 1.3Mb |

| 登録カテゴリ | |

| 取り扱い企業 | TiMotion Japan株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

MA1

series

Product Segments TiMOTION’s MA1 series linear actuator is the proven choice for applications

requiring a durable, long life solution. Specifically designed for harsh working

• Industrial Motion environments, the MA1 linear actuator is ideal for use in heavy-duty machinery,

industrial equipment and off road vehicles. This linear actuator has been

certified for applications requiring IP69K compliance. Available options for the

MA1 linear actuator include AC or DC power, ball or acme spindles, mechanical

or electrical braking and a load limiting clutch or limit switches.

General Features

Max. load ACME screw: 2,500N (push / pull)

Ball screw: 4,500N (push / pull)

Max. speed at max. load 14.3mm/s (ACME screw, DC motor)

14mm/s (Ball screw, DC motor)

Max. speed at no load 58.5mm/s (Ball screw, DC motor)

Retracted length ≥ Stroke + 160mm (ACME screw, without POT)

≥ Stroke + 201mm (Ball screw, without POT)

IP rating IP69K

Certificate UL73, EMC

Stroke 20~1000mm (ACME screw);

50~800mm (Ball screw)

Options Overload clutch, electromagnetic brake,

Hall sensors, POT, manual crank function

Voltage 12 / 24 / 36V DC; 110 / 220V AC

Spindle ACME or Ball screw

Color Black

Operational temperature range -30°C~+65°C

Operational temperature range +5°C~+45°C

at full performance

Mechanical or electromagnetic brake

Higher duty cycle (25%), corrosion proof

1

Page2

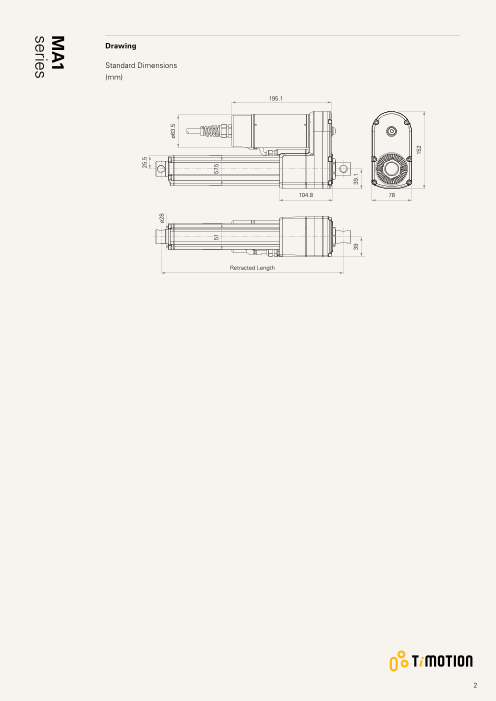

Drawing

Standard Dimensions

(mm)

195.1

104.8 78

Retracted Length

2

25.5

ø28

ø63.5

51 57.5

39 39.1

152

MA1

series

Page3

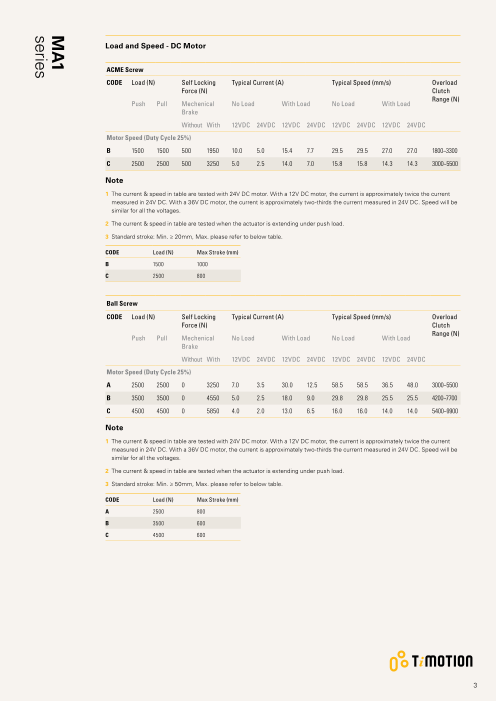

Load and Speed - DC Motor

ACME Screw

CODE Load (N) Self Locking Typical Current (A) Typical Speed (mm/s) Overload

Force (N) Clutch

Range (N)

Push Pull Mechenical No Load With Load No Load With Load

Brake

Without With 12VDC 24VDC 12VDC 24VDC 12VDC 24VDC 12VDC 24VDC

Motor Speed (Duty Cycle 25%)

B 1500 1500 500 1950 10.0 5.0 15.4 7.7 29.5 29.5 27.0 27.0 1800~3300

C 2500 2500 500 3250 5.0 2.5 14.0 7.0 15.8 15.8 14.3 14.3 3000~5500

Note

1 T he current & speed in table are tested with 24V DC motor. With a 12V DC motor, the current is approximately twice the current

measured in 24V DC. With a 36V DC motor, the current is approximately two-thirds the current measured in 24V DC. Speed will be

similar for all the voltages.

2 The current & speed in table are tested when the actuator is extending under push load.

3 Standard stroke: Min. ≥ 20mm, Max. please refer to below table.

CODE Load (N) Max Stroke (mm)

B 1500 1000

C 2500 800

Ball Screw

CODE Load (N) Self Locking Typical Current (A) Typical Speed (mm/s) Overload

Force (N) Clutch

Range (N)

Push Pull Mechenical No Load With Load No Load With Load

Brake

Without With 12VDC 24VDC 12VDC 24VDC 12VDC 24VDC 12VDC 24VDC

Motor Speed (Duty Cycle 25%)

A 2500 2500 0 3250 7.0 3.5 30.0 12.5 58.5 58.5 36.5 48.0 3000~5500

B 3500 3500 0 4550 5.0 2.5 18.0 9.0 29.8 29.8 25.5 25.5 4200~7700

C 4500 4500 0 5850 4.0 2.0 13.0 6.5 16.0 16.0 14.0 14.0 5400~9900

Note

1 The current & speed in table are tested with 24V DC motor. With a 12V DC motor, the current is approximately twice the current

measured in 24V DC. With a 36V DC motor, the current is approximately two-thirds the current measured in 24V DC. Speed will be

similar for all the voltages.

2 The current & speed in table are tested when the actuator is extending under push load.

3 Standard stroke: Min. ≥ 50mm, Max. please refer to below table.

CODE Load (N) Max Stroke (mm)

A 2500 800

B 3500 600

C 4500 600

3

MA1

series

Page4

Load and Speed - AC Motor

ACME Screw

CODE Load (N) Self Locking Typical Current (A) Typical Speed (mm/s) Overload

Force (N) Clutch

Range (N)

Push Pull Mechenical No Load With Load No Load With Load

Brake

Without With 110VAC 220VAC 110VAC 220VAC 110VAC 220VAC 110VAC 220VAC

Motor Speed (Duty Cycle 25%)

B 1500 1500 500 1950 1.9 0.9 2.0 1.0 26.1 22.5 23.0 21.0 1800~3300

C 2500 2500 500 3250 1.9 0.9 2.0 1.0 14.1 12.0 12.8 11.2 3000~5500

Note

1 The current & speed in table are tested when the actuator is extending under push load.

2 Standard stroke: Min. ≥ 20mm, Max. please refer to below table.

CODE Load (N) Max Stroke (mm)

B 1500 1000

C 2500 800

Ball Screw

CODE Load (N) Self Locking Typical Current (A) Typical Speed (mm/s) Overload

Force (N) Clutch

Range (N)

Push Pull Mechenical No Load With Load No Load With Load

Brake

Without With 110VAC 220VAC 110VAC 220VAC 110VAC 220VAC 110VAC 220VAC

Motor Speed (Duty Cycle 25%)

A 2500 2500 0 3250 2.0 0.9 2.5 1.3 53.0 46.0 38.5 40.0 3000~5500

B 3500 3500 0 4550 1.9 0.9 2.1 1.1 27.0 23.5 22.5 21.5 4200~7700

C 4500 4500 0 5850 1.9 0.9 2.0 1.0 14.5 12.0 13.0 11.5 5400~9900

Note

1 The current & speed in table are tested when the actuator is extending under push load.

2 S tandard stroke: Min. ≥ 50mm, Max. please refer to below table.

CODE Load (N) Max Stroke (mm)

A 2500 800

B 3500 600

C 4500 600

4

MA1

series

Page5

Performance Data (12V DC Motor)

ACME Screw (Duty Cycle 25%)

Speed vs. Load

35.0

30.0

B

25.0

20.0

15.0 C

10.0

5.0

0.0

0 1000 2000 3000 4000

Load (N)

Current vs. Load

17.0

16.0 B

15.0

C

14.0

13.0

12.0

11.0

10.0

9.0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0.0

0 1000 2000 3000 4000

Load (N)

5

Current (A) Speed (mm/s)

MA1

series

Page6

Performance Data (24V DC Motor)

ACME Screw (Duty Cycle 25%)

Speed vs. Load

35.0

30.0

B

25.0

20.0

15.0 C

10.0

5.0

0.0

0 1000 2000 3000 4000

Load (N)

Current vs. Load

9.0

8.0 B

C

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0.0

0 1000 2000 3000 4000

Load (N)

6

Current (A) Speed (mm/s)

MA1

series

Page7

Performance Data (12V DC Motor)

Ball Screw (Duty Cycle 25%)

Speed vs. Load

65.0

60.0

55.0

50.0

45.0

40.0

A

35.0

30.0

25.0 B

20.0

15.0 C

10.0

5.0

0.0

0 1000 2000 3000 4000 5000 6000

Load (N)

Current vs. Load

35.0

A

30.0

25.0

20.0 B

15.0

C

10.0

5.0

0.0

0 1000 2000 3000 4000 5000 6000

Load (N)

7

Current (A) Speed (mm/s)

MA1

series

Page8

Performance Data (24V DC Motor)

Ball Screw (Duty Cycle 25%)

Speed vs. Load

65.0

60.0

55.0

50.0 A

45.0

40.0

35.0

30.0

25.0 B

20.0

15.0 C

10.0

5.0

0.0

0 1000 2000 3000 4000 5000 6000

Load (N)

Current vs. Load

14.0

13.0 A

12.0

11.0

10.0

B

9.0

8.0

7.0 C

6.0

5.0

4.0

3.0

2.0

1.0

0.0

0 1000 2000 3000 4000 5000 6000

Load (N)

8

Current (A) Speed (mm/s)

MA1

series

Page9

Performance Data (110V AC Motor)

ACME Screw (Duty Cycle 25%)

Speed vs. Load

35.0

30.0

25.0

B

20.0

15.0

C

10.0

5.0

0.0

0 1000 2000 3000 4000

Load (N)

Current vs. Load

3.0

2.0

B C

1.0

0.0

0 1000 2000 3000 4000

Load (N)

9

Current (A) Speed (mm/s)

MA1

series

Page10

Performance Data (220V AC Motor)

ACME Screw (Duty Cycle 25%)

Speed vs. Load

30.0

25.0

B

20.0

15.0

C

10.0

5.0

0.0

0 1000 2000 3000 4000

Load (N)

Current vs. Load

2.0

B C

1.0

0.0

0 1000 2000 3000 4000

Load (N)

10

Current (A) Speed (mm/s)

MA1

series

Page11

Performance Data (110V AC Motor)

Ball Screw (Duty Cycle 25%)

Speed vs. Load

60.0

55.0

50.0

45.0

40.0 A

35.0

30.0

25.0

B

20.0

15.0 C

10.0

5.0

0.0

0 1000 2000 3000 4000 5000 6000

Load (N)

Current vs. Load

4.0

3.0

A

B

2.0 C

1.0

0.0

0 1000 2000 3000 4000 5000 6000

Load (N)

11

Current (A) Speed (mm/s)

MA1

series

Page12

Performance Data (220V AC Motor)

Ball Screw (Duty Cycle 25%)

Speed vs. Load

55.0

50.0

45.0

40.0 A

35.0

30.0

25.0

B

20.0

15.0

C

10.0

5.0

0.0

0 1000 2000 3000 4000 5000 6000

Load (N)

Current vs. Load

3.0

2.0

A

B

1.0 C

0.0

0 1000 2000 3000 4000 5000 6000

Load (N)

12

Current (A) Speed (mm/s)

MA1

series

Page13

MA1 Ordering Key

MA1

Version: 20200710-E

Spindle Type A = ACME Screw B = BALL Screw

Voltage 1 = 12V DC 3 = 36V DC 5 = 220V AC 50Hz

2 = 24V DC 4 = 110V AC 60Hz

Load and Speed See page 3 See page 4

Stroke (mm) See page 3 See page 4

Retracted Length See page 14

(mm)

Rear Attachment 1 = #45 Steel CNC, without slot, hole 13.0

(mm)

See page 14

Front Attachment 1 = #45 Steel CNC, without slot, hole 13.0

(mm)

See page 14

Direction of 1 = 90° (Standard) 2 = 0°

Rear Attachment

(Counterclockwise)

See page 15

Functions for 0 = Without (Needs to choose overload clutch)

Limit Switches 1 = Two switches at full retracted / extended positions to cut current

2 = Two switches at full retracted / extended positions to send signal

Overload Clutch 0 = Without 1 = With

Mechanical Brake 0 = Without 1 = With (Not support the control box with PWM speed adjustment function, such as

See page 15 slow start / stop or sync)

Electromagnetic 0 = Without (Standard) 1 = With

Brake

See page 15

IP Rating 6 = IP66D 8 = IP69K

Manual Drive 0 = Without 1 = With

Output Signals 0 = Without 1 = POT 5 = Hall sensors * 2

See page 16

Connector 1 = Tinned leads

Cable Length (mm) 1 = Straight, 500

13

Page14

MA1 Ordering Key Appendix

Retracted Length (mm)

1. Calculate A+B+C = Y

2. Retracted length needs to ≥ Stroke + Y

A. Type B. Mechanical Brake

ACME, DC Ball, DC ACME, AC Ball, AC ACME, DC Ball, DC ACME, AC Ball, AC

+160 +201 +160 +201 0 - - - -

1 +35 - +35 -

C. Output Signals

ACME, DC Ball, DC ACME, AC Ball, AC

0 - - - -

1 +36 +40 +36 +40

5 - - +36 +40

Rear Attachment (mm)

1 = #45 Steel CNC, without slot, hole

13.0

ø13

14

16.3

Front Attachment (mm)

1 = # 45 Steel CNC, without slot, hole

13.0

11.5

ø13

14

ø28

ø28

ø25.4

Page15

MA1 Ordering Key Appendix

Direction of Rear Attachment (Counterclockwise)

1 = 90° (Standard) 2 = 0°

Mechanical Brake

0 = Without 1 = With (Ball Screw's standard option)

17.3 53 51.8 53

Electromagnetic Brake

0 = Without (Standard, DC) 0 = Without (Standard, AC) 1 = With (DC)

195.1 286.8 227.1

38 113.7 105 138.4 70 113.7

15

ø63.5

ø87

ø63.5

Page16

MA1 Ordering Key Appendix

Output Signals

Wire Definitions AWG Output Signal Code

0. Without 1. POT 5. 2 Hall

DC Motor Motor Side Black 26 - - GND

Blue 26 - - S2

White 26 - - S1

Red 26 - - +5V

Red 14 Stretch+ Stretch+ Stretch+

Black 14 Retract+ Retract+ Retract+

Gear Box Side Red 26 - pin 1 -

White 26 - pin 2 -

Black 26 - pin 3 -

AC Motor Motor Side Black 18 Retract+ Retract+ Retract+

Grey 18 Stretch+ Stretch+ Stretch+

Brown 18 PCBA+ PCBA+ PCBA+

Blue 18 Neutral Neutral Neutral

Green/Yellow 18 GND GND GND

Gear Box Side Red 20 - pin1 +5V

White 20 - pin2 S1

Blue 20 - - S2

Black 20 - pin3 GND

POT

Motor Side Gear Box Side Red

White

Black

Terms of Use

The user is responsible for determining the suitability of TiMOTION products for a specific application.

TiMOTION products are subject to change without prior notice.

16