1/12ページ

ダウンロード(1.4Mb)

TiMOTIONのTL3シリーズは、3段式リフティングコラムで、高いモーメント強度と高推力設計により安定した垂直昇降を提供します。

TL3は工学的な設計プロセスを経て多くの駆動パーツを使用しており、従来のパンタグラフ式昇降機構から置き換えることで、より安全でかつ省スペース化を実現します。3段階の伸縮設計が、短い取付寸法と安定性を高めながらも、ロングストロークを可能とします。

【主な特長】

最大負荷: 4,000N

最大曲げモーメント(動荷重): 1,000Nm

最大曲げモーメント(静荷重): 2,000Nm

速度(定格負荷時): 39mm/sec

取付寸法: ≥ ストローク/2 + 150mm

コラムの寸法: 177.4x150.7 mm

ストローク: 250~1200mm

認証: IEC60601-1、EMC

オプション: POT、ホールセンサー、ダイレクトカットシステム

使用温度範囲: +5°C~+45°C

このカタログについて

| ドキュメント名 | 電動昇降装置【TL3】 |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 1.4Mb |

| 登録カテゴリ | |

| 取り扱い企業 | TiMotion Japan株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

TL3

series

Product Segments The TL3 columns from TiMOTION are made up of three extruded aluminum

tubes of rectangular shape that give the system great stability and a high stroke

• Care Motion with reduced retracted length. This electric lifting column allows for an easy

• Comfort Motion integration into many height adjustable workstation applications, such as an

exam chair in healthcare industry.

• Ergo Motion

• Industrial Motion General Features

Max. load & self - locking force 4,000N (push)

Max. dynamic bending moment 1,000Nm

Max. static bending moment 2,000Nm

Max. speed at max. load 13.7mm/s

Max. speed at no load 39mm/s

Retracted length ≥ Stroke / 2+150mm

IP rating IPX6

Dimension of outer tube 3-stage, 177.4*150.7mm rectangular

Stroke 250~1200mm

Certificate IEC60601-1, EMC

Options POT, Hall sensors, direct cut system

Operational temperature range +5°C~+45°C

1

Page2

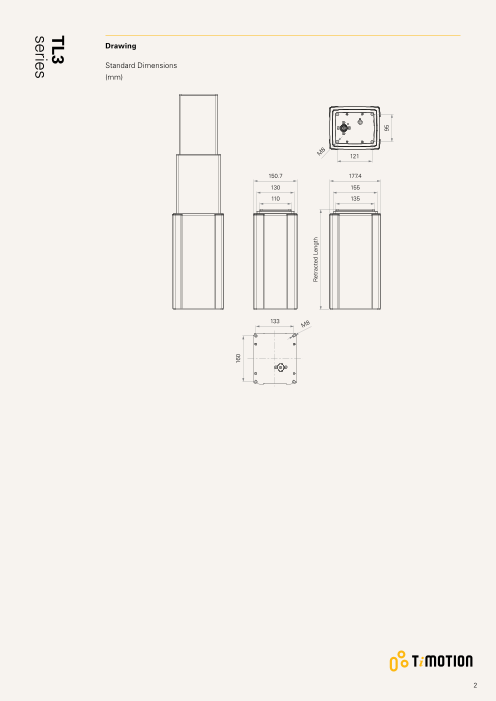

Drawing

Standard Dimensions

(mm)

121

150.7 177.4

130 155

110 135

133

M8

2

160

Retracted Length M

8

95

TL3

series

Page3

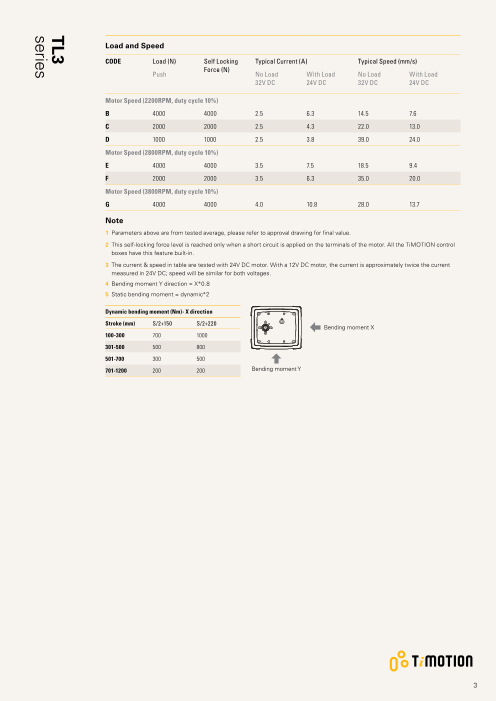

Load and Speed

CODE Load (N) Self Locking Typical Current (A) Typical Speed (mm/s)

Force (N)

Push No Load With Load No Load With Load

32V DC 24V DC 32V DC 24V DC

Motor Speed (2200RPM, duty cycle 10%)

B 4000 4000 2.5 6.3 14.5 7.6

C 2000 2000 2.5 4.3 22.0 13.0

D 1000 1000 2.5 3.8 39.0 24.0

Motor Speed (2800RPM, duty cycle 10%)

E 4000 4000 3.5 7.5 18.5 9.4

F 2000 2000 3.5 6.3 35.0 20.0

Motor Speed (3800RPM, duty cycle 10%)

G 4000 4000 4.0 10.8 28.0 13.7

Note

1 Parameters above are from tested average, please refer to approval drawing for final value.

2 This self-locking force level is reached only when a short circuit is applied on the terminals of the motor. All the TiMOTION control

boxes have this feature built-in.

3 T he current & speed in table are tested with 24V DC motor. With a 12V DC motor, the current is approximately twice the current

measured in 24V DC; speed will be similar for both voltages.

4 Bending moment Y direction = X*0.8

5 Static bending moment = dynamic*2

Dynamic bending moment (Nm)- X direction

Stroke (mm) S/2+150 S/2+220

Bending moment X

100-300 700 1000

301-500 500 800

501-700 300 500

701-1200 200 200 Bending moment Y

3

TL3

series

Page4

Performance Data (24V DC Motor)

Motor Speed (2200RPM, Duty cycle 10%)

Speed vs. Load

40.0

35.0

30.0

D

25.0

20.0

15.0 C

10.0 B

5.0

0.0

0 500 1000 1500 2000 2500 3000 3500 4000

Load (N)

Current vs. Load

10.0

8.0

B

6.0

C

D

4.0

2.0

0.0

0 500 1000 1500 2000 2500 3000 3500 4000

Load (N)

4

Current (A) Speed (mm/s)

TL3

series

Page5

Performance Data (24V DC Motor)

Motor Speed (2800RPM, Duty cycle 10%)

Speed vs. Load

40.0

35.0

30.0

25.0 F

20.0

15.0

E

10.0

5.0

0.0

0 500 1000 1500 2000 2500 3000 3500 4000

Load (N)

Current vs. Load

10.0

8.0 E

F

6.0

4.0

2.0

0.0

0 500 1000 1500 2000 2500 3000 3500 4000

Load (N)

5

Current (A) Speed (mm/s)

TL3

series

Page6

Performance Data (24V DC Motor)

Motor Speed (3800RPM, Duty cycle 10%)

Speed vs. Load

35.0

30.0

25.0

20.0

G

15.0

10.0

5.0

0.0

0 500 1000 1500 2000 2500 3000 3500 4000

Load (N)

Current vs. Load

G

10.0

8.0

6.0

4.0

2.0

0.0

0 500 1000 1500 2000 2500 3000 3500 4000

Load (N)

6

Current (A) Speed (mm/s)

TL3

series

Page7

TL3 Ordering Key - Top End Socket

TL3

Version: 20200421-U

Voltage 1 = 12V DC 5 = 24V DC, thermal control

Load and Speed See page 3

Stroke (mm) 250~1200

Retracted Length See page 10

(mm)

Cable Exit 1 = T op end socket

See page 10

Special Functions 0 = Without (Standard) 1 = Safety nut

for Spindle

Sub-assembly

Functions for Limit 1 = Two switches at full retracted / extended positions to cut current

Switches 3 = Two switches at full retracted / extended positions to send signal

See page 11

IP Rating 1 = Without 2 = IPX4 3 = IPX6

Output Signals 0 = Without 2 = Hall sensors*2 3 = POT

Connector 1 = DIN 6P, socket

See page 11

Cable Length (mm) 0 = Without (The corresponding extension cable TEC needs to be ordered seperately*)

Note: please contact TiMOTION before making an order

Color 1 = Black 2 = Matte silver

Tubes Direction 0 = Thinner on top

See page 12

Grounding Function 0 = Without 1 = With

Note

1 The TL3 is designed especially for push applications, not suitable for pull applications.

7

Page8

TL3 Ordering Key - Side Cable

TL3

Version: 20200421-U

Voltage 1 = 12V DC 5 = 24V DC, thermal control

Load and Speed See page 3

Stroke (mm) 250~1200

Retracted Length See page 10

(mm)

Cable Exit 2 = Bottom side cable 3 = Top side cable 4 = Top (to TC) + Bottom (to TH) side cable

See page 10

Special Functions 0 = Without (Standard) 1 = Safety nut

for Spindle

Sub-assembly

Functions for Limit 1 = Two switches at full retracted / extended positions to cut current

Switches 3 = Two switches at full retracted / extended positions to send signal

See page 11

IP Rating 1 = Without 2 = IPX4 3 = IPX6

Output Signals 0 = Without 2 = Hall sensors*2 3 = POT

Connector 1 = DIN 6P, 90° plug F = DIN 6P, 180° plug H = Molex 8P 180°

See page 11 2 = Tinned leads G = Molex 8P 90°

Cable Length (mm) 1 = Straight, 500 3 = Straight, 1000 5 = Straight, 1500 7 = Straight, 2000

2 = Straight, 750 4 = Straight, 1250 6 = Straight, 1750

Color 1 = Black (Black cable set) 3 = Silver (Black cable set)

2 = Silver (428C color cable set)

Tubes Direction 0 = Thinner on top 1 = Wider on top Note: If "top+bottom cable" in Cable Exit section is

See page 12 selected , could only select #0

Grounding Function 0 = Without 1 = With

Note

1 The TL3 is designed especially for push applications, not suitable for pull applications.

8

Page9

TL3 Ordering Key - Direct Cut

TL3

Version: 20200421-U

Voltage 5 = 24V DC, thermal protector

Load and Speed See page 3

Stroke (mm) 100~1200

Retracted Length See page 10

(mm)

Cable Exit B = Top side - for TH; Bottom side - for TP

See page 10 C = Bottom side - Y cable, for TH + TP

D = Top side - for the 2nd column; Bottom side - for TH & TP; direct cut operation with 2 columns

E = Top side - for the 2nd column & TH; Bottom side - for TP; direct cut operation with 2 columns

Special Functions 0 = Without (Standard) 1 = Safety nut

for Spindle

Sub-assembly

Functions for Limit 1 = Two switches at full retracted / extended positions to cut current

Switches

See page 11

IP Rating 1 = Without 2 = IPX4 3 = IPX6

Output Signals 0 = Without

Connector C = Direct cut, water proof, anti-pull

See page 11

Cable Length (mm) B = Cable exit #B, L2 = L3 = 100 D = Cable exit #D, L2 = L3 = L4 = 100

See page 12 C = Cable exit #C, L1 = L2 = L3 = 100 E = Cable exit #E, L2 = L3 = L4 = 100

Color 1 = Black (With black cable set) 3 = Matte silver (With black cable set)

2 = Matte silver (With 428C color cable set)

Tubes Direction 0 = Thinner on top 1 = Wider on top

See page 12

Grounding Function 0 = Without 1 = With

Note

1 The TL3 is designed especially for push applications, not suitable for pull applications.

9

Page10

TL3 Ordering Key Appendix

Retracted Length (mm)

1. Retracted length needs to ≥ A+B+C

A. Load (N) 1000 2000 4000

Stroke / 2+150 or Stroke / 2+220

Note

1 The minimum retracted length generated by the formula - Stroke / 2+150

applies to the minimum bending moment rating. Please refer to the left column

of the “Dynamic bending moment chart “ on page 3.

B. Cable Exit

CODE Top End Socket Bottom Side Cable Top Side Cable Top + Bottom side cable Direct Cut

1 - - - - -

2 - - - - -

3 - - +15 - -

B - - - +35 -

B, D, E - - - - +35

C - - - - -

C. When with POT (When without POT, C = 0)

Cable Exit Code Top End Bottom Side Cable Top Side

Socket Cable

1 +40 - -

2 - +40 -

3 - - +40

Cable Exit

1 = T op end socket 2 = B ottom side cable

Socket

3 = Top side cable

4 = Top(to TC)+Bottom(to TH) side

cable

10

Page11

TL3 Ordering Key Appendix

Cable Exit

B = Top side - for TH; Bottom side - C = Bottom side - Y cable, for TH + TP D = Top side - for the 2nd column; E = Top side - for the 2nd column &

for TP Bottom side - for TH & TP; direct TH; Bottom side - for TP; direct

cut operation with 2 columns cut operation with 2 columns

Functions for Limit Switches

Wire Definitions

CODE Pin

1 (Green) 2 (Red) 3 (White) 4 (Black) 5 (Yellow) 6 (Blue)

1 extend (VDC+) N/A N/A N/A retract (VDC+) N/A

3 extend (VDC+) common upper limit switch N/A retract (VDC+) lower limit switch

Connector

1 = DIN 6P, socket (Top end socket) 1 = DIN 6P, 90° plug (Side cable) 2 = Tinned leads F = DIN 6P, 180° plug

4

50

G = Molex 8P 90° H = Molex 8P 180°

C = Direct cut, water proof, anti-pull

For TH: For TP: For Columm 2:

long DIN 5P (Pin array 240°), long DIN 5P (Pin array 240°), long DIN 6P (Pin array 240°),

180° socket (with anti-pull clip) 180° plug (with O-ring) 180° plug (with anti-pull clip)

11

Page12

TL3 Ordering Key Appendix

Cable Length (mm)

B = Cable exit #B, L2 = L3 = 100 C = Cable exit #C, L1 = L2 = L3 = 100 D, E = Cable exit #D, #E, L2 = L3 = L4 = 100

L2 L3 L3 L2 L3 L4

TL3

L2 L1

TP TH TH TP TP TH Column 2

Tubes Direction

0 = Thinner on top 1 = Wider on top

Terms of Use

The user is responsible for determining the suitability of TiMOTION products for a specific application.

TiMOTION products are subject to change without prior notice.

12