1/12ページ

Download(3.1Mb)

EV Part Machining Solutions

Product Catalog

Document Information

| Document Title | EV Part Machining Solutions |

|---|---|

| Document Type | Product Catalog |

| File size | 3.1Mb |

| Category | |

| Company | TAKAMAZ (TAKAMATSU MACHINERY Co.,ltd) (Documents List) |

Documents related to this company

Document Contents

Page1

Part Machining Solutions

Page2

The Changing Automobile Market

World’s Biggest Industry

The total annual production of the

automobile industry globally is 170 trillion

yen, making it the biggest manufacturing

industry in the world. For comparison, the

size of the Japanese automobile industry is

about 45 trillion yen.

The medical equipment industry is 40 trillion

yen, with Japan accounting for 4 trillion yen,

while the aircraft industry is 35 trillion yen

with Japan accounting for 1.4 trillion yen.

This automobile industry is now undergoing

a transformation.

A Market Dominated by China

World automobile production stands at 90

million units, and the Chinese market takes

30% of that, or 30 million units.

Japan ranks third among the world’s

automobile manufacturing countries.

An Uncertain Outlook

EU policy is to effectively ban sales of

gasoline vehicles by 2035, but with changes

in the regulatory status in individual

countries, for example altering course to

permit sales under certain conditions, the

future course is not clear.

1

Page3

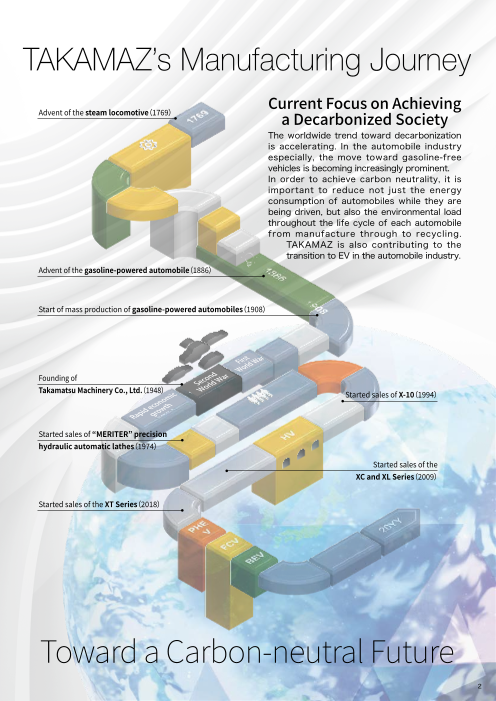

TAKAMAZ’s Manufacturing Journey

Current Focus on Achieving

Advent of the steam locomotive(����) a Decarbonized Society

The worldwide trend toward decarbonization

is accelerating. In the automobile industry

especially, the move toward gasoline-free

vehicles is becoming increasingly prominent.

In order to achieve carbon neutrality, it is

important to reduce not just the energy

consumption of automobiles while they are

being driven, but also the environmental load

throughout the life cycle of each automobile

from manufacture through to recycling.

TAKAMAZ is also contributing to the

transition to EV in the automobile industry.

Advent of the gasoline-powered automobile(����)

Start of mass production of gasoline-powered automobiles(����)

First

Worl

d Wa

r

Founding of Seco

nd

Wor

ld W

ar

Takamatsu Machinery Co., Ltd(. ����)

Rap

id ec

ono

mic Started sales of X-��(����)

grow

th

Started sales of “MERITER” precision

hydraulic automatic lathes(����)

Started sales of the

XC and XL Series(����)

Started sales of the XT Series(����)

Toward a Carbon-neutral Future

2

Page4

BEV & HEV

Made by TAKAMAZ

e-Axle / HEV-System PARTS

e-Axle

● Differential case pinion gear

spider

● Gear carrier output shaft

● Parking gear

● Sun gear

The e-Axle integrates a motor, inverter

● Output shaft and reduction gear. It is a unit that rests

● Input shaft on the chassis and drives the vehicle

when supplied with power.

● Final gear

BEV development takes place in an

● Output gear extremely competitive environment, and

one of the requirements for development

HEV motor unit is speed, but by adopting the “e-Axle”,

automobile manufacturers can develop

● Shaft motor rotor BEVs in a very short time.

3

Page5

Models for Machining BEV & HEV Parts

Differential case Pinion gear

【Material:Ductile cast iron】 【Material:Chrome molybdenum steel】

XL-200 XT-6 XW-130

Spider Shaft motor rotor

【Material:Chrome steel】 【Materia:l Medium-carbon steel】

XT-8 XT-8

4

Page6

Models for Machining BEV & HEV Parts

Shaft generator rotor Shaft

【Materia:l Medium-carbon steel】 【Materia:l Medium-carbon steel】

XT-8 XL-200

Parking wheel Output shaft

【Material:Chrome steel】 【Material:Chrome steel】

XW-130 XW-200

5

Page7

Models for Machining BEV & HEV Parts

Input shaft Output gear

【Material:Chrome steel】 【Material:Chrome steel】

XT-8 XW-130 XW-130

Final gear Gear input shaft

【Material:Chrome steel】 【Material:Chrome steel】

XW-200 XT-8 XW-130

6

Page8

CVJs

Made by TAKAMAZ

Constant Velocity Joint PARTS

These are the constant velocity joints that transmit the

vehicle’s power (torque) to the tires.

Constant velocity joints are also called drive shafts,

and they connect differential gears to the wheels. The

power generated by the engine or motor is transmitted

to differential gears via the transmission, and then

through constant velocity joints to the wheels.

A FWD vehicle is equipped with two CVJs at the front,

a RWD vehicle with two at the rear, and a 4WD vehicle

with four.

Fixed-type CVJ (Ball Joint) Sliding-type CVJ (Tripod Joint)

7

Page9

Models for Machining CVJ Parts

Housing shaft Bar shaft( RWD) Shaft-less outer race

【Material:Chrome molybdenum steel】 【Materia:l Medium-carbon steel】 【Materia:l Medium-carbon steel】

XL-200 X-S700 X-S700 XT-8

Female housing Cage Retainer

【Materia:l Medium-carbon steel】 【Material:Chrome molybdenum steel】 【Materia:l Medium-carbon steel】

XT-8 XT-8 XW-130 XT-6

Spider( tripod) Inner race Outer race with shaft

【Material:Chrome steel】 【Material:Chrome molybdenum steel】 【Material:High-carbon steel】

XT-6 XT-6 XT-8

8

Page10

A Concentration of our Comprehensive

Technological Capabilities Mill/Turn Cutting Improved Durability

Ideal for Shaft Work Improvements in productivity are achieved with power X, Z, Y and Tailstock Axes

tool drive motor outputs of AC 5.5/3.7/2.2 kW and a

milling unit with a maximum tool size of φ20 mm. All Use Square Box-way Slides

5.5/3.7/2.2 kW motors used The square box-way slide construction reputed for its rigidity

MAX.4,000min-1XT-8 is adopted on all axes, so high accuracy can be maintained

Max. torque 70 Nm (3x more than existing TAKAMAZ models)

MY even over long periods of use. And equipping offset

■ Max.4,000min-1(AC 5.5/3.7/2.2kW) management systems including a thermal displacement

750min-1 compensation system(Thermony) and spindle base cooling

6 has enabled even more stable control of dimensions.

CNC 1 SPINDLE 1 TURRET PRECISION LATHE 5 5.5kW(10min. S3 25% operation area)

T=70.0N・m

8 4

(10) inch Chuck 3.7kW(15min. S3 60% operation area)

3

T=47.0N・m

(kW)2 2.2kW Cont. rating area

T=28.0N・m

Number of Y-axis control Power tool Spindle CS-axis Tailstock CE type Environmentally 1

turret stations indexing friendly design

00 1 2 3 4

Spindle speed(×1,000min-1)

XT-8MY with gantry F loader installed

Capacity

15/11 kW high-efficiency Space savings

motors used for high cutting Smallest floor space

performance in the class

Offers the greatest compactness when compared to

competitors’ models in the same class. Even machines

equipped with a Y axis allow efficient use of the floor

space.

Depth of cut: 5mm

Feed rate: 0.4mm/rev

Cutting cross

sectional area: 2.0m㎡ -axi

s:42

0st

Adoption of BMT Turret Z

300

mm

Heavy-duty (for short-term rating)

cutting on O.D. (d×f) The bolt mounting system( BMT55) is used for the

turret, allowing quicker setups. The turret half-indexing

O.D. grooving mechanism allows up to 24 tools to be mounted,

Depth of cut: 7mm ■ Max.4,000min(-1 AC 15/11kW) φ100 making it possible to shorten setup times.

Feed rate: 0.1mm/rev 18 1,333min-1 2,333min-1

(A maximum of 12 power tools can be mounted.)

Groove width: 5mm 15kW

15 (15min. S3 25% operation area) BMT55

Distance from

T=143N・m Maximum tool size: φ20 mm

chuck nose: 94mm 12 60min. S3 40% operation area 11.2kW

Groove width / distance from chuck 11kW

9 Cont. rating area

Drilling 8.2kW

(kW) T=105N・m

6 T=79N・m

Drill diameter: 25mm Holder for half-indexing

3

Feed rate: 0.28mm/rev ■ Ability to accommodate diverse tooling layouts with full lineup

0 of attachments

0 1 2 3 4 ■ Improved repeat accuracy in holder mounting 2.4m2

Feed rate Spindle speed(×1,000min-1) ■ Half-indexing support for mounting tools at up to 24 stations

9

Output

Output

Page11

A Concentration of our Comprehensive

Technological Capabilities Mill/Turn Cutting Improved Durability

Ideal for Shaft Work Improvements in productivity are achieved with power X, Z, Y and Tailstock Axes

tool drive motor outputs of AC 5.5/3.7/2.2 kW and a

milling unit with a maximum tool size of φ20 mm. All Use Square Box-way Slides

5.5/3.7/2.2 kW motors used The square box-way slide construction reputed for its rigidity

MAX.4,000min-1XT-8 is adopted on all axes, so high accuracy can be maintained

Max. torque 70 Nm (3x more than existing TAKAMAZ models)

MY even over long periods of use. And equipping offset

■ Max.4,000min-1(AC 5.5/3.7/2.2kW) management systems including a thermal displacement

750min-1 compensation system(Thermony) and spindle base cooling

6 has enabled even more stable control of dimensions.

CNC 1 SPINDLE 1 TURRET PRECISION LATHE 5 5.5kW(10min. S3 25% operation area)

T=70.0N・m

8 4

(10) inch Chuck 3.7kW(15min. S3 60% operation area)

3

T=47.0N・m

(kW)2 2.2kW Cont. rating area

T=28.0N・m

Number of Y-axis control Power tool Spindle CS-axis Tailstock CE type Environmentally 1

turret stations indexing friendly design

00 1 2 3 4

Spindle speed(×1,000min-1)

XT-8MY with gantry F loader installed

Capacity

15/11 kW high-efficiency Space savings

motors used for high cutting Smallest floor space

performance in the class

Offers the greatest compactness when compared to

competitors’ models in the same class. Even machines

equipped with a Y axis allow efficient use of the floor

space.

Depth of cut: 5mm

Feed rate: 0.4mm/rev

Cutting cross

sectional area: 2.0m㎡ -axi

s:42

0st

Adoption of BMT Turret Z

300

mm

Heavy-duty (for short-term rating)

cutting on O.D. (d×f) The bolt mounting system( BMT55) is used for the

turret, allowing quicker setups. The turret half-indexing

O.D. grooving mechanism allows up to 24 tools to be mounted,

Depth of cut: 7mm ■ Max.4,000min(-1 AC 15/11kW) φ100 making it possible to shorten setup times.

Feed rate: 0.1mm/rev 18 1,333min-1 2,333min-1

(A maximum of 12 power tools can be mounted.)

Groove width: 5mm 15kW

15 (15min. S3 25% operation area) BMT55

Distance from

T=143N・m Maximum tool size: φ20 mm

chuck nose: 94mm 12 60min. S3 40% operation area 11.2kW

Groove width / distance from chuck 11kW

9 Cont. rating area

Drilling 8.2kW

(kW) T=105N・m

6 T=79N・m

Drill diameter: 25mm Holder for half-indexing

3

Feed rate: 0.28mm/rev ■ Ability to accommodate diverse tooling layouts with full lineup

0 of attachments

0 1 2 3 4 ■ Improved repeat accuracy in holder mounting 2.4m2

Feed rate Spindle speed(×1,000min-1) ■ Half-indexing support for mounting tools at up to 24 stations

10

Output

Output

Page12

Head Office and Plant

■TAKAMATSU MACHINERY CO., LTD.

・ HEAD OFFICE

1-8 ASAHIGAOKA HAKUSAN-CITY ISHIKAWA JAPAN. 924-8558

TEL +81-(0)76-207-6155 FAX +81-(0)76-274-1418

・ ASAHI PLANT

4-13 ASAHIGAOKA HAKUSAN-CITY ISHIKAWA JAPAN. 924-0004

TEL +81-(0)76-274-0123 FAX +81-(0)76-274-8530

Overseas Bases

■TAKAMATSU MACHINERY U.S.A., INC.

・ CHICAGO HEAD OFFICE

1280 LANDMEIER ROAD ELK GROVE VILLAGE, IL 60007 USA

TEL +1-(0)847-981-8577 FAX +1-(0)847-981-8599

■TAKAMAZ MACHINERY EUROPE GmbH

IM HÜLSENFELD 19, 40721 HILDEN, GERMANY

TEL +49-(0)2103-789-4882 FAX +49-(0)2103-789-4883

■TAKAMAZ MACHINERY( HANGZHOU) CO., LTD.

・ HANGZHOU HEAD OFFICE

NO.6800, JIANGDONG 3RD ROAD, JIANGDONG INDUSTRIAL PARK,

XIAOSHAN, HANGZHOU, ZHEJIANG, CHINA

TEL +86(- 0)571-8287-9709 FAX +86(- 0)571-8215-3732

■TAKAMATSU MACHINERY( THAILAND) CO., LTD.

・ BANGKOK HEAD OFFICE

888/59 MOO 9, TAMBOL BANGPLA, AMPHUR BANGPLEE,

SAMUTPRAKARN PROVINCE, THAILAND

TEL +66(- 0)2-136-7831 FAX +66(- 0)2-136-7834

■PT. TAKAMAZ INDONESIA

JL. FESTIVAL BOULEVARD BLOK AA 11 NO.30,31 GRAND WISATA TAMBUN, BEKASI 17510

TEL +62-(0)21-8261-6431 FAX +62-(0)21-8261-6430

■TAKAMAZ MACHINERY MEXICO, S.A.DE C.V.

AVENIDA DE LOS INDUSTRIALES 522, LOCAL 4, INDUSTRIAL JULIAN DE OBREGON,

37290 LEON, GUANAJUATO MEXICO

TEL +52-477-784-0468

■TAKAMATSU MACHINERY VIETNAM CO., LTD

NO.76 M HOANG QUOC VIET, PHU MY WARD, DISTRICT 7, HO CHI MINH CITY, VIETNAM

TEL +84-(0)28-3620-5671 FAX +84-(0)28-3620-5673

Affiliated Companies

■HANGZHOU FEELER TAKAMATSU MACHINERY CO., LTD.

NO.6800, JIANGDONG 3RD ROAD, JIANGDONG INDUSTRIAL PARK,

XIAOSHAN, HANGZHOU, ZHEJIANG, CHINA

TEL +86(- 0)571-8215-3760 FAX +86(- 0)571-8286-5311

https://www.takamaz.co.jp Electric vehicles are used for

transportation between the

Scan this QR Code

for more details. head office and the Asahi Plant.

23.10.1B(O)