1/20ページ

Download(4.2Mb)

TAKAMAZ XY Series Catalog

Product Catalog

CNC Multi turning center

Document Information

| Document Title | TAKAMAZ XY Series Catalog |

|---|---|

| Document Type | Product Catalog |

| File size | 4.2Mb |

| Category | |

| Company | TAKAMAZ (TAKAMATSU MACHINERY Co.,ltd) (Documents List) |

Documents related to this company

Document Contents

Page1

CNC Multi-Turning Center

XYseries

TAKAMATSU MACHINERY CO., LTD. TAKAMAZ MACHINERY MEXICO, S.A.DE C.V.

■HEAD OFFICE & PLANT AVENIDA DE LOS INDUSTRIALES 522, LOCAL 4, INDUSTRIAL JULIAN DE OBREGON, 37290 LEON,

1-8 ASAHIGAOKA HAKUSAN-CITY ISHIKAWA JAPAN. 924-8558 TEL +81-(0)76-207-6155 FAX +81-(0)76-274-1418 GUANAJUATO MEXICO

■ASAHI PLANT TEL +52-477-784-0468

4-13 ASAHIGAOKA HAKUSAN-CITY ISHIKAWA JAPAN. 924-0004 TEL +81-(0)76-274-0123 FAX +81-(0)76-274-8530 TAKAMATSU MACHINERY VIETNAM CO., LTD

TAKAMATSU MACHINERY U.S.A., INC. NO.76 M HOANG QUOC VIET, PHU MY WARD, DISTRICT 7, HO CHI MINH CITY, VIETNAM

■CHICAGO HEAD OFFICE TEL +84-(0)28-3620-5671 FAX +84-(0)28-3620-5673

1280 LANDMEIER ROAD ELK GROVE VILLAGE, IL 60007 USA TEL +1-(0)847-981-8577 FAX +1-(0)847-981-8599

TAKAMAZ MACHINERY EUROPE GmbH

IM HÜLSENFELD 19, 40721 HILDEN, GERMANY TEL +49-(0)2103-789-4882 FAX +49-(0)2103-789-4883

TAKAMAZ MACHINERY( HANGZHOU) CO., LTD.

■HANGZHOU HEAD OFFICE

NO.6800, JIANGDONG 3RD ROAD, JIANGDONG INDUSTRIAL PARK, XIAOSHAN, HANGZHOU, ZHEJIANG, CHINA

TEL +86-(0)571-8287-9709 FAX +86-(0)571-8215-3732 Precautions Related to Foreign Exchange and Foreign Trade Control Laws

TAKAMATSU MACHINERY( THAILAND) CO., LTD. This product (machine and ancillary equipment) may fall under the category of controlled

goods by the foreign exchange and foreign trade control laws.

■BANGKOK HEAD OFFICE As such, the exportation must be authorized by the Japanese government as stipulated in the laws

888/59 MOO 9, TAMBOL BANGPLA, AMPHUR BANGPLEE, SAMUTPRAKARN PROVINCE, THAILAND This product is manufactured in accordance with the regulations and standards that prevail in the

TEL +66-(0)2-136-7831 FAX +66-(0)2-136-7834 country or region of destination.

PT. TAKAMAZ INDONESIA The user must not export, sell, or relocate the product, to anycountry with different regulations or standards.

JL. FESTIVAL BOULEVARD BLOK AA 11 NO.30,31 GRAND WISATA TAMBUN, BEKASI 17510

TEL +62-(0)21-8261-6431 FAX +62-(0)21-8261-6430

23.07.1B(O)

Page2

CNC Multi-Turning Center

This middle size multi-turning center

is equipped with the sub-spindle X2

axis to enable superimposed cutting

and can be installed with an optional

sub-turret, which further helps short-

en turning time.

Compared to conventional machines,

higher-grade motors are used to

achieve an OD turning area of 0.87

mm2 (10% increase) on the main-spin-

dle side and 0.5 mm2 (13% increase)

on the sub-spindle side.

※Cutting amount×Feedrate.

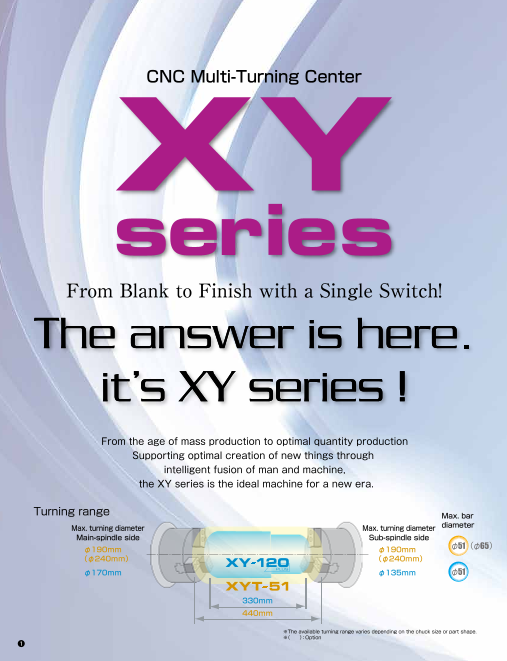

From Blank to Finish with a Single Switch! Main-turret Y1

X1

(12-station)

Z1

Main-spindle (6") Sub-spindle (5")

CS1 CS2 Z2

X2

Both spindles are

fully synchronized.

Sub-turret

(12-station)

From the age of mass production to optimal quantity production

Supporting optimal creation of new things through Suited to bar work up to max. φ51 mm

intelligent fusion of man and machine, (φ65 mm), and able to accommodate

the XY series is the ideal machine for a new era. a maximum of 48 turning tools through

half indexing or 24 power tools.

Increasing motor output beyond that

Turning range of the existing machines allows it

Max. bar to handle heavy-duty cutting and

Max. turning diameter Max. turning diameter diameter compound machining.

Main-spindle side Sub-spindle side

φ190mm φ190mm φ51(φ65) Y1

X1 #1 Turret

(φ240mm) (φ240mm) Z1 (12-station)

φ170mm φ135mm φ51 Main-spindle (6") Sub-spindle (6")

C1 C2 A

Both spindles are

330mm fully synchronized.

440mm #2 Turret Z2

(12-station) X2

※The available turning range varies depending on the chuck size or part shape.

※( ):Option

1 2

Page3

CNC Multi-Turning Center

This middle size multi-turning center

is equipped with the sub-spindle X2

axis to enable superimposed cutting

and can be installed with an optional

sub-turret, which further helps short-

en turning time.

Compared to conventional machines,

higher-grade motors are used to

achieve an OD turning area of 0.87

mm2 (10% increase) on the main-spin-

dle side and 0.5 mm2 (13% increase)

on the sub-spindle side.

※Cutting amount×Feedrate.

From Blank to Finish with a Single Switch! Main-turret Y1

X1

(12-station)

Z1

Main-spindle (6") Sub-spindle (5")

CS1 CS2 Z2

X2

Both spindles are

fully synchronized.

Sub-turret

(12-station)

From the age of mass production to optimal quantity production

Supporting optimal creation of new things through Suited to bar work up to max. φ51 mm

intelligent fusion of man and machine, (φ65 mm), and able to accommodate

the XY series is the ideal machine for a new era. a maximum of 48 turning tools through

half indexing or 24 power tools.

Increasing motor output beyond that

Turning range of the existing machines allows it

Max. bar to handle heavy-duty cutting and

Max. turning diameter Max. turning diameter diameter compound machining.

Main-spindle side Sub-spindle side

φ190mm φ190mm φ51(φ65) Y1

X1 #1 Turret

(φ240mm) (φ240mm) Z1 (12-station)

φ170mm φ135mm φ51 Main-spindle (6") Sub-spindle (6")

C1 C2 A

Both spindles are

330mm fully synchronized.

440mm #2 Turret Z2

(12-station) X2

※The available turning range varies depending on the chuck size or part shape.

※( ):Option

1 2

Page4

Turning and milling available with the Y axis for power tools

Equipped with a Y axis and milling function, multi-turning operation equi-

valent to machining centers is possible. By using the Y axis, multi-turning

operations such as polar coordinate interpolation and cylindrical interpo-

lation which were conventionally difficult with turning machines are

made simpler with high precision.

Y-axis Power tool Power tool

cutting range storage capacity capacity Cylinder blocks

(car air-conditioners) Bar work automated FANUC Manual Guide i

with parts catcher installed for good and

± 35mm 12 tools / turret φ13mm,M8mm easy-to-use programming

The parts catcher can be configured to Cutting cycles for milling, turning, inclined

the most appropriate part-receiving timing cutting and more can be programmed

± 35mm 12 tools / #1 turret φ13mm,M12mm by programming and, if combined with an with ease and simulated in realistic

12 tools / #2 turret φ13mm,M12mm automatic bar feeder, enables extended graphical representation, which will

unmanned operation of bar work. dramatically shorten programming time.

Pistons

Sub-spindle provided for shaft work and

blank-to-finish cutting on both front and back faces

A sub-spindle having the same capability as the main-spindle enables

back face cutting of the second process in a single machine struc-

ture. Fully synchronized rotation of both spindles offers high precision Swivable operation panel Chip conveyor for chip

and uniform finish shaft work. Sleeves, body valves for good operability accumulation prevention

To reduce the operator's burden, a The slant bed structure of the XY series

Sub-spindle

Chuck size Spindle speed Stroke swivable operation panel is employed in assures a smooth flow of chips. Even if

cons i de ra t i on o f m in im i z i ng t he chips have complex shapes depending

operator’s motion area. Operations in on cutting conditions, using a chip

good posture support a strain-free, conveyor in combination can remove

5 inches Max.5,000min-1 440mm efficient and safe working environment. such chips smoothly from the machine.

Consideration to maintenance and environment

6 inches Max.5,000min-1 550mm For ease of maintenance and good operability, the chuck pressure regulating valve and lubrication

pump are arranged on the front face of the machine. A periodical inspection notice function notifies

Gear sleeves the time of battery replacement and hydraulic pump inspection to support control of maintenance

and help keep the machine in top condition all the time. In addition, the XY-120plus is equipped with

high-performance motors.

φ51 Specification φ65 Specification(OP)

Power Main-spindle Sub-spindle Power tools Main-spindle Sub-spindle Main-spindle Sub-spindle Power tools

AC7.5/5.5kW AC11/7.5kW(OP) AC5.5/3.7kW AC3.7/2.2/1.5kW AC18.5/15/11kW AC9/7.5/5.5kW AC18.5/15/11kW AC9/7.5/5.5kW AC3.7/2.2kW

Characteristic Max. 5,000min-1 Max. 4,000min-1 Max. 5,000min-1 Max. 4,000min-1 Max. 5,000min-1 MAX.5,000min-1 Max. 4,000min-1 MAX.4,000min-1 Max. 4,000min-1

12 12 12 4 21

750 3,000 1,5003.7kW 5 min rated 18.5kW S3 15% operating area 12 21 18.5kW S3 15% operating area 12 4 1,500

18 1,500 2,500

10 9kW S3 15% operating area 3.7kW 15min, S3 60%

T=118N・m 18 1,250 2,083

Curve operating area

10 7.5kW 15 min, S3 25% 10 11kW 15 min, S3 10 10 9kW S3 15% operating area

operating area 25% operating area T=141N・m

1,500 4,500 operating area

3 15 T=95.5N・m 3,500 15 T=114N・m 1,125 3,375

2,916 3

8 1,250 3,750 8 1,333 7.5kW Continuous 8

A wide range of high operating area 5.5kW 15 min, S3 40% 2.2kW 15 min, rated 15kW 8 T=57.3N・m 15kW 8 T=76N・m

operating area operating area 12 15min, S3 25% operating area 15min, S3 25% operating area

2,000 7.5kW 15min, S3 25% operating area 12 1,666 7.5kW 15min, S3 25% operating area

performance motors are 6 1,666 5.5kW Continuous 6 T=105.0N・m

T=70.5N・m 6 1,125 3,375 2 1.5kW Continuous rated (kW)

9 11kW Continuous (kW)6 2,000 (kW) (kW)6 1,500 (kW)2 2.2kW Continuous

(kW) operating area operating area 5.5kW Continuous 9 11kW Continuous

T=57.6N・m (kW) T=55.5N・m (kW) 1,500 3.7kW (kW) operating area operating area 5.5kW Continuous operating area

available according to your 4 T=42.0N・m 4 4 Continuous operating area

6 60min, S3 40% 4 operating area 4 operating are

operating area T=47.8N・m 6 60min, S3 40%

60 min, S3 40% T=46.6N・m 1 T=23.6N・m operating area T=62.7N・m

T=31.2N・m

needs from high horsepower 2 2 operating area 1

2 T=36.0N・m

T=24.0N・m T=13.9N・m 3 T=70N・m 2 T=35.0N・m

T=26.3N・m 3 T=84N・m T=46.7N・m

60 min, S3 40% 2 T=34.7N・m

T=52.5N・m 60min, S3 40% operating area T=63N・m

to high speed rotation. operating area T=9.54N・m

0 0 0 60 min, S3 40% operating area 60min, S3 40% operating area

0 0 0 0 0 0

0 1 2 3 4 5 0 1 2 3 4 5 0 1 2 3 4 5 0 1 2 3 4 0 1 2 3 4 5 0 1 2 3 4 5 0 1 2 3 4 5 0 1 2 3 4 5 0 1 2 3 4

Spindle speed (×1,000min-1) Spindle speed (×1,000min-1) Spindle speed (×1,000min-1) Spindle speed (×1,000min-1) Spindle speed (×1,000min-1) Spindle speed (×1,000min-1) Spindle speed (×1,000min-1) Spindle speed (×1,000min-1) Spindle speed (×1,000min-1)

3 4

Output

Output

Output

Output

Output

Output

Output

Output

Output

Page5

Turning and milling available with the Y axis for power tools

Equipped with a Y axis and milling function, multi-turning operation equi-

valent to machining centers is possible. By using the Y axis, multi-turning

operations such as polar coordinate interpolation and cylindrical interpo-

lation which were conventionally difficult with turning machines are

made simpler with high precision.

Y-axis Power tool Power tool

cutting range storage capacity capacity Cylinder blocks

(car air-conditioners) Bar work automated FANUC Manual Guide i

with parts catcher installed for good and

± 35mm 12 tools / turret φ13mm,M8mm easy-to-use programming

The parts catcher can be configured to Cutting cycles for milling, turning, inclined

the most appropriate part-receiving timing cutting and more can be programmed

± 35mm 12 tools / #1 turret φ13mm,M12mm by programming and, if combined with an with ease and simulated in realistic

12 tools / #2 turret φ13mm,M12mm automatic bar feeder, enables extended graphical representation, which will

unmanned operation of bar work. dramatically shorten programming time.

Pistons

Sub-spindle provided for shaft work and

blank-to-finish cutting on both front and back faces

A sub-spindle having the same capability as the main-spindle enables

back face cutting of the second process in a single machine struc-

ture. Fully synchronized rotation of both spindles offers high precision Swivable operation panel Chip conveyor for chip

and uniform finish shaft work. Sleeves, body valves for good operability accumulation prevention

To reduce the operator's burden, a The slant bed structure of the XY series

Sub-spindle

Chuck size Spindle speed Stroke swivable operation panel is employed in assures a smooth flow of chips. Even if

cons i de ra t i on o f m in im i z i ng t he chips have complex shapes depending

operator’s motion area. Operations in on cutting conditions, using a chip

good posture support a strain-free, conveyor in combination can remove

5 inches Max.5,000min-1 440mm efficient and safe working environment. such chips smoothly from the machine.

Consideration to maintenance and environment

6 inches Max.5,000min-1 550mm For ease of maintenance and good operability, the chuck pressure regulating valve and lubrication

pump are arranged on the front face of the machine. A periodical inspection notice function notifies

Gear sleeves the time of battery replacement and hydraulic pump inspection to support control of maintenance

and help keep the machine in top condition all the time. In addition, the XY-120plus is equipped with

high-performance motors.

φ51 Specification φ65 Specification(OP)

Power Main-spindle Sub-spindle Power tools Main-spindle Sub-spindle Main-spindle Sub-spindle Power tools

AC7.5/5.5kW AC11/7.5kW(OP) AC5.5/3.7kW AC3.7/2.2/1.5kW AC18.5/15/11kW AC9/7.5/5.5kW AC18.5/15/11kW AC9/7.5/5.5kW AC3.7/2.2kW

Characteristic Max. 5,000min-1 Max. 4,000min-1 Max. 5,000min-1 Max. 4,000min-1 Max. 5,000min-1 MAX.5,000min-1 Max. 4,000min-1 MAX.4,000min-1 Max. 4,000min-1

12 12 12 4 21

750 3,000 1,5003.7kW 5 min rated 18.5kW S3 15% operating area 12 21 18.5kW S3 15% operating area 12 4 1,500

18 1,500 2,500

10 9kW S3 15% operating area 3.7kW 15min, S3 60%

T=118N・m 18 1,250 2,083

Curve operating area

10 7.5kW 15 min, S3 25% 10 11kW 15 min, S3 10 10 9kW S3 15% operating area

operating area 25% operating area T=141N・m

1,500 4,500 operating area

3 15 T=95.5N・m 3,500 15 T=114N・m 1,125 3,375

2,916 3

8 1,250 3,750 8 1,333 7.5kW Continuous 8

A wide range of high operating area 5.5kW 15 min, S3 40% 2.2kW 15 min, rated 15kW 8 T=57.3N・m 15kW 8 T=76N・m

operating area operating area 12 15min, S3 25% operating area 15min, S3 25% operating area

2,000 7.5kW 15min, S3 25% operating area 12 1,666 7.5kW 15min, S3 25% operating area

performance motors are 6 1,666 5.5kW Continuous 6 T=105.0N・m

T=70.5N・m 6 1,125 3,375 2 1.5kW Continuous rated (kW)

9 11kW Continuous (kW)6 2,000 (kW) (kW)6 1,500 (kW)2 2.2kW Continuous

(kW) operating area operating area 5.5kW Continuous 9 11kW Continuous

T=57.6N・m (kW) T=55.5N・m (kW) 1,500 3.7kW (kW) operating area operating area 5.5kW Continuous operating area

available according to your 4 T=42.0N・m 4 4 Continuous operating area

6 60min, S3 40% 4 operating area 4 operating are

operating area T=47.8N・m 6 60min, S3 40%

60 min, S3 40% T=46.6N・m 1 T=23.6N・m operating area T=62.7N・m

T=31.2N・m

needs from high horsepower 2 2 operating area 1

2 T=36.0N・m

T=24.0N・m T=13.9N・m 3 T=70N・m 2 T=35.0N・m

T=26.3N・m 3 T=84N・m T=46.7N・m

60 min, S3 40% 2 T=34.7N・m

T=52.5N・m 60min, S3 40% operating area T=63N・m

to high speed rotation. operating area T=9.54N・m

0 0 0 60 min, S3 40% operating area 60min, S3 40% operating area

0 0 0 0 0 0

0 1 2 3 4 5 0 1 2 3 4 5 0 1 2 3 4 5 0 1 2 3 4 0 1 2 3 4 5 0 1 2 3 4 5 0 1 2 3 4 5 0 1 2 3 4 5 0 1 2 3 4

Spindle speed (×1,000min-1) Spindle speed (×1,000min-1) Spindle speed (×1,000min-1) Spindle speed (×1,000min-1) Spindle speed (×1,000min-1) Spindle speed (×1,000min-1) Spindle speed (×1,000min-1) Spindle speed (×1,000min-1) Spindle speed (×1,000min-1)

3 4

Output

Output

Output

Output

Output

Output

Output

Output

Output

Page6

Cycle time shortened with superimposed cutting The XY series machines have a spacious cutting chamber which makes

Superimposed in-machine work such as setup changes easier and provides a turning

Cutting X2 axis configuration is added to the sub-spindle slide to enable X- and Z-axis range flexible with varied workpieces.

superimposed cutting. An optional sub-turret further enables superimposed cutting

simultaneously on the main-spindle and the sub-spindle, which contributes to drastic Chip expulsion and dust-proofing are also improved compared to existing

cycle time reduction. (See the chart below.) machines, and the 60°angled cover under the turret reduces retention of

chips in the machine, and improves the chip removal capability which is

required by a mult i -turning center. Linear guides with excel lent

Main-spindle Cut

off Supply OD turning ID turning Drill Endmill Waiting dust-proofing are adopted.

Passing

Sub-spindle Waiting OD turning ID turning Drill Drill Discharge

Cover angle 60° Sliding slideway cover of

single-plate construction

Max. 50% time reduction

Simultaneous front and back face cutting is ※Excluding part supply, passing and discharge time

available by using the sub-spindle axis.

Main-spindle Cut

off Supply OD turning ID turning Drill Endmill

Passing

Sub-spindle OD turning ID turning Drill Drill Discharge

Superimposed cutting Cutting with sub-turret

Sufficient tool storage capacity

The 12-station main-turret with the intermediate indexing function has 24 tool

storage positions or if a sub-turret is installed 36 tool storage positions, reducing the

number of tool setup times that might be required frequently during various kinds

various volumes production.

A maximum of 12 power tools for drilling of up to φ13 mm can be installed. 60°

Sliding door adopted for ease of maintenance

The right side cover of the machine can be slid as a maintenance door.

A large maintenance area can be secured, which facilitates maintenance

or inspections and helps to reduce machine failures and trouble.

By applying two synchronized turning tools (for example, a rough turning tool and a

BALANCE CUT finish turning tool) simultaneously from both sides, part deflection can be dampened,

achieving high cutting precision and shorter cycle times.

Main-spindle side On the Sub-spindle side

#1 Turret

Use of bolt mount system (BMT45, 55)

#1 and #2 turrets are synchronized during The XYT-51 adopts the new global standard BMT system. This is a holder

OD turning for high precision balance cutting. securing system using four bolts and key grooves.

It is compatible with a wide range of attachments and a variety of tooling layouts

by each holder manufacturer, enabling turning and milling tailored to your needs

#2 Turret of production.

5 6

Conventional machine This machine

Page7

Cycle time shortened with superimposed cutting The XY series machines have a spacious cutting chamber which makes

Superimposed in-machine work such as setup changes easier and provides a turning

Cutting X2 axis configuration is added to the sub-spindle slide to enable X- and Z-axis range flexible with varied workpieces.

superimposed cutting. An optional sub-turret further enables superimposed cutting

simultaneously on the main-spindle and the sub-spindle, which contributes to drastic Chip expulsion and dust-proofing are also improved compared to existing

cycle time reduction. (See the chart below.) machines, and the 60°angled cover under the turret reduces retention of

chips in the machine, and improves the chip removal capability which is

required by a mult i -turning center. Linear guides with excel lent

Main-spindle Cut

off Supply OD turning ID turning Drill Endmill Waiting dust-proofing are adopted.

Passing

Sub-spindle Waiting OD turning ID turning Drill Drill Discharge

Cover angle 60° Sliding slideway cover of

single-plate construction

Max. 50% time reduction

Simultaneous front and back face cutting is ※Excluding part supply, passing and discharge time

available by using the sub-spindle axis.

Main-spindle Cut

off Supply OD turning ID turning Drill Endmill

Passing

Sub-spindle OD turning ID turning Drill Drill Discharge

Superimposed cutting Cutting with sub-turret

Sufficient tool storage capacity

The 12-station main-turret with the intermediate indexing function has 24 tool

storage positions or if a sub-turret is installed 36 tool storage positions, reducing the

number of tool setup times that might be required frequently during various kinds

various volumes production.

A maximum of 12 power tools for drilling of up to φ13 mm can be installed. 60°

Sliding door adopted for ease of maintenance

The right side cover of the machine can be slid as a maintenance door.

A large maintenance area can be secured, which facilitates maintenance

or inspections and helps to reduce machine failures and trouble.

By applying two synchronized turning tools (for example, a rough turning tool and a

BALANCE CUT finish turning tool) simultaneously from both sides, part deflection can be dampened,

achieving high cutting precision and shorter cycle times.

Main-spindle side On the Sub-spindle side

#1 Turret

Use of bolt mount system (BMT45, 55)

#1 and #2 turrets are synchronized during The XYT-51 adopts the new global standard BMT system. This is a holder

OD turning for high precision balance cutting. securing system using four bolts and key grooves.

It is compatible with a wide range of attachments and a variety of tooling layouts

by each holder manufacturer, enabling turning and milling tailored to your needs

#2 Turret of production.

5 6

Conventional machine This machine

Page8

T OOLING SYSTEM TURRET

Tooling System Turret interference

O.D./Face/Grooving tool□20

Clamp block C

O.D. holder S

O.D. holder(W)

O.D./Face tool□20 □20

Clamp block C

φ 1

2 6

0 5

Turning holder

Tap Tap holder 80

□1

6 16

Round hole bush 5

φ20 φ 3

13 75

φ16

Boring bar φ12 30

Maxφ25 φ10

φ8 12-station main-turret 75 210

Blank Plug

φ25 boring holder 25

100 105

φ100

5

φ11 85

U-drill Round hole bush

Maxφ25 φ20 120

φ

φ25 U-drill holder 110

5

φ1

3

φ17

0

Cut-off tool□20

95

30

Cut-off holder

φ13

5 φ5

1

Clamp block16(A) φ13 150

□ s

Straight drill Tool□16 2 t φ

0 6 2

5 00

Endmill 60

26 1

Maxφ13 Clamp block16(B) 20

Collet chuck φ

1 4 2

ER20-φD Face milling holder 0

5

Tap (also for rear milling) 0st 2 8

0 5

5

Max.M8

Sub-turret

Boring bar Round hole bush

Maxφ20 φ16 12-station sub-turre(t OP.)

Center φ12

φ10

straight φ8

drill φ6

Side milling holder Blank

Round hole bush

Boring bar φ16

Maxφ20 φ12

φ10

φ8

φ6

Blank Boring holde(r 24ST)

24ST

Clamp block16(A)

Tool□16

Clamp block16(B)

O.D. holder S(24ST)

Uni(t mm) Uni(t mm)

7 8

□16

φ115

φ20

φ20

φ2 1035 80

10

7 75

φ51

φ135

φ51

φ5

φ 151

□1

6

1

φ5

□1

6

φ115

φ580

Page9

T OOLING SYSTEM TURRET

Tooling System Turret interference

O.D./Face/Grooving tool□20

Clamp block C

O.D. holder S

O.D. holder(W)

O.D./Face tool□20 □20

Clamp block C

φ 1

2 6

0 5

Turning holder

Tap Tap holder 80

□1

6 16

Round hole bush 5

φ20 φ 3

13 75

φ16

Boring bar φ12 30

Maxφ25 φ10

φ8 12-station main-turret 75 210

Blank Plug

φ25 boring holder 25

100 105

φ100

5

φ11 85

U-drill Round hole bush

Maxφ25 φ20 120

φ

φ25 U-drill holder 110

5

φ1

3

φ17

0

Cut-off tool□20

95

30

Cut-off holder

φ13

5 φ5

1

Clamp block16(A) φ13 150

□ s

Straight drill Tool□16 2 t φ

0 6 2

5 00

Endmill 60

26 1

Maxφ13 Clamp block16(B) 20

Collet chuck φ

1 4 2

ER20-φD Face milling holder 0

5

Tap (also for rear milling) 0st 2 8

0 5

5

Max.M8

Sub-turret

Boring bar Round hole bush

Maxφ20 φ16 12-station sub-turre(t OP.)

Center φ12

φ10

straight φ8

drill φ6

Side milling holder Blank

Round hole bush

Boring bar φ16

Maxφ20 φ12

φ10

φ8

φ6

Blank Boring holde(r 24ST)

24ST

Clamp block16(A)

Tool□16

Clamp block16(B)

O.D. holder S(24ST)

Uni(t mm) Uni(t mm)

7 8

□16

φ115

φ20

φ20

φ2 1035 80

10

7 75

φ51

φ135

φ51

φ5

φ 151

□1

6

1

φ5

□1

6

φ115

φ580

Page10

STROKE TOOLING SYSTEM

Stroke-Related Drawing Tooling System

BMT45

Turning holder Boring holder

O.D./Face/Grooving tool □20

Clamp block C

O.D. holder

90 250 60 60 260 95 250 55 50 270

100 100

636 85

47 14 Max85

O.D./Face tool □20

11.1 37 11.1 37

330st

(Z-axis) 157.5 70 157.5 Clamp block C

(HAINBUCH) 250 80 (HAINBUCH) (HAINBUCH) 250 80 (HAINBUCH)

Colet Colet Colet Colet

JIS A2-6 169 JIS A2-4 JIS A2-6 169 JIS A2-4 Turning holder

(SMW) (SMW) (SMW)

6’chuck 5’chuck (SMW)

6’chuck 78 85 110 80 38 5’chuck Tap Tap holder

JIS A2-5 JIS A2-4 JIS A2-5 182 JIS A2-4

47 13

182

92 90 25 Round hole bush

Boring bar φ20

Maxφ25 φ16

φ12

440st 440st φ10

182 391 (Z2-axis) 147 182 391 (Z2-axis) 147 φ8 φ25 boring holder

720 720 Blank

U-drill Round hole bush

Maxφ25 φ20

φ16 12-station turret(BMT45)

φ12

φ10 φ25 U-drill holder

Z-Axis (Face) milling holder X-Axis (Side) milling holder φ8

Blank

Plug

65 250 85 52.5 267.5 150 250 50 270 Cut-off tool

□20

100 100

Cut-off holder (reverse) Cut-off holder (normal)

636

11.1 37 169 11.1 37

250 80 85 Max50 157.5

(HAINBUCH) (HAINBUCH) (HAINBUCH) 250 80 (HAINBUCH) Straight drill

Colet 169 Colet Colet

JIS A2-4 Colet

JIS A2-6 157.5 JIS A2-6 JIS A2-4 Endmill

Maxφ13

(SMW) 330st (SMW) (SMW)

6’chuck 5’chuck 6’chuck (SMW)

JIS A2-5 (Z-axis) JIS A2-4 JIS A2-5 5’chuck Collet chuck

JIS A2-4 AR20-φD

330st Tap Z-Axis(Face)milling holder

(Z-axis) Max.M12 (Doubles for back face use)

440st 440st

(Z2-axis) (Z2-axis)

182 391 147 182 391 147

720 720

X-Axis(Side)milling holder

Uni(t mm) Uni(t mm)

9 10

205 205

16 φ165

150st 75 165

(X-axis) 4 φ51 150st 125 165

25φ51 135 (X1-axis)

85 30

φ51

49.5 29.5

160 140 134 140

124 26

15 375

89.5 26

0st 375150st

(X2-axis) (X2-axis)

205 205

150st 80 165

(X1-axis)

150st 50 75 165

(X-axis)

φ51

130

85

160 140 160 140

124 26 375 4 120 26 375

150st 150st

(X2-axis) (X2-axis)

Page11

STROKE TOOLING SYSTEM

Stroke-Related Drawing Tooling System

BMT45

Turning holder Boring holder

O.D./Face/Grooving tool □20

Clamp block C

O.D. holder

90 250 60 60 260 95 250 55 50 270

100 100

636 85

47 14 Max85

O.D./Face tool □20

11.1 37 11.1 37

330st

(Z-axis) 157.5 70 157.5 Clamp block C

(HAINBUCH) 250 80 (HAINBUCH) (HAINBUCH) 250 80 (HAINBUCH)

Colet Colet Colet Colet

JIS A2-6 169 JIS A2-4 JIS A2-6 169 JIS A2-4 Turning holder

(SMW) (SMW) (SMW)

6’chuck 5’chuck (SMW)

6’chuck 78 85 110 80 38 5’chuck Tap Tap holder

JIS A2-5 JIS A2-4 JIS A2-5 182 JIS A2-4

47 13

182

92 90 25 Round hole bush

Boring bar φ20

Maxφ25 φ16

φ12

440st 440st φ10

182 391 (Z2-axis) 147 182 391 (Z2-axis) 147 φ8 φ25 boring holder

720 720 Blank

U-drill Round hole bush

Maxφ25 φ20

φ16 12-station turret(BMT45)

φ12

φ10 φ25 U-drill holder

Z-Axis (Face) milling holder X-Axis (Side) milling holder φ8

Blank

Plug

65 250 85 52.5 267.5 150 250 50 270 Cut-off tool

□20

100 100

Cut-off holder (reverse) Cut-off holder (normal)

636

11.1 37 169 11.1 37

250 80 85 Max50 157.5

(HAINBUCH) (HAINBUCH) (HAINBUCH) 250 80 (HAINBUCH) Straight drill

Colet 169 Colet Colet

JIS A2-4 Colet

JIS A2-6 157.5 JIS A2-6 JIS A2-4 Endmill

Maxφ13

(SMW) 330st (SMW) (SMW)

6’chuck 5’chuck 6’chuck (SMW)

JIS A2-5 (Z-axis) JIS A2-4 JIS A2-5 5’chuck Collet chuck

JIS A2-4 AR20-φD

330st Tap Z-Axis(Face)milling holder

(Z-axis) Max.M12 (Doubles for back face use)

440st 440st

(Z2-axis) (Z2-axis)

182 391 147 182 391 147

720 720

X-Axis(Side)milling holder

Uni(t mm) Uni(t mm)

9 10

205 205

16 φ165

150st 75 165

(X-axis) 4 φ51 150st 125 165

25φ51 135 (X1-axis)

85 30

φ51

49.5 29.5

160 140 134 140

124 26

15 375

89.5 26

0st 375150st

(X2-axis) (X2-axis)

205 205

150st 80 165

(X1-axis)

150st 50 75 165

(X-axis)

φ51

130

85

160 140 160 140

124 26 375 4 120 26 375

150st 150st

(X2-axis) (X2-axis)

Page12

TOOLING SYSTEM TURRET

Tooling System Turret interference

BMT55 BMT45

O.D./Face/Grooving tool □25

Clamp block

O.D. holder

O.D./Face tool □25

Clamp block TM112-10000

Turning holder

95 X1 Distance between

centers:300

Boring bar 75

Maxφ40 X2 Distance between

centers:315

50

g d

iam

ete

r

φ40 boring holderS

U-drill holder Round hole bush cki

n

Maxφ40 φ32 (T x c

huTM112-11000

M112-12000)

0 M

a .φ25

φ20 φ1

7

φ16

35s

t

φ12

φ10

Tap φ8

Tap holder Blank

Drill t

35sDrill holder

φ40 U-drill holder 12-station turret(BMT55)

75

Plug ia.

φ580 M

ax. turnin

g d

Cut-off tool

□25

75

Cut-off holder (reverse) Cut-off holder (normal)

50

Straight drill

Endmill

Maxφ20

Collet chuck

AR32-φD Z-Axis(Face)milling holder

(Doubles for back face use)

Tap

Max.M16

X-Axis(Side)milling holder

単位(mm) Uni(t mm)

11 12

□20

φ580 Max. turning dia.

75

φ25

(T

T MM 11 11 22 -- 11 21 00 00 00 )

TM112-10000

165

.

402

5

165

157

.5

150

237

.5

395

230

φ170

165

165

-10

000

12

TM1

80 φ

13

MAX

170

st

MAX

162

.5st

80

TM1

12-

100

00

0

φ1

7

φ13

Page13

TOOLING SYSTEM TURRET

Tooling System Turret interference

BMT55 BMT45

O.D./Face/Grooving tool □25

Clamp block

O.D. holder

O.D./Face tool □25

Clamp block TM112-10000

Turning holder

95 X1 Distance between

centers:300

Boring bar 75

Maxφ40 X2 Distance between

centers:315

50

g d

iam

ete

r

φ40 boring holderS

U-drill holder Round hole bush cki

n

Maxφ40 φ32 (T x c

huTM112-11000

M112-12000)

0 M

a .φ25

φ20 φ1

7

φ16

35s

t

φ12

φ10

Tap φ8

Tap holder Blank

Drill t

35sDrill holder

φ40 U-drill holder 12-station turret(BMT55)

75

Plug ia.

φ580 M

ax. turnin

g d

Cut-off tool

□25

75

Cut-off holder (reverse) Cut-off holder (normal)

50

Straight drill

Endmill

Maxφ20

Collet chuck

AR32-φD Z-Axis(Face)milling holder

(Doubles for back face use)

Tap

Max.M16

X-Axis(Side)milling holder

単位(mm) Uni(t mm)

11 12

□20

φ580 Max. turning dia.

75

φ25

(T

T MM 11 11 22 -- 11 21 00 00 00 )

TM112-10000

165

.

402

5

165

157

.5

150

237

.5

395

230

φ170

165

165

-10

000

12

TM1

80 φ

13

MAX

170

st

MAX

162

.5st

80

TM1

12-

100

00

0

φ1

7

φ13

Page14

TURRET STROKE

Turret interference Stroke-Related Drawing BMT45

BMT55

O.D. holder Z-Axis(Face)milling holder

915 915

455 460 455 460

143 Z1:500st 75 Z1:500st

393 50 35 45

192 192

TSC D42 flange (RIKEN)SAD-40

(2A Collet) A2-5 TSC D42 flange (RIKEN)SAD-40

A2-6 (2A Collet) A2-5

A2-6

(KITAGAWA)B206 (KITAGAWA)B206 (KITAGAWA)B206 (KITAGAWA)B206

A2-6 A2-5 A2-6 A2-5

φ21 145

0 145

189 189

X1 Distance between 398 45 50

64 centers:320 35

Z2:500st 148 Z2:500st 80

A:550st 172 172

67

60

φ2

10

Ma

x. c

huc

kin

g d

iam

ete

r X2 Distance between

centers:320 Boring holder, U-drill holder X-Axis(Side)milling holder

915 915

455 460 455 460

105 Z1:500st 205 Z1:500st

355 55 45

40

st

192 192

TSC D42 flange 理研SAD-40

t

35

s (2A Collet) A2-5 TSC D42 flange (RIKEN)SAD-40

A (2A Collet) A2-5

2-6 A2-6

(KITAGAWA)B206 北川B206

A2-6 A2-5 (KITAGAWA)B206 (KITAGAWA)B206

A2-6 A2-5

145 145

189 189

45 55 360

φ580 M

ax. turnin

g radius

Z2:500st 110 Z2:500st 210

172 172

67

Turning holder Cut-off holder

60 915 915

455 460 455 460

140.5 Z1:500st 140.5 Z1:500st

375 388

192 192

TSC D42 flange (RIKEN)SAD-40 TSC D42 flange (RIKEN)SAD-40

(2A Collet) A2-5 (2A Collet) A2-5

A2-6 A2-6

(KITAGAWA)B206 (KITAGAWA)B206 (KITAGAWA)B206 (KITAGAWA)B206

A2-6 A2-5 A2-6 A2-5

145 145

189 189

380 527

Z2:500st 130 Z2:500st 274.5

172 A:550st 172

単位(mm)

13 14

φ646 M □25ax. turning radius

41

φ634 limi φte 2

φ4

d 4

0

0Turning radius

φ210

395 395 395

X1:162.5st X1:162.5st

2.5 165 80 X1:162.5st

13

165 70 0.5 165 125

70 165 0.5 123 165

13

2.5 X2:170st 80 165 X2:170stX2:170st

402.5 402.5 402.5

395 395 395

X1:162.5st

X1:162.5st 165 75 50 X1:162.5st 165 75 7.5

165 127.5 105

127.5 165 112.5

X2:170st 50 75 165 7.5X2:170st 75 165X2:170st

402.5 402.5 402.5

19

0

0 19

0

0 41

16

0

0 22

16 60

MA

X

17

0s

t

0 0

41 22

10

0

19

19

0

2.5 φ1

6

MA

X

16

2.5

st

60

6

φ1

Page15

TURRET STROKE

Turret interference Stroke-Related Drawing BMT45

BMT55

O.D. holder Z-Axis(Face)milling holder

915 915

455 460 455 460

143 Z1:500st 75 Z1:500st

393 50 35 45

192 192

TSC D42 flange (RIKEN)SAD-40

(2A Collet) A2-5 TSC D42 flange (RIKEN)SAD-40

A2-6 (2A Collet) A2-5

A2-6

(KITAGAWA)B206 (KITAGAWA)B206 (KITAGAWA)B206 (KITAGAWA)B206

A2-6 A2-5 A2-6 A2-5

φ21 145

0 145

189 189

X1 Distance between 398 45 50

64 centers:320 35

Z2:500st 148 Z2:500st 80

A:550st 172 172

67

60

φ2

10

Ma

x. c

huc

kin

g d

iam

ete

r X2 Distance between

centers:320 Boring holder, U-drill holder X-Axis(Side)milling holder

915 915

455 460 455 460

105 Z1:500st 205 Z1:500st

355 55 45

40

st

192 192

TSC D42 flange 理研SAD-40

t

35

s (2A Collet) A2-5 TSC D42 flange (RIKEN)SAD-40

A (2A Collet) A2-5

2-6 A2-6

(KITAGAWA)B206 北川B206

A2-6 A2-5 (KITAGAWA)B206 (KITAGAWA)B206

A2-6 A2-5

145 145

189 189

45 55 360

φ580 M

ax. turnin

g radius

Z2:500st 110 Z2:500st 210

172 172

67

Turning holder Cut-off holder

60 915 915

455 460 455 460

140.5 Z1:500st 140.5 Z1:500st

375 388

192 192

TSC D42 flange (RIKEN)SAD-40 TSC D42 flange (RIKEN)SAD-40

(2A Collet) A2-5 (2A Collet) A2-5

A2-6 A2-6

(KITAGAWA)B206 (KITAGAWA)B206 (KITAGAWA)B206 (KITAGAWA)B206

A2-6 A2-5 A2-6 A2-5

145 145

189 189

380 527

Z2:500st 130 Z2:500st 274.5

172 A:550st 172

単位(mm)

13 14

φ646 M □25ax. turning radius

41

φ634 limi φte 2

φ4

d 4

0

0Turning radius

φ210

395 395 395

X1:162.5st X1:162.5st

2.5 165 80 X1:162.5st

13

165 70 0.5 165 125

70 165 0.5 123 165

13

2.5 X2:170st 80 165 X2:170stX2:170st

402.5 402.5 402.5

395 395 395

X1:162.5st

X1:162.5st 165 75 50 X1:162.5st 165 75 7.5

165 127.5 105

127.5 165 112.5

X2:170st 50 75 165 7.5X2:170st 75 165X2:170st

402.5 402.5 402.5

19

0

0 19

0

0 41

16

0

0 22

16 60

MA

X

17

0s

t

0 0

41 22

10

0

19

19

0

2.5 φ1

6

MA

X

16

2.5

st

60

6

φ1

Page16

STROKE FLOOR SPACE

Stroke-Related Drawing BMT55 Floor Space Drawing

O.D. holder Z-Axis(Face)milling holder

R840

915 915

455 460 455 460

128 Z1:500st 75 Z1:500st

378 40 45 45

214 214

(RIKEN)SAD-65 (RIKEN)SAD-65 (RIKEN)SAD-65 (RIKEN)SAD-65

A2-8 A2-6 A2-8 A2-6

SMW BHM210 SMW BHM210 SMW BHM210 SMW BHM210

A2-8 A2-6 A2-8 A2-6

227 190

232 232

383 45 45 40

Z2:500st 133 Z2:500st 80

A:550st 219 219

Boring holder, U-drill holder X-Axis(Side)milling holder

915 915

455 460 455 460 520 1,550 560

105 Z1:500st 205 Z1:500st 630 (200) 200 2,015 415

355 55 45 330 1,025 2,630 830

200 (3,660)

Uni(t mm)

214 214

(RIKEN)SAD-65 (RIKEN)SAD-65 (RIKEN)SAD-65 (RIKEN)SAD-65

A2-8 A2-6 A2-8 A2-6

SMW BHM210 SMW BHM210 SMW BHM210 SMW BHM210

A2-8 A2-6 A2-8 A2-6

227 190

232 232

45 55 360

Z2:500st 110 Z2:500st 210

219 219

Turning holder Cut-off holder

915 915

455 460 455 460 2,988(3,000:φ65 specification)

95 Z1:500st 132.5 Z1:500st

345 380 3,160(3,172:φ65 specification)

80

214 214 (1,093)

(RIKEN)SAD-65 (RIKEN)SAD-65 (RIKEN)SAD-65 (RIKEN)SAD-65

A2-8 A2-6 A2-8 A2-6

SMW BHM210 SMW BHM210 SMW BHM210 SMW BHM210

A2-8 A2-6 A2-8 A2-6

227 227

232 232

350 535 695 4,078(4,090:φ65 specification)

Z2:500st 100 Z2:500st 282.5

219 A:550st 219

Uni(t mm)

15 16

410 410 410

X1:162.5st X1:162.5st X1:162.5st

21.5 190 60 13

190 36 10.5 190 95

3

36 190 95 190

14 13

X2:170st X2:170st 60 190 X2:170st

410 410 410

410 410 410

X1:162.5st X1:162.5st

X1:162.5st

60 190 60 2.5

190 130 190 67 93

130 190 93 67 190

60 10 60 190X2:170st

X2:170st X2:170st

410 410 410

1,455 310 1,400

1,240 1,050

955

2,163

2,130 380

2,158

10

(48)

1,000

800 367 567

1,410 215 1,410 105 810 755

1,730 80 158

1,950

0

R51

Page17

STROKE FLOOR SPACE

Stroke-Related Drawing BMT55 Floor Space Drawing

O.D. holder Z-Axis(Face)milling holder

R840

915 915

455 460 455 460

128 Z1:500st 75 Z1:500st

378 40 45 45

214 214

(RIKEN)SAD-65 (RIKEN)SAD-65 (RIKEN)SAD-65 (RIKEN)SAD-65

A2-8 A2-6 A2-8 A2-6

SMW BHM210 SMW BHM210 SMW BHM210 SMW BHM210

A2-8 A2-6 A2-8 A2-6

227 190

232 232

383 45 45 40

Z2:500st 133 Z2:500st 80

A:550st 219 219

Boring holder, U-drill holder X-Axis(Side)milling holder

915 915

455 460 455 460 520 1,550 560

105 Z1:500st 205 Z1:500st 630 (200) 200 2,015 415

355 55 45 330 1,025 2,630 830

200 (3,660)

Uni(t mm)

214 214

(RIKEN)SAD-65 (RIKEN)SAD-65 (RIKEN)SAD-65 (RIKEN)SAD-65

A2-8 A2-6 A2-8 A2-6

SMW BHM210 SMW BHM210 SMW BHM210 SMW BHM210

A2-8 A2-6 A2-8 A2-6

227 190

232 232

45 55 360

Z2:500st 110 Z2:500st 210

219 219

Turning holder Cut-off holder

915 915

455 460 455 460 2,988(3,000:φ65 specification)

95 Z1:500st 132.5 Z1:500st

345 380 3,160(3,172:φ65 specification)

80

214 214 (1,093)

(RIKEN)SAD-65 (RIKEN)SAD-65 (RIKEN)SAD-65 (RIKEN)SAD-65

A2-8 A2-6 A2-8 A2-6

SMW BHM210 SMW BHM210 SMW BHM210 SMW BHM210

A2-8 A2-6 A2-8 A2-6

227 227

232 232

350 535 695 4,078(4,090:φ65 specification)

Z2:500st 100 Z2:500st 282.5

219 A:550st 219

Uni(t mm)

15 16

410 410 410

X1:162.5st X1:162.5st X1:162.5st

21.5 190 60 13

190 36 10.5 190 95

3

36 190 95 190

14 13

X2:170st X2:170st 60 190 X2:170st

410 410 410

410 410 410

X1:162.5st X1:162.5st

X1:162.5st

60 190 60 2.5

190 130 190 67 93

130 190 93 67 190

60 10 60 190X2:170st

X2:170st X2:170st

410 410 410

1,455 310 1,400

1,240 1,050

955

2,163

2,130 380

2,158

10

(48)

1,000

800 367 567

1,410 215 1,410 105 810 755

1,730 80 158

1,950

0

R51

Page18

SPECIFICATION

Machine Specifications Controller Specifications

φ51 THRU,BMT45 Specification φ65 THRU,BMT55 Specification(OP) Item TAKAMAZ&FANUC 0i-TD TAKAMAZ & FANUC 32i-B

Item Unit Main-spindle Main-spindle

Main-spindle Sub-spindle Main-spindle Sub-spindle Controlled axes 7 axes(X1, Z1, C1, Y, X2, Z2, C2) 8 axes (X1, Z1, C1, Y, X2, Z2, C2, A)

Simultaneously controllable axes Simultaneous 4 axes

Max. turning diameter mm φ170 φ135 φ190 φ240 Least input increment 0.001mm (X in diameter)

Max. turning length mm 330 150(440:One-side operation) 150(440:One-side operation) Least command increment X: 0.0005mm Z, Y: 0.001mm X: 0.0005mm Z, Y, A: 0.001mm C: 0.001deg.

Max. bar diameter mm φ42 (φ51) φ20 φ51 φ42 φ65 φ51 Auxiliary function M3 digits

Chuck size Inch Collet, 6 Collet, 5 Collet, 6 8 Spindle function S4 digits

Spindle nose JIS A2-5 (A2-6) A2-4 A2-6 A2-5 A2-8 A2-6 Tool function T4 digits

Spindle bearing I.D. mm φ85 (φ100) φ65 φ100 φ85 φ120 φ100 Tape code EIA(RS232C) / ISO(840)automatic recognition

Through-hole on spindle mm φ52 (φ61) φ36 φ52 φ43 φ66 φ52 Cutting feedrate 1~ 5,000mm/min 1~7,000mm/min

Spindle speed min-1 Max.5,000(Max.4,000) Max.5,000 Max.5,000 Max.4,000 Command system Incremental / Absolute

Type 12-station turret 24st. 12-station turret 24st. BMT45 12-station turret 24st. BMT55 Linear interpolation G01

Tool shank mm □20 □20 □25 Circular interpolation G02, G03

Boring holder I.D. mm φ25 φ25 φ40 Cutting feedrate override 0~ 150%

Max. stroke mm X1:150 Z1:330 Y:±35 X1:162.5 Z1:500 Y:±35 X1:162.5 Z1:500 Y:+40-35 Rapid traverse override F0, 100% F0, 25%, 50%, 100%

X2:150 Z2:440 X2:170 Z2:500 A:550 X2:170 Z2:500 A:550 Program number 4 digits Program file name 32 characters

Rapid traverse rate m/min X1:18 Z1:24 Y:12

X2:18 Z2:18 X:18 Z:30 Y:12 A:30 X:18 Z:30 Y:12 A:30 Backlash compensation 0~ 9,999μm

Program memory capacity 1Mbyte(2,560m)(Dual systems total) 64Kbyte(160m)(Dual systems total)

Tool storage capacity pcs. 12 12 12 Tool offsets 128 sets(Dual systems total) 99 sets(Dual systems total)

Rotation speed min-1 Max.4,000 Max.4,000 Max.4,000 Registered programs 800 pcs.(Dual systems total) 63 pcs(. Dual systems total)

Drill mm φ13 φ13 φ20 Tool geometry /Wear offset Standard

C a pacity Endmill mm φ13 φ13 φ20 Canned cycle G90, G92, G94

Tap mm M8 M12 M16 Radius designation on arc Standard

Rapid traverse rate deg./min 21,600 24,000 24,000 Tool offset measurement input Standard

C axis motor kW Cs-axis AC 0.75 - Background editing Standard

Spindle motor kW AC7.5/5.5(AC11/7.5) AC5.5/3.7 AC18.5/15/11 AC9/7.5/5.5 AC18.5/15/11 AC9/7.5/5.5 Direct drawing dimension programming Standard Option

Feed motor kW X1:AC1.2 Z1:AC1.8 Y:AC0.75

X2:AC0.75 Z2:AC1.2 X:1.8 Z:1.8 Y:1.4 A:1.2 X:1.8 Z:1.8 Y:1.4 A:1.2 Custom macro Standard

Custom macro common variables #100~#199, #500~#999 Option

Coolant motor kW AC 0.25/0.25 AC 0.4 AC 0.4 Pattern data input Standard ー

Hydraulic motor kW AC1.5 AC 0.75 AC 0.75 Nose R compensation G40, G41, G42

Power tools motor kW AC3.7/2.2/1.5 AC3.7/2.2 AC3.7/2.2 Inch /Metric conversion G20/G21 Option

Spindle center height mm 1,050 1,240 1,240 Programmable data input G10

L×W×H mm 2,630 × 1,950 × 1,730 2,988×2,163×2,158(3,490※1) 3,000×2,163×2,158 Run hour / Parts count display Standard Option

Machine weight kg 4,500 7,400(8,250※1) 7,500 Extended part program editing Standard

Total electric capacity KVA 27(31) 44 44 Multiple repetitive cycle G70~G76

※1 Gantry Loader type ( ):Option Multiple repetitive cycleⅡ Pocket-shaped Option

Spindle synchronous control Standard

Standard Accessories Sub-spindle torque skip Standard

Y-axis offset Standard

Canned drilling cycle Standard

Constant surface speed control G96, G97

□Boring holder 2 sets Continuous thread cutting G32

□O.D. holder 2 sets Variable lead thread cutting G34 Option

□Cut-off holder 1 set Thread cutting retract Standard Option

□Collet flange 1 set ea(. Main, Sub) Clock function Standard

□Hydraulic chuck Option Help function Standard

□Hydraulic chucking cylinder ー 1 set ea(. Main, Sub) Alarm history display 50 pcs.

□Y-axis function 1 set(Main) 1 set(#1 Turret) Self-diagnosis function Standard

□Spindle indexing device Cs-axis 1 set ea(. Main, Sub) Cs-axis 1 set ea(. Main, Sub) Sub-program call Up to 10 loops

□Power tools drive unit 1 set(Main) 1 set(For both turrets) Decimal point input Standard

□Sub-spindle 1 set 2nd reference point return G30

□Coolant unit 1 set(200lit.) 1 set(360lit.) Work coordinate system setting G50, G54~G59

□Service tool kit 1 set Rigid tapping For Power Tool only

□TAKAMAZ Instruction manual 1 set Polar coordinate interpolation Standard

Cylindrical interpolation Standard

Stored stroke check 1 Standard

Optional Accessories Stored stroke check 2,3 Standard

Input / Output interface USB Flash Memory, Memory card, Ethernet

Alarm message Standard

□Tool holders ○ Graphic display Standard

□Stroke adjusting cylinder ○ Spindle orientation Standard

□Collet chucks ○ Conversational programming with graphic function Standard ー

□Hydraulic chucks ○(Main:6 Inch Sub:5 Inch) ○ Abnormal load detection Standard

□Chuck clamp detector ○ (Standard) Overlap Cutting Process Standard

□Sub-spindle parts ejector ○ (Standard) Balance cut ー G68, 69

□Sub turret(□16, φ20) ○(12-station) ー Manual handle trace Standard

□TAKAMAZ loader system ○ ー Automatic data backup Max.3

□Bar feeder system ○ Automatic screen deletion function Standard

□Unloader unit(Out-conveyor) ○ (Standard) TAKAMAZ management support function Work / Tool counter, Tool load monitor, Others

□Work set detector ○ TAKAMAZ maintenance function Standard

□Cut-off check device ○ FANUC set of manuals CD-ROM DVD-ROM

□Power tools(Face / Side milling) ○ ー

□Chip conveyor Optional Specifications

(Floor type/Spiral type) ○(Right)

□Front air blower ○

□Rear air blower ○ ー Item TAKAMAZ&FANUC 0i-TD TAKAMAZ & FANUC 32i-B

□Rear coolant unit ○ Tool life management

□Signal light(1-tier / 2-tier / 3-tier) ○ Multiple M codes in one block Max. 3

□Automatic fire extinguisher ○ Dynamic graphic display※

□Automatic power shut-off device ○ Manual guide i※

□Automatic door system ○ ー Helical interpolation

□Special color ○ RS232C

□Others※ ○ FANUC instruction manuals Bound

17 ※For more information on attachments, consult our sales representative. ※These cannot be used together. 18

Size Motors C-axis Power tools Tool post Spindle Capacity

Page19

SPECIFICATION

Machine Specifications Controller Specifications

φ51 THRU,BMT45 Specification φ65 THRU,BMT55 Specification(OP) Item TAKAMAZ&FANUC 0i-TD TAKAMAZ & FANUC 32i-B

Item Unit Main-spindle Main-spindle

Main-spindle Sub-spindle Main-spindle Sub-spindle Controlled axes 7 axes(X1, Z1, C1, Y, X2, Z2, C2) 8 axes (X1, Z1, C1, Y, X2, Z2, C2, A)

Simultaneously controllable axes Simultaneous 4 axes

Max. turning diameter mm φ170 φ135 φ190 φ240 Least input increment 0.001mm (X in diameter)

Max. turning length mm 330 150(440:One-side operation) 150(440:One-side operation) Least command increment X: 0.0005mm Z, Y: 0.001mm X: 0.0005mm Z, Y, A: 0.001mm C: 0.001deg.

Max. bar diameter mm φ42 (φ51) φ20 φ51 φ42 φ65 φ51 Auxiliary function M3 digits

Chuck size Inch Collet, 6 Collet, 5 Collet, 6 8 Spindle function S4 digits

Spindle nose JIS A2-5 (A2-6) A2-4 A2-6 A2-5 A2-8 A2-6 Tool function T4 digits

Spindle bearing I.D. mm φ85 (φ100) φ65 φ100 φ85 φ120 φ100 Tape code EIA(RS232C) / ISO(840)automatic recognition

Through-hole on spindle mm φ52 (φ61) φ36 φ52 φ43 φ66 φ52 Cutting feedrate 1~ 5,000mm/min 1~7,000mm/min

Spindle speed min-1 Max.5,000(Max.4,000) Max.5,000 Max.5,000 Max.4,000 Command system Incremental / Absolute

Type 12-station turret 24st. 12-station turret 24st. BMT45 12-station turret 24st. BMT55 Linear interpolation G01

Tool shank mm □20 □20 □25 Circular interpolation G02, G03

Boring holder I.D. mm φ25 φ25 φ40 Cutting feedrate override 0~ 150%

Max. stroke mm X1:150 Z1:330 Y:±35 X1:162.5 Z1:500 Y:±35 X1:162.5 Z1:500 Y:+40-35 Rapid traverse override F0, 100% F0, 25%, 50%, 100%

X2:150 Z2:440 X2:170 Z2:500 A:550 X2:170 Z2:500 A:550 Program number 4 digits Program file name 32 characters

Rapid traverse rate m/min X1:18 Z1:24 Y:12

X2:18 Z2:18 X:18 Z:30 Y:12 A:30 X:18 Z:30 Y:12 A:30 Backlash compensation 0~ 9,999μm

Program memory capacity 1Mbyte(2,560m)(Dual systems total) 64Kbyte(160m)(Dual systems total)

Tool storage capacity pcs. 12 12 12 Tool offsets 128 sets(Dual systems total) 99 sets(Dual systems total)

Rotation speed min-1 Max.4,000 Max.4,000 Max.4,000 Registered programs 800 pcs.(Dual systems total) 63 pcs(. Dual systems total)

Drill mm φ13 φ13 φ20 Tool geometry /Wear offset Standard

C a pacity Endmill mm φ13 φ13 φ20 Canned cycle G90, G92, G94

Tap mm M8 M12 M16 Radius designation on arc Standard

Rapid traverse rate deg./min 21,600 24,000 24,000 Tool offset measurement input Standard

C axis motor kW Cs-axis AC 0.75 - Background editing Standard

Spindle motor kW AC7.5/5.5(AC11/7.5) AC5.5/3.7 AC18.5/15/11 AC9/7.5/5.5 AC18.5/15/11 AC9/7.5/5.5 Direct drawing dimension programming Standard Option

Feed motor kW X1:AC1.2 Z1:AC1.8 Y:AC0.75

X2:AC0.75 Z2:AC1.2 X:1.8 Z:1.8 Y:1.4 A:1.2 X:1.8 Z:1.8 Y:1.4 A:1.2 Custom macro Standard

Custom macro common variables #100~#199, #500~#999 Option

Coolant motor kW AC 0.25/0.25 AC 0.4 AC 0.4 Pattern data input Standard ー

Hydraulic motor kW AC1.5 AC 0.75 AC 0.75 Nose R compensation G40, G41, G42

Power tools motor kW AC3.7/2.2/1.5 AC3.7/2.2 AC3.7/2.2 Inch /Metric conversion G20/G21 Option

Spindle center height mm 1,050 1,240 1,240 Programmable data input G10

L×W×H mm 2,630 × 1,950 × 1,730 2,988×2,163×2,158(3,490※1) 3,000×2,163×2,158 Run hour / Parts count display Standard Option

Machine weight kg 4,500 7,400(8,250※1) 7,500 Extended part program editing Standard

Total electric capacity KVA 27(31) 44 44 Multiple repetitive cycle G70~G76

※1 Gantry Loader type ( ):Option Multiple repetitive cycleⅡ Pocket-shaped Option

Spindle synchronous control Standard

Standard Accessories Sub-spindle torque skip Standard

Y-axis offset Standard

Canned drilling cycle Standard

Constant surface speed control G96, G97

□Boring holder 2 sets Continuous thread cutting G32

□O.D. holder 2 sets Variable lead thread cutting G34 Option

□Cut-off holder 1 set Thread cutting retract Standard Option

□Collet flange 1 set ea(. Main, Sub) Clock function Standard

□Hydraulic chuck Option Help function Standard

□Hydraulic chucking cylinder ー 1 set ea(. Main, Sub) Alarm history display 50 pcs.

□Y-axis function 1 set(Main) 1 set(#1 Turret) Self-diagnosis function Standard

□Spindle indexing device Cs-axis 1 set ea(. Main, Sub) Cs-axis 1 set ea(. Main, Sub) Sub-program call Up to 10 loops

□Power tools drive unit 1 set(Main) 1 set(For both turrets) Decimal point input Standard

□Sub-spindle 1 set 2nd reference point return G30

□Coolant unit 1 set(200lit.) 1 set(360lit.) Work coordinate system setting G50, G54~G59

□Service tool kit 1 set Rigid tapping For Power Tool only

□TAKAMAZ Instruction manual 1 set Polar coordinate interpolation Standard

Cylindrical interpolation Standard

Stored stroke check 1 Standard

Optional Accessories Stored stroke check 2,3 Standard

Input / Output interface USB Flash Memory, Memory card, Ethernet

Alarm message Standard

□Tool holders ○ Graphic display Standard

□Stroke adjusting cylinder ○ Spindle orientation Standard

□Collet chucks ○ Conversational programming with graphic function Standard ー

□Hydraulic chucks ○(Main:6 Inch Sub:5 Inch) ○ Abnormal load detection Standard

□Chuck clamp detector ○ (Standard) Overlap Cutting Process Standard

□Sub-spindle parts ejector ○ (Standard) Balance cut ー G68, 69

□Sub turret(□16, φ20) ○(12-station) ー Manual handle trace Standard

□TAKAMAZ loader system ○ ー Automatic data backup Max.3

□Bar feeder system ○ Automatic screen deletion function Standard

□Unloader unit(Out-conveyor) ○ (Standard) TAKAMAZ management support function Work / Tool counter, Tool load monitor, Others

□Work set detector ○ TAKAMAZ maintenance function Standard

□Cut-off check device ○ FANUC set of manuals CD-ROM DVD-ROM

□Power tools(Face / Side milling) ○ ー

□Chip conveyor Optional Specifications

(Floor type/Spiral type) ○(Right)

□Front air blower ○

□Rear air blower ○ ー Item TAKAMAZ&FANUC 0i-TD TAKAMAZ & FANUC 32i-B

□Rear coolant unit ○ Tool life management

□Signal light(1-tier / 2-tier / 3-tier) ○ Multiple M codes in one block Max. 3

□Automatic fire extinguisher ○ Dynamic graphic display※

□Automatic power shut-off device ○ Manual guide i※

□Automatic door system ○ ー Helical interpolation

□Special color ○ RS232C

□Others※ ○ FANUC instruction manuals Bound

17 ※For more information on attachments, consult our sales representative. ※These cannot be used together. 18

Size Motors C-axis Power tools Tool post Spindle Capacity

Page20

CNC Multi-Turning Center

XYseries

TAKAMATSU MACHINERY CO., LTD. TAKAMAZ MACHINERY MEXICO, S.A.DE C.V.

■HEAD OFFICE & PLANT AVENIDA DE LOS INDUSTRIALES 522, LOCAL 4, INDUSTRIAL JULIAN DE OBREGON, 37290 LEON,

1-8 ASAHIGAOKA HAKUSAN-CITY ISHIKAWA JAPAN. 924-8558 TEL +81-(0)76-207-6155 FAX +81-(0)76-274-1418 GUANAJUATO MEXICO

■ASAHI PLANT TEL +52-477-784-0468

4-13 ASAHIGAOKA HAKUSAN-CITY ISHIKAWA JAPAN. 924-0004 TEL +81-(0)76-274-0123 FAX +81-(0)76-274-8530 TAKAMATSU MACHINERY VIETNAM CO., LTD

TAKAMATSU MACHINERY U.S.A., INC. NO.76 M HOANG QUOC VIET, PHU MY WARD, DISTRICT 7, HO CHI MINH CITY, VIETNAM

■CHICAGO HEAD OFFICE TEL +84-(0)28-3620-5671 FAX +84-(0)28-3620-5673

1280 LANDMEIER ROAD ELK GROVE VILLAGE, IL 60007 USA TEL +1-(0)847-981-8577 FAX +1-(0)847-981-8599

TAKAMAZ MACHINERY EUROPE GmbH

IM HÜLSENFELD 19, 40721 HILDEN, GERMANY TEL +49-(0)2103-789-4882 FAX +49-(0)2103-789-4883

TAKAMAZ MACHINERY( HANGZHOU) CO., LTD.

■HANGZHOU HEAD OFFICE

NO.6800, JIANGDONG 3RD ROAD, JIANGDONG INDUSTRIAL PARK, XIAOSHAN, HANGZHOU, ZHEJIANG, CHINA

TEL +86-(0)571-8287-9709 FAX +86-(0)571-8215-3732 Precautions Related to Foreign Exchange and Foreign Trade Control Laws

TAKAMATSU MACHINERY( THAILAND) CO., LTD. This product (machine and ancillary equipment) may fall under the category of controlled

goods by the foreign exchange and foreign trade control laws.

■BANGKOK HEAD OFFICE As such, the exportation must be authorized by the Japanese government as stipulated in the laws

888/59 MOO 9, TAMBOL BANGPLA, AMPHUR BANGPLEE, SAMUTPRAKARN PROVINCE, THAILAND This product is manufactured in accordance with the regulations and standards that prevail in the

TEL +66-(0)2-136-7831 FAX +66-(0)2-136-7834 country or region of destination.

PT. TAKAMAZ INDONESIA The user must not export, sell, or relocate the product, to anycountry with different regulations or standards.

JL. FESTIVAL BOULEVARD BLOK AA 11 NO.30,31 GRAND WISATA TAMBUN, BEKASI 17510

TEL +62-(0)21-8261-6431 FAX +62-(0)21-8261-6430

23.07.1B(O)