1/8ページ

ダウンロード(543.3Kb)

Enhancing efficiency and economics in process development and manufacturing of biotherapeutics

ホワイトペーパー

このカタログについて

| ドキュメント名 | Enhancing efficiency and economics in process development and manufacturing of biotherapeutics |

|---|---|

| ドキュメント種別 | ホワイトペーパー |

| ファイルサイズ | 543.3Kb |

| 取り扱い企業 | ザルトリウス・ジャパン株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

APPLICATION NOTE 11

Enhancing efficiency and economics in process

development and manufacturing of biotherapeutics

Rashi Takkar, Applications Scientist; Sriram Kumaraswamy, Director, Marketing Field Applications

Introduction to improve the efficiency and economics in all stages of devel-

opment. These key drivers have fueled the search for innovative

Analytical techniques that measure protein quantity and quality analytical techniques that provide improved performance and

are used in nearly all stages of research, process development speed without increasing costs. Biopharmaceutical companies

and manufacturing of biotherapeutics. UV spectroscopy, ELISA have enthusiastically adopted ForteBio’s Octet® systems due to

and HPLC have been in use for decades for protein quantitation their broad utility in protein quantitation and functional character-

in physiological and process samples, and continue to be the ization combined with enhanced throughput, decreased sample

workhorses despite their many limitations. To characterize the preparation requirements, and low cost of operation. This white

functional activity of proteins during biotherapeutic development, paper describes the use of Octet instruments for protein quan-

label-free biosensor-based binding assays are increasingly being titation, particularly in the areas of process development and

utilized. The high cost and lengthy times associated with drug quality control.

discovery and development have forced biopharm companies

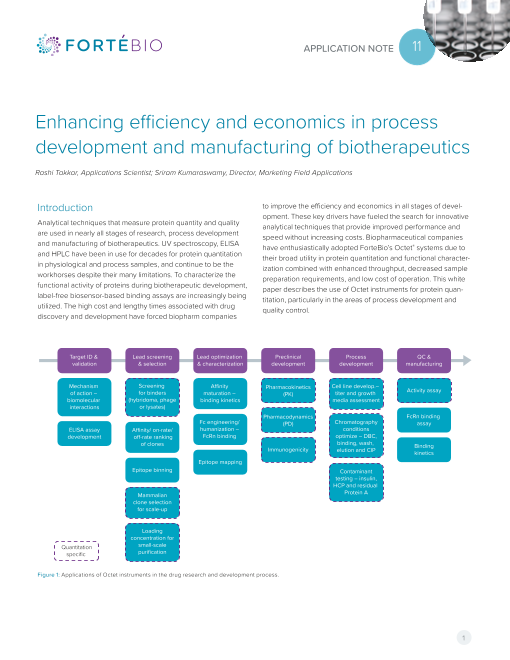

Target ID & Lead screening Lead optimization Preclinical Process QC &

validation & selection & characterization development development manufacturing

Mechanism Screening Anity Pharmacokinetics Cell line develop.–

of action – for binders maturation – (PK) titer and growth Activity assay

biomolecular (hybridoma, phage binding kinetics media assessment

interactions or lysates)

Pharmacodynamics FcRn binding

Fc engineering/ (PD) Chromatography assay

ELISA assay Anity/ on-rate/ humanization – conditions

development o-rate ranking FcRn binding optimize – DBC,

of clones binding, wash,

Immunogenicity Binding

elution and CIP kinetics

Epitope mapping

Epitope binning Contaminant

testing – insulin,

HCP and residual

Mammalian Protein A

clone selection

for scale-up

Loading

concentration for

Quantitation small-scale

specific purification

Figure 1: Applications of Octet instruments in the drug research and development process.

1

Page2

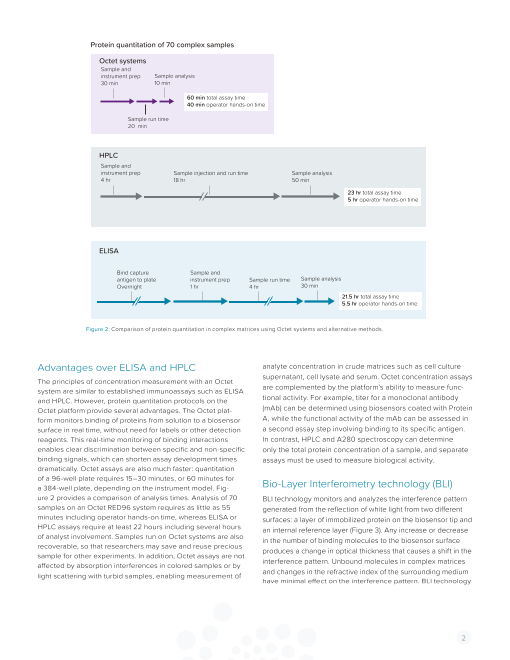

Protein quantitation of 70 complex samples

Octet systems

Sample and

instrument prep Sample analysis

30 min 10 min

60 min total assay time

40 min operator hands-on time

Sample run time

20 min

HPLC

Sample and

instrument prep Sample injection and run time Sample analysis

4 hr 18 hr 50 min

23 hr total assay time

5 hr operator hands-on time

ELISA

Bind capture Sample and

antigen to plate instrument prep Sample run time Sample analysis

Overnight 1 hr 4 hr 30 min

21.5 hr total assay time

5.5 hr operator hands-on time

Figure 2: Comparison of protein quantitation in complex matrices using Octet systems and alternative methods.

Advantages over ELISA and HPLC analyte concentration in crude matrices such as cell culture

supernatant, cell lysate and serum. Octet concentration assays

The principles of concentration measurement with an Octet

system are similar to established immunoassays such as ELISA are complemented by the platform’s ability to measure func-

and HPLC. However, protein quantitation protocols on the tional activity. For example, titer for a monoclonal antibody

Octet platform provide several advantages. The Octet plat- (mAb) can be determined using biosensors coated with Protein

form monitors binding of proteins from solution to a biosensor A, while the functional activity of the mAb can be assessed in

surface in real time, without need for labels or other detection a second assay step involving binding to its specific antigen.

reagents. This real-time monitoring of binding interactions In contrast, HPLC and A280 spectroscopy can determine

enables clear discrimination between specific and non-specific only the total protein concentration of a sample, and separate

binding signals, which can shorten assay development times assays must be used to measure biological activity.

dramatically. Octet assays are also much faster: quantitation

of a 96-well plate requires 15–30 minutes, or 60 minutes for

a 384-well plate, depending on the instrument model. Fig- Bio-Layer Interferometry technology (BLI)

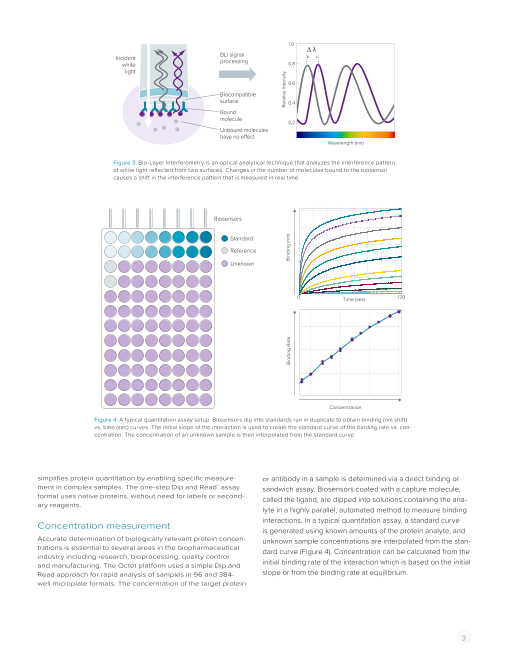

ure 2 provides a comparison of analysis times. Analysis of 70 BLI technology monitors and analyzes the interference pattern

samples on an Octet RED96 system requires as little as 55 generated from the reflection of white light from two different

minutes including operator hands-on time, whereas ELISA or surfaces: a layer of immobilized protein on the biosensor tip and

HPLC assays require at least 22 hours including several hours an internal reference layer (Figure 3). Any increase or decrease

of analyst involvement. Samples run on Octet systems are also in the number of binding molecules to the biosensor surface

recoverable, so that researchers may save and reuse precious produces a change in optical thickness that causes a shift in the

sample for other experiments. In addition, Octet assays are not

affected by absorption interferences in colored samples or by interference pattern. Unbound molecules in complex matrices

light scattering with turbid samples, enabling measurement of and changes in the refractive index of the surrounding medium

have minimal effect on the interference pattern. BLI technology

2

Page3

1.0

Incident BLI signal

white processing 0.8

light

0.6

Biocompatible

surface 0.4

Bound

molecule 0.2

Unbound molecules

have no effect

Wavelength (nm)

Figure 3: Bio-Layer Interferometry is an optical analytical technique that analyzes the interference pattern

of white light reflected from two surfaces. Changes in the number of molecules bound to the biosensor

causes a shift in the interference pattern that is measured in real time.

Biosensors

Standard

Reference

Unknown

0 Time (sec) 120

Concentration

Figure 4: A typical quantitation assay setup. Biosensors dip into standards run in duplicate to obtain binding (nm shift)

vs. time (sec) curves. The initial slope of the interaction is used to create the standard curve of the binding rate vs. con-

centration. The concentration of an unknown sample is then interpolated from the standard curve.

simplifies protein quantitation by enabling specific measure- or antibody in a sample is determined via a direct binding or

ment in complex samples. The one-step Dip and Read™ assay sandwich assay. Biosensors coated with a capture molecule,

format uses native proteins, without need for labels or second- called the ligand, are dipped into solutions containing the ana-

ary reagents.

lyte in a highly parallel, automated method to measure binding

Concentration measurement interactions. In a typical quantitation assay, a standard curve

is generated using known amounts of the protein analyte, and

Accurate determination of biologically relevant protein concen- unknown sample concentrations are interpolated from the stan-

trations is essential to several areas in the biopharmaceutical dard curve (Figure 4). Concentration can be calculated from the

industry including research, bioprocessing, quality control

and manufacturing. The Octet platform uses a simple Dip and initial binding rate of the interaction which is based on the initial

Read approach for rapid analysis of samples in 96 and 384- slope or from the binding rate at equilibrium.

well microplate formats. The concentration of the target protein

3

Relative Intensity

Binding Rate Binding (nm)

Page4

Quantitation applications for drug Titer assessment and growth media optimization

development using the Octet platform

RESEARCH AND EARLY BIOPROCESS

DEVELOPMENT

The Octet platform is a useful tool for cost-effective protein

expression screening in research and early bioprocess devel- Pe-adapted

opment with several significant benefits. Host Cells Vector

Octet platform advantages

Transfections

• Antibody and protein concentrationst can be determined in

crude matrices, such as cell lysates or hybridoma superna- 96-well Plates

tants, saving time and resources when processing a large Range: 1–300 µg/mL

Throughput: 1000s clones

number of samples.

• Octet assays have a dynamic range of greater than two or-

Octet system

ders of magnitude, enabling a single quantitation assay to be 24-, 12- and 6-well Plates

utilized across all development stages – from early cell culture Range: 1–500 µg/mL

Throughput: 200–500 clones

to production bioreactors.

• Octet systems perform rapid quantitation with minimal user in- Octet system

volvement. 96 samples are analyzed in as little as 20 minutes,

and 384 samples in 70 minutes. With additional plate handling T-flasks

automation, Octet 384 systems can process more than 1200 Range: 1–500 µg/mL

samples per day. Throughput: 100–150 clones

• Samples are analyzed in a non-destructive method and are

fully recoverable, which is advantageous when working with

low sample volumes and precious samples. Octet system

• Octet systems are easy to learn and operate. Multiple analysts

can operate the instrument with minimal training, allowing Shake Flasks

rapid integration of these systems into laboratory workflows. Range: 1–700 µg/mL

Throughput: 50–100 clones

Early clone selection

In clone selection, thousands of hybridoma or phage clones

are screened to determine positive binding clones and their Octet system

protein secretion levels. Titer measurements are used to select

high-producing clones and to normalize the functional activ- Fed-batch Shake Flasks

ity of these clones in crude matrices. Integration of an Octet Range: 1–700 µg/mL

system into the antibody discovery workflow affords increased Throughput: 12–20 clones

screening throughput. With Octet RED384 and Octet QK384

instruments, automated plate handling can also be added to

achieve even higher throughput. Octet quantitation assays Octet system

are also used to determine loading levels of chromatography

columns for small-scale purification.

Cell line development 1–3 L Seed Bioreactors

Harvest samples are screened on Octet systems to select Range: 1–4 g/L

Throughput: 2–5 clones

high-expressing clones during various scale-up procedures

involving 96-, 48-, 24- and 6-well plates, fed batch shake flasks,

and bioreactors (Figure 5). Octet assays also are used to de-

termine protein levels during media development for fed-batch

and bioreactor processes (Figure 5). This is performed by com- Figure 5: Protein titer assessment and growth media optimization using

paring protein secretion levels following variations in feeding the Octet system at different stages of cell line development.

regimes, strategies and concentrations. Data acquisition and

4

Page5

Polishing

Cell culture Anity chromatography Viral Ultrafiltration

harvest chromatography (at least 2 steps) filtration diafiltration

Optimizing dynamic binding Optimizing dynamic binding Optimize different

capacity of column resins capacity of resins formulations based on:

• Detect protein breakthrough • Bind and elute mode: determine • Protein concentration

in flow-through in crude protein breakthrough point required for stability

matrix • Flow-through mode: determine • Protein activity/binding

Optimizing binding, wash and final fraction when target protein

elution conditions detectable

• Protein binding/activity Optimizing binding, elution, and

• Residual Protein A wash conditions

• HCP (general & specific) • Protein recovery

• Protein recovery • Protein binding/activity

• Residual protein A

• HCP

Figure 6: Use of Octet systems in the downstream purification process of proteins and antibodies.

subsequent data analysis can be performed rapidly for hun- containing a known concentration of target protein and moni-

dreds of samples, bypassing traditional processing bottlenecks. toring this protein in the flow-through fractions. Quick determi-

Please see ForteBio Application Note 13, Fc-Fusion Protein nation of DBC using HPLC or A280 spectroscopy is hampered

Quantitation in Cell Culture Supernatants, for more information. by the presence of large amounts of host cell proteins in the

flow-through fractions. Specific detection of the protein of inter-

DOWNSTREAM PROCESS DEVELOPMENT est among contaminants is straightforward with Octet systems,

reducing the time required to optimize purification conditions

Efficient development of manufacturing processes for anti- (Figure 6).

bodies and recombinant proteins is a critical need for bio-

pharmaceutical companies. Increasingly stringent regulatory

requirements targeting better understanding and control of Binding, wash and elution conditions

manufacturing processes are expected to impact product qual- Numerous chromatography binding and elution conditions are

ity and performance. The Octet platform can quickly determine tested during optimization studies, including different buffer

the impact of multiple process variables at different stages of compositions, salt, pH, operating temperature and sample

the purification process, and help identify optimal conditions injection volume. High-throughput tools, such as mini columns

that provide protein product with the desired yield, binding and 96-well filter plates, often are used to screen these process

specificity and potency (Figure 6). Pre-configured reagents variables. The impact of different conditions on product titer

and protocols are available for rapid quantitation of protein and quality can be analyzed rapidly and effectively on Octet

products, host cell proteins (HCP), and residual Protein A levels systems, speeding identification of optimal chromatography

during purification processes. conditions (Figure 6).

Octet platform advantages Contaminant testing

• One Octet instrument can be used to measure protein titer, Downstream purification processes must remove host cell pro-

host cell proteins and residual Protein A contaminant levels. teins, residual Protein A and residual DNA impurities. According

• Octet assays are faster to develop and run than ELISA and to guidance from regulatory authorities, host cell proteins in a

HPLC assays. drug substance should be below detectable levels using a high-

ly sensitive analytical method, and as a rule this level should not

• Octet assays can be automated with robotic and liquid han- exceed 100 ppm. The type of assay required for HCP determi-

dling systems for complete, walk-away screening. nations depends on the phase of clinical studies for which the

material is produced. For earlier clinical phases, a generic assay

Dynamic binding capacity (DBC) of chromatography columns may be sufficient. However, a process-specific HCP assay gen-

Affinity chromatography often is the first major purification pro- erally is required for phase 3 and later studies. Leached Protein

cedure performed on harvested cell culture samples in down- A is another contaminant of concern in process development.

stream bioprocessing. The dynamic binding capacity (DBC) of The elution of antibodies during Protein A chromatography

an affinity chromatography column is defined as the amount requires acidic conditions, which in turn can accelerate leaching

of protein that will bind to the column resin under a defined of Protein A from the column. Residual Protein A levels should

condition. DBC is determined by continuously loading a sample not exceed 10 ppm in the final drug product.

5

Page6

Customer highlight: GlaxoSmithKline Benefits of automated Octet CHO HCP assay compared to

manual ELISA

The analytical lab at GlaxoSmithKline incorporated a generic

HCP assay on the Octet QK384 system to streamline their Benefit Details

workflow in process development. The automated Octet HCP

Precision Liquid handling robot reduces pipetting variation

assay required minimal analyst intervention and provided inherent in manual pipetting

more accurate and precise results than their manual ELISA

assay (Figure 7). Hands-on time for preparation and process- Reliability Method performed exactly the same each time

ing of 1–3 assay plates was reduced to 30 minutes from the Streamlined Worklist drives robotic method and creates sample

previous 2.5 hours with manual ELISA, and antibody consump- process plate importation files

Robotic method automatically creates and executes

tion decreased by 40%. Octet method file

More information on the development of the HCP assay on Walk away No analyst intervention needed to complete method

Octet systems can be found in Technical Note 24, Host Cell after instrument loaded and diluent volumes are

checked

Protein Dectection on the ForteBio website.

Washing No washing steps needed and plate washer

Process development assays for residual Protein A and prod- steps integration not required

uct titer can be fully automated on Octet 384 systems using Analysts Automated Octet ~30 minutes for 1–3 assay plates

external liquid handling platforms. The Octet assay for leached involvement Manual ELISA ~2.5 hours per assay plate

Protein A is highly sensitive with a LLOQ of 0.20 ppm, has >2.5

Throughput 3 assay plates can be run in ~5 hours

logs of dynamic range, and is faster than competing methods. 38 samples/plate in duplicate wells > 108 samples in

A residual Protein A assay on the Octet RED384 system can 3 plates

be completed in 1 hour and 45 minutes per plate with minimal Antibody Re-use of coating antibody can significantly reduce

analyst involvement, compared to a minimum of 3.5 hours for consumed consumption over multiple assay plates

ELISA (including significant analyst hands-on time). For more

information on the Octet residual Protein A quantitation proto- Figure 7: Benefits of automated Octet CHO HCP assay compared to manu-

al ELISA summarized by GSK.

col, see Technical Note 18, Dip and Read Residual Protein A

Detection Kit on the ForteBio website.

QUALITY CONTROL

Octet platform advantages

Octet systems provide robust and highly reproducible assays • Octet systems are designed for GLP/GMP environments, and

for protein concentration and functional activity, and are suit-

provide 21 CFR Part 11 compliance tools.

able for operation in quality control and manufacturing environ-

ments. Protein activity and various kinetic assays are used to • Octet assays provide detailed information about the binding

support in-process testing, drug potency, lot-to-lot variability behavior of protein products, and reveal subtle differences in

and stability studies. binding activity between production lots.

Activity assay Quantitation assay

Streptavidin

Biotin Fab

Ligand — binds Fab Antibody Fc Protein A — binds Fc

Figure 8: An activity assay can be developed on the Octet platform by immobilizing a specific biotinylated ligand on the biosensor and then detecting binding

of an analyte, FAb or protein. In the quantitation assay, mAb titer is determined using Protein A-loaded biosensors, which does not measure mAb activity

towards its target.

6

Page7

Customer highlight: Aragen Biosciences • Octet quantitation assays provide a direct measure of the

biological activity of the analyte(s) (Figure 8).

Aragen Biosciences created a stable and scalable CHO cell

line, purification platform and manufacturing process for a • Octet assays can be easily transferred to manufacturing oper-

particular product in a GMP environment. They developed ations.

an Octet assay to compare the activity and quality of a new

product lot (Lot 2) with a reference lot (Lot 1) throughout Activity assays

their bioprocess and manufacturing processes. The as- An activity assay is generally utilized during process develop-

say involved loading a biotinylated ligand on Streptavidin ment, QC and manufacturing to compare various prepared lots

biosensors, and measuring binding interaction of the ligand of the drug molecule, as well as its stability. Activity assays are

with the protein analyte. As seen in Figure 9, Lot 2 contained critical because they differentiate active protein from inactive

a large second peak that was absent in the Lot 1 reference or clipped variants, as those species will not bind the ligand.

material. The second peak in Lot 2 exhibited a slower on-rate Active protein concentration can be determined using a binding

and much faster off-rate, indicative of a less-active fraction assay on the Octet platform by immobilizing a specific ligand

(Figure 10). Octet system activity data results were confirmed against the target analyte onto the biosensor, and then measur-

with a cell-based assay, and Aragen was able to modify their ing its binding interaction with the analyte as shown in Figure 8.

production conditions to significantly reduce this second

peak fraction.

Lot 1 Lot 2

High Specific Low Specific

Binding Activity Binding Activity

Peak 2

Presence of large

Peak 1 second peak

Peak 1 correlated with

reduced specific

Peak 2 binding activity

30 35 30 35

Figure 9: HPLC spectra of Lot 1 and Lot 2 of a drug molecule. Lot 2 was made by Aragen Biosciences and had

an additional peak (Peak 2) compared to the reference lot (Lot 1) provided by their customer. Data provided

courtesy of Aragen Biosciences.

Peak 2

Peak 1

30 35

A lower on-rate and an

increased o -rate was

clearly indicative of a

less-active fraction

Figure 10: The Octet binding kinetics or functional assay demonstrated that Peak 1 was the active fraction. Peak 2 was the less-active fraction,

with a lower on-rate and a much faster off-rate in a binding experiment. Data provided courtesy of Aragen Biosciences.

7

Page8

Conclusion

Octet systems deliver comprehensive characterization of the high throughput needed to screen through large libraries of

biotherapeutics, as well as rapid and reproducible determi- candidate drug molecules. In later stages of process develop-

nation of protein concentrations during different stages of the ment and manufacturing, Octet systems provide the required

development process. Titer and functional activity assays on reliability, robustness and measurement accuracy. The broad

Octet systems are useful for a broad array of applications in utility of this single platform makes the Octet instrument unique

target identification, lead selection, process development, in its ability to deliver high value across a wide range of appli-

formulation development, quality control, and manufacturing. cation needs in biopharmaceutical discovery, development and

In early stages of drug development, Octet systems provide manufacturing processes.

ForteBio ForteBio Analytics (Shanghai) Co., Ltd. Molecular Devices (UK) Ltd. Molecular Devices (Germany) GmbH

47661 Fremont Boulevard No. 88 Shang Ke Road 660-665 Eskdale Bismarckring 39

Fremont, CA 94538 Zhangjiang Hi-tech Park Winnersh Triangle 88400 Biberach an der Riss

888.OCTET-75 or 650.322.1360 Shanghai, China 201210 Wokingham, Berkshire Germany

www.fortebio.com fortebio.info@moldev.com salesops.china@moldev.com RG41 5TS, United Kingdom + 00800 665 32860

+44 118 944 8000

uk@moldev.com

©2019 Molecular Devices, LLC. All trademarks used herein are the property of Molecular Devices, LLC. Specifications subject to change without

notice. Patents: www.moleculardevices.com/product patents. FOR RESEARCH USE ONLY. NOT FOR USE IN DIAGNOSTIC PROCEDURES.

AN-4011 Rev B