1/9ページ

ダウンロード(1.7Mb)

このカタログについて

| ドキュメント名 | Technical Note 41「CHO Host Cell Protein Detection」 |

|---|---|

| ドキュメント種別 | ホワイトペーパー |

| ファイルサイズ | 1.7Mb |

| 取り扱い企業 | ザルトリウス・ジャパン株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

TECHNICAL NOTE 41

CHO host cell protein detection

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 host cell protein contaminants and methods that reduce them

Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 to the lowest acceptable levels have become critical aspects of

drug safety and qualification.

Assay accuracy and specificity . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Materials required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 HCP analyses can be broadly classified into two categories,

generic assays and process-specific assays. Commercially avail-

Storage and stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 able generic assays are intended to detect HCPs that might

Assay matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 contaminate a product independent of downstream purification

Octet HTX system HCP assay protocol: processes. These assays normally use HCPs obtained from

a completely walk-away assay . . . . . . . . . . . . . . . . . . . . . . . . . . 3 far upstream (e.g., conditioned media) or after some minimally

Prepare samples and detection plates . . . . . . . . . . . . . . . . . 3 selective purification step (e.g., clarification or filtration) as an

antigen to generate broadly-reactive polyclonal antibodies for

Run the assay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 detection. They are very useful when most HCPs are conserved

Analyze data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 among related strains and processes. On the other hand,

Octet QK384, QKe, Red384, and Red96 system HCP assay process-specific assays are those derived from an immunogen

protocol with Sidekick Station . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 which is specific to a defined purification process. These assays

Process samples on the Sidekick Station . . . . . . . . . . . . . . . 5 are tailor-made for an established process and thus have the

potential to be more specific to the panel of HCPs produced

Example data from a routine assay . . . . . . . . . . . . . . . . . . . . 5 within such processes. However, high specificity for typical

Run the assay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 HCPs occurring within the process carries the risk that any atyp-

Analyze data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 ical HCPs arising due to unintended and undetected deviations

Example Data from a Routine Assay . . . . . . . . . . . . . . . . . . 8 in a purification process may go undetected — potentially lead-

ing to substantial setbacks in the drug development timeline.

Assay troubleshooting guide . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

The vast majority of process-specific assays are developed

only after a process is set and defined, which typically occurs

at the later stages of drug development. Detection antibodies

Overview for process-specific assays also require substantial time and

Host cell proteins (HCPs) are contaminants found in biopharma- cost to develop. Since the FDA generally does not require

ceuticals expressed in bacterial, yeast or mammalian produc- process-specific HCP analyses until phase III trials, generic

tion cell lines. Among protein expression cell lines, Chinese assays are typically employed for overall HCP detection until a

hamster ovary (CHO) cells are the most commonly used mam- drug candidate survives the initial phases of clinical trials. Even

malian hosts for industrial production of recombinant protein after a process-specific assay is developed and implement-

therapeutics. However, manufacturing and production process- ed, generic assays can still be used routinely to complement

es of biopharmaceuticals often leave behind contaminating process-specific testing to maximize detection of any potential

HCPs from CHO cells. Such residual HCPs carry substantial risk atypical HCPs. Because of all these factors, generic assays will

of decreasing efficacy of the drug and causing adverse immu- always remain the most easily assessable and highly useful

nogenic reactions in patients. Hence, the detection of residual tools in any drug development program.

1

Page2

Assay accuracy and specificity

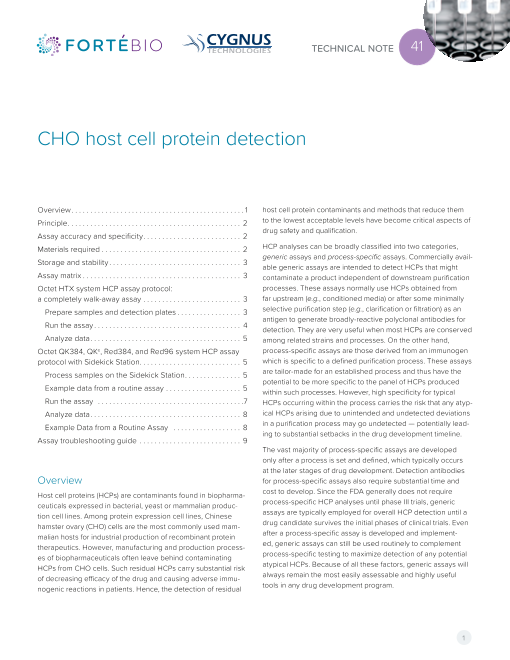

Anti-CHO HCP Biosensor In certain cases, the drug products themselves or components

in the formulation buffer may interfere with the assay’s ability

Cygnus 3G anti-HCP to detect HCPs. Factors such as extremes in pH, detergents,

organic solvents, high protein concentration, and high buffer

HCP salt concentrations are all potential interference factors. It is

therefore necessary to validate by established experimental

Fluorescein-tagged

anti-HCP procedures (i.e. ICH and FDA guidelines) that the assay results

will be accurate. We recommend users perform two critical ex-

periments in establishing assay accuracy and specificity: spike

HRP anti-tag conjugate recovery and dilutional linearity (please also refer to “Assay

HRP

HRP HRP HRP HRP matrix” on page 3). If it is determined that there is significant

Metal DAB product or matrix interference in the assay, further dilution or

buffer exchange of the product to render it into a more assay

Precipitation compatible buffer might be necessary. The same diluent used

Figure 1: Biosensor-based assay format for the detection of CHO HCP. to prepare the kit standards is ideally the preferred material for

dilution or buffer exchange of your samples. For each sample

Principle type to be tested, users should demonstrate that the assay

can recover added HCP or other contaminants spiked into that

Among existing HCP analytical methods, ELISA is perhaps the sample matrix. This can be performed by spiking the highest

more commonly used analytical method. Western blots and standard provided with the kit into your sample types and then

SDS-PAGE are also used, but are limited by their qualitative testing in the assay.

nature and lack of quantitation sensitivity.

There are several inherent problems with ELISA, stemming from Materials required

its reliance on highly manual processing steps that introduce • Octet HTX, QK384, QKe, RED384, or RED96e instrument with

variability in measurement, multiple time-consuming incuba- Octet Data Acquisition and Analysis Software version 8.1 or

tion steps, and reliance on colorimetric or fluorescent probes later.

that can yield false positive signals. ForteBio’s Octet® platform

provides a superior alternative to ELISA with improved precision • Sidekick Offline Biosensor Immobilization Station for high

in measurements, better or equivalent sensitivity and dynamic throughput assays if using Octet QKe, QK384, RED96e, or

range, low user intervention, rapid assay development enabled RED384 instrument (not needed with the Octet HTX instru-

by real-time monitoring, and much faster time-to-results. The ment).

platform is used for generic CHO HCP assays in early phases of • Black polypropylene 96-well or 384-well microplates

clinical product development, and process-specific CHO HCP (Greiner Bio-One part no. 655209 or 781209).

assays can also be constructed using the same assay format if a • Volume of samples to be analyzed (including positive and

process-specific antibody has been developed. negative controls): 80 µL (384-well microplate) or 200 µL

This Technical Note outlines a protocol for using the (96-well microplate).

ForteBio-Cygnus Anti-CHO HCP Detection Kit in developing • Anti-CHO HCP Detection Kit (ForteBio part no. 18-5081), con-

and routine running of process-independent assays on the taining the following:

Octet platform. The measurement involves a sandwich-type • Anti-CHO HCP Reagents A

assay on an Anti-CHO HCP Biosensor that is pre-coated with • CHO Antigen, 48 µL, 20 µg/mL

the gold-standard 3G Anti-CHO HCP antibody from Cygnus

Technologies (Figure 1). A completely hands-off, walk-away HCP • Fluorescein anti-CHO, 240 µL, 100X concentrate

assay analyzing 96 samples can be set up to run automatically • Anti-FITC HRP, 480 µL, 50X concentrate

on an Octet HTX instrument with results obtained in one hour. • Sample Diluent with Kathon, azide-free, 3 x 50 mL

The assay can also be run on other 8- and 16-channel Octet • Anti-CHO HCP Reagents B

instruments together with the Sidekick Station with time-to-re-

sults of 75 and 90 minutes, respectively. • Metal Enhanced DAB concentrate, 2.4 mL, 10X

concentrate

• Stable Peroxide Buffer, 46 mL

• One tray of 96 Anti-CHO HCP biosensors

2

Page3

Storage and stability dards selected should cover the HCP assay range from

0.5–200 ng/mL, and the recommended calibrator concen-

• Anti-CHO HCP Reagents A should be stored at 4°C. The CHO trations are 0.5, 1, 2, 8, 25, 75, and 200 ng/mL. It is also

Antigen can be stored short-term up to one month at 4°C and recommended to run buffer-only controls as references. A

long-term at -20°C. More than three freeze-thaw cycles should calibration curve should be included in each run.

be avoided.

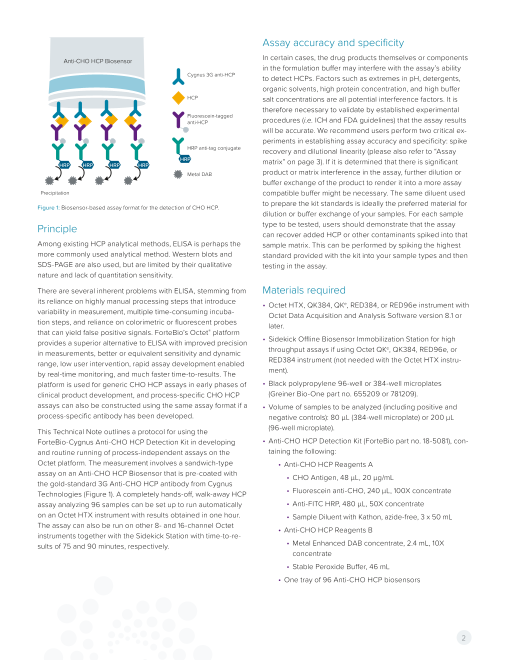

• Anti-CHO HCP Reagents B - Upon arrival, Stable Peroxide 3 Prepare the Sample Plate (example plate layout shown in

Buffer should be stored at 4°C and Metal Enhanced DAB Figure 2):

should be stored at -20°C. a Pipette 80 µL of standard and unknown samples pre-

• Anti-CHO HCP biosensors should be stored at room pared in Sample Diluent with Proclin 300 into the wells of

temperature. a 384-well microplate.

b Pipette 80 µL of Fluorescein anti-CHO prepared at 1:100

Assay matrix dilution in Sample Diluent with Proclin 300 into the wells

Differences between matrices can potentially influence assay of the 384-well microplate.

performance. Diluting the sample matrix using ForteBio’s Sam- c Pipette 80 µL of Sample Diluent with Proclin 300 into the

ple Diluent with Kathon is an effective way to minimize matrix wells of the 384-well microplate.

effects. Prior to running the assay, we recommend an optimiza-

tion step where samples are diluted with varying amounts

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

of Sample Diluent in order to determine the minimum dilution A

factor required for optimal assay performance. It is also im- B

C

portant to test the dilution linearity of the sample to ensure no D

interference from matrix. E

F

G

Octet HTX system HCP assay protocol: H

a completely walk-away assay I

J

The entire CHO HCP assay can be set up on the Octet HTX K

L

system to enable high throughput, walk-away assays. This au- M

tomated assay format eliminates any potential user-related data N

variation that can be caused by manual processing and helps O

P

achieve the most streamlined and efficient laboratory workflow.

A full assay can be performed and data obtained in about one Standards and samples prepared in Sample Diluent with Proclin 300

hour with excellent assay precision and run-to-run consistency. Fluorescein anti-CHO prepared 1:100 in Sample Diluent with Proclin 300

Buer: Sample Diluent with Proclin 300

PREPARE SAMPLES AND DETECTION PLATES Figure 2: Sample Plate layout for 96 biosensor mode in 384-well plate for

Octet HTX system.

Notes:

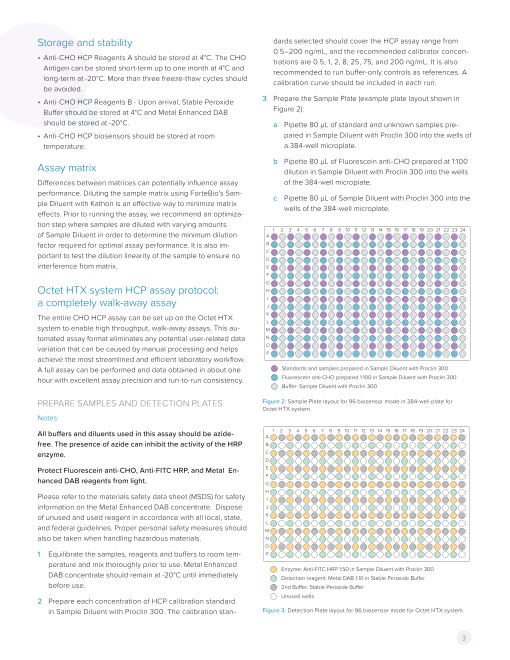

All buffers and diluents used in this assay should be azide- 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

A

free. The presence of azide can inhibit the activity of the HRP B

enzyme. C

D

Protect Fluorescein anti-CHO, Anti-FITC HRP, and Metal En- E

F

hanced DAB reagents from light. G

H

Please refer to the materials safety data sheet (MSDS) for safety I

information on the Metal Enhanced DAB concentrate. Dispose J

of unused and used reagent in accordance with all local, state, K

L

and federal guidelines. Proper personal safety measures should M

also be taken when handling hazardous materials. N

O

1 Equilibrate the samples, reagents and buffers to room tem- P

perature and mix thoroughly prior to use. Metal Enhanced

Enzyme: Anti-FITC HRP 1:50 in Sample Diluent with Proclin 300

DAB concentrate should remain at -20°C until immediately Detection reagent: Metal DAB 1:10 in Stable Peroxide Buer

before use. 2nd Buer: Stable Peroxide Buer

Unused wells

2 Prepare each concentration of HCP calibration standard

in Sample Diluent with Proclin 300. The calibration stan- Figure 3: Detection Plate layout for 96 biosensor mode for Octet HTX system.

3

Page4

4 Prepare the Detection Plate (example plate layout shown in RUN THE ASSAY

Figure 3): 1 Place the Sample and Detection Plates in the Octet HTX

a Pipette 80 µL of Anti-FITC HRP prepared at 1:50 dilution instrument on the defined plate stations.

in Sample Diluent with Proclin 300 into the wells of a 2 Launch Octet Data Acquisition Software and choose the

384-well microplate. Advanced Quantitation option in the Experiment Wizard. In

b Pipette 80 µL of Stable Peroxide Buffer into the wells of the Assay Settings window, click Modify to set up the assay

the 384-well microplate. parameters as shown in Figure 4. The 96 biosensor mode

settings are shown in the left and right panels. Note that the

c Pipette 80 µL of Metal Enhanced DAB prepared at long sample incubation and Fluorescein anti-CHO incuba-

1:10 dilution in Stable Peroxide Buffer into the wells of the tion steps (run in 96 biosensor mode) are defined in the

384-well microplate. Sensor Loading tab, and the remaining steps are defined in

5 Prepare the Biosensor Tray. Biosensor locations should the Plate Definition tab. Alternatively, users with Octet Data

correspond to filled wells in the Sample Plate (one biosensor Acquisition Software v8.1.0.45 can open pre-set method files

for each filled well in the Sample Plate). by choosing Experiment from the main menu, then Tem-

plates, then Quantitation, then Advanced Quantitation, and

6 Prepare a Hydration Plate by pipetting 200 µL of Sample choose the appropriate method file.

Diluent with Kathon into each well of a 96-well polypropyl-

ene plate. Well locations filled with Sample Diluent in the 3 Click OK when assay parameters have been defined.

Hydration Plate should correspond to biosensor locations in

Biosensor Tray.

Figure 4: Settings for Advanced Quantitation assays for HCP detection on the Octet HTX system. The left panel shows the Sample Plate configuration and assay set-

tings in 96 biosensor mode which contains a sample incubation step, an Fluorescein anti-CHO incubation step, and two wash steps with Sample Diluent. The right panel

shows the Detection Plate configuration and assay settings for detection using 96 biosensor mode.

4

Page5

4 Define the Sample Plate layout to correspond to the layout EXAMPLE DATA FROM A ROUTINE ASSAY

in Figure 2.

40

5 Define the Detection Plate layout to correspond to the layout

in Figure 3.

6 Enter Sample and Sensor information in the Plate Definition 30

tab and the Sensor Assignment tab as desired.

7 In the Run Experiment tab, enter a delay time of 600 sec-

onds in order to give the plates at least 10 minutes inside the 20

Octet instrument to equilibrate to assay temperature.

8 Enter a location and file name for saving the data.

10

9 Click GO to run the assay.

ANALYZE DATA 0

The analysis of the data obtained on the Octet HTX system is 125 130 135 140 145 150 155 160 165 170 175 180

Time (sec)

identical to the analysis of data obtained from other instru-

ments. To analyze the data: Expected Calculated

concentration concentration

1 In Octet Data Analysis Software, load the data folder to be (ng/mL) (ng/mL) Recovery %CV

analyzed.

200.0 200.0 100% 4.2%

2 Select the reference well and perform reference subtraction

75.0 76.3 102% 5.0%

if needed.

25.0 25.3 101% 4.4%

3 Group and Concentration information can be modified in the

table if needed. 8.0 8.08 101% 6.2%

4 In the Results tab: 2.0 2.01 100% 4.2%

a Select R equilibrium as the binding rate equation. This 1.0 1.00 100% 5.0%

equation will fit the binding curve generated during the 0.5 0.52 104% 9.8%

experiment and calculate a response at equilibrium as

the output signal. Figure 5: Example data from a CHO HCP assay on the Octet HTX system. The

data shows a dose response for the calibration standards (N=12). The calculated

b Click Calculate Binding Rate. Results will be displayed concentrations and %CV values resulting from the analysis of the data are shown

automatically in the table. in the accompanying table.

c Click Save Report or select File > Save Report to gener-

ate a Microsoft® Excel® report file. PROCESS SAMPLES ON THE SIDEKICK STATION

Notes:

Octet QK384, QKe, RED384, and RED96e All buffers and diluents used in this assay should be azide-

system HCP assay protocol with Sidekick free. The presence of azide can inhibit the activity of the HRP

Station enzyme.

The HCP assay for 8- and 16-channel Octet instruments is per- Protect Fluorescein anti-CHO, Anti-FITC HRP, and Metal En-

formed according to the steps shown in Figure 6. When using hanced DAB reagents from light.

these systems, the initial incubation steps are processed using Please refer to the safety data sheet for safety information on

the Sidekick Station. After biosensors are incubated with HCP the Metal Enhanced DAB concentrate. Dispose of unused and

samples and Fluorescein anti-CHO antibody, the remaining used reagent in accordance with all local, state, and federal

steps are performed on the Octet instrument. guidelines. Proper personal safety measures should also be

taken when handling hazardous materials.

5

Binding (nm)

Page6

1 Equilibrate the samples, reagents and buffers to room

temperature and mix thoroughly prior to use. Metal En- Sidekick Station:

Sidekick Station: CHO HCP plate

hanced DAB concentrate should remain at -20°C until imme- Hydration plate (200 µL/well) (200 µL/well)

Sample Diluent Proclin 300

diately before use. CHO HCP Standards and Samples

1 min, 30˚C, 1000 rpm 30 mins, 30˚C, 1000 rpm

2 Prepare each concentration of HCP calibration standard in

Sample Diluent with Proclin 300. The calibration standards

selected should cover the HCP assay range from 0.5–200

ng/mL, and the recommended calibrator concentrations are Sidekick Station:

Sidekick Station:

0.5, 1, 2, 8, 25, 75, and 200 ng/mL. It is also recommended Fluorescein anti-CHO plate

Wash Plate (200 µL/well) (200 µL/well)

to run buffer-only controls as references. A calibration curve Sample Diluent Proclin 300 Fluorescein anti-CHO antibody

should be included in each run. 30 secs, 30˚C, 1000 rpm 30 mins, 30˚C, 1000 rpm

3 Prepare the Sample Plate (example plate layout shown in

Figure 7):

a Pipette 200 µL of each standard into the wells of a Sidekick Station: Octet System:

96-well microplate. Wash/hydration plate (200 µL/well) Detection plate (200 µL/well)

Sample Diluent Proclin 300 Buer (Sample Diluent Proclin 300)

b Pipette 200 µL of each unknown sample into the wells in 30 secs, 30˚C, 1000 rpm Enzyme (Anti-FITC HRP antibody)

2nd Buer (Stable Peroxide Buer)

the remainder of the microplate. Octet System: 600 sec, RT, 0 rpm Detection (Metal DAB)

4 Prepare the Biosensor Tray. Biosensor locations should Figure 6: Flow chart of HCP assay steps on 8- and 16-channel Octet systems

correspond to filled wells in the Sample Plate (one biosensor with the Sidekick Offline Immobilization Station.

for each filled well in the Sample Plate).

5 Prepare one Hydration Plate and two additional Wash Plates

by pipetting 200 µL of Sample Diluent with Proclin 300 into 11 During this incubation, prepare the Detection Plate. Either

each well of three polypropylene 96-well plates. Well loca- a 96-well or a 384-well microplate can be used depend-

tions filled with Sample Diluent in the Hydration Plate should ing on the Octet instrument being used. The fill volumes

correspond to biosensor locations in Biosensor Tray. for 96- and 384-well microplates are 200 µL and 80 µL,

respectively.

6 Using the Sidekick Station, hydrate biosensors in the Hydra-

tion Plate at 1000 rpm and 30°C for 1 minute. a Prepare an appropriate volume for the plate type of:

7 Incubate hydrated biosensors in the Sample Plate on the • A 1:50 dilution of the Anti-FITC HRP antibody in Sam-

Sidekick Station at 1000 rpm and 30°C for 30 minutes. ple Diluent with Proclin 300

• A 1:10 dilution of Metal Enhanced DAB in Stable

8 During this incubation, prepare the Fluorescein anti-CHO Peroxide Buffer

Antibody Plate:

b In a black, flat-bottomed 96- or 384-well microplate,

a Prepare a 1:100 dilution of Fluorescein anti-CHO antibody pipette 200 µL or 80 µL respectively of each reagent

in Sample Diluent with Proclin 300. specified into the wells of the microplate using the plate

b Pipette 200 µL into each well of a new 96-well micro- layout shown in Figure 8). Each reagent needs to be filled

plate. Filled wells should correspond to biosensor loca- into all wells of one column (for 8-channel assays) or two

tion and number in the Biosensor Tray. columns (for 16-channel assays) in the Detection Plate.

9 After 30 minutes of sample incubation, replace the Sample 12 After 30 minutes of Fluorescein anti-CHO incubation,

Plate with the first Wash Plate on the Sidekick Station and replace the Sample Plate with second Wash Plate on the

incubate at 1000 rpm and 30°C for 30 seconds. Sidekick Station and incubate at 1000 rpm and 30°C for

30 seconds.

10 Replace the Wash Plate with the Fluorescein anti-CHO

Antibody Plate. Incubate on the Sidekick Station at 1000 rpm

and 30°C for 30 minutes.

6

Page7

1 2 3 4 5 6 7 8 9 10 11 12

A

B

C

D

E

F

G

H

HCP standards

HCP unknown Figure 9: Settings for Advanced Quantitation assays for HCP detection on 8- and

16-channel Octet systems.

Figure 7: Sample Plate layout for incubation with biosensors on the Sidekick

Station.

1 2 3 4 5 6 7 8 9 10 11 12 RUN THE ASSAY

A 1 After the second wash step on the Sidekick Station is com-

B plete, place the Biosensor Tray over the second Wash Plate

(the same plate used on the Sidekick Station for the last

C wash) into the Octet instrument.

D

2 Place the Detection Plate into the Octet Instrument. For

E Octet QKe, RED, and RED96e systems, place the Detection

F Plate in the single plate station (Plate 1) in the instrument.

For Octet RED384 and QK384 systems, place the Detection

G

Plate in the reagent plate station (Plate 2).

H

3 Launch Octet Data Acquisition Software and choose the

Advanced Quantitation option in the Experiment wizard. In

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 the Assay Settings window, click Modify to set up the assay

A

B parameters as shown in Figure 9. Note that the sample step

C is specified to have been carried out offline.

D

E 4 Click OK once the assay parameters have been defined.

F

G 5 Define the Sample and Detection Plate layouts:

H

I For Octet RED384 and QK384 systems:

J

K a Define the Sample Plate layout to correspond to the

L

M layout in Figure 7. The Sample Plate Layout needs to

N be defined in the Octet Data Acquisition Software even

O

P though the Sample step has been performed offline as

this enables the software to assign the correct Sample

Sample Diluent IDs to the biosensors during analysis.

Anti-FITC HRP

Stable Peroxide Buer b Define the Detection Plate layout to correspond to the

Metal Enhanced DAB appropriate layout in Figure 9:

Empty

• Sample Diluent with Proclin 300 = B (Buffer)

Figure 8: Detection Plate layout for 8-channel assays on Octet RED, RED96e

and QKe systems (top) and for 16-channel assays on Octet RED384 and QK384 • Anti-FITC HRP antibody = E (Enzyme)

systems (bottom). • Stable Peroxide Buffer = 2 (2nd Buffer)

• Metal Enhanced DAB = D (Detection)

7

Page8

For Octet RED96e and QKe systems:

35

1 2 3 4

a Specifying the Sample step to be carried out offline

enables two plates to be opened in the software (even 30

though there is only one plate position in the instrument).

The first plate (Plate 1) has the same layout as the Sample 25

Plate layout used in the Sidekick Station incubation.

20

b The layout of the second plate (Plate 2) is defined to

correspond to the appropriate Detection Plate layout in 15

Figure 9 where:

10

• Sample Diluent in Proclin 300 = B (Buffer)

• Anti-FITC HRP antibody = E (Enzyme) 5

• Stable Peroxide Buffer = 2 (2nd Buffer) 0

• Metal Enhanced DAB = D (Detection) 0 20 40 60 80 100 120 140 160 180

Time (sec)

6 Enter Sample and Sensor information in the Plate Definition

tab and the Sensor Assignment tab as desired. Figure 10: Real time data from detection steps measured on the Octet RED384

system with the CHO HCP assay. Processing of the biosensors with samples

7 In the Run Experiment tab, enter a delay time of 600 sec- and the binding of the Fluorescein anti-CHO antibody were performed using

the Sidekick Station. The steps shown include 1) baseline in Sample Diluent, 2)

onds in order to give the plates at least 10 minutes inside the binding of Anti-FITC HRP antibody, 3) Stable Peroxide Buffer equilibration and

Octet instrument to equilibrate to assay temperature. 4) detection of signal using Metal Enhanced DAB substrate. The assay was run

according to the procedure outlined in this technical note.

8 Enter a location and file name for saving the data.

9 Click GO to run the assay. 40

35

ANALYZE DATA

1 In Octet Data Analysis Software, load the data folder to be 30

analyzed.

25

2 Select the reference well and perform reference subtraction

if needed. 20

3 Group and Concentration information can be modified in the 15

table if needed.

10

4 In the Results tab:

5

a Select R equilibrium as the binding rate equation. This

equation will fit the binding curve generated during the 0

0 10 20 30 40 50 60

experiment and calculate a response at equilibrium as Time (sec)

the output signal.

Expected Calc.

b Click Calculate Binding Rate. Results will be displayed concentration concentration

automatically in the table. (ng/mL) (ng/mL) Recovery %CV

c Click Save Report or select File > Save Report to gener- 200.0 201.0 101% 2.1%

ate a Microsoft® Excel® report file. 75.0 73.9 99% 0.7%

EXAMPLE DATA FROM A ROUTINE ASSAY 25.0 25.5 102% 2.3%

The data shown was generated on the Octet RED384 system 8.0 8.08 101% 2.8%

using the protocol outlined in this technical note. CHO-HCP 2.0 2.01 101% 1.8%

standards at 200, 75, 25, 8, 2, 1, and 0.5 ng/mL in Sample 1.0 1.00 100% 1.7%

Diluent with Proclin 300 were prepared and run in triplicate.

Three unknowns (Samples 1, 2 and 3) were run in 8 replicates to 0.5 0.50 100% 3.3%

assess assay precision.

Figure 11: The data shows a dose response for the calibration standards in

triplicate. The calculated concentrations and %CV values resulting from the

analysis of the data are shown in the accompanying table.

8

Binding (nm) Binding (nm)

Page9

40

Calc. concentration

35 Sample (ng/mL) %CV

Sample 1 137.5 4.1%

30

Sample 2 10.6 4.0%

25

Sample 3 0.43 5.1%

20

15

10

Figure 12: Graph showing data for three unknown samples, each having eight

5 replicates. The calculated concentrations and %CV are shown in the accom-

panying table. The concentrations were calculated using the calibration data

shown in Figure 11.

0

0 10 20 30 40 50 60

Time (sec)

Assay troubleshooting guide

Issue Possible reasons Suggested solutions

Stable Peroxide Buffer and Sample Re-run assay taking care to dilute the Metal Enhanced DAB

Diluent switched. concentrate in Stable Peroxide Buffer and samples and

standards in Sample Diluent with Proclin 300.

Stable Peroxide Buffer or Metal Enhanced Check for activity by combining Stable Peroxide Buffer and

No signal from HCP standards DAB is no longer active. Metal Enhanced DAB with 1 μL of HRP anti-FITC antibody. A

dark precipitate should appear if all are active.

Confirm that the Metal Enhanced DAB has been stored at

Reagents no longer active. -20°C, the Stable Peroxide Buffer at either -20°C or 4°C (after

opening), the biosensors at room temperature and the CHO

standards, Fluorescein anti-CHO and HRP anti-FITC at 4°C.

Perform a dilution series of the sample in order to determine

HCP concentration is below the LOD. what dilution is required to bring the sample signal within the

No sample signal dynamic range of the assay.

Azide present in samples. Dialyze sample to remove azide.

Sample signal is too high HCP concentration is above the Perform a dilution series of the sample in order to determine

concentration of the highest standard. what dilution is required to bring the sample signal within the

dynamic range of the assay.

For best results, assay step times should be consistent across

Inconsistency in incubation times. standards and samples. For incubation steps involving manual

intervention, use a lab timer to ensure all samples and assays

are treated similarly.

High variability between runs Protect Fluorescein anti-CHO, anti-FITC HRP and Metal

Fluorescein anti-CHO, anti-FITC HRP and Enhanced DAB from light by storing in a dark, dry place

Metal Enhanced DAB not protected from when not in use. Additionally, dilutions of these materials

light. should be stored in a dark place until they are pipetted into

micro plates and placed either into the instrument or onto

the Sidekick Station.

ForteBio ForteBio Analytics (Shanghai) Co., Ltd. Molecular Devices (UK) Ltd. Molecular Devices (Germany) GmbH

47661 Fremont Boulevard No. 88 Shang Ke Road 660-665 Eskdale Bismarckring 39

Fremont, CA 94538 Zhangjiang Hi-tech Park Winnersh Triangle 88400 Biberach an der Riss

888.OCTET-75 or 650.322.1360 Shanghai, China 201210 Wokingham, Berkshire Germany

www.fortebio.com fortebio.info@moldev.com salesops.china@moldev.com RG41 5TS, United Kingdom + 00800 665 32860

+44 118 944 8000

uk@moldev.com

©2019 Molecular Devices, LLC. All trademarks used herein are the property of Molecular Devices, LLC. Specifications subject to change without

notice. Patents: www.moleculardevices.com/product patents. FOR RESEARCH USE ONLY. NOT FOR USE IN DIAGNOSTIC PROCEDURES.

TN-4041 Rev D

Binding (nm)