1/16ページ

ダウンロード(5Mb)

Precision modular connectors to suit your application

This series of connectors stems from the series 00 and has been specifically developed for applications where the connection

must be guaranteed under very high pressure.

※レモコネクタはモジュール方式のため、共通部品を組み合せることにより様々なコネクタに変えることができます。このため、カタログに掲載されている写真や図は、色、形状などが実物とは微妙に異なっている場合や、写真撮影の方向が一定していない場合がございます。ご注意いただきますようお願いいたします。

このカタログについて

| ドキュメント名 | 小型水中コネクタ 03シリーズ |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 5Mb |

| 登録カテゴリ | |

| 取り扱い企業 | レモジャパン株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

HIGH PRESSURE

CONNECTORS

Page2

® ®

Precision modular connectors to suit your application

Since its creation in Switzerland in 1946 the LEMO Group has been recognized as a global leader of circular Push-Pull

connectors and connector solutions. Today LEMO and its affiliated companies, REDEL and COELVER, are active in more

than 80 countries with the help of over 40 subsidiaries and distributors.

Over 75000 connectors

The modular design of the LEMO range provides over 75000 connectors from miniature ø 3 mm to ø 50 mm, capable of

handling cable diameters up to 30 mm and for up to 114 contacts.

This vast portfolio enables you to select the ideal connector configuration to suit almost any specific requirement in most

markets, including medical devices, test and measurement instruments, machinery, audio video broadcast, telecommuni-

cations and military.

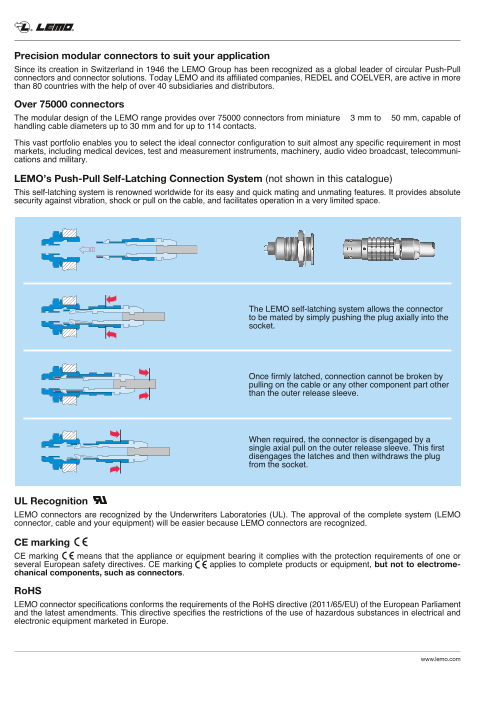

LEMO’s Push-Pull Self-Latching Connection System (not shown in this catalogue)

This self-latching system is renowned worldwide for its easy and quick mating and unmating features. It provides absolute

security against vibration, shock or pull on the cable, and facilitates operation in a very limited space.

The LEMO self-latching system allows the connector

to be mated by simply pushing the plug axially into the

socket.

Once firmly latched, connection cannot be broken by

pulling on the cable or any other component part other

than the outer release sleeve.

When required, the connector is disengaged by a

single axial pull on the outer release sleeve. This first

disengages the latches and then withdraws the plug

from the socket.

UL Recognition

LEMO connectors are recognized by the Underwriters Laboratories (UL). The approval of the complete system (LEMO

connector, cable and your equipment) will be easier because LEMO connectors are recognized.

CE marking

CE marking means that the appliance or equipment bearing it complies with the protection requirements of one or

several European safety directives. CE marking applies to complete products or equipment, but not to electrome-

chanical components, such as connectors.

RoHS

LEMO connector specifications conforms the requirements of the RoHS directive (2011/65/EU) of the European Parliament

and the latest amendments. This directive specifies the restrictions of the use of hazardous substances in electrical and

electronic equipment marketed in Europe.

www.lemo.com

Page3

® ®

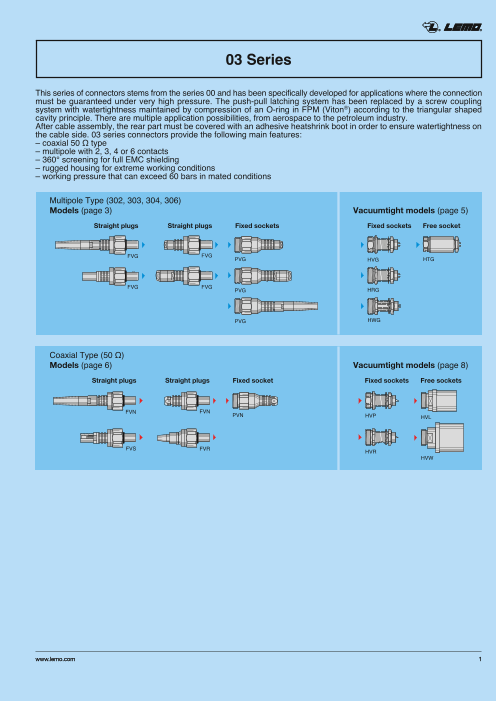

03 Series

This series of connectors stems from the series 00 and has been specifically developed for applications where the connection

must be guaranteed under very high pressure. The push-pull latching system has been replaced by a screw coupling

system with watertightness maintained by compression of an O-ring in FPM (Viton®) according to the triangular shaped

cavity principle. There are multiple application possibilities, from aerospace to the petroleum industry.

After cable assembly, the rear part must be covered with an adhesive heatshrink boot in order to ensure watertightness on

the cable side. 03 series connectors provide the following main features:

– coaxial 50 Ω type

– multipole with 2, 3, 4 or 6 contacts

– 360° screening for full EMC shielding

– rugged housing for extreme working conditions

– working pressure that can exceed 60 bars in mated conditions

Multipole Type (302, 303, 304, 306)

Models (page 3) Vacuumtight models (page 5)

Straight plugs Straight plugs Fixed sockets Fixed sockets Free socket

FVG FVG PVG HVG HTG

FVG FVG PVG HRG

PVG HWG

Coaxial Type (50 Ω)

Models (page 6) Vacuumtight models (page 8)

Straight plugs Straight plugs Fixed socket Fixed sockets Free sockets

FVN FVN PVN HVP HVL

FVS FVR HVR

HVW

www.lemo.com 1

Page4

® ®

Part Numbering System

Plug F V G 0 3 3 0 2 C L A C 2 7

Free socket P V G 0 3 3 0 2 C L L C 2 7

Variant: (page 11)

Cable ø

Collet type:

C = cable collet

E = crimping

K = oversized cable collet

Fixed socket H V G 0 3 3 0 2 C L L P V

V = vacuumtight

Model: (page 3-8) Sealing epoxy resin:

Alignment key: (page 9) P = Araldite® S = Stycast®

(only for multipole)

Contact: (page 10)

Series: 03

Insert configuration: Insulator: L = PEEK

– Multipole (page 10)

– Coax (page 10) Housing: (page 10)

FVG.03.302.CLAC27 = straight plug with key (G) and cable collet, 03 series, multipole type with 2 contacts, outer shell in chrome-plated

brass, PEEK insulator, male solder contacts, C type collet for 2.7 mm diameter cable.

PVG.03.302.CLLC27 = free socket with key (G) and cable collet, 03 series, multipole type with 2 contacts, outer shell in chrome-plated

brass, PEEK insulator, female solder contacts, C type collet for 2.7 mm diameter cable.

HVG.03.302.CLLPV = fixed socket, nut fixing, with key (G), 03 series, multipole type with 2 contacts, outer shell in chrome-plated brass,

PEEK insulator, female solder contacts, sealed with Araldite® epoxy resin.

Part Section Showing Internal Components (multipole)

Straight plug

Fixed socket 1 outer shell

1 outer shell 2 coupling nut9 4 5 3 2 6 8 7 1 1 6 11 5 2 11 10 4 7 11 9 8 3

2 earthing crown 3 collet nut

3 retaining ring 4 centre-piece

4 hexagonal nut 5 insulator

5 locking washer 6 male contact

6 insulator 7 earthing cone

7 female contact 8 collet

8 o-ring 9 compression ring

9 epoxy resin 10 circlip

11 o-ring

2 www.lemo.com

Page5

® ®

Models (multipole type)

Technical Characteristics

Mechanical and Climatical Electrical

Characteristics Value Standard Characteristics Value Standard Section

Endurance > 1000 cycles IEC 60512-5 test 9a Insulation resistance (new) > 1012 Ω IEC 60512-2 test 3a

Humidity up to 95% at 60° C Insulation resistance 3) > 1010 Ω IEC 60512-2 test 3a

Temperature range -20° C, +200° C Shell electrical continuity 5.0 mΩ IEC 60512-2 test 2f

Salt spray corrosion test > 144 h IEC 60512-6 test 11f Shielding at 10 MHz > 100 dB IEC 60169-1-3

Protection index 2) > IP68 IEC 60529 efficiency at 1 GHz > 80 dB IEC 60169-1-3

Resistance to hydrostatic

pressure 2) ~ 60 bars

1) IEC 60512-7 test 14d Contact ø A = 0.5 mm ≤ 8.7 mΩ IEC 60512-2 test 2a

resistance 4) ø A = 0.7 mm ≤ 6.1 mΩ IEC 60512-2 test 2a

Climatical category 20/200/21 IEC 60068-1

Note: Note:

1) in order to perform correctly and withstand the pressure, cable assembly 3) after humidity test: 21 days at 95% RH according to IEC 60068-2.

shall be made according to instruction we recommand. See page 12. 4) after 5000 mating cycles and the salt spray test according to IEC 60512-6

2) For mated plug and socket. test 11 f.

FVG Straight plug, key (G) or key (B), cable collet

Cable ø (mm)

33.7 Part number min. max.

25.5 FVG.03.30l.CLAC27 2.4 2.6

FVG.03.30l.SLAC27 2.4 2.6

FVG.03.30l.CLAC31 2.7 3.0

S 5 S 11 FVG.03.30l.SLAC31 2.7 3.0

Note: l = insert configuration (page 10)

FVG Straight plug, key (G) or key (B), cable collet and nut for fitting a bend relief

Cable ø (mm)

Part number min. max.

38.5

30.3 FVG.03.30l.CLAC27Z 2.4 2.6

FVG.03.30l.SLAC27Z 2.4 2.6

FVG.03.30l.CLAC31Z 2.7 3.0

FVG.03.30l.SLAC31Z 2.7 3.0

S 6 S 11

Note: l = insert configuration (page 10).

The bend relief must be ordered separately (page 11)

FVG Straight plug, key (G) or key (B) and oversize cable collet

Cable ø (mm)

Part number

38.7 min. max.

30.5 FVG.03.30l.CLAK35 3.1 3.5

FVG.03.30l.CLAK40 3.6 4.0

FVG.03.30l.CLAK45 4.1 4.5

FVG.03.30l.CLAK50 4.6 5.0

S 7 S 7 S 11

Note: l = insert configuration (page 10)

Correspond to K type of collet. Also available with nut for fitting a bend relief.

www.lemo.com 3

ø 11.8

ø 11.8 ø 11.8

Page6

® ®

FVG Straight plug, key (G) for cable crimping

Cable ø (mm)

34.7 Part number max.

26.5 FVG.03.30l.CLAE44 4.3

FVG.03.30l.SLAE44 4.3

FVG.03.30l.CLAE52 5.1

S 11 FVG.03.30l.SLAE52 5.1

Note: l = insert configuration (page 10)

PVG Free socket, key (G) and cable collet

36.7

32.7

Cable ø (mm)

Part number min. max.

PVG.03.30l.CLLC27 2.4 2.6

S 5 S 11 PVG.03.30l.CLLC31 2.7 3.0

Note: l = insert configuration (page 10)

PVG Free socket, key (G), cable collet and nut for fitting a bend relief

41.5

37.5 Cable ø (mm)

Part number min. max.

PVG.03.30l.CLLC27Z 2.4 2.6

PVG.03.30l.CLLC31Z 2.7 3.0

S 6 S 11

Note: l = insert configuration (page 10).

The bend relief must be ordered separately (page 11)

PVG Free socket, key (G) and oversize cable collet

Cable ø (mm)

Part number min. max.

52.7

48.7 PVG.03.30l.CLLK35 3.1 3.5

PVG.03.30l.CLLK40 3.6 4.0

PVG.03.30l.CLLK45 4.1 4.5

PVG.03.30l.CLLK50 4.6 5.0

S 7 S 7 S 11

Note: l = insert configuration (page 10)

Correspond to K type of collet. Also available with nut for fitting a bend relief.

4 www.lemo.com

ø 11.8

ø 11.8 ø 11.8ø 11.8

Page7

® ®

Vacuumtight models (multipole type)

These sockets models allow the device on which they are fitted to reach a protection index of IP68 as per IEC 60529. They

are fully compatible with plugs of the same series and are widely used for portable radios, military, laboratory equipment,

aviation, etc.

These models are identified by a letter «P» or «S» at the last but one character of the reference. The Stycast® sealant can

be used over a larger temperature range than the Araldite® sealant.

Vaccumtight models are identified by an additional letter «V» at the end of the part number (certificate on request). Epoxy

resin is used to seal these models.

Technical Characteristics

Mechanical and Climatical

Characteristics Value Standard Characteristics Value Standard

Endurance > 1000 cycles IEC 60512-5 test 9a Climatical category 20/80/21 IEC 60068-1

Humidity up to 95% at 60° C Leakage rate (He) 1) < 10-7 mbar.l.s-1 IEC 60512-7 test 14b

Temperature range -20° C, +100° C Max. operating pressure 2) 60 bars IEC 60512-7 test 14d

Salt spray corrosion test > 144h IEC 60512-6 test 11f Note: 1) only for vacuumtight models. 2) this value corresponds to the

maximum allowed pressure difference for the assembled socket.

HVG Fixed socket, key (G) or key (B), round flange, nut fixing, vacuumtight

22

6 S 9 Part number Sealing resin

HVG.03.30l.CLLPV Araldite®

HVG.03.30l.SLLPV Araldite®

S 9 6.5 maxi HVG.03.30l.CLLSV Stycast® Panel cut-out (page 11)

HVG.03.30 .SLLSV Stycast® Note: l = insert l configuration (page 10)

HWG Fixed socket, key (G), hexagonal flange, nut fixing, vacuumtight

21

S 9 S 11 6

Part number Sealing resin

®

S 6.3 6.5 maxi HWG.03.30l.CLLPV Araldite Panel cut-out (page 11)

HWG.03.30 ® Note: l = insert l.CLLSV Stycast configuration (page 10)

HRG Fixed socket, key (G), hexagonal flange, nut fixing, no flats on fixing thread, vacuumtight

22

S 11 Part number Sealing resin

6

HRG.03.30l.CLLPV Araldite®

HRG.03.30l.SLLPV Araldite®

® Panel cut-out (page 11)

S 9 6.5 maxi HRG.03.30l.CLLSV Stycast

HRG.03.30l.SLLSV Stycast® Note: l = insert configuration (page 10)

www.lemo.com 5

ø 10.2 ø 10.2 ø 10.2

M7x0.5 M7x0.5 M7x0.5

ø 11.8 ø 11.8 ø 11

Page8

® ®

HTG Fixed socket, key (G), nut fixing, long shell

26 S 9

S 9 Part number Sealing resin Panel cut-out (page 11)

HTG.03.30l.CLLSV Stycast® Note: l = insert configuration (page 10)

Models (coaxial type)

Technical Characteristics

Mechanical and Climatical Electrical

Characteristics Value Standard Characteristics Value Standard Section

Endurance > 1000 cycles IEC 60512-5 test 9a Insulation resistance (new) > 1012 Ω IEC 60512-2 test 3a

Humidity up to 95% at 60° C Insulation resistance 3) > 1010 Ω IEC 60512-2 test 3a

Temperature range -20° C, +200° C Shell electrical continuity 5.0 mΩ IEC 60512-2 test 2f

Salt spray corrosion test > 144 h IEC 60512-6 test 11f Shielding at 10 MHz > 100 dB IEC 60169-1-3

Protection index 2) > IP68 IEC 60529 efficiency at 1 GHz > 80 dB IEC 60169-1-3

Resistance to hydrostatic Contact ø A = 0.5 mm ≤ 8.7 mΩ IEC 60512-2 test 2a

2) ~ 60 bars 1)pressure IEC 60512-7 test 14d resistance 4) ø A = 0.7 mm ≤ 6.1 mΩ IEC 60512-2 test 2a

Climatical category 20/200/21 IEC 60068-1 Max. working frequency 500 MHz For coaxial type

Note: Note:

1) in order to perform correctly and withstand the pressure, cable assembly 3) after humidity test: 21 days at 95% RH according to IEC 60068-2.

shall be made according to instruction we recommand. See page 12. 4) after 5000 mating cycles and the salt spray test according to IEC 60512-6

2) For mated plug and socket. test 11 f.

FVN Straight plug, cable collet

Part number Cable group

29.5

21.2 FVN.03.250.CLAC27 4

FVN.03.250.SLAC27 4

FVN.03.250.CLAC31 3

S 4.5 S 11 FVN.03.250.SLAC31 3

Cable assembly (page 12)

6 www.lemo.com

ø 10.2

M7x0.5

ø 11.8

ø 11

Page9

® ®

FVN Straight plug, cable collet and nut for fitting a bend relief

38.5

Part number Cable group

30.3

FVN.03.250.CLAC27Z 4

FVN.03.250.SLAC27Z 4 Cable assembly (page 12)

S 6 S 11 FVN.03.250.CLAC31Z 3 Note: The bend relief must

FVN.03.250.SLAC31Z 3 be ordered separately (page 11).

FVS Straight plug for cable crimping

35.3

26.5 Part number Cable group

FVS.03.250.CLAE24 1

FVS.03.250.CLCE24 1

S 5.5 S 11 FVS.03.250.CLCE31 3-4

Cable assembly (page 12)

FVR Straight plug with brazing ferrule

32.9

Cable ø (mm)

24.6 Part number max.

FVR.03.250.SLAV16B 1.55

FVR.03.250.SLAV20B 1.95

S 11 Cable assembly (page 12)

Note: The shell of the connector is in stainless steel AISI 316L.

PVN Free socket and cable collet

36.7

32.7 Part number Cable group

PVN.03.250.CLLC27 4

PVN.03.250.CLLC31 3

S 4.5 S 11 Cable assembly (page 12)

Note: Also available with nut for fitting a bend relief (page 11).

www.lemo.com 7

ø 11.8 ø 11.8 ø 11.8

ø 11.8

Page10

® ®

Vacuumtight models (coaxial type)

These sockets models allow the device on which they are fitted to reach a protection index of IP68 as per IEC 60529. They

are fully compatible with plugs of the same series and are widely used for portable radios, military, laboratory equipment,

aviation, etc.

These models are identified by a letter «P» or «S» at the last but one character of the reference. The Stycast® sealant can

be used over a larger temperature range than the Araldite® sealant.

All these models are available in a watertight or vacuumtight version. Vaccumtight models are identified by an additional

letter «V» at the end of the part number (certificate on request). Epoxy resin is used to seal these models.

Technical Characteristics

Mechanical and Climatical

Characteristics Value Standard Characteristics Value Standard

Endurance > 1000 cycles IEC 60512-5 test 9a Climatical category 20/80/21 IEC 60068-1

Humidity up to 95% at 60° C Leakage rate (He) 1) < 10-7 mbar.l.s-1 IEC 60512-7 test 14b

Temperature range -20° C, +100° C Max. operating pressure 2) 60 bars IEC 60512-7 test 14d

Salt spray corrosion test > 144h IEC 60512-6 test 11f Note: 1) only for vacuumtight models. 2) this value corresponds to the

maximum allowed pressure difference for the assembled socket.

HVR Fixed socket, hexagonal flange, nut fixing, vacuumtight

Part number Sealing resin

21

S 11 6 HVR.03.250.CLLPV Araldite®

HVR.03.250.SLLPV Araldite®

HVR.03.250.CLLSV Stycast®

®

S 9 6.5 maxi HVR.03.250.SLLSV Stycast

Panel cut-out (page 11)

HVP Fixed socket, round flange, nut fixing, vacuumtight

21

6 S 9

Part number Sealing resin

HVP.03.250.CLLPV Araldite®

S 9 6.5 maxi HVP.03.250.CLLSV Stycast®

Panel cut-out (page 11)

HVL Free socket, for device overmolding

24.2

Part number

S 11 HVL.03.250.NLL

8 www.lemo.com

ø 10.2 ø 10.2

M7x0.5 M7x0.5

M10x0.75

ø 13.9

ø 11 ø 11.8

Page11

® ®

HVW Free socket, for device overmolding, large shell

28

18

Part number

HVW.03.250.NLL

S 11

Note: Vacuumtightness is achieved after customer overmolding.

Alignment Key

Alignment Key and Polarized Keying System for Multipole Types

03 series connector model part numbers are composed of three letters. The LAST LETTER indicates the key position and

the contact type (male or female).

Front view of a socket Series Contact type

Nb of

α keys

03 Plug Socket

G 1 0° male female

B 2 α 60° male female

Insert configuration

Coaxial, multipole

1 4 4 1

2 3 3 2

Male solder contacts Female solder contacts

Coaxial

1 250 03 0.7 1-3-4 – 50 2.1 2.10 4.0

Multipole

2 302 03 0.5 – 30 – 1.0 0.95 5.0

Multipole

3 303 03 0.5 – 30 – 0.8 0.95 3.0

Multipole

4 304 03 0.5 – 30 – 0.8 0.95 2.0

Multipole

6 306 03 0.35 – 30 – 0.7 0.95 1.7

Note: 1) Test voltage measured according to IEC 60512-2 test 4a standard.

www.lemo.com 9

Key

Angles

M10x0.75

ø 19.9

Reference

Series

Contact ø (mm)

Cable group

AWG max.

Impedance (Ω)

Test voltage (kV rms)1)

Contact-contact

Test voltage (kV rms)1)

Contact-shell

Rated current (A)1)

Page12

® ®

H ousings

Outer shell and collet nut Latch sleeve + earthing crown Other metallic components

Ref. Remarks Note

Material Surf. treatment Material Surf. treatment Material Surf. treatment

C Brass chrome brass/bronze nickel brass nickel For multipole and coaxial l

S Stainless steel – brass/bronze nickel brass nickel For multipole and coaxial l

Note: detailed characteristics of these materials and treatments are presented in the Unipole-Multipole catalogue.

l First choice alternative

Special order alternative

Contacts

Ref. Contact type Remarks

A Male solder For multipole and coaxial

C Male crimp For coaxial

L Female solder For multipole or coaxial type sockets

Variant

Bend relief for models with collet

Need to be ordered

Collet Dim . (mm)Need to be ordered Cable ø

Type Code separately max. min.

C 27 GMB.00.025.DG 2.8 2.5

03 C 31 GMB.00.028.DG 3.1 2.8

Z

C 27 GMD.00.025.DG 2.8 2.5

C 31 GMD.00.028.DG 3.1 2.8

K 35 GMA.0B.030.DG 3.4 3.0

K 40 GMA.0B.035.DG 3.9 3.5

Z

K 45 GMA.0B.040.DG 4.4 4.0 Note: The «GMD» are thin bend reliefs (for very flexible cables).

K 50 GMA.0B.045.DG 5.2 4.5 The last letter «G» of the part number indicates the grey colour of the bend relief.

Accessories

For accessories and tooling, please contact us.

10 www.lemo.com

Ref.

Page13

® ®

Tooling

DCG Spanner for hexagonal nut

50

Part number Part numberof the nut

ø 14 DCG.91.149.0TN GEA.00.240.LN

l Material: Blackened steel

DCP Flat spanners for collet nut

N M

Dimensions

Part number L M N S1

DCP.99.045.TC 70 2 10.5 4.5

DCP.99.050.TC 78 2 12.6 5.0

DCP.99.055.TC 78 2 12.6 5.5

DCP.99.060.TC 78 2 12.6 6.0

S1

l Material: Chrome-plated steel

DPE Crimping tool with die (coaxial connectors)

Part number Cablegroup

DPE.99.123.1K 1

DPE.99.123.8K 2-3-4

DPN Dies

A Die dimension

L A Part number Cablegroup For contacts For shield

A B L A B

DPN.99.123.1K 1 1.29 0.91 2.0 3.10 2.70

B DPN.99.123.8K 2-3-4 1.29 0.91 2.0 3.80 3.30

for contacts for shield

l Dies material: Blackened steel

www.lemo.com 11

L

40

B

S1

Page14

® ®

Panel cut-outs

Panel Cut-outs

HWG HRG, HTG, HVG,

13 HVP, HVR 13

6.4 +0.1 +0.1 +0.1 0 ø 7.1 0 ø 7.1 0

Mounting nuts torque

Component Torque (Nm)

Retaining nut 0.25

Hexagonal nut 2.00

Coupling nut 2.00 1N = 0.102 kg

Cable assembly

Assembly instructions

In order to ensure the sealing of plugs and sockets on the cable side, it is imperatively necessary to complete their assembly

by realizing it with an adapted technique.

We recommend the fitting of an heatshrink boot with inner melting coating of type ATUM (manufactured by the RAYCHEM

company) or similar.

This heatshrink boot is not provided with the connector. Please consult us.

Cable stripping lengths

Connector Cable stripping

L lengths (mm)

T Series Type L S T

250 0.7 6 2.5 3

03 302/303/304 0.5 6 2.5 3S Note: the tolerances on these dimensions are:

302/303/3041) 0.5 13.5 – 2.5 L: ± 0.5 mm; S: ± 0.5 mm; T: ± 0.2 mm.1) for FVG model with cable crimping.

Recommended coaxial cables

Recommended cables for coaxial types

Cable Standard Imp.

group MIL-C-17 IEC 96-2 CCTU 10-01A Reference (Ω)

KX 3A CCX.50.RG1.74AU27N

3 RG.174 A/U 50.2.1 50 ± 2 Ω

KX 38 CCX.50.RG1.74U25N

1 RG.178 B/U 50.1.1 KX 21A CCX.50.RG1.78BU18M 50 ± 2 Ω

4 RG.188 A/U 50.2.3 CCX.50.RG1.88AU24B 50 ± 2 Ω

1 RG.196 A/U 50.1.2 CCX.50.RG1.96AU20B 50 ± 2 Ω

4 RG.316 /U 50.2.2 KX 22A CCX.50.RG3.16BU26M 50 ± 2 Ω

12 www.lemo.com

ø contact A

(mm)

Page15

® ®

Product safety notice

PLEASE READ AND FOLLOW ALL INSTUCTIONS CAREFULLY AND CONSULT ALL RELEVENT NATIONAL AND

INTERNATIONAL SAFETY REGULATIONS FOR YOUR APPLICATION.

IMPROPER HANDLING, CABLE ASSEMBLY, OR WRONG USE OF CONNECTORS CAN RESULT IN HAZARDOUS

SITUATIONS.

1. SHOCK AND FIRE HAZARD

Incorrect wiring, the use of damaged components, presence of foreign objects (such as metal debris), and / or residue

(such as cleaning fluids), can result in short circuits, overheating, and / or risk of electric shock.

Mated components should never be disconnected while live as this may result in an exposed electric arc and local

overheating, resulting in possible damage to components.

2. HANDLING

Connectors and their components should be visually inspected for damage prior to installation and assembly. Suspect

components should be rejected or returned to the factory for verification.

Connector assembly and installation should only be carried out by properly trained personnel. Proper tools must be used

during installation and / or assembly in order to obtain safe and reliable performance.

3. USE

Connectors with exposed contacts should never be live (or on the current supply side of a circuit). Under general

conditions voltages above 30 VAC and 42 VDC are considered hazardous and proper measures should be taken to

eliminate all risk of transmission of such voltages to any exposed metal part of the connector.

4. TEST AND OPERATING VOLTAGES

The maximum admissible operating voltage depends upon the national or international standards in force for the

application in question. Air and creepage distances impact the operating voltage; reference values are indicated in the

catalog however these may be influenced by PC board design and / or wiring harnesses.

The test voltage indicated in the catalog is 75% of the mean breakdown voltage; the test is applied at 500 V/s and the

test duration is 1 minute.

5. CE MARKING

CE marking means that the appliance or equipment bearing it complies with the protection requirements of one or

several European safety directives.

CE marking applies to complete products or equipment, but not to electromechanical components, such as

connectors.

6. PRODUCT IMPROVEMENTS

The LEMO Group reserves the right to modify and improve to our products or specifications without providing prior

notification.

7. WARNING (Prop 65 State of California)

This product may contain one or more substances or chemicals known to the state of California to cause cancer.

Disclaimers

LEMO works constantly to improve the quality of its products; the information and illustrations figuring in this document may

therefore vary and are not binding. In any case, LEMO makes no specific warranty of merchantability, fitness for a particu-

lar purpose, third party components as such or included in assembly, non-infringement, title, accuracy, completeness, or

security. The user is fully responsible for his products and applications using LEMO component.

In no event shall LEMO, its affiliates, officers, agents or employees be liable for any incidental, indirect, special or consequen-

tial damages in connection with the products or services provided by LEMO, including (without limitation) loss of profits

or revenues, interruption of business, loss of use of the products or any associated equipment, materials, components or

products, damages to associated equipment or in combination with other components, materials.

Reproduction of significant portions of LEMO information in LEMO data books or data sheets is permissible only if repro-

duction is without alteration and is accompanied by all associated warranties, conditions, limitations, and notices. LEMO is

not responsible or liable for such altered documentation. Information of third parties may be subject to additional restrictions.

www.lemo.com

Page16

LEMO HEADQUARTERS

SWITZERLAND

LEMO SA

Chemin des Champs-Courbes 28 - P.O. Box 194 - CH-1024 Ecublens

Tel. (+41 21) 695 16 00 - Fax (+41 21) 695 16 02 - e-mail: info@lemo.com

LEMO SUBSIDIARIES

AUSTRIA JAPAN

LEMO Elektronik GesmbH LEMO Japan Ltd

Lemböckgasse 49/E6-3 2-7-22, Mita,

1230 Wien Minato-ku, Tokyo, 108-0073

Tel: (+43 1) 914 23 20 0 Tel: (+81 3) 54 46 55 10

Fax:(+43 1) 914 23 20 11 Fax: (+81 3) 54 46 55 11

sales@lemo.at lemoinfo@lemo.co.jp

BRAZIL MIDDLE EAST

LEMO Latin America Ltda LEMO Middle East Gen. Trad. LLC

Av. José Rocha Bonfim, Concorde Tower 6th Floor,

214 Salas 224 / 225 Dubai Media City, P.O. Box 126732

Condomínio Praça Capital Dubai, United Arab Emirates

Ed. Chicago Tel: +971 55 222 36 77

Campinas / SP - Brasil 13080-650 info-me@lemo.com

Tel: +55 (11) 98689 4736

info-la@lemo.com NETHERLANDS / BELGIUM

LEMO Connectors Benelux

CANADA De Trompet 1060

LEMO Canada Inc 1967 DA Heemskerk

44 East Beaver Creek Road, unit 20 Tel. (+31) 251 25 78 20

Richmond Hill, Ontario L4B 1G8 Fax (+31) 251 25 78 21

Tel: (+1 905) 889 56 78 info@lemo.nl

Fax: (+1 905) 889 49 70

info-canada@lemo.com NORWAY / ICELAND

LEMO Norway A/S

CHINA / HONG KONG Soerumsandvegen 69,

LEMO Electronics (Shanghai) Co., Ltd 1920 Soerumsand

First Floor, Block E, Tel: (+47) 22 91 70 40

18 Jindian Road, Pudong Fax: (+47) 22 91 70 41

Shanghai, China, 201206 info-no@lemo.com

Tel: (+86 21) 5899 7721

Fax: (+86 21) 5899 7727 SINGAPORE

cn.sales@lemo.com LEMO Asia Pte Ltd

4 Leng Kee Road,

DENMARK #06-09 SiS Building

LEMO Denmark A/S Singapore 159088

Nybrovej 97 Tel: (+65) 6476 0672

2820 Gentofte Fax: (+65) 6474 0672

Tel: (+45) 45 20 44 00 sg.sales@lemo.com

Fax: (+45) 45 20 44 01

info-dk@lemo.com SPAIN / PORTUGAL

IBERLEMO SAU

FRANCE Brasil, 45, 08402 Granollers

LEMO France Sàrl Barcelona

24/28 Avenue Graham Bell Tel: (+34 93) 860 44 20

Bâtiment Balthus 4 Fax: (+34 93) 879 10 77

Bussy Saint Georges info-es@lemo.com

77607 Marne la Vallée Cedex 3

Tel: (+33 1) 60 94 60 94 SWEDEN / FINLAND

Fax: (+33 1) 60 94 60 90 LEMO Nordic AB

info-fr@lemo.com Gunnebogatan 30, Box 8201

163 08 Spånga

GERMANY Tel: (+46 8) 635 60 60

LEMO Elektronik GmbH Fax: (+46 8) 635 60 61

Hanns-Schwindt-Str. 6 info-se@lemo.com

81829 München

Tel: (+49 89) 42 77 03 SWITZERLAND

Fax: (+49 89) 420 21 92 LEMO Verkauf AG

info@lemo.de Grundstrasse 22 B, 6343 Rotkreuz

Tel: (+41 41) 790 49 40

HUNGARY ch.sales@lemo.com

REDEL Elektronika Kft

Nagysándor József u. 6-12 UNITED KINGDOM

1201 Budapest LEMO UK Ltd

Tel: (+36 1) 421 47 10 12-20 North Street, Worthing,

Fax: (+36 1) 421 47 57 West Sussex, BN11 1DU

info-hu@lemo.com Tel: (+44 1903) 23 45 43

lemouk@lemo.com

ITALY

LEMO Italia srl USA

Viale Lunigiana 25 LEMO USA Inc

20125 Milano P.O. Box 2408

Tel: (+39 02) 66 71 10 46 Rohnert Park, CA 94927-2408

Fax: (+39 02) 66 71 10 66 Tel: (+1 707) 578 88 11

sales.it@lemo.com (+1 800) 444 53 66

Fax:(+1 707) 578 08 69

info-US@lemo.com

LEMO DISTRIBUTORS

ARGENTINA, AUSTRALIA, BRAZIL, CHILE, COLOMBIA, CZECH REPUBLIC,

GREECE, INDIA, ISRAEL, NEW ZEALAND, PERU, POLAND, RUSSIA,

SOUTH AFRICA, SOUTH KOREA, TAIWAN, TURKEY, UKRAINE

www.lemo.com

© CAT.03.LEN.P1008, updated November 2016