1/23ページ

ダウンロード(1.6Mb)

HIGH VOLTAGE CONNECTORS FOR SPECIAL APPLICATIONS

※レモコネクタはモジュール方式のため、共通部品を組み合せることにより様々なコネクタに変えることができます。このため、カタログに掲載されている写真や図は、色、形状などが実物とは微妙に異なっている場合や、写真撮影の方向が一定していない場合がございます。ご注意いただきますようお願いいたします。

このカタログについて

| ドキュメント名 | 高電圧コネクタ(05, 5G, K/S) |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 1.6Mb |

| 登録カテゴリ | |

| 取り扱い企業 | レモジャパン株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

HIGH VOLTAGE CONNECTORS

FOR SPECIAL APPLICATIONS

05 Series

® ®

5G Series

® REDEL Kft ®

K and S Series

Page2

No reproduction or use without express permission of editorial or pictorial content, in any manner. Printed in Switzerland, july 2000 © LEMO SA

LEMO reserve the right at all times to modify and improve specifications without any notification. Pdf updated, april 2007

Page3

® ®

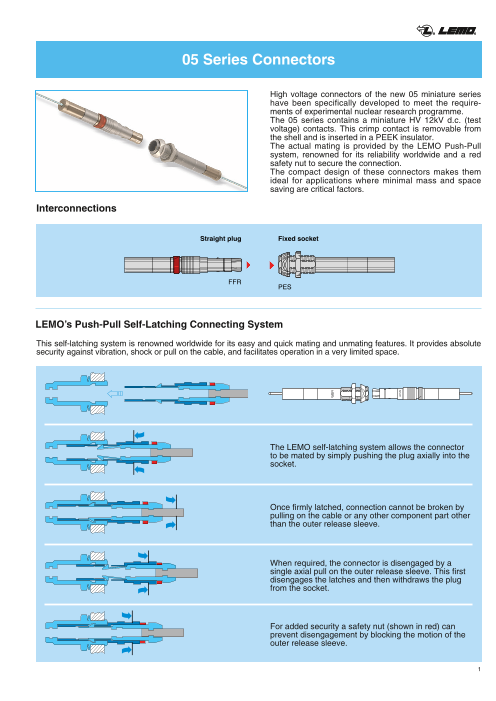

05 Series Connectors

High voltage connectors of the new 05 miniature series

have been specifically developed to meet the require-

ments of experimental nuclear research programme.

The 05 series contains a miniature HV 12kV d.c. (test

voltage) contacts. This crimp contact is removable from

the shell and is inserted in a PEEK insulator.

The actual mating is provided by the LEMO Push-Pull

system, renowned for its reliability worldwide and a red

safety nut to secure the connection.

The compact design of these connectors makes them

ideal for applications where minimal mass and space

saving are critical factors.

Interconnections

Straight plug Fixed socket

FFR

PES

LEMO’s Push-Pull Self-Latching Connecting System

This self-latching system is renowned worldwide for its easy and quick mating and unmating features. It provides absolute

security against vibration, shock or pull on the cable, and facilitates operation in a very limited space.

The LEMO self-latching system allows the connector

to be mated by simply pushing the plug axially into the

socket.

Once firmly latched, connection cannot be broken by

pulling on the cable or any other component part other

than the outer release sleeve.

When required, the connector is disengaged by a

single axial pull on the outer release sleeve. This first

disengages the latches and then withdraws the plug

from the socket.

For added security a safety nut (shown in red) can

prevent disengagement by blocking the motion of the

outer release sleeve.

1

Page4

® ®

Part Section Showing Internal Components

Connector

Straight plug

Fixed socket

7 2 1 5 6 3 4 8 6 5 1 3 2 4 7 1 outer shell

1 shell 2 latch sleeve

2 crimp back end 3 safety nut

3 hexagonal nut 4 crimp back end

4 conical nut 5 insulator

5 insulator 6 HV male contact

6 HV female contact 7 crimp ferrule

7 crimp ferrule 8 earthing crown

HV Contact

2 1 4 1 2

Male contact 3 3 Female contact

1 male contact 1 female contact

2 insulator 2 insulator

3 clips 3 clips

4 sealing gland

Technical characteristics

Mechanical and climatical Electrical characteristics

Characteristic Value Standard Characteristic Value Standard

Contact retention force 40 N IEC 60512-8 test 15a Test voltage d.c.1) 12 kV (1 min.) IEC 60512-2 test 4a

Working temperature -20 °C to +125°C Rated current 4 A IEC 60512-3 test 5a

Mechanical life > 200 cycles IEC 60512-5 test 9a Contact resistance ≤ 8 mΩ IEC 60512-2 test 2a

Climatic class 20/125/21 IEC 60068-1 Screen resistance ≤150 mΩ IEC 60512-2 test 2f

Radiation resistance > 106 Gy Insulation resistance ≥ 1012 Ω IEC 60512-2 test 3a

Note:

1) specific assembly instructions shall be respected. (see page 6 and 7)

Materials and Treatment – Connector Contact

Surface treatment Surface treatment

Component Material (standard) (µm) Component Material (standard) (µm)

Ni Cu Ni Au

Outershell + crimpend Aluminium (AA 6012) 5 Male contact Brass (UNS C38500) 0.5 3 1.0

Safety nut Aluminium (AA 6012) Anodized red Female contact Bronze (UNS C54400) 0.5 3 1.5

Earthing crown Aluminium special 5 Contact clips Cu-Be (QQ-C-530) –

Latch sleeve Aluminium special 5 Insulator PEEK –

Hex and conical nut Aluminium (AA 6012) Anodized natural Sealing gland Silicone PVMQ –

Insulator PEEK –

Crimp ferrule Aluminium (AA 6012) 5

2

Page5

® ®

Models

FFR Straight plug for cable crimping,

with safety nut

Part Number Cablegroup

42 FFR.05.403.LLAE141 1

FFR.05.403.LLAE142 2

29.8

PES Fixed socket, with two nuts, for cable crimping

Part Number Cablegroup

42

S 5.7 S 8 2.5 PES.05.403.LLLE141 1

PES.05.403.LLLE142 2

8.5 max. S 7

Recommanded high voltage cables

Construction and dimensions

Cable group Manufacturer CERN Type Conductor Dielectric Screen SheathPart Number Corona

Constr. Mat. ø Mat. ø Mat. Mat. ø screen

7x0.17 CuSn 0.51 PE solid 1.5 CuSn Polyo-1 ABBNK - 45/94 HTC 50-1-1 16x4x0.1 lefine 3.3 yes

HABIA Drain 2x0.12 HFI 150 mini coax

31789-004-001 Mono Cu 0.16 HFI150 0.5 + HFI150 1.15 noAlu polyester

3

M6.5x0.6

ø 8.5 ø 6

ø 9.2

Page6

® ®

Accessories

FFA-ERA High Voltage Contacts

Contact Part Number Cable L

Male contact Female contact group (mm)

male FFA.05.403.ZLA1 ERA.05.403.ZLL1 1 4

L FFA.05.403.ZLA2 ERA.05.403.ZLL2 2 6

female

GMA Heatshrink tube

Shall be ordered separately

Supplier

Part number Cable øD LL group Name Product reference (mm) (mm)

GMA.30.010.ST 1+2 RAYCHEM® RNF 3000 3/1 3.0 13

GMA.15.010.ST 2 RAYCHEM® RNF 3000 1.5/0.5 1.5 9

Note: for cable group 2, the two heatshrink tubes are necessary

● Material: Polyolefin transparent

FFS Crimp ferrule

10

ø 4.1

Model 1

Part number Cablegroup Model

FFS.05.160.PM 1 1

10 FFS.05.161.PM 2 2

ø 1.4

Model 2

● Material: Aluminium alloy (AA6012) nickel plated

GEC Conical nut

7

M 6.5 x 0.6 2.5

Part number

GEC.05.241.PT

● Material: Aluminium alloy (AA 6012) natural anodized.

GEA Hexagonal nuts

8

M 6.5 x 0.6 2

Part number

GEA.05.241.PT

● Material: Aluminium alloy (AA 6012) natural anodized.

4

9.2 ø 8.5

ø D min.

Page7

® ®

Tooling

37 DCH Spanner for conical nut

Part Number

DCH.91.113.9TN

ø 11

● Material: Blackened steel.

DCF Extraction tools for HV contacts

Part Number

DCF.91.133.5LT

Automatic model

DPH Crimping tool with die and positioner

Part Number Applications Cablegroup Marking on die

DPH.99.005.2K shield 1-2 DPH.91.005.2K

DPH.99.060.11K centre contact 1 DPH.91.001.16K

DPH.99.065.11K centre contact 2 DPK.91.001.16K

DPN Dies and positioner

Part Number Applications Cablegroup Marking on die

DPN.99.005.2K shield 1-2 DPH.91.005.2K

DPN.99.060.11K centre contact 1 DPH.91.001.16K

DPN.99.065.11K centre contact 2 DPK.91.001.16K

● Dies material: Blackened steel

Panel cut-out

10 min.

+ 0.1

5.8 0

Recommended mounting nut torque: 0.8 Nm.

5

ø 6.6 + 0.1 0

39.7

Page8

® ®

Termination Instructions Cable Group 1

5 3 4

FFR

1

5 3 4

PES

1. Strip the cable according to the given dimensions,

remove carefully the cable corona screen, making sure

9 ±0.2

3 ±0.2 that the cable dielectric is not damaged. Remove also

±0.2 the aluminium foil and the textile tape. 3.5

Clean the dielectric with isopropylic alcool.

Dimensions in mm.

Apply laquer 2. Place the crimp ferrule ➀ on the cable. Widen comple-3 4 1 tely the shield braid and fold it back over the jacket.

Introduce the cable center conductor into the HV

contact ➃ until the contact end rests against the dielec-

Crimp tric and the conductor is visible through the contact ins-

3 4 A 1 pection hole. Crimp with the LEMO crimping tool

DPH.99.060.11K. Cover the crimp section of the

contact and the Peek end of the HV contact with a layer

of insulating laquer. Let the laquer dry, approx.15 min.

Apply laquer Note: We recommand the laquer Urethan

ref: Cellpack n° 912110

3. Slide the heatshrink tube ➂ over the HV contact until it

4 3 rests against the contact insulator.

One end of the heatshrink tube shall be located at the

position A of the HV contact insulator. Shrink the tube.

Shrink

A

4 3

Shrink

4. Fully introduce the HV contact into the connector shell

5 1 ➄. Check that the contact is correctly located and

remains in position when given a gentle pull. Place the

cable shield braid strand over the shell crimp back end,

cut the length of braid in excess.

5 1

5. Slide the crimp ferrule over the cable shield until it

5 rests against the connector shell. Crimp with the

LEMO crimping tool DPH.99.005.2K.

Crimp

5

Crimp

6

Page9

® ®

Termination Instructions Cable Group 2

5 3 4 2

FFR

1

5 3 4 2

PES

14 ±0.2

1. Strip the cable according to the given dimensions, cut

10 ±0.2 the aluminium foil making sure that the dielectric is not

3 ±0.2 damaged. Do not damage the 2 drain wires.

Fold the drain wires back over the outer jacket and

slide over the small heatshrink tube ➁.

Clean the dielectric with isopropylic alcool.

2

Dimensions in mm.

2. Place the crimp ferrule ➀ introducing first the small dia-

meter on the cable. Introduce the cable center

3 4 Apply laquer 2 1 conductor and a part of the dielectric into the HV

contact ➃ until the conductor is fully visible through the

contact inspection hole. Crimp with the LEMO crimping

Crimp tool DPH.99.065.11K. Cover the crimp section of the

A B contact and a short length of the dielectric with a layer

of insulating laquer. Let the laquer dry, approx. 15 min.

Note: We recommand the laquer Urethan

3 4 2 1 ref: Cellpack n° 912110

Slide the heatskrink tube ➁ over the HV contact until it

rests against the contact insulator at the position B.

Apply laquer Shrink Shrink the tube. Cover the Peek end of the HV contact

and the first heatshrink tube with a layer of the insula-

ting laquer. Let the laquer dry, approx. 15 min.

4 3 1 3. Slide the heatshrink tube ➂ over the HV contact until itShrink rests against the contact insulator.

One end of the heatshrink tube shall be located at the

position A of the HV contact insulator. Shrink the tube.

A

4 3 1

Shrink

5 4. Fully introduce the HV contact into the connector shell

4 3 1 ➄. Check that the contact is correctly located and

remains in position when given a gentle pull. Place the 2

drain wire around the shell crimp back end.

5 A

4 3 1

5 5. Slide the crimp ferrule over the cable shield until it

rests against the connector shell. Crimp with the

LEMO crimping tool DPH.99.005.2K.

5 Crimp

Crimp

7

Page10

® ®

5G Series Connectors

High voltage cylindrical connectors of the new 5G series

have been specifically developed to meet the require-

ments of the “ATLAS” experimental nuclear research pro-

gramme at the CERN.

The 5G series contains 50 miniature HV 12kV d.c. (test

voltage) contacts. These crimp contacts are removable

from the shell and are inserted in a PEEK insulator. The

same HV contacts are used in the 05 series.

The actual mating is provided by the LEMO Push-Pull

system, renowned for its reliability worldwide and a red

safety nut to secure the connection.

Two keying alternative (code R or W) are available.

The compact design of these connectors makes them

ideal for applications where minimal mass and space

saving are critical factors.

Interconnections

Straight plug Fixed socket

FG

PH

LEMO’s Push-Pull Self-Latching Connecting System

This self-latching system is renowned worldwide for its easy and quick mating and unmating features. It provides absolute

security against vibration, shock or pull on the cable, and facilitates operation in a very limited space.

The LEMO self-latching system allows the connector

to be mated by simply pushing the plug axially into the

socket.

Once firmly latched, connection cannot be broken by

pulling on the cable or any other component part other

than the outer release sleeve.

When required, the connector is disengaged by a

single axial pull on the outer release sleeve. This first

disengages the latches and then withdraws the plug

from the socket.

For added security a safety nut (shown in red) can

prevent disengagement by blocking the motion of the

outer release sleeve.

8

DANGER

DANGER

DANGER

DANGER

Page11

® ®

Part Section Showing Internal Components

Connector

7 8 4 1 2 3 5 6 10 9 8 2 7 1 3 4 6 5

Fixed socket Straight plug

1 outer shell 6 conical nut 1 outer shell 5 adapter w. cable collet

2 earthing crown 7 adapter w. cable collet 2 latch sleeve 6 keyed mid-piece

3 retaining ring 8 keyed mid-piece 3 safety nut 7 insulator

4 clamp collet nut 9 insulator 4 clamp collet nut 8 HV female contact

5 round nut 10 HV male contact

HV Contact

2 3 1 4 1 2Male contact 3 Female contact

1 male contact 1 female contact

2 insulator 2 insulator

3 clips 3 clips

4 sealing gland

Technical characteristics

Mechanical and climatical Electrical characteristics

Characteristic Value Standard Characteristic Value Standard

Contact retention force 40 N IEC 60512-8 test 15a Test voltage d.c.1) 12 kV (1 min.) IEC 60512-2 test 4a

Working temperature -20 °C to +125°C Rated current 4 A IEC 60512-3 test 5a

Mechanical life > 100 cycles IEC 60512-5 test 9a Contact resistance ≤ 8 mΩ IEC 60512-2 test 2a

Climatic class 20/125/21 IEC 60068-1 Screen resistance ≤150 mΩ IEC 60512-2 test 2f

Radiation resistance >106 Gy Insulation resistance ≥ 1012 Ω IEC 60512-2 test 3a

Note: 1) specific assembly instructions shall be respected.

Materials and Treatment – Connector Contact

Surface treatment Surface treatment

Component Material (standard) (µm) Component Material (standard) (µm)

Ni Cu Ni Au

Outershell + collet nut Aluminium (AA 6012) Anodized natural Male contact Brass (UNS C38500) 0.5 3 1.0

Safety nut Aluminium (AA 6012) Anodized red Female contact Bronze (UNS C54400) 0.5 3 1.5

Earthing crown Aluminium special 5 Contact clips Cu-Be (QQ-C-530) –

Latch sleeve Aluminium special 5 Insulator PEEK –

Round and conical nut Aluminium (AA 6012) Anodized natural Sealing gland Silicone PVMQ –

Insulator PEEK –

Other metallic pieces Aluminium Anodized natural

9

DANGER

DANGER

Page12

® ®

Alignment key and polarized keying system

Angle HV contact type

β Ref. DotColour α β γ δ Plug Socket

●●R yellow 110° 105° 25° 35° male female

Front view of a socket ●●W red 95° 115° 20° 30° female male

Models

FG● Straight plug with keys (code R or W),

cable clamp-collet and safety nut

Part Number Cable Group

67

52 FGR.5G.450.LLAY5T1 1

FGR.5G.450.LLAY5T2 2

FGW.5G.450.LLLY5T1 1

FGW.5G.450.LLLY5T2 2

S 30 S 31

PH● Fixed socket with keys (code R or W),

cable clamp-collet, 2 nuts fixing

(back panel mounting)

S 37

~64.7 Part Number Cable Group

5 max. 5

PHR.5G.450.LLLY5T1 1

PHR.5G.450.LLLY5T2 2

PHW.5G.450.LLAY5T1 1

PHW.5G.450.LLAY5T2 2

S 30 S 31 S 33.5

Recommanded high voltage cables

Construction and dimensions

Cable group Manufacturer Type/Nb. of Conductor Dielectric Screen SheathPart Number CERN Type conductor Corona

Constr. Mat. ø Mat. ø Mat. Mat. ø screen

SILISOL

1 CEPMB -

CuSn

2 Multi/56 7x0.15 CuSn 0.45 PE 1.5 Silic 14.5 no56x0.12 mm + Alu

1 ABBNK - 45/94 HTC 50-1-1 Mono/1 7x0.17 CuSn 0.51 PE solid 1.5 CuSn Polyo- yes16x4x0.1 3.3lefine

Drain 2x0.1

2 HABIA HFI 150 mini Mono/1 Mono Cu 0.16 HFI150 0.5 + HFI150 1.15 no

31789-004-001 coax Alu polyester

10

α

ø 35

Cable ø Cable ø

14.0 min. 14.0 min.

16.5 max. 16.5 max.

δ

ø 41 ø 35

DANGER

DANGER

γ

Page13

® ®

Accessories

FFA-ERA HV Contacts

Contact Part Number Cable L

Male contact Female contact group (mm)

male FFA.05.403.ZLA1 ERA.05.403.ZLL1 1 4

L FFA.05.403.ZLA2 ERA.05.403.ZLL2 2 6

female

GMA Heatshrink tube

Shall be ordered separately

Supplier

L Part number Cable øD Lgroup Name Product reference (mm) (mm)

GMA.30.010.ST 1+2 RAYCHEM® RNF 3000 3/1 3.0 13

GMA.15.010.ST 2 RAYCHEM® RNF 3000 1.5/0.5 1.5 9

Note: for cable group 2, the two heatshrink tubes are necessary

● Material: Polyolefin transparent

GEC Conical nut

37

5

M 35 x 1

Part number

GEC.5G.240.PT

● Material: Aluminium alloy (AA6012) natural anodized

GEB Round nut

ø 40

M 35 x 1 8

Part number

GEB.5G.240.PT

● Material: Aluminium alloy (AA6012) natural anodized

FGG Extension piece

36

Part Number

FGG.5G.815.PN

Note: allows an extension of the plug or the socket to make cable strip-

ping and mounting easier when weight and size are not critical

● Material: Aluminium alloy (AA6012) natural anodized

11

ø 27.9

ø 41 ø D min.

ø 29

Page14

® ®

Tooling

90 DCH Spanner for conical nut

Part Number

DCH.91.418.0TN

ø 45

● Material: Blackened steel.

54 DCP Set of flat spanners for collet nuts and round nuts

31.1

30.1 3.5

Part Number

DCP.91.005.TN

● Material: Blackened steel.

DCF Extraction tools for HV contacts

Part Number

DCF.91.133.5LT

Automatic model

DPH Crimping tool with die and positioner

Part Number Applications Cablegroup Marking on die

DPH.99.005.2K shield 1-2 DPH.91.005.2K

DPH.99.060.11K centre contact 1 DPH.91.001.16K

DPH.99.065.11K centre contact 2 DPK.91.001.16K

Note: DPN Dies and positioner: See 05 series data sheet.

Panel cut-out

42 min.

+ 0.1

33.5 0 Recommended mounting nut torque: 7 Nm.

12

ø 35.2 + 0.1

0

160

81.5

Page15

® ®

Termination Instructions Cable Group 1 (multi HT cable)

7 5 3 4

6 1

FG•

7 5 3 4

PH•

2

500 1. Strip the cable according to the given dimensions.

A 500 mm length is necessary to give enough flexibi-

24 lity to the cable.

3.5 ±0.2 Remove first the outer jacket and the screen then the

dielectric of each individual high-voltage conductor,

making sure that the cable dielectric is not damaged.

Dimensions in mm.

2. Slide 2 pieces of 55mm heat-shrink tubing, (not sup-

plied) of the correct size, the clamp collet nut ➀ and

55 1 55 the adapter with cable collet ➁ on the cable.

2

Apply laquer 3. For each individual high-voltage conductor install a

3 4 HV contact as follow:Crimp

3.1 Introduce the cable center conductor into the HV

contact ➃ until the conductor end rests against the

dielectric and the conductor is visible through the

contact inspection hole. Crimp with the LEMO crim-

ping tool DPH.99.060.11K. Cover the crimp section of

A the contact and the Peek end of the HV contact with

3 4 Crimp a layer of insulating laquer. Let the laquer dry,

approx. 15 min.

Note: We recommand the laquer Urethan

ref: Cellpack n° 912110

Apply laquer

3.2 Slide the heatshrink tube ➂ over the HV contact until

it rests against the contact insulator.

4 3 Shrink One end of the heatshrink tube shall be located at the

position A of the HV contact insulator. Shrink the

tube.

A

4 3 Shrink

13

Page16

® ®

5 4. Fully introduce the HV contacts into the insulator ➄.

– The short insulator shall be fitted with the female

HV contacts.

– The long insulator shall be fitted with the male

HV contacts.

5 Check that the contacts are correctly located and

remains in position when given a gentle pull.

solder ground wire L = 130 mm 5. Install a ground wire (not supplied) as follow:

5.1 Wrap a tin copper wire 0.5 mm2 over a 6 mm length

of the cable screen and hold the ground wire as

shown. Then solder.

Solder an earthing washer with a 3.5 mm hole on the

other side.

6

solder ground wire L = 130 mm

6

Shrink Shrink 5.2 Cover the end of the cable screen with the first heat-

25 shrink tube and the end of the cable jacket with the

second heat-shrink tube, then shrink.

55 55

Shrink Shrink

25

55 55

6 6. Push the adapter with cable collet ➁ forward over the

cable until the insulator locate into the groove on the

adapter.

Then fit the keyed mid-piece ➅ onto the insulator,

make sure that the key of the insulator is correctly

located into the key of the mid-piece.

2

6

2

7 1 7. Next slide the connector shell ➆ over the insulator

assembly making sure that the key on the keyed mid

piece goes into the key-way (under the color

point/inside the shell).

– Note that the HV contact type shall be respected

depending upon the keying code as indicated on

7 1 page 10.Screw the collet nut ➀ and tighten to the maximum

torque value of 4 Nm.

Tight the two screws of the adapter and in between

on an appropriate manner the washer of the ground

wire.

14

Page17

REDEL Kft

Elektronika

K and S Series Connectors

High voltage rectangular connectors of the new K and S

series have been specially developed to meet the

requirements of the “ATLAS” experimental nuclear

research programme at the CERN.

The K series contains 22 miniature HV contacts (12kV

d.c. test voltage).

The S series contains 51 miniature HV contacts (12kV

d.c. test voltage). These crimp contacts are removable

from the shell and are inserted in a PEEK insulator. The

mating is assured by guide pins and sleeves. Two red

sliding tabs secure the connection by locking a pair of

levers to a bracket mounted on the housing. The rectan-

gular design of these connectors makes them ideal for

applications where space saving is critical; for example

on narrow panels.

INTERCONNECTION

Straight socket Fixed socket Straight plug

KR/SR KL/SL KA/SA

SELF-1LATCHING CONNECTING SYSTEM 3

1 3

1

The REDEL Self-Latching connecting system allows the connectors The connectors are disengaged by pressing down on the latch

to be mated by simply pushing the plug axially into the socket levers and then withdrawing the plug from the socket

1

2 4

Once latched, connection cannot be broken by pulling on the For added security two red tabs can be slid forward, locking the

cable o2r any other component part latch leve4rs in place.

2

ALIGNMENT KEY

Code G Code A

2

KRG/SRG KLG/SLG KAG/SAG KRA/SRA KLA/SLA KAA/SAA

Modification 08.05 15

REDEL REDEL

KLG.H22 KLG.H22

REDEL

KAG.H22

REDEL

KLG.H22

REDEL

KAG.H22

REDEL

KAG.H22

REDEL

KLG.H22

REDEL REDEL

KLG.H22 KLG.H22

REDEL REDEL

REDEL KAG.H22 KAG.H22

KLA.H22

REDEL

KAG.H22

REDEL

KAA.H22

REDEL

KRA.H22

REDEL

KRG.H22

REDEL

KRG.H22

Page18

REDEL Kft

PART SECTION SHOWING INTERNAL COMPONENTS

Connector

Rectangular plug

7 6 8 1 5 2 3 4 7 6 5 3 2 8 4 1 9 11 10

Rectangular socket 1 outer shell

2 latch lever

1 outer shell 3 locking clip

2 insulator 4 security tab

3 HV male contact 5 insulator

4 male guide pin 6 HV female contact

5 threaded insert 7 female guide pin

6 cable clamp 8 threaded insert

7 earthing insert 9 cable clamp

8 earthing tag 10 earthing insert

11 earthing tag

HV Contact

2 3 1 4 1 3 2Male contact Female contact

1 male contact 1 female contact

2 insulator 2 insulator

3 clips 3 clips

4 sealing gland

TECHNICAL CHARACTERISTICS

Mechanical and climatical Electrical characteristics

Characteristic Value Standard Characteristic Value Standard

Contact retention force 40 N IEC 60512-8 test 15a Test voltage d.c.1) 9/12 kV (1 min.) IEC 60512-2 test 4a

Working temperature -20 °C to +125°C Rated current 4 A IEC 60512-3 test 5a

Mechanical life > 100 cycles IEC 60512-5 test 9a Contact resistance ≤ 8 mΩ IEC 60512-2 test 2a

Climatic class 20/125/21 IEC 60068-1 Screen resistance ≤150 mΩ IEC 60512-2 test 2f

Radiation resistance > 106 Gy Insulation resistance ≥ 1012 Ω IEC 60512-2 test 3a

Note: 1) specific assembly instructions shall be respected.

9 kV dc apply to the pair KA●/KL● and SA●/SL●.

12 kV dc apply to the pair KA●/KR● and SA●/SR●.

Materials and Treatment – Connector Contact

Surface treatment Surface treatment

Component Material (standard) (µm) Component Material (standard) (µm)

Ni Cu Ni Au

Outershell Aluminium 5 Male contact Brass (UNS C38500) 0.5 3 1.0

Latching mechanism Bronze 5 Female contact Bronze (UNS C54400) 0.5 3 1.5

Insulator PEEK – Contact clips Cu-Be (QQ-C-530) –

cable clamp PSU – Insulator PEEK –

Other met. pieces Stainless Steel – Sealing gland Silicone PVMQ –

Other plastic pieces PSU –

16 Modification 08.05

KAG

.H22

Page19

REDEL Kft

MODELS K series (22 contacts)

KA● Straight plug with key (code G or A)

and cable collet

Part Number Cable Group ContactType Marking68.5

KAG.H22.LLZBG female black

no contact

KAA.H22.LLZBG male red

KAG.H22.LLLB1G female black

1

KAA.H22.LLAB1G male red

KAG.H22.LLLB2G female black

2

KAA.H22.LLAB2G male red

46.6

KL● Fixed socket with key (code G or A),

two screw fixing

23 Part Number Cable Group ContactType Marking

KLG.H22.LLZG male black

no contact

KLA.H22.LLZG female red

KLG.H22.LLA1G male black

1

KLA.H22.LLL1G female red

1 17

7 12 KLG.H22.LLA2G male black

2

KLA.H22.LLL2G female red

11 16

6 22

36

KR● Straight socket with key (code G or A)

and cable collet

69.6

Part Number Cable Group ContactType Marking

KRG.H22.LLZBG male black

no contact

KRA.H22.LLZBG female red

KRG.H22.LLAB1G male black

1

KRA.H22.LLLB1G female red

1 17

7 12 KRG.H22.LLAB2G male black

2

KRA.H22.LLLB2G female red

11 16

6 22

Modification 08.05 17

Cable ø

6 mm min. Cable ø

9.5 mm max. 6 mm min.

9.5 mm max.

REDEL

KLG.H22

33.4 16

37.4

33.4 16

43.4 16

37.4

17 1

12 7

16 11

22 6

REDEL REDEL

KRG.H22

KAG.H22

Page20

REDEL Kft

MODELS S series (51 contacts)

SA● Straight plug with key (code G or A)

and cable collet

Part Number Cable Group ContactType Marking

75.5

SAG.H51.LLZBG female black

no contact

SAA.H51.LLZBG male red

SAG.H51.LLLB1G female black

1

SAA.H51.LLAB1G male red

SAG.H51.LLLB2G female black

2

SAA.H51.LLAB2G male red

53.6

SL● Fixed socket with key (code G or A),

two screw fixing

Part Number Cable Group ContactType Marking

23

SLG.H51.LLZG male black

no contact

SLA.H51.LLZG female red

SLG.H51.LLA1G male black

1

SLA.H51.LLL1G female red

1 41

12 31

22 SLG.H51.LLA2G male black

2

SLA.H51.LLL2G female red

30

21 40

11 51

36

SR● Straight socket with key (code G or A)

and cable collet

76.6 Part Number Cable Group ContactType Marking

SRG.H51.LLZBG male black

no contact

SRA.H51.LLZBG female red

SRG.H51.LLAB1G male black

1

1 41

12 31 SRA.H51.LLLB1G female red

22

SRG.H51.LLAB2G male black

2

SRA.H51.LLLB2G female red

30

21 40

11 51

18 Modification 08.05

Cable ø

7.5 mm min. Cable ø

12.5 mm max. 7.5 mm min.

12.5 mm max.

REDEL

SLG.H51

43 19.6

43 19.6 47

53 19.6

47

41 1

31 12

22

30

40 21

51 11

REDEL REDEL

SRG.H51

SAG.H51