1/36ページ

ダウンロード(3.2Mb)

COAXIAL, TRIAXIAL,MULTI & MIXED CONNECTORS

※レモコネクタはモジュール方式のため、共通部品を組み合せることにより様々なコネクタに変えることができます。このため、カタログに掲載されている写真や図は、色、形状などが実物とは微妙に異なっている場合や、写真撮影の方向が一定していない場合がございます。ご注意いただきますようお願いいたします。

このカタログについて

| ドキュメント名 | 各種同軸複合コネクタ |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 3.2Mb |

| 登録カテゴリ | |

| 取り扱い企業 | レモジャパン株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

COAXIAL, TRIAXIAL, SHORT FORM

MULTI & MIXED CONNECTORS CATALOGUE

Page2

® ®

Precision modular connectors to suit your application

Since its creation in Switzerland in 1946 the LEMO Group has been recognized as a global leader of circular Push-Pull con-

nectors and connector solutions. Today LEMO and its affiliated companies, REDEL and COELVER, are active in more than

80 countries with the help of over 40 subsidiaries and distributors.

Over 75’000 connectors

The modular design of the LEMO range provides over 75’000 connectors from miniature ø 3 mm to ø 50 mm, capable of han-

dling cable diameters up to 30 mm and for up to 114 contacts.

This vast portfolio enables you to select the ideal connector configuration to suit almost any specific requirement in most mar-

kets, including medical devices, test and measurement instruments, machinery, audio video broadcast, telecommunications

and military.

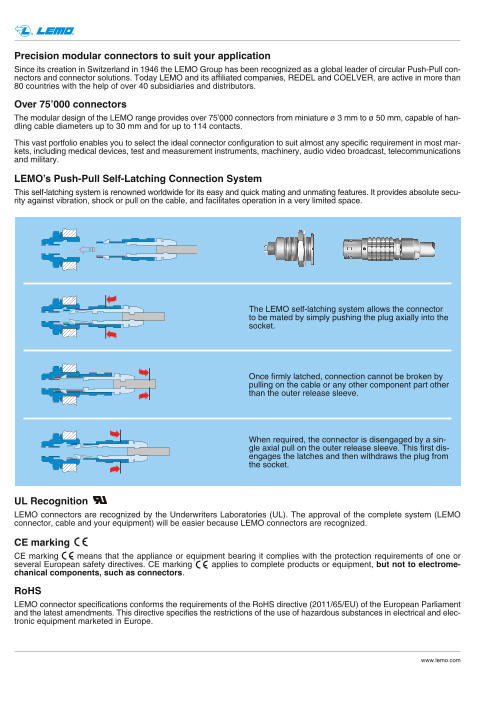

LEMO’s Push-Pull Self-Latching Connection System

This self-latching system is renowned worldwide for its easy and quick mating and unmating features. It provides absolute secu-

rity against vibration, shock or pull on the cable, and facilitates operation in a very limited space.

The LEMO self-latching system allows the connector

to be mated by simply pushing the plug axially into the

socket.

Once firmly latched, connection cannot be broken by

pulling on the cable or any other component part other

than the outer release sleeve.

When required, the connector is disengaged by a sin-

gle axial pull on the outer release sleeve. This first dis-

engages the latches and then withdraws the plug from

the socket.

UL Recognition

LEMO connectors are recognized by the Underwriters Laboratories (UL). The approval of the complete system (LEMO

connector, cable and your equipment) will be easier because LEMO connectors are recognized.

CE marking

CE marking means that the appliance or equipment bearing it complies with the protection requirements of one or

several European safety directives. CE marking applies to complete products or equipment, but not to electrome-

chanical components, such as connectors.

RoHS

LEMO connector specifications conforms the requirements of the RoHS directive (2011/65/EU) of the European Parliament

and the latest amendments. This directive specifies the restrictions of the use of hazardous substances in electrical and elec-

tronic equipment marketed in Europe.

www.lemo.com

Page3

® ®

Introduction

This catalogue gives the complete description of LEMO connectors with coaxial, triaxial and mixed contacts.

Mixed contacts include coaxial and low voltage contact configurations, as well as multi-coaxial contact configurations.

The LEMO manufacturing programme has been extended to almost 40 series divided into 7 product families with specific

mating and environmental characteristics. Each series includes a wide variety of plug, socket and coupler models, avail-

able in contact configurations adapted to all round cables. The catalogue includes the B, K, S and E Series of the LEMO

product range. In addition the 00 Series (triaxial) connector is also represented.

Watertight and vacuumtight models are also available. Since LEMO connectors are perfectly screened and designed to guar-

antee very low resistance to shell electrical continuity, they are particularly adapted to applications where electromagnetic

compatibility (EMC) is important.

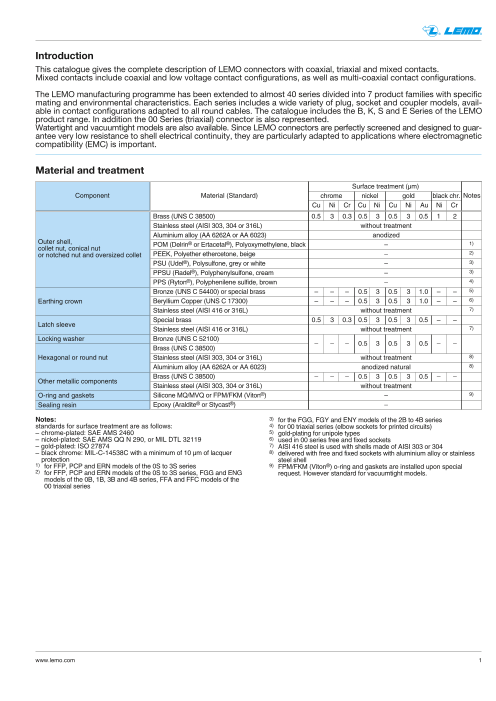

Material and treatment

Surface treatment (µm)

Component Material (Standard) chrome nickel gold black chr. Notes

Cu Ni Cr Cu Ni Cu Ni Au Ni Cr

Brass (UNS C 38500) 0.5 3 0.3 0.5 3 0.5 3 0.5 1 2

Stainless steel (AISI 303, 304 or 316L) without treatment

Aluminium alloy (AA 6262A or AA 6023) anodized

Outer shell, ® ® 1)

collet nut, conical nut POM (Delrin or Ertacetal ), Polyoxymethylene, black –

or notched nut and oversized collet PEEK, Polyether ethercetone, beige – 2)

PSU (Udel®), Polysulfone, grey or white – 3)

PPSU (Radel®), Polyphenylsulfone, cream – 3)

PPS (Ryton®), Polyphenilene sulfide, brown – 4)

Bronze (UNS C 54400) or special brass – – – 0.5 3 0.5 3 1.0 – – 5)

Earthing crown Beryllium Copper (UNS C 17300) – – – 0.5 3 0.5 3 1.0 – – 6)

Stainless steel (AISI 416 or 316L) without treatment 7)

Special brass 0.5 3 0.3 0.5 3 0.5 3 0.5 – –

Latch sleeve

Stainless steel (AISI 416 or 316L) without treatment 7)

Locking washer Bronze (UNS C 52100)

– – – 0.5 3 0.5 3 0.5 – –

Brass (UNS C 38500)

Hexagonal or round nut Stainless steel (AISI 303, 304 or 316L) without treatment 8)

Aluminium alloy (AA 6262A or AA 6023) anodized natural 8)

Brass (UNS C 38500) – – – 0.5 3 0.5 3 0.5 – –

Other metallic components

Stainless steel (AISI 303, 304 or 316L) without treatment

O-ring and gaskets Silicone MQ/MVQ or FPM/FKM (Viton®) – 9)

Sealing resin Epoxy (Araldite® or Stycast®) –

Notes: 3) for the FGG, FGY and ENY models of the 2B to 4B series

standards for surface treatment are as follows: 4) for 00 triaxial series (elbow sockets for printed circuits)

– chrome-plated: SAE AMS 2460 5) gold-plating for unipole types

– nickel-plated: SAE AMS QQ N 290, or MIL DTL 32119 6) used in 00 series free and fixed sockets

– gold-plated: ISO 27874 7) AISI 416 steel is used with shells made of AISI 303 or 304

– black chrome: MIL-C-14538C with a minimum of 10 µm of lacquer 8) delivered with free and fixed sockets with aluminium alloy or stainless

protection steel shell

1) for FFP, PCP and ERN models of the 0S to 3S series 9) FPM/FKM (Viton®) o-ring and gaskets are installed upon special

2) for FFP, PCP and ERN models of the 0S to 3S series, FGG and ENG request. However standard for vacuumtight models.

models of the 0B, 1B, 3B and 4B series, FFA and FFC models of the

00 triaxial series

www.lemo.com 1

Page4

® ®

B Series

B series connectors provide the following main features:

– security of the Push-Pull self-latching system – up to 10 coaxial contacts

– coaxial, triaxial and mixed contact configurations – solder or crimp contacts

– plastic models made of PSU or PPSU – high packing density for space savings

– multiple key options to avoid cross mating – 360° screening for full EMC shielding

of similar connectors («G» key standard).

Metal housing models

Fixed plugs Straight plugs Fixed sockets Free sockets

FWG FGG EGG EJG PHG

FAG FGG ENG EEG PHG

Elbow plugs

FFG EKG ECG PNG

FHG Fixed sockets

FNG EHG

PKG

FKG FEG

PFG

FDG

PEG

FIG

Plastic housing models

Straight plugs Fixed sockets

FGG FGG ENG

FGY FGY ENY

Model Description

ECG Fixed socket with two nuts, key (G) or keys FEG Straight plug, key (G) or keys (A…L), cable FKG Elbow (90°) plug for remote handling,

(A…L and R) (back panel mounting) collet, front seal and nut for fitting a bend key (G) or keys (A…L), special alignment

EEG Fixed socket, nut fixing, key (G) or keys relief (IP 54 protection index when mated) mark, knurled handling surface,

(A…L and R) (back panel mounting) FFG Straight plug, non-latching, key (G) cable collet

EGG Fixed socket, nut fixing, key (G) or keys (A…L), cable collet FNG Straight plug, key (G) or keys (A…L and R),

or keys (A…L and R) FGG Straight plug, key (G) or keys (A…L and R), cable collet and lanyard release

EHG Fixed socket, nut fixing, key (G) or keys cable collet FWG Fixed plug, nut fixing, key (G) or keys (A…L)

(A…L and R), and protruding shell FGG Straight plug, key (G) or keys (A…L), PEG Fixed socket, nut fixing, key (G) or keys

EJG Fixed socket, press or adhesive fit, cable collet and nut for fitting a bend relief (A…L), cable collet (back panel mounting)

key (G) or keys (A…L) FGG Straight plug, key (G or J), cable collet, PFG Fixed socket, with two nuts, key (G)

EKG Fixed socket, nut fixing, key (G) or keys PEEK outer shell or keys (A…L and R), cable collet

(A…L and R), special alignment mark FGG Straight plug, key (G or J), cable collet, (back panel mounting)

on the front PEEK outer shell, nut for fitting a bend relief PHG Free socket, key (G) or keys (A…L and R),

ENG Fixed socket with earthing tag, nut fixing, FGY Straight plug, keys (Y), cable collet cable collet

key (G) or keys (A…L) and PSU or PPSU outer shell PHG Free socket, key (G) or keys (A…L),

ENG Fixed socket with earthing tag, nut fixing, FGY Straight plug, keys (Y), cable collet cable collet and nut for fitting a bend relief

key (G or J), PEEK outer shell and PSU or PPSU outer shell and nut PKG Fixed socket, nut fixing, key (G)

ENY Fixed socket with earthing tag, nut fixing, for fitting a bend relief or keys (A…L and R), cable collet

keys (Y), PSU or PPSU outer shell FHG Elbow (90°) plug, key (G) or keys PNG Free socket, nut fixing, key (G) or keys

FAG Fixed plug, non-latching, nut fixing, (A…L and R), cable collet (A…L and R), cable collet with lanyard

key (G) or keys (A…L and R) FIG Straight plug for remote handling, key (G) release

FDG Straight plug, long version, or keys (A…L and R), special alignment

key (G) or keys (A…L), cable collet mark, knurled handling surface, cable collet

2 www.lemo.com

Page5

® ®

Part Numbering System

Plug FG G . 3B . 844 . C L A D 11 1

Free socket PH G . 3B . 844 . C L L D 11 1

Cable group

Variant: Z = collet nut for bend relief

Cable ø max. 1)

Collet type: D or M

Fixed socket EG G . 3B . 844 . C L L 1

Cable group

Contact type:

A = male solder

Model C = male crimpL = female solder

M = female crimp

Alignment key: G

Insulator: L = PEEK

Series

Housing:

Insert configuration: C = brass chrome-plated

multi coax, coax + LV P = PSU

Part Number Example

Straight plug with cable collet:

FGG.3B.844.CLAD111 = straight plug with key (G) and cable collet, 3B series, mixed coax & low voltage type (1 coax and

4 low voltage contacts), outer shell in chrome-plated brass, PEEK insulator, male solder contacts, D type collet for up to

11 mm diameter cable. Cable group 1.

Free socket:

PHG.3B.844.CLLD111 = free socket with key (G) and cable collet, 3B series, mixed coax & low voltage type (1 coax and

4 low voltage contacts), outer shell in chrome-plated brass, PEEK insulator, female solder contacts, D type collet for up to

11 mm diameter cable. Cable group 1.

Fixed socket:

EGG.3B.844.CLL1= fixed socket, nut fixing, with key (G), 3B series, mixed coax & low voltage type (1 coax and 4 low volt-

age contacts), outer shell in chrome plated brass, PEEK insulator, female solder contacts. Cable group 1.

Note: 1) see unipole-multipole catalogue (p. 52).

Part Section Showing Internal Components (mixed coax + LV)

Fixed socket Straight plug

8 7 6 2 3 4 5 1 1 8 6 5 4 2 7 3

1 outer shell 1 outer shell

2 earthing crown 2 latch sleeve

3 retaining ring 3 collet nut

4 hexagonal nut 4 split insert carrier

5 locking washer 5 insulator

6 insulator 6 male contact

7 female contact 7 collet

8 female coaxial contact 8 male coaxial contact

www.lemo.com 3

Page6

® ®

K Series

K series connectors have been specifically designed for outdoor applications.

They include an inner sleeve and two seals to prevent penetration of solids or liquids into the housing formed by the plug,

free socket or fixed socket. All models of this series are watertight when mated to give a protection index of IP68 as per

IEC 60529 standard (in mated condition) when correctly assembled to an appropriate cable (IP66 otherwise).

K series connectors have the same insulators as the B series and have the following main features:

– security of the Push-Pull latching system – watertight connection (IP 68/IP 66)

– coaxial, triaxial and mixed contact configurations – up to 10 coaxial contacts

– solder or crimp contacts – 360° screening for full EMC shielding

– multiple key options to avoid cross mating – high packing density for space savings

of similar connectors («G» key standard) – rugged housing for extreme working conditions.

Models

Fixed plugs Straight plugs Fixed sockets Free sockets Fixed sockets

FGG PHG

FXG EGG PKG

FAG FGG PHG

EEG PEG

Elbow plug

FGG PHG

FHG EBG

EDG

EHG

Model Description

EBG Fixed socket with square flange, FGG Straight plug, key (G) or keys PHG Free socket, key (G) or keys (A to F, L and

key (G) or keys (A to F, L and R) (A to F, L and R), cable collet R), cable collet

and screw fixing FGG Straight plug, key (G) or keys (A to F, L PHG Free socket, key (G) or keys (A to F, L and

EDG Fixed socket with square flange, key (G) and R), cable collet and oversize cable R), cable collet and oversize cable collet

or keys (A to F, L and R), protruding shell collet PHG Free socket, key (G) or keys (A to F, L and

and earthing tag, screw fixing FGG Straight plug, key (G) or keys (A to F, L R), cable collet and nut for fitting a bend

EEG Fixed socket, nut fixing, key (G) and R), cable collet and nut for fitting a relief

or keys (A to F, L and R) bend relief PKG Fixed socket, nut fixing, key (G)

(back panel mounting) FHG Elbow (90°) plug, key (G) or keys (A to F, L or keys (A to F, L and R), cable collet

EGG Fixed socket, nut fixing, key (G) and R), cable collet

or keys (A to F, L and R) FXG Fixed plug with round flange, key (G)

EHG Fixed socket, nut fixing, key (G) or keys (A to F, L and R) and screw fixing

or keys (A to F and L), protruding shell PEG Fixed socket, nut fixing, key (G)

FAG Fixed plug, nut fixing, non-latching, or keys (A to F, L and R), cable collet

key (G) or keys (A to F, L and R) (back panel mounting)

4 www.lemo.com

Page7

® ®

Part Numbering System

Plug FG G . 3K . 844 . C L A C 11 3

Free socket PH G . 3K . 844 . C L L C 11 3

Cable group

Variant: Z = collet nut for bend relief

Cable ø max. 1)

Collet type: C or K

Fixed socket EG G . 3K . 844 . C L L 1

Cable group

Contact type:

Model A = male solder

C = male crimp

L = female solder

Alignment key: G M = female crimp

Series Insulator: L = PEEK

Insert configuration: Housing:

multi coax, coax + LV C = brass chrome-plated

Part Number Example

Straight plug with cable collet:

FGG.3K.844.CLAC113 = straight plug with key (G) and cable collet, 3K series, mixed coax & low voltage type (1 coax and

4 low voltage contacts), outer shell in chrome-plated brass, PEEK insulator, male solder contacts, C type collet for 10.5 mm

diameter cable. Cable group 3.

Free socket:

PHG.3K.844.CLLC113 = free socket with key (G) and cable collet, 3K series, mixed coax & low voltage type (1 coax and

4 low voltage contacts), outer shell in chrome-plated brass, PEEK insulator, female solder contacts, C type collet for 10.5

mm diameter cable. Cable group 3.

Fixed socket:

EGG.3K.844.CLL1 = fixed socket, nut fixing, with key (G), 3K series, mixed coax & low voltage type (1 coax and 4 low volt-

age contacts), outer shell in chrome-plated brass, PEEK insulator, female solder contacts. Cable group 1.

Note: 1) see unipole-multipole catalogue (p. 53).

Part Section Showing Internal Components (mixed coax + LV)

Straight plug

Fixed socket 1 outer shell

2 latch sleeve

1 outer shell 8 5 2 3 4 7 1 6 13 8 2 3 7 6 4 1 9 11 12 10 5 3 inner shell

2 earthing crown 4 retaining ring

3 retaining ring 5 collet nut

4 hexagonal nut 6 split insert carrier

5 insulator 7 insulator

6 female contact 8 male contact

7 o-ring 9 earthing cone

8 female coaxial contact 10 collet

11 gasket

12 washer

13 male coaxial contact

www.lemo.com 5

Page8

® ®

Insert configuration (B and K series)

Mixed: multi coax, coax + LV

Coax Low voltage (LV)

Coax Contacts

type

1B 801 1 50 F 2 1 0.9 ● ● 0.85 1.20 10

1K

803 1 50 F 2 3 0.9 ● ● 0.75 1.05 10

2B 802 1 50 A1 1-2-3 2 0.9 ● ● 0.85 1.20 10

2K

804 1 50 A1 1-2-3 4 0.7 ● ● 0.75 1.05 7

806 1 50 A1 1-2-3 6 0.7 ● ● 0.75 1.05 7

810 1 50 C 1-2-3 10 0.7 ● ● 0.95 1.35 7

841 2 50 E 2 1 1.6 ● ● 1.90 2.70 17

232 2 50 G – – – – – – – –

243 3 50 E 2 – – – – – – –

3B 803 1 50 A0 6 3 0.9 ● – 1.10 1.55 8

3K

806 1 50 A1 1-2-3 6 0.7 ● ● 1.00 1.50 7

809 1 50 A1 1-2-3 9 0.7 ● ● 1.00 1.50 7

812 1 50 A1 1-2-3 12 0.9 ● ● 0.90 1.30 9

813 1 50 A1 1-2-3 13 0.7 ● ● 0.90 1.30 7

822 1 50 C 1-2-3 22 0.7 ● ● 0.70 1.00 5

844 2 50 C 1-2-3 4 0.9 ● ● 0.90 1.30 10

846 2 50 C 1-2-3 6 0.9 ● ● 0.90 1.30 10

850 2 50 C 1-2-3 10 0.7 ● ● 0.75 1.05 8

856 2 50 C 1-2-3 16 0.7 ● ● 0.70 1.00 7

242 2 50 C 1-2-3 – – – – – – –

B R

G 243 3 50 C 1-2-3 – – – – – – –

862 3 50 C 1-2-3 2 0.9 ● ● 1.10 1.60 9

● First choice alternative

● Special order alternative

6 www.lemo.com

ø A

Reference

Number of contacts

Impedance (Ω)

Type (see page 10)

Cable group

Number of contacts

ø A (mm)

Solder

Crimp

Test voltage

(kV rms)

Test voltage

(kV dc)

Rated current (A)

Page9

® ®

Mixed: multi coax, coax + LV

Coax Low voltage (LV)

Coax Contacts

type

4B 802 50 A 5-6

822 1 75 A 4 to 6 2 0.9 ● ● 1.00 1.40 124K

804 1 50 A 5-6824 75 A 4 to 6 4 0.9 ● ● 1.00 1.40 10

806 1 50 A 5-6826 75 A 4 to 6 6 0.9 ● ● 1.00 1.40 10

842 2 50 A1 1-2-3 2 0.9 ● ● 1.70 2.40 12

844 2 50 A1 1-2-3 4 0.9 ● ● 1.70 2.40 10

852 2 50 C 1-2-3 12 0.9 ● ● 0.90 1.30 8

856 2 50 C 1-2-3 16 0.9 ● ● 0.90 1.30 8

858 2 50 C 1-2-3 18 0.7 ● ● 0.80 1.10 7

866 3 50 C 1 6 0.7 ● ● 0.80 1.10 7

885 3 50 C 1-2-3 12 0.7 ● ● 0.80 1.10 8

244 4 50 C 1-2-3 – – – – – – –

879 4 50 C 1-2-3 9 0.7 ● ● 0.90 1.30 8

890 6 50 E 2 18 0.7 ● ● 0.90 1.30 5

894 6 50 E 2 22 0.7 ● ● 0.90 1.30 4

5B

5K

997 1) 1 75 A4 N/A 32 1.3 ● ● 1.20 1.70 8

840 1 50 A 5-6 40 0.9 ● ● 1.30 1.80 7

● First choice alternative ● Special order alternative Note: 1) only available in 5B series. Solution for triaxial cable fixing.

www.lemo.com 7

ø A

Reference

Number of contacts

Impedance (Ω)

Type (see page 10)

Cable group

Number of contacts

ø A (mm)

Solder

Crimp

Test voltage

(kV rms)

Test voltage

(kV dc)

Rated current (A)

Page10

® ®

Mixed: multi coax, coax + LV

Coax Low voltage (LV)

Coax Contacts

type

5B

5K 868 1 50 B 6 4 3.044 0.9 ● ● 0.80 1.15 356

850

870 2

50 B 6

75 B 3-5 10 0.9 ● ● 1.40 2.00 8

856 50 B 6

876 2 75 B 3-5 16 0.9 ● ● 1.40 2.00 7

857 2 50 B 6 2 2.0

● ● 1.40 2.00 30

877 75 B 3-5 15 0.9 ● ● 1.40 2.00 7

C1

864 2 75 B0 1-6 24 1.3 ● ● 0.90 1.30 8

C2

273 3 75 B1 5 – – – – – – –

274 4 75 B1 5 – – – – – – –

892 6 75 D 5-8-9 10 0.9 ● ● 0.70 1.00 7

260 7 75 D 5-8-9 – – – – – – –

240 10 50 C 1-2-3 – – – – – – –

● First choice alternative ● Special order alternative

8 www.lemo.com

ø A

Reference

Number of contacts

Impedance (Ω)

Type (see page 10)

Cable group

Number of contacts

ø A (mm)

Solder

Crimp

Test voltage

(kV rms)

Test voltage

(kV dc)

Rated current (A)

Page11

® ®

Mixed: coax + LV + HV, coax + LV + Fluidic, coax + LV + Fibre optic

Coax Low volt. High volt. Fibre optic Fluidic(LV) (HV) (FO) (FL)

Coax

2B

2K 932 1 50 2.0 C 1 21) 0.7 1 2) 0.7 – – – –

3B 934 1 50 2.0 C 1 4 0.9 1 0.9 – – – –

3K

970 1 50 2.0 C 1 10 0.7 – – – – 1 1.3

986 1 50 2.0 C 1 16 0.7 – – 1 F2 – –

Note: 1) Test voltage LV contact-shell 1.9 (kV rms). 2) Test voltage HV contact-shell 7.5 (kV rms). Total rated current for 2B.932 configuration 6 (A).

www.lemo.com 9

ø A

Reference

Number of contacts

Impedance (Ω)

Rated current (A)

Type (see page 10)

Cable group

Number of contacts

ø A (mm)

Number of contacts

ø A (mm)

Number of contacts

Type

Number of contacts

Inner tube ø (mm)

Page12

® ®

Coaxial contacts for B and K series

Sheath ø

F 1) 50 0.5 solder crimp 2 0.35 1.05 – 2.10 1.05+1.83f 0.8 2

1 0.60 1.90 2.5 3.00

A1 50 0.7 solder collet 2 0.60 1.90 1.7 2.10 1.01 0.9 5

3 0.60 1.90 2.2 2.60 +0.127f

1 0.50 0.58 1.65 3.00

C 1) 50 0.6 crimp crimp 2 0.28 0.35 1.05 – 2.35 1.04 1.6 2

3 0.28 0.35 1.65 3.00 +0.1f

E 1) 50 0.5 solder crimp 2 0.35 0.95 – 2.00 1.02+0.93f 0.8 2

50 1.6 solder collet 5 1.35 3.95 4.3 5.10 1.016 1.35 3.95 5.3 6.10 +0.146f 1.8 12

A

4 1.05 3.95 3.8 4.60

75 1.3 solder collet 5 1.05 3.95 4.3 5.10 1.01

6 1.05 3.95 5.3 6.10 +0.19f

2.4 7

A4 75 1.3 solder collet none 1.05 3.95 6.7 7.60 1.01+0.19f 2.4 7

1.06

50 0.9 solder crimp 6 1.05 3.75 – 6.25 +0.156f 0.8 11

B 1)

75 0.6 solder crimp 3 0.80 2.45 1.005 0.80 3.75 – 6.25 2.1 6+0.22f

1 0.75 2.95

B0 75 0.6 solder solder 6 0.75 3.75 – 4.25

1.00

+0.22f 2.1 6

B1 1) 75 0.6 crimp crimp 5 0.55 0.80 3.75 – 6.25 1.00 2.1 6+0.22f

5 0.75 3.75 5.40

D 1) 75 0.5 solder crimp 8 0.75 2.45 – 3.90 1.00 1.0 5

9 0.75 3.00 4.90 +0.38f

G 50 0.5 solder crimp 1 0.35 1.65 – 3.00 1.01+0.73f 0.4 2

A0 50 1.3 solder collet 6 0.95 – 3.3 4.10 1.02+0.3f 2) 3.0 12

Note:

1) These contacts require specific tools for assembly on the cable, see page 11.

2) Frequency range with SWR ≤ 1.2 = 0 - 1.5 GHz.

10 www.lemo.com

Type

Impedance (Ω)

ø A (mm)

Cond. fixing

Screen fixing

Cable group

Mini

Cond. ø maxi

Maxi

Dielectric ø maxi

Mini

Maxi

VSWR (f=GHz)

Test voltage (kV rms)

Rated current (A)

Page13

® ®

Recommended coaxial cables for mixed coax, multi coax for B and K Series

LEMO cable Type LEMO Impedance Conductor Dielectric Screen SheathPart Number cable group (Ω) ø (mm) ø (mm) ø (mm) ø (mm)

RG 6 A/U 7 75 ± 3 0.73 4.70 6.20 8.45

311 100 LEDE RG 11 A/U 9 75 ± 2 1.17 7.25 8.15 10.10

CCX.50.RG5.8CU50N RG 58 C/U 5 50 ± 2 0.90 2.95 3.60 5.00

CCX.50.RG5.9BU62N RG 59 B/U 6 75 ± 3 0.60 3.70 4.50 6.20

CCX.50.RG1.74AU27N RG 174 A/U 1 50 ± 2 0.48 1.50 2.00 2.80

CCX.50.RG1.78BU18M RG 178 B/U 2 50 ± 2 0.30 0.84 1.30 1.80

CCX.75.RG1.79BU26M RG 179 B/U 3 75 ± 3 0.30 1.50 2.00 2.50

RG 180 B/U 4 95 ± 5 1) 0.30 2.60 3.10 3.60

CCX.75.RG1.87AU26B RG 187 A/U 2 75 ± 3 0.30 1.50 2.00 2.60

CCX.50.RG1.88AU26B RG 188 A/U 1 50 ± 2 0.54 1.50 2.00 2.60

CCX.50.RG1.96AU20B RG 196 A/U 1 50 ± 2 0.30 0.84 1.30 1.95

CCX.50.RG3.16U26M RG 316 /U 1 50 ± 2 0.60 1.60 2.10 2.80

Note: 1) when no defined impedance is required.

The cable group number corresponding to the chosen cable must be written in the variant position, see pages 3 and 5.

Tooling for coaxial contacts of B and K series

Reference

Coaxial Imp. Cable

contact type Ω group Crimping tool Spanner for

with die tightening the contact Extractor

F 50 2 DPE.99.025.45K DCC.91.019.1LA –

1-3 DPE.99.103.8K – DCC.91.384.5LA

C 1) 50

2 DPE.99.103.1K – DCC.91.384.5LA

E 50 2 DPE.99.002.5K DCC.91. 050.2LA –

50 6 DPE.99.176.2K – DCC.91.804.5LA

B 75 3 DPE.99.125.2K – DCC.91.804.5LA

75 5 DPE.99.127.0K – DCC.91.804.5LA

B1 75 5 DPE.99.127.0K – DCC.91.808.0LC

5 DPE.99.006.2K DCB.91.685.8TN –

D 75 8 DPE.99.005.2K DCB.91. 685.8TN –

9 DPE.99.005.5K DCB.91.685.8TN –

Note: 1) for the 3B.243/3K.243 and 3B.862/3K.862 the extractor is part number DCC.91.393.4LT.

www.lemo.com 1 1

Page14

® ®

00.650 Series

The 00 Series are available in triax configuration, allowing a very compact solution for triaxial cables.

These connectors are designed for small diameter ranging from 1.1 to 3.5 mm.

Either twinax (2 shielded connectors) or triax (1 conductor and 2 concentric separate screens) can be used with the 00 Series.

The 00 Series with a 650 configuration insert are mostly used in audio-video applications where a large density of connection

is required.

LEMO 00 Series connectors offer customers many benefits including:

– self-latching push-pull system – ease of use

– aesthetically pleasing appearance – low weight

– small size – reliable performances

– high packing density – wide choice to suit application

– rugged construction.

Metal housing models

Elbow plug Straight plugs Fixed and free sockets Free socket

FLA FFC ERN EPA PCA

Elbow socket Fixed socket

FFC ECP

EPL PSA

FFY ERX

Plastic housing model Threaded latching models

FAA

Straight plug ERC Straight plug Fixed socket

FFC FAR ELF FVN ELF

Model Description

ECP Fixed socket with 2 round nuts ERN Fixed socket with nut fixing and tags FFC Straight plug with flats on latch sleeve and

(back panel mounting) ERX Fixed socket with nut fixing, cable collet, black POM (Delrin® outershell)

ELF Fixed socket, nut fixing, threaded shell slots on flange and tags FFY Straight plug, large shell with cable collet

with tag (back panel mounting) FAA Straight plug non latching with nut FLA Elbow socket (90°) with cable collet

ELF Fixed socket, nut fixing, threaded shell FAR Straight plug non latching with 2 nuts FVN Straight plug with cable collet,

with tag, black chromium-plated outer shell (back panel mounting) black chromium-plated outer shell

(back panel mounting) FFC Straight plug with flats on latch sleeve PCA Free socket with cable collet

EPA Straight socket for printed circuit board and cable collet PSA Fixed socket, nut fixing, cable collet

EPL Elbow plug (90°) for printed circuit board FFC Straight plug with flats on latch sleeve

ERC Fixed socket, with thread, with slots and cable collet and nut for fitting

in flange a bend relief

Part Section Showing Internal Components

Fixed socket Straight plug

outer shell 7 6 3 4 5 2 1 1 7 6 2 5 4 8 3 1 outer shell1

earthing crown 2 latch sleeve2

3 retaining ring 3 collet nut

hexagonal nut 44 earthing sleeve

5 locking washer 5 rear insulator

6 insulator 6 insulator

7 female triaxial contact 7 male triaxial contact

8 collet

12 www.lemo.com

Page15

® ®

Part Numbering System

Plug FFC . 00 . 650 . C L A C 27

Free socket PCA . 00 . 650 . C L L C 27 Z

Variant

Cable ø max.:

from 1.1 to 3.5 mm

Collet type:

C = with cable collet clamping

Contact type:

A = male solder

L = female solder

Fixed socket ERN . 00 . 650 . C L L

Model

Series: 00

Variant

Insert configuration:

650 = triaxial (50 Ω )

Contact type:

Housing : A = male solder

N = brass nickel-plated 3) D = male print

C = brass chrome-plated 3) 1) L = female solder

K = brass black chrome 1) N = female print

B = black POM 2)

G = PEEK (natural) Insulator: L = PEEK

Part Number Example

Straight plug with cable collet:

FFC.00.650.CLAC27 = straight plug with flats on latch sleeve and cable collet, 00 Series, triaxial (50 Ω), outer shell in chrome-

plated brass, PEEK insulator, C type collet for an up to 2.6 mm diameter cable.

Free socket:

PCA.00.650.CLLC27Z = free socket with cable collet, 00 Series, triaxial (50 Ω), outer shell in chrome-plated brass, PEEK

insulator, C type collet for an up to 2.6 mm diameter cable and nut for fitting a bend relief.

Fixed socket:

ERN.00.650.CLL = fixed socket with nut fixing and tags, 00 Series, triaxial (50 Ω), outer shell in chrome-plated brass,

PEEK insulator.

Note: 1) treatment not available for the printed circuit models. 2) available for the FFC model only. 3) standard.

Insert configuration

Series

650 00 – 50 0.5 1) 0.55 2.9 3.5 1.02+0.9f 0.6 4

Note: 1) 00.650 is designed for use with 2 conductors screened cable (twinax).

www.lemo.com 1 3

ø A

Reference

Standard

Watertight

Impedance (Ω)

ø A (mm)

Cable group

Cond. ø max

Dielectric ø maxi

Sheath ø maxi

VSWR (f=GHz)

Test voltage (kV rms)

Rated current (A)

Page16

® ®

S Series

S series connectors have main features as follows:

– security of the Push-Pull self-latching system – coaxial, triaxial and mixed contact configurations

– solder contacts, print contacts only for coaxial – polarisation by stepped insert (half-moon)

and triaxial configurations – up to 8 coaxial contacts

– 360° screening for full EMC shielding.

Metal housing models

Straight plugs Straight plugs Fixed sockets Free sockets Fixed sockets

FFF FFA, FFP ERA EBS PCA, PCP PSA, PSP

FFS FFA EBCERN PCA

PSS

FZP FFA, FFP ERC ERD PCA

Elbow plug

Fixed plug Free coupler with socket

FFB EHP ECP

FAA RMA

Elbow plugs FFE Fixed coupler FTR

EBD

Straight plug with resistor

FLS FLA

RAD

FRT

Plastic housing models Watertight or vacuumtight models

Straight plugs Fixed socket Fixed sockets Fixed coupler

FFP FFA, FFP

HGP EWB

ERN SWH

FFL

HCP HGW

Model Description

EBC Fixed socket with square flange, FFA Straight plug, cable collet, HCP Fixed socket, nut fixing, watertight

protruding shell and screw fixing PEEK or POM outer shell or vacuumtight (back panel mounting)

EBD Fixed socket with square flange FFB Straight plug, cable collet HGP Fixed socket, nut fixing, watertight

and screw fixing and safety locking ring or vacuumtight

EBS Fixed socket with round flange FFE Straight plug, cable collet, front seal HGW Fixed socket, nut fixing, with back

and screw fixing and nut for fitting a bend relief washer, watertight or vacuumtight

ECP Fixed socket with two nuts, long threaded (protected to IP54 when mated) PCA Free socket, cable collet

shell (back panel mounting) FFF Straight plug, non-latching, cable collet PCA Free socket with oversize cable collet

EHP Fixed socket, nut fixing, protruding shell FFP Straight plug, cable collet PCA Free socket, cable collet and nut for fitting

ERA Fixed socket, nut fixing and inner anti-rotating device a bend relief

ERC Fixed socket, nut fixing with slot FFP Straight plug, cable collet, PCP Free socket, cable collet and inner

in the flange PEEK or POM outer shell anti-rotating device

ERD Fixed socket with two nuts and inner anti-rotating device PSA Fixed socket, nut fixing, cable collet

(back panel mounting) FFP Straight plug, cable collet, PEEK or POM PSP Fixed socket, nut fixing, cable collet

ERN Fixed socket, nut fixing, outer shell, inner anti-rotating device and inner anti-rotating device

with earthing tag and nut for fitting a bend relief PSS Free socket, nut fixing for cable crimping

ERN Fixed socket, nut fixing, with earthing tag, FFS Straight plug for cable crimping RAD Fixed coupler, nut fixing

PEEK or POM outer shell FLA Elbow (90°) plug, cable collet RMA Free coupler

EWB Fixed socket, nut fixing, with two flats FLA Elbow (90°) plug, cable collet SWH Fixed coupler, nut fixing, watertight

on the flange, watertight or vacuumtight and nut for fitting a bend relief or vacuumtight

FAA Fixed plug non-latching, nut fixing FLS Elbow (90°) plug for cable crimping

FFA Straight plug, cable collet FRT Straight plug with resistor

FFA Straight plug with oversize cable collet FTR Elbow (90°) plug with socket

FFA Straight plug, cable collet FZP Straight plug for remote handling,

and nut for fitting a bend relief cable collet and inner anti-rotating device

14 www.lemo.com

Page17

® ®

Part Numbering System

Plug FFA . 1S . 250 . C T A C 32

Free socket PCA . 1S . 250 . C T L C 32 Z

Variant 1)

Cable ø max. 2)

Collet type: C, K or L

Fixed socket ERA . 1S . 250 . C T L

Variant 1)

Contact type:

A = male solder

C = male crimp

L = female solder

M = female crimp

Model Insulator:

L = PEEK

T = PTFE

Series

Housing:

Insert configuration: C = brass chrome-plated

coaxial, triaxial, N = brass nickel-plated

multi coax, coax + LV B = POM (black)

Part Number Example

Straight plug with cable collet:

FFA.1S.250.CTAC32 = straight plug with cable collet, 1S series, coaxial (50 Ω), outer shell in chrome-plated brass, PTFE

insulator, male solder contact, C type collet for a 3.2 mm diameter cable.

Free socket:

PCA.1S.250.CTLC32Z = free socket with cable collet, 1S series, coaxial (50 Ω), outer shell in chrome-plated brass, PTFE

insulator, female solder contact, C type collet for a 3.2 mm diameter cable and nut for fitting a bend relief.

Fixed socket:

ERA.1S.250.CTL = fixed socket, nut fixing, 1S series, coaxial (50 Ω), outer shell in chrome-plated brass, PTFE insulator,

female solder contact.

Note: 1) for mixed contacts, add cable group to the part number.

2) see unipole-multipole catalogue (p. 102).

Part Section Showing Internal Components (mixed coax + LV)

Fixed socket Straight plug

1 outer shell 8 7 6 2 3 4 5 1 1 6 5 4 2 7 3

1 outer shell

2 earthing crown

2 latch sleeve

3 retaining ring

3 collet nut

4 hexagonal nut

4 centre-piece

5 locking washer

5 insulator

6 insulator

6 female coaxial contact

7 male coaxial contact

7 collet

8 female contact

www.lemo.com 1 5

Page18

® ®

E Series

E series connectors have been specifically designed for outdoor applications.

They include an inner sleeve and two seals to prevent penetration of solids or liquids into the housing formed by the plug,

free socket or fixed socket. All models of these series are watertight when mated and give a protection index of IP 68 as

per IEC 60529 standard (in mated condition) when correctly assembled to an appropriate cable (IP 66 otherwise).

– security of the Push-Pull latching system – coaxial, triaxial and mixed contact configurations

– watertight connection (IP 68/IP 66) – polarization by stepped insert (half-moon)

– solder contacts, print contacts only – 360° screening for full EMC shielding

for coaxial and triaxial configurations – rugged housing for extreme working condition.

Models

Straight plug Straight plugs Fixed sockets Free sockets

FZP FFA PCA

ERA

Fixed plug

FFA PCA

ERB

FAA

Elbow plug

FFA PCA

EEP

Fixed socket

FLA

FFF

EHP

Watertight or vacuumtight models PSA

Fixed sockets Fixed coupler Free coupler

HGP EBR SWH RMA

Model Description

EBR Fixed socket with round flange, water- FFA Straight plug with oversize cable collet PCA Free socket with oversize cable collet

tight, protruding shell and screw fixing FFA Straight plug, cable collet PCA Free socket, cable collet

EEP Fixed socket, nut fixing (back panel and nut for fitting a bend relief and nut for fitting a bend relief

mounting) FFF Straight plug non-latching, cable collet PSA Fixed socket, nut fixing, cable collet

EHP Fixed socket, nut fixing, protruding shell FLA Elbow (90°) plug, cable collet RMA Free coupler

ERA Fixed socket, nut fixing FZP Straight plug for remote handling, SWH Fixed coupler, nut fixing, watertight

ERB Fixed socket, nut fixing with two flats cable collet and inner anti-rotating device or vacuumtight

in the flange HGP Fixed socket, nut fixing,

FAA Fixed plug non-latching, nut fixing watertight or vacuumtight

FFA Straight plug, cable collet PCA Free socket, cable collet

16 www.lemo.com

Page19

® ®

Part Numbering System

Plug FFA . 1E . 250 . C T A C 50

Free socket PCA . 1E . 250 . C T L C 50 Z

Variant 1)

Cable ø max. 2)

Collet type: C or K

Fixed socket ERA . 1E . 250 . C T L

Variant 1)

Contact type:

A = male solder

L = female solder

Model Insulator:

L = PEEK

T = PTFE

Series

Housing:

Insert configuration: C = brass chrome-plated

coaxial, triaxial, K = brass black chrome

multi coax, coax + LV T = stainless steel

Part Number Example

Straight plug with cable collet:

FFA.1E.250.CTAC50 = straight plug with cable collet, 1E series, coaxial (50 Ω), outer shell in chrome-plated brass, PTFE

insulator, C type collet for an up to 5.0 mm diameter cable.

Free socket:

PCA.1E.250.CTLC50Z = free socket with cable collet, 1E series, coaxial (50 Ω), outer shell in chrome-plated brass, PTFE

insulator, C type collet for an up to 5.0 mm diameter cable and collet nut for fitting a bend relief.

Fixed socket:

ERA.1E.250.CTL = fixed socket, nut fixing, 1E series, coaxial (50 Ω), outer shell in chrome-plated brass, PTFE insulator.

Note: 1) for mixed contacts, add cable group to the part number.

2) see unipole-multipole catalogue (p. 105).

Part Section Showing Internal Components (mixed coax + LV)

Straight plug

Fixed socket

1 outer shell

7 6 5 2 3 4 8 1 8 2 3 7 6 1 4 10 12 13 11 5

2 latch sleeve

1 outer shell

3 inner shell

2 earthing crown

4 retaining ring

3 retaining ring

5 collet nut

4 hexagonal nut

6 centre-piece

5 insulator

7 insulator

6 male coaxial contact

8 female coaxial contact

7 female contact

9 earthing cone

8 o-ring

10 collet

11 gasket

12 washer

www.lemo.com 17

Page20

® ®

Insert configuration (S and E series)

Coaxial

Series Sheath ø

00 250 1) 00 – 50 0.7 1 to 9 1.05 3.05 5.5 1.09+0.11f 2.1 4

0S

250 0S 0E 50 0.9 1-2 0.95 2.95 6.7 5.0 1.02

0E 3-4 +0.25f

3.0 6

1S 250 1S 1E 50 1.6 1-23-4 1.35 3.95 8.5 8.5 1.01 3.0 121E +0.23f

275 1S 1E 75 1.3 5-6-7 1.05 3.95 8.5 8.5 1.02+0.08f 2.4 10

2S 250 2S 2E 50 2.0 6-7 1.75 5.95 10.5 10.5 1.01

2E +0.95f

3.0 15

275 2S 2E 75 1.6 6-7 1.35 5.95 10.5 10.5 1.02+0.03f 1.5 12

3S

3E 250 3S 3E 50 3.0 8 2.65 8.15 13.0 15.0

1.06

+0.5f 3.0 26

275 3S 3E 75 2.0 8 1.75 8.15 13.0 15.0 1.04+0.05f 2.7 15

4S

4E 250 4S 4E 50 4.0 8-9 3.65 10.05 22.0 23.5 1.01+1.9f 2.1 36

275 4S 4E 75 3.0 8-9-0 2.65 10.05 22.0 23.5 1.01+0.12f 1.8 26

5S

250 5S – 50 5.0 9 5.15 17.45 30.0 30.0 1.02+2.3f 3.0 45

Note: 1) see NIM-CAMAC catalogue.

1 8 www.lemo.com

ø A

Reference

Standard

Watertight

Impedance (Ω)

ø A (mm)

Cable group

Cond. ø max

Dielectric ø maxi

Maxi S series

Maxi E series

VSWR (f=GHz)

Test voltage (kV rms)

Rated current (A)