1/31ページ

ダウンロード(858.6Kb)

※レモコネクタはモジュール方式のため、共通部品を組み合せることにより様々なコネクタに変えることができます。このため、カタログに掲載されている写真や図は、色、形状などが実物とは微妙に異なっている場合や、写真撮影の方向が一定していない場合がございます。ご注意いただきますようお願いいたします。

このカタログについて

| ドキュメント名 | PLASTIC R SERIES CONNECTORS Rシリーズ(直方体) |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 858.6Kb |

| 登録カテゴリ | |

| 取り扱い企業 | レモジャパン株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

PLASTIC R SERIES

CONNECTORS SERIES

Page2

® ®

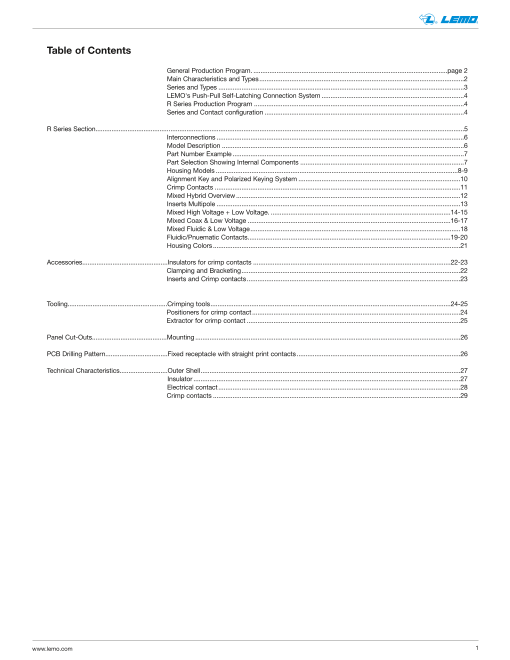

Table of Contents

General Production Program. .............................................................................................................page 2

Main Characteristics and Types...................................................................................................................2

Series and Types ..........................................................................................................................................3

LEMO's Push-Pull Self-Latching Connection System ................................................................................4

R Series Production Program ......................................................................................................................4

Series and Contact configuration ................................................................................................................4

R Series Section...............................................................................................................................................................................................................5

Interconnections ...........................................................................................................................................6

Model Description ........................................................................................................................................6

Part Number Example ..................................................................................................................................7

Part Selection Showing Internal Components ............................................................................................7

Housing Models ........................................................................................................................................8-9

Alignment Key and Polarized Keying System ...........................................................................................10

Crimp Contacts ..........................................................................................................................................11

Mixed Hybrid Overview ..............................................................................................................................12

Inserts Multipole .........................................................................................................................................13

Mixed High Voltage + Low Voltage. .....................................................................................................14-15

Mixed Coax & Low Voltage ..................................................................................................................16-17

Mixed Fluidic & Low Voltage......................................................................................................................18

Fluidic/Pnuematic Contacts..................................................................................................................19-20

Housing Colors ...........................................................................................................................................21

Accessories................................................Insulators for crimp contacts ...............................................................................................................22-23

Clamping and Bracketing...........................................................................................................................22

Inserts and Crimp contacts........................................................................................................................23

Tooling........................................................Crimping tools.......................................................................................................................................24-25

Positioners for crimp contact .....................................................................................................................24

Extractor for crimp contact ........................................................................................................................25

Panel Cut-Outs..........................................Mounting .....................................................................................................................................................26

PCB Drilling Pattern...................................Fixed receptacle with straight print contacts ............................................................................................26

Technical Characteristics...........................Outer Shell..................................................................................................................................................27

Insulator ......................................................................................................................................................27

Electrical contact ........................................................................................................................................28

Crimp contacts ...........................................................................................................................................29

www.lemo.com 1

Page3

® ®

General Production Program

Connectors Unipole from 2 to 150 Amps Patch Panels For fiber optic applications

Coaxial 50 and 75 Ω

Coaxial 50 Ω (NIM-CAMAC) Adapters For BNC, C, UHF, N, CINCH, GEN-RADIO connectors

Coaxial 50 Ω for frequency Õ 12 GHz For TNC, SMA connectors

Multicoaxial 50 and 75 Ω

l Multipole from 2 to 66 contacts Accessories l Insulator for crimp contacts

Multipole up to 106 contacts l Crimp contacts

High Voltage 3, 5, 8, 10, 15, 30 and 50 kV cc l Coaxial contacts

Multi High Voltage 3, 5, and 10 kV cc Triaxial contacts

Triaxial 50 and 75 Ω l Fiber optic contacts

Quadrax l Fiber optic ferrules

l Mixed: High Voltage (HV) + Low Voltage (LV) Caps

l Mixed: Coax + LV Bend relief

Mixed: Triax + LV Heatshrink boot

Thermocouple Insulating washers

Multithermocouple Double plastic panel washers

Fiber optic singlemode Locking washers

Fiber optic multimode Tapered washers

l Mixed: fiber optic + LV Hexagonal nuts

Mixed: fiber optic + coax + LV Conical nuts

Fluidic Round nuts

Multifluidic Notched nuts

l Mixed: fluidic + LV Earthing washers

Subminiature Lead-through with cable collet

Miniature

Plastic Tooling Wrenches

Printed circuit board Assembly tool

Remote handling Pliers

Watertight Taps

Sealed (pressure and/or vacuum) l Crimping tools

l With plastic outer shell l Positioners

With aluminum outer shell Crimping dies

With stainless steel outer shell l Extractors

With special radiation resistant insulator material Banding tool

With screw thread coupling for very high pressure Retention testing tool for crimp contacts

With microswitch Fiber optic termination workstationFiber optic polishing tools

Patch Panels For audio-mono applications: triax On request Filtered connectors

For audio-mono applications: 3 contacts Connectors with special housing

For audio-stereo applications: quadrax Mixed special configuration

For audio-stereo applications: 6 contacts Assembly onto cable

For video applications: coax 75 Ω

For video HDTV applications: 3 coax 75 Ω + 2LV l Connectors, accessories and tools found in this catalog.

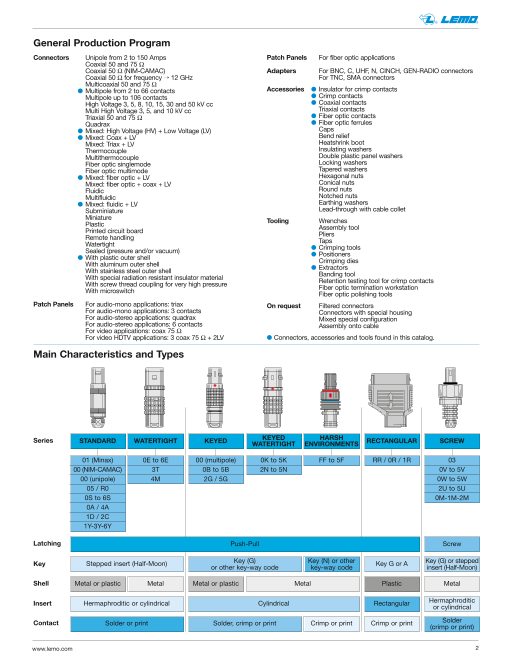

Main Characteristics and Types

Series STANDARD WATERTIGHT KEYED KEYED HARSHWATERTIGHT ENVIRONMENTS RECTANGULAR SCREW

01 (Minax) 0E to 6E 00 (multipole) 0K to 5K FF to 5F RR / 0R / 1R 03

00 (NIM-CAMAC) 3T 0B to 5B 2N to 5N 0V to 5V

00 (unipole) 4M 2G / 5G 0W to 5W

05 / R0 2U to 5U

0S to 6S 0M-1M-2M

0A / 4A

1D / 2C

1Y-3Y-6Y

Latching Push-Pull Screw

Key Stepped insert (Half-Moon) Key (G) Key (N) or otheror other key-way code key-way code Key G or A

Key (G) or stepped

insert (Half-Moon)

Shell Metal or plastic Metal Metal or plastic Metal Plastic Metal

Insert Hermaphroditic or cylindrical Cylindrical Rectangular Hermaphroditic or cylindrical

Contact Solder or print Solder, crimp or print Crimp or print Crimp or print Solder(crimp or print)

www.lemo.com 2

Page4

® ®

Series and Types

Types

Series

01 l

00 l l l l

05 l

R0 l

0A l l

0S l l l l l l

1S l l l l l l l

l l l l l l l l l

Standard 2S

3S l l l l l l l l l l

4S l l l l l l l l l l l

5S l l l l l l l l

6S l l l

1D l

2C l l

4A l

1Y-3Y-6Y l

0E l l l l l l

1E l l l l l l l

2E l l l l l l l l l

3E l l l l l l l l l l

Watertight 4E l l l l l l l l

5E l l l l l l

6E l l l

3T l l

4M l l

00 l l

0B l l l l

1B l l l

2B l l l l l l l l l

Keyed 3B l l l l l l l l l

4B l l l l l l l l l l

5B l l l l l l l

2G l

5G l

0K l l l l

1K l l l

2K l l l l l l l l

Keyed 3K l l l l l l l l l l

watertight 4K l l l l l l l l l l

5K l l l l l l l

FF to 5F l

2N to 5N l

RR l l

Rectangular 0R l l l l

1R l l l l

03 l l

0V l l l l l

1V l l l l l l

2V l l l l l l l l

l l l l l l l l l

Screw 3V

4V l l l l l l l l

5V l l l l l l

0W to 5W l l l l l l l l

2U to 5U l l l l

0M to 2M l

Note: l = included in this catalog, l = available but not included in this catalog.

www.lemo.com 3

Unipole

Coaxial 50 Ω

Coaxial 75 Ω

Multipole

High Voltage

Triaxial 50 Ω

Triaxial 75 Ω

Quadrax

Multi HV

Multi Coaxial

Mixed HV+LV

Mixed Coax+LV

Mixed Triax+LV

Fiber Optic

Multi FO

Mixed FO+LV

Fluidic

Multi fluidic

Mixed fluidic+LV

Thermocouple

Page5

® ®

LEMO’s Push-Pull Self-Latching Connection System

This self-latching system is renowned worldwide for its easy and quick mating and unmating features. It provides absolute

security against vibration, shock or pull on the cable, and facilitates operation in a very limited space.

The plug and the receptacle can be mated

by simply pushing axially the outer shell of the plug.

Pulling on the cable or any other component

of the plug than the outer release sleeve

cannot break the connection.

The connector can be unmated by a single axial

pull on the plug outer release sleeve.

R Series Production Program

Series RR 0R 1R

min. 1.0 1.5 2.0

Cable ø range (mm)

max. 4.0 6.2 9.2

Number of contacts (multipole) 13 10, 17, 37 28, 36, 67

Number of contacts (mixed HV+LV) – 4 HV + 4 LV, 2 HV + 13 LV 8 HV + 3 LV

Number of contacts (mixed coax+LV) 1 coax + 4 LV 4 coax + 4 LV, 2 coax + 13 LV 8 coax + 3 LV

Number of contacts (mixed fluidic+LV) – 4 fluidic + 4 LV, 2 fluidic + 13 LV 8 fluidic + 3 LV

Note: «LV» stands for low voltage.

www.lemo.com 4

Page6

R SERIES

Page7

® ®

R Series

The R series is a rectangular connector with high pin density in a flat profile. It uses LEMO’s well proven Push-Pull

latching system for a smooth, hassle free connection. The ergonomic and flat profile offers high panel density, in a wide

choice of colors for excellent visual aesthetics.

The R series is made of lightweight polyester resin Crastin® PBT from DupontTM. The high flexibility of its design enables

various contact configuration, such as multipole, coaxial, high voltage and fluidic.

R series connectors provide the following main features:

– plastic shell for lightweight yet rugged structure – high pin density for improved panel space

– push-pull latching enable fast and secure connections – 3 sizes and various models for design choices

– crimp or printed circuit contacts – standard or hybrid pin configurations for flexibility

– choice of 4 colors for aesthetics – thin footprint for reduced rack space

and quick identification and high density panel.

The R series, is initially designed to interconnect systems in medical application where aesthetics and safety is required.

This connector series can also be used for test & measurement, aerospace and automotive testing, where an extensive

number of contacts are needed in a limited space.

Plastic material used for manufacturing insulators is selected according to the required electric and thermal properties.

The thermoplastic used is PEEK (Polyether-Etherketone) with the addition of glass fibers to improve mechanical charac-

teristics and to increase dielectric strength.

Plastic housing models

Straight plug Fixed receptacles Free receptacles

EGG PHG

FGG

EBG PBG

www.lemo.com 6

Page8

® ®

Part Numbering System

Plug FG G . 1R . 336 . G L C 92

Free receptacle PH G . 1R . 336 . G L M 92

Fixed receptacle EG G . 1R . 336 . G L M

Variant:Cable Group: (page 17)

Model: (page 8-9) Cable ø: (page 22)

Alignment key: (page 10) Contact: (page 11)

Series: (page 12) Insulator: L = PEEK

Insert configuration: (page 13-18) Housing color: (page 21)

Part Number Example

Straight plug with cable collet:

FGG.1R.336.GLC92 = straight plug with key (G) and cable collet, 1R series, multipole type with 36 contacts, outer shell in

gray PBT, PEEK insulator, male crimp contacts, collet for 9.2 mm maximum diameter cable.

Free receptacle:

PHG.1R.336.GLM92 = free receptacle with key (G) and cable collet, 1R series, multipole type with 36 contacts, outer shell

in gray PBT, PEEK insulator, female crimp contacts, collet for 9.2 mm maximum diameter cable.

Fixed receptacle:

EGG.1R.336.GLM = fixed receptacle, nut fixing, with key (G), 1R series, multipole type with 36 contacts, outer shell in gray

PBT, PEEK insulator, female crimp contacts.

Part Section Showing Internal Components

2 3 4 5 6 1 2 4 3 5 1 6

Fixed receptacle

Straight plug

1 outer shell

1 outer shell

2 hexagonal nut

2 latch sleeve

3 locking washer

3 screw

4 screw

4 insulator

5 insulator

5 male contact

6 female contact

6 cable clamping

www.lemo.com 7

Page9

® ®

Housing models

FGG Straight plug, key (G) or key (A),

L with cable collet

B M

Reference Dimensions (mm)

Model Series A B L M

FGG RR 18.0 6.0 21.5 17.0

FGG 0R 24.5 9.0 30.5 23.5

FGG 1R 37.0 12.5 39.0 31.0

EGG Fixed receptacle, key (G) or key (A)

L

B M

Reference Dimensions (mm)

Model Series A B L M

EGG RR 18.0 6.0 12.0 7.0

EGG 0R 24.5 9.0 14.0 12.0

EGG 1R 37.0 12.5 18.0 14.5

P1 Panel cut-out page 26)

EGG Fixed socket, key (G) or key (A) with

L visible shell

B M

Reference Dimensions (mm)

Model Series A B L M

EGG RR 18.0 6.0 12.0 7.0

EGG 0R 24.5 9.0 14.0 12.0

EGG 1R 37.0 12.5 18.0 14.5

P1 Panel cut-out page 26)

www.lemo.com 8

A A

A

Page10

® ®

L EBG Fixed receptacle, key (G) or key (A), with flange

M

E

B

Reference Dimensions (mm)

Model Series A B C E G L M

EBG 1R 37.0 15.0 51.0 4.5 3.2 19.5 14.5

EBG 0R 24.5 10.5 24.5 3.2 2.2 18.0 12.0

P2 Panel cut-out page 26

ø G

PHG Free receptacle, key (G) or key (A), with

cable collet

B L

Reference Dimensions (mm)

Model Series A B L

PHG RR 18.0 6.0 22.3

PHG 0R 24.5 9.0 31.5

PHG 1R 37.0 12.5 39.0

PBG Fixed receptacle, key (G) or key (A),

L with flange and cable collet

E

B

Reference Dimensions (mm)

Model Series A B C E G L

PBG 1R 37.0 15.0 51.0 4.5 3.2 39.0

PBG 0R 24.5 10.5 34.5 3.2 2.2 31.5

P2 Panel cut-out page 26

ø G

www.lemo.com 9

C

C

A

A A

Page11

® ®

Alignment Key

Alignment Key and Polarized Keying System

R series connector model part numbers are composed of three letters. The LAST LETTER indicates the key position.

Front view of a receptacle

Series Contact type

Nb of

keys Note

RR 0R 1R Plug Receptacle

α 50° 50° 50° male female l

llG 2

β 30° 30° 30° male female l

α 42° 42° 42° male female l

llA 2

γ 30° 30° 30° male female l

l First choice alternative

l Special order alternative

www.lemo.com 10

Model

Angles

Page12

® ®

Crimp Contacts

Contacts for plugs, free or fixed receptacles Dimension of crimp barrels

Contact Ref. contact type Conductor

Ref. Contact type Ref. Contact type

ø A ø C Form AWG Section (mm2)Male Female

C Male crimp (fig. 1)1) P Female crimp (fig. 2)1) (mm) (mm) per fig. min. max. min. max.

B Male crimp (fig. 2)1) U Female crimp (fig. 2)1) 0.5 0.45 1 C M 32 28 0.035 0.09

G Male crimp (fig. 2)1) N Female straight print 0.80 1 C M 26 22 0.140 0.34

0.7

M Female crimp (fig. 1)1) 0.45 2 B P 32 28 0.035 0.09

1.10 1 C M 24 20 0.250 0.50

Note: 1) there are two forms of crimp barrels. Please consult adjacent

table for contact selection 0.9 0.80 2 B P 26 22 0.140 0.34

0.45 2 G U 32 28 0.035 0.09

Contacts reference for plugs, free or fixed receptacles

Conductor

Reference Contact

Stranded

Contact type AWG Section (mm2)

Male Female ø A ø C Form(mm) (mm) per fig. min. max. min. max.

Crimp C M 0.5 0.45 1 32 28 0.035 0.09

fig. 1 fig. 2

ø A ø C ø A ø C C M 0.80 1 26 221) 0.140 0.34

0.7

B P 0.45 2 32 28 0.035 0.09

ø A ø C ø A ø C C M 1.10 1 24 20 0.250 0.50

B P 0.9 0.80 2 26 221) 0.140 0.34

G U 0.45 2 32 28 0.035 0.09

Print

ø A ø C

C dimensions are detailed

– N in the section on PCB drilling pattern.

See page 26.

Note: 1) for a given AWG, the diameter of some stranded conductor designs is larger than the crimp barrel diameter.

Make sure that the maximum conductor diameter is smaller than ø C.

www.lemo.com 11

Page13

® ®

Mixed / Hybrid Overview

Size Ref Number of Diameter Number of Hybrid Insert

LV Contact and Type

Contacts

RR 804 4 0.5mm 1 coax, 50 ohm

4 pneumatic/fluidic

0R 004 4 0.7mm 5 bars max pressure

3mm tube diameter

4 high voltage

0R 704 4 0.7mm 2.7 kV rms (test volt)

7.5 kV dc (test volt)

0R 804 4 0.7mm 4 coax, 50 ohms

0R 813 13 0.7mm 2 coax, 50 ohm

8 high voltage

1R 703 3 0.9mm 2.7 kV rms (test volt)

7.5 kV dc (test volt)

1R 803 3 0.9mm 8 coax, 50 ohm

1R 855 22 0.5mm 1 coax, 50 ohm

33 0.7mm

www.lemo.com 12

Page14

® ®

Insert configuration

Multipole

Contact type Crimpcontact

Male crimp contacts Female crimp contacts

RR 1 1

313 13 0.5 l l – 0.6 0.5

13 13

0R 6 1 1 6 310 10 0.9 l l – 1.5 3.5

12 1 10 5 1 12 5 10

7 7

317 17 0.7 l l l 1.35 2.0

11 11

17 6 31 1 6 17 1 31

337 37 0.5 l l – 0.6 0.5

37 7 7 37

1R

1 1

22 9 9 22

16 16 328 28 0.9 l l – 1.5 3.0

21 21

28 15 15 28

8 8

1 1

20 11 11 20

29 29

336 36 0.7 l l – 1.5 2.5

36 36

28 19 19 28

10 10

56 1 1 56

365 65 0.5 l l – 0.6 0.5

65 65

11 11

58 1 1 58

367 67 0.5 l l – 0.6 0.5

67 67

11 11

www.lemo.com 13

Reference

Number of contacts

ø A (mm)

Crimp

Print (straight)

Print (elbow)

Test voltage (kV rms)1)

Contact-contact

Rated current (A)1)

Page15

® ®

Mixed: High Voltage + Low Voltage

High Voltage (HV) Low Voltage (LV)

Male HV contacts Female HV contacts

0R 1 1

704 4 7.5 2.0 4 0.7 l 1.35 2.0

2 2

3 3

11 1 4 1 11 4

713 2 7.5 2.0 13 0.7 l 1.35 3.0

7 7

1R

E A A E

1 1

F B B F

2 2 703 8 7.5 2.0 3 0.9 l 1.5 3.5G C C G

3 3

H D D H

www.lemo.com 14

Reference

Number of Contacts

Test voltage (kV dc)1)

Rated current (A)

Number of contacts

ø A (mm)

Crimp

Test voltage (kV rms)1)

Contact-contact

Rated Current (A)1)

Page16

® ®

Male

FGG.0R.403.ZLME15

HV contact

Contact HT

Female

EGG.0R.403.ZLCE15

HV contact

Contact HT

Typical Assembly of High Voltage Contact

HV Contacts: Fit the HV sleeve onto the cable dielectric, check that all

the HV conductor strands pass through the small hole.

Crimp the contact using tool DPC.91.701.V fitted with positioner

DCE.91.051.BVCM, set to position 3. Fit by turning the HV sub-assembly

on the HV sleeve and push until it butts. The two insulators should

be at the same level.

HV Contact Conductor Range 26-28 AWG

HV Contact Maximum Dielectric 1.5mm

www.lemo.com 15

Page17

® ®

Mixed Coax + Low Voltage

Coax Low voltage (LV)

Male coax contacts Female coax contacts

RR 3 1 1 3

804 1 0.5 RR 1 4 0.5 l 0.6 0.5

4 2 2 4

0R 1 1

804 4 50 0R 1 4 0.7 l 1.35 2

2 2

3 3

11 1 4 1 11 4

813 2 50 0R 1 13 0.7 l 1.35 2

7 7

1R

E A A E

1 1

F B B F 803 8 50 1R 1 3 0.9 l 1.5 3

2 2

G C C G

3 3

H D D H

1 1

22 0.5 l 0.6 0.5

855 1 50 1R 1

33 0.7 l 1.35 2.0

55 55

www.lemo.com 16

Reference

Number of contacts

Impedance (Ω)

Type

Cable group

Number of contacts

ø A (mm)

Crimp contact

Test voltage (kV rms)1)

Rated current (A)1)

Page18

® ®

Male

FGG.0R.250.ZLME28

Coax contact

Contact coax

Female

EGG.0R.250.ZLCE28

Coax contact

Contact coax

Typical Assembly of Coax Contact (Coax Types - RG-174/U, RG-188 A/U, RG-316/U) = Cable Group 1

Coax contacts: Fit the crimp ferrule onto the cable. Crimp the contact using tool DPC.91.701.V fitted with postion-

er DCE.91.050.RVCM, set to position 3. Fit by turning the coax sub-assembly on the central contact until the stop

is reached, check that the central contact is in the correct position in relation to the sub-assembly (0.5 mm), fold

back the cable screen, place the crimp ferrule over the crimping area and complete the crimp using tool

DPE.99.003.1K.

Male

Female

Typical Performance

VSWR / T.O.S.

www.lemo.com 17

Page19

® ®

Mixed: Fluidic + Low Voltage

Fluidic Low voltage (LV)

Male fluidic contacts Female fluidic contacts

0R 1 1

004 4 8 5 4 0.7 l 1.35 2.0

2 2

3 3

11 1 4 1 11 4

013 2 8 5 13 0.7 l 1.35 2.0

7 7

1R

E A A E

1 1

F B B F

2 2

G C C G 003 8 8 5 3 0.9 l 1.5 3.0

3 3

H D D H

www.lemo.com 18

Reference

Number of contacts

Flow (l/min)

Operating pressure (bars)

Number of contacts

ø A (mm)

Crimp contact

Test voltage (kV rms)1)

Rated current (A)1)

Page20

® ®

Fluidic / Pneumatic Contacts

Fluidic / pneumatic male contact

FGG.0R.010.AZ05 Male fluidic / pnuematic contact

Part number

FGG.0R.010.AZ05 (2.7mm hose barb and valve)

Note: 3 – Hose fitting/ barb, 2 – retaining clips, 1 – male sleeve

Fluidic / pneumatic male contact

FGG.0R.010.AZL05 Male fluidic /pnuematic contact

Part number

FGG.0R.010.AZL05 (1.7mm hose barb and non-valve)

Note: 3 – Hose fitting/ barb, 2 – retaining clips, 1 – male sleeve

www.lemo.com 19