1/16ページ

Download(3.6Mb)

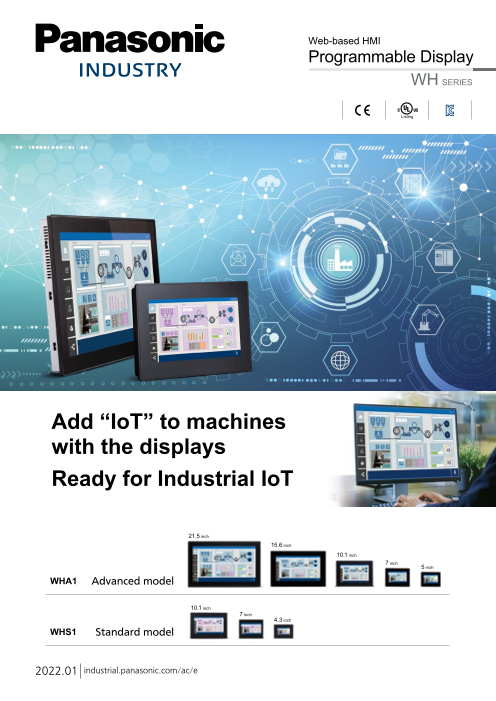

Web-based HMI Programmable Display WH SERIES

Product Catalog

Document Information

| Document Title | Web-based HMI Programmable Display WH SERIES |

|---|---|

| Document Type | Product Catalog |

| File size | 3.6Mb |

| Category | |

| Company | Panasonic Industry Co., Ltd. (Documents List) |

Documents related to this company

Document Contents

Page1

WWebe-b-absaesde dH HMMII I

PProroggrarammmmaabblele D Disispplalayy

WWHHSESREIIREISES

LLiissttiiLnniggsting

Add “IoT” to machines

with the displays

Ready for Industrial IoT

21.5 inch

15.6 inch

10.1 inch

7 inch

5 inch

WWHAH1A1 AAdvdavnacnecde dm modoedllel

10.1 inch

7 inch

4.3 inch

WWHSH1S1 StSatnadnadradr dm modoedllel

202202.20.101iindinudsutrsiitarlli..apl.apnaansaosnoiicn..ico.cmom/a/ca/ce/e

Page2

Providing new information to the production site with web technology

Operation panels

Programmable displays in the past were used to operate FROM

machines and display information at the production site

■Previous issues

Machine status Information displayed Production information

visible only on indicator were manually

at the production site must be transcribed converted into data

A visit to the production site was The operator has to regularly Information of production results

required every time to check the transcribe the production results written by hand had to be entered

machine status. of the equipment to the ledger. manually into an office PC.

2

Page3

—— “Web-based Human Machine Interface” WH SERIES

TO Information panels

The new programmable displays can access machine

information anytime, anywhere

■Features of the information panel

Production site can be Data can be Production information can

checked from automatically be automatically stored in

anywhere with a browser transcribed higher-level systems

You can check the machine status Equipment and production records and The data collected by the WH

via PC and smartphone without going daily reports that used to be handwritten series is automatically stored in

to the production site. Details of the can now be automatically converted to higher-level systems such as

problems that occur can be checked with data. Total work hours can be reduced, and databases and on the cloud.

notification e-mail sent automatically. omissions and mistakes can be prevented.

3

Page4

Display connects the PLC to higher-level systems without programming

The WH series supports various communication protocols and can be used as a gateway to connect lower-level control

systems to higher-level information systems without programming.

Connection with various higher-level systems

The WH series supports OPC UA client/server, MQTT and SQL*1, etc., and

can be connected to higher-level systems such as databases, file servers and

various cloud services without programming. The WH series can be used as a

gateway to existing equipment for data communication with high security using

OPC UA*2 and data analysis using various cloud services.

Database / File server

Information system Office PC

(Web browser)

•V arious cloud services such as AWS

(Amazon Web Services*3)

11:35:25 •OPC UA

Process 1 Process 2 Process 3

1 2 3

4

100

1 2 3 4

50

TENSION METER 36 48

m •SQL

0

14:00:00 15:00:00 16:00:00 17:00:00

Time A B

17:00 153.8 132.5

16:00 158.2 117.2 TENSION METER 22 60

15:00 150.1 122.5 m

USER •FTP •MQTT

Smartphone

Production site PC

*4G Router + Internet SIM (Web browser)

(Web browser)

*1: SQL4Automation from Inasoft System GmbH is required.

*2: T he OPC Unified Architecture (UA) is a secure, reliable and open data

communication standard developed by the OPC Foundation and internationally

standardized as IEC 62541.

Display *3: Amazon Web Services is a trademark of Amazon.com, Inc. or its affiliates in the

United States and other countries.

as a gateway

WH series IP camera

Control system

PLC PLC PLC Image sensor

Various field devices

Programming-free connection Simultaneous connection to

to PLCs of different companies different communication protocols

Able to handle communications protocols used The advanced model can connect using a total of 8

by various PLCs. Naturally, the gateway can be different communication protocols (AWHA1C050: Up to

implemented when you install new equipment, but it can 4 different communication protocols), and the standard

also be used to connect existing equipment. By simply model can connect using as many as 4 different

replacing the display on newly installed equipment and, protocols.

even, legacy equipment you can remotely visualize the Data can be transferred between multiple PLC models

status of field devices. without programming.

4

Page5

APPLICATION

Supports IoT conversion / data utilization of equipment

Web server function

Visualization of the operational Existing equipment

status of existing equipment

Information on equipment operations can be +

collected from PLCs of existing equipment without

programming. The web server functions can be used Real-time information

to check the operational status of equipment and is displayed

identify bottlenecks from the office.

Connection with higher-level systems

Connect to database / cloud services Office Production site

Equipment information can be connected to databases,

cloud services and other higher-le+vel systems without using

PC and programming*.

The display can be used as a gateway to lower the cost of +

introducing IoT.

* Programming with JavaScript may be required in some cases.

JavaScript is a registered trademark of Oracle Corporation and its

subsidiaries and affiliates in the United States and other countries.

E-mail sending function

Notification by e-mail when an Office Production site

equipment abnormality occurs

An error signal from the equipment triggers the WH

series to automatically send an e-mail to the concerned

personnel notifying the error. +

Operators can access the display screen of equipment

from the office and smartphone using the web server

function. The error details can be checked before going

to the production site.

Setting multiple IP addresses

Reduce the burden of managing

IP addresses Higher-level network

The higher-level networks can be separated from the

lower-level networks in the advanced models using the IP address

Ethernet multiple port function. Lower-level network

Local IP addresses can be assigned to the lower-level

equipment, reducing the company’s burden of IP address

management.

* Only advanced models. Up to three IP addresses, one for each port can

be set. (Note that the AWHA1C050 is limited to two ports) Local Local Local

IP address IP address IP address

5

Page6

Assisting digital transformation of manufacturing production site with web technology

HIM software (freeware)

xAscender Studio

The screens of the WH series can

be created with simple and intuitive

operations. Since web server screens

can be created with the same operations,

web pages can be easily created without

specialized knowledge of computer

languages such as HTML.

Draw with abundant variety of Supports connection to

widgets and simple operations database / cloud services

Easily place screen elements: drag and drop widgets from The software supports connection with various cloud

the gallery. services such as AWS, OPC UA client/server function

and SQL connection, and WH data can be linked with

the higher-level systems.

Simulator function

The project file created in xAscender Studio can be checked in a simulator on PC without transferring to the WH main

unit, enabling debugging to be performed easily.

6

Page7

Easy creation of QR codes* from URLs

URLs to access the web server screen or URLs of any

website can be converted into QR codes and displayed on

the screen.

The QR codes can be used to access the screens and

websites using cameras of tablets and smartphones. The

QR codes can also be automatically regenerated when

the IP address of the WH main unit is changed.

*QR code is a registered trademark of DENSO WAVE INCORPORATED.

P.8: APPLICATION “QR code”

PDF reports output function

Daily and monthly logs of equipment operation data

and can be automatically converted into forms. Output

is available in optional formats such as tables (alarms,

trends, audit records) for multiple data and trend graphs.

This helps to cut the amount of production site hand-

written data collection.

P.9: APPLICATION “PDF reports”

FDA "21 CFR Part 11" support functions

To support user management, audit-trail-record traceability

and issuance of digital certification (x.509), items required

in the food, pharmaceutical and biotechnology industries,

the system provides functions to enable compliance* with

FDA “21 CFR Title Part 11”.

*T he administrator at the customer site is responsible for building the

system.

System security

Equipped with features for cyber security measures of ISO27002, IEC 62443-2-4 and NIST Cyber security Framework 1.0.

Multilingual

Switching between up to 24 languages is available on the user input screen. In addition, batches of entire text data can

be exported for translation in CSV format and then imported after translation.

Batch editing in Excel

Multiple tags, recipes and alarms can be modified and registered in a batch with Microsoft Excel*, etc.

*Microsoft Excel is a registered trademark or trademark of Microsoft Corporation in the United States and other countries.

Remote monitoring software xAscender Client

The monitoring application “xAscender Client” has been prepared for users not using a

general-purpose browser when browsing a web server from PC.

*The xAscender Client is set up along with xAscender Studio when the xAscender Suite is installed.

7

Page8

APPLICATION

Improved work efficiency using “QR code” and “Tablet”

Quickly bring up the screen you want to see!

Contributes to increased maintenance efficiency

Previous Since the display must be operated simultaneously in large equipment, two persons must perform

issues the work.

With WH 1. Read the QR code on the display with a tablet and go with the screen to check

series at the work location.

2. When inspecting multiple equipment, the screen for each equipment can be

displayed on a tablet, and one person can handle the work.

Quickly check the recovery procedure! Speedy troubleshooting

Previous When a problem occurs, finding the documents, drawings and other necessary items requires

issues time, delaying recovery.

With WH 1. Quickly access the required page by reading the QR code on the display with

series tablet.

2. Operate the display while viewing the tablet for quick recovery.

(The URLs of various manuals and drawings, etc., can be switched and displayed according to the

problem using QR codes. The operation manual can be viewed on the tablet while performing the recovery

operations, reducing the time spent searching for the drawings.)

Operating

Web site PDF manual instruction video

Web site PDF manual Operating

instruction video

Display various documents on your tablet

8

Page9

APPLICATION

Reduce manual labor and change to a paperless environment!

Automatic inspection data storage and ledger creation

Product number Serial number Inspection date and time Inspection results Two types of ledger output

Outputs screenshot of the

inspection results

Screen captures of the inspection results screen

can be directly converted into PDF files.

Output PDF with an arbitrary

layout

If the layout to be displayed is set in advance,

PDF files can be output according to the layout.

The file name can be set to a combination of

“date, time and product number, etc.”.

Supports storage on a network or recording media

The emitted PDF files can be saved not only in

the WH main unit, but also in the USB memory PDF file

or SD card via the USB port or SD card slot of automatic FTP server

output

the display. Transfer to an FTP server is also SD card

possible. USB memory

Existing equipment PLC WH series

Automatic saving of screen and operation history saving

when a problem occurs in the equipment

Input/output information Camera image Error occurrence date and time Various equipment data Two types of output timing

Automatic screen output

when an error occurs

Prepare the parameters necessary for checking

the status of problems on the WH screen. When

an error occurs, it triggers the automatic capture

of the display screen at that moment.

The parameters when the failure occurred can

be checked in the PDF.

Screen output at an arbitrary

timing

The image displayed at the time of capture can be saved A “Report output button” can be created on the

by displaying the image on the screen by connecting the screen, allowing the operator to save the screen

display unit to an IP camera, etc. captured at an arbitrary time as a PDF. This can

be used to retain a record of the screen.

9

Page10

Advanced model 16,770,000 colors Max. 21.5 inch SD memory card

WHA1 Capacitive type Front pure glass Web server

Equipped with 3 Ethernet ports* and a capacitive type, the large, high end model enables gesture control.

*AWHA1C050 is equipped with two Ethernet ports.

AWHA1C215 AWHA1C156 AWHA1C101 AWHA1C070 AWHA1C050

Screen size 21.5 inch wide 15.6 inch wide 10.1 inch wide 7 inch wide 5 inch wide

Full HD HD WXGA WVGA WVGA

Resolution

1920 × 1080 1366 × 768 1280 × 800 800 × 480 800 × 480

Memory (RAM) 2 GB 2 GB 1 GB 1 GB 512 MB

Equipped with 3 Ethernet ports* Web server functions*

*AWHA1C050 has only two Ethernet ports. All models are equipped with web server functions.

Pages can be created according to the device terminal

on which they will be displayed. The functions can be

SD card slot Ethernet port × 3 used for settings, such as preventing switch operations

from a remote location or allowing viewing only by

administrators.

Monitoring of operations

IP camera from a camera

Serial port USB port × 2 Wi-Fi

WH series router Smart devices

(Web browser)

*Standard models are also supported.

Operations can be performed Support for control gestures

while wearing gloves Supports smooth sliding display of areas outside the

The projected capacitive type touchscreen allows screen size and ease of viewing in PDF viewers with

comfortable operations with gloves such as rubber scrolling (panning) and pinching operations*.

gloves or without gloves.

*Performing operations with all types of gloves is not guaranteed. * Pinch operation is supported only by the advanced models, and

Check the operations in advance. programming with JavaScript is required.

JavaScript is a registered trademark of Oracle Corporation and its

subsidiaries and affiliates in the United States and other countries.

10

Page11

Standard model 65,536 colors Resistive film type Web server

WHS1

Standard model with mid-sized, wide resistive film type for users with focused needs.

Simple interface

Ethernet port

AWHS1R101 AWHS1R070 AWHS1R043

Screen size 10.1 inch wide 7 inch wide 4.3 inch wide

——— WVGA WQVGA

Resolution

1024 × 600 800 × 480 480 × 272

Memory (RAM) 512 MB 512 MB 512 MB Serial port USB

* Intel is a registered trademark or trademark of Intel Corporation in the United States and

Supported protocols Same for both advanced other countries.

and standard models *Motorola is a registered trademark or trademark of Motorola Trademark Holdings, LLC.

*EtherNet/IP is a trademark of ODVA.

Company name Protocol PLC model Ethernet Serial (Note 1)

Our company Panasonic FP, FP7 FP, FP7 ○ ○

ABB SattCon COMLI Sattcon PLC ○

ABB

ABB Mint Controller HCP ABB Mint Controller ○

Beckhoff Beckhoff ADS BC/BX, PC/CX ○

CODESYS V2 ETH Intel, Motorola ○

3S CODESYS V2 SER Intel, Motorola ○

CODESYS V3 ETH CODESYS 3 ○

Delta Delta Modbus RTU DELTA DVP-PLC ○

ESTA DMX512 Digital Multiplex — ○

Eaton Eaton Suconet-K PS4, PS341, PS306-316, PS416 ○

Fatek FACON ETH FB Series ○

Fatek

Fatek FACON SER FB Series ○

GE Intelligent Platforms SNP 90 series, VersaMax series, etc. ○

GE GE Intelligent Platforms SRTP 90 series, VersaMax series, etc. ○

GE SRTP 90 series, VersaMax series, etc. ○

Hitachi ETH EH150 CPU316/CPU516/CPU548, EHV CPU16.32.64/CPU128,

Hitachi Industrial Equipment EH-W 10.23, MicroEH 20.40.64 ○

Systems Hitachi SER EH150 CPU104/208/316/516/548, EHV CPU16.32.64/CPU128,

EH-W 10.23, MicroEH 10.14.23.28/20.40.64 ○

IDEC IDEC Maintenance FC6A-MicroSmart/MicroSmart Plus, FC5A-MicroSmart Pentra,

FC4A-MicroSmart, FT1A-SmartAxis ○ ○

Jetter Jetter Ext ETH JetControl 3xx pcom7 ○

KEYENCE Keyence KV KV10/16/24/40/80/300/700/1000/3000/5000/5500/7300/7500/8000 ○ ○

KOYO ELECTRONICS Koyo DL DL105/240/250/260/340/440/450 ○

INDUSTRIES Koyo DL ETH ECOM, EBC ○

Mitsubishi FX ETH FX1N, FX2N, FX3G, FX3U ○

Mitsubishi FX SER FX, FX0/FX0S, FX0N, FX1N, FX1S, FX2N, FX3G, FX3U ○

Mitsubishi Electric

Mitsubishi iQ/Q/L ETH iQ-FX5U, iQ-R, Q00J/Q00/Q01, Q02/Q02H/Q06H/Q12H/Q25H, QnU,

Q170M-PLC CPU, Q170M-Motion CPU, L02CPU, L26CPU-BT ○

Mitsubishi iQ/Q/L SER Q00J/Q00/Q01, Q02/Q02H/Q06H/Q12H/Q25H ○

Nidec/Control Techniques Control Techniques Modbus TCP — ○

Omron FINS ETH CJx/CS1x/CP1x ○

Omron

Omron FINS SER CJx/CS1x/CP1x ○

A-B DF1 PLC3, PLC5/10/12/15/25/40/40L/60/60L, SLC500 Fixed I/O,

Modular I/O, Micrologix 1000/1500, Ultra 5000 ○

Rockwell Automation

(Allen-Bradley) A-B DH-485 SLC500 Fixed I/O, Modular I/O, Micrologix 1000/1500 ○

A-B ENET PLC5 via NET-ENI, PLC5/10-25, Micrologix 1100/1400,

SLC500/Micrologix 1000/1200/1500 via NET-ENI ○

SAIA S-BUS PCD1/2/3 ○

SAIA

SAIA S-BUS ETH PCD3 ○

Simatic S7 ETH S7-313/314/315/317/318/319/412/413/414/416/417, S7-1200 CPU

1211/1212/1214/1215/15xx, LOGO! 0BAx/S7-200 SMART ○

Siemens Simatic S7 MPI S7-313/314/315/317/318/319/412/413/414/416/417 ○

Simatic S7 PPI S7-212/214/215/216/221/222/224/226/226MX ○

Siemens S7 Optimized S7-1200/1500 ○

Other protocol Protocol Remarks Ethernet Serial (Note 1)

BACnet BACnet — ○ ○

ODVA Ethernet/IP CIP Logix 5000, Micro800, Omron NJ/CJ Series only ○

Modicon Modbus (1-based), Generic Modbus (0-based) ○

Modbus RTU, Modbus RTU Server

Enron Modbus (1-based/0-based) with 32bit registers ○

Modbus

Modicon Modbus (1-based), Generic Modbus (0-based) ○

Modbus TCP, Modbus TCP Server

Enron Modbus (1-based/0-based) with 32bit registers ○

OPC OPC UA Client — ○

Notes: 1) The serial conforms to the serial port (RS-232C, RS-422 or RS-485) of the other device.

2) Some of the supported protocols are given in the list. Refer to the manual for more details.

3) Using PLCs other than the FP series of our company may restrict the types of devices and addresses that can be used. Refer to the manual for more details.

4) Communication may not be possible when using RS-485, depending on the transmission and reception timing with the other device. Check with actual devices

such as samples in advance. 11

Page12

WH

ORDER GUIDE

Main unit

Descriptions

Type Front Power Communication

Display Touch switch cover supply Ethernet Serial USB SD Part No.

4.3 inch wide TFT AWHS1R043

Standard 7.0 inch wide TFT Resistive film

model type Black 1 port 1 port AWHS1R070

1 port

10.1 inch wide TFT RS-232C / AWHS1R101

5.0 inch wide TFT 24 V DC 2 ports RS-422 / 1 port AWHA1C050

7.0 inch wide TFT RS-485 AWHA1C070

Advanced 10.1 inch wide TFT Capacitive type *Software

model 3 ports 2 ports 1 slot AWHA1C101

configurable

15.6 inch wide TFT AWHA1C156

21.5 inch wide TFT AWHA1C215

Tool software

Product name Descriptions Remarks

xAscender Studio Screen configuration tool for WH series

programmable displays You can download “xAscender Suite” for free from our

xAscender Client Tool to enable remote viewing of WH series website. (Membership registration is required.) “xAscender

programmable displays Suite” includes “xAscender Studio” and “xAscender Client”.

Note: G T series “Terminal GTWIN” programmable display software cannot be used with the WH series.

In addition, WH series cannot be detected with our IP address search tool, “Configurator WD”.

SPECIFICATIONS

Main unit specifications

Standard model Advanced model

Type 4.3 inch 7 inch 10.1 inch 5 inch 7 inch 10.1 inch 15.6 inch 21.5 inch

Item Part No. AWHS1R043 AWHS1R070 AWHS1R101 AWHA1C050 AWHA1C070 AWHA1C101 AWHA1C156 AWHA1C215

Regulatory compliance EMC Directive, RoHS Directive, UL/c-UL Listing certification, Korea Radio Wave Regulations (Radio Wave Act KC)

Rated Voltage 24 V DC

Operating voltage range 10 to 32 V DC 10 to 32 V DC (Note 1)

Current consumption (at 24 V DC) 0.25 A or less 0.3 A or less 0.38 A or less 0.6 A or less 0.7 A or less 1 A or less 1.2 A or less 1.7 A or less

Ambient temperature 0 to +50 °C +32 to +122 °F (Note 2), -20 to +50 °C -4 to +122 °F (Note 2),

Storage -20 to +70 °C -4 to +158 °F Storage -20 to +70 °C -4 to +158 °F

Ambient humidity 5 to 85% RH (at +25 °C +77 °F, No condensation or icing allowed, Same when storing)

Vibration resistance 5 to 9 Hz, 3.5 mm 0.138 in single amplitude, 9 to 150 Hz, Acceleration 9.8 m/s2 (1 G)

Shock resistance 490 m/s2 (50 G), 11 ms, 3 times in the X, Y, Z directions

Protection Front panel: IP66 (Initial value) (Note 3), Rear: IP20

Pollution degree 2

Net weight 0.4 kg approx. 0.6 kg approx. 1 kg approx. 1 kg approx. 1.3 kg approx. 2.5 kg approx. 4.1 kg approx. 6.1 kg approx.

Notes: 1) The voltage tolerance range for maintaining a 10 ms voltage dips is limited to 20.4 to 32 V DC. * Does not include connection of external devices.

2) In vertical installation conditions

3) The IP66 is guaranteed only if:

• Max deviation from the plane surface to the cut-out: ≦ 0.5 mm 0.020 in

• Thickness of the case where is mounted the equipment: from 1.5 mm to 6 mm 0.059 in to 0.236 in

• Max surface roughness where the gasket is applied: ≦ 120 μm

Also, tightening torque: 0.75 N•m (for advanced type: 1.3 N•m) or screw each fixing screw until the bezel corner gets in contact with the panel.

Function specifications

Type Standard model Advanced model

4.3 inch 7 inch 10.1 inch 5 inch 7 inch 10.1 inch 15.6 inch 21.5 inch

Item Part No. AWHS1R043 AWHS1R070 AWHS1R101 AWHA1C050 AWHA1C070 AWHA1C101 AWHA1C156 AWHA1C215

Displayable fonts Fixed font, True Type font, Fonts installed in Windows® (Note 1) (Note 2)

Number of registerable

screens (pages) (Note 3) Max. 1,000

Registerable screen Pages: 1,000

number Dialog: 50

Template: 50

Types of widget Basic (text, numerics), Button, Meter, Switch, Light, Media, Icon, Custom, etc.

Main functions Trends, Reports, Alarms, Scheduler, Database, Data transfers, Recipe, Keypads, Web server, etc.

Through function If a PC is connected to the LAN port of a WH series and a PLC is connected into the serial port, the PLC program

can be debugged without a direct connection between the computer and the PLC. (Note 4)

Notes: 1) Windows is a registered trademark of Microsoft Corporation in the United States and other countries.

2) A license (permission to use) is required to add the font.

3) Maximum allowable number varies depending on registered contents.

4) The only supported PLC is our FP series.

12

Page13

WH

SPECIFICATIONS

Performance specifications

Type Standard model Advanced model

4.3 inch 7 inch 10.1 inch 5 inch 7 inch 10.1 inch 15.6 inch 21.5 inch

Item Part No. AWHS1R043 AWHS1R070 AWHS1R101 AWHA1C050 AWHA1C070 AWHA1C101 AWHA1C156 AWHA1C215

Display unit 4.3 inch 7 inch 10.1 inch 5.0 inch 7.0 inch 10.1 inch 15.6 inch 21.5 inch

wide TFT wide TFT wide TFT wide TFT wide TFT wide TFT wide TFT wide TFT

Resolution 480 × 272, 800 × 480, 1,024 × 600 800 × 480, 800 × 480, 1,280 × 800, 1,366 × 768, 1,920 × 1,080,

WQVGA WVGA WVGA WVGA WXGA HD Full HD

Displayable area 96.4 × 55.2 mm 155.5 × 88 mm 224.3 × 126.8 mm 109 × 65.8 mm 152.6 × 91.6 mm 217.9 × 136.6 mm 345.5 × 195 mm 478 × 269.5 mm

3.795 × 2.173 in 6.122× 3.465 in 8.831 × 4.992 in 4.291 × 2.591 in 6.008 × 3.606 in 8.579 × 5.378 in 13.602 × 7.677 in 18.819 × 10.610 in

Display Colors 65,536 colors 65,536 colors 16,770,000 colors

Backlight White LED

Backlight 2 2 2

2 300 cd/m 2 400 cd/m 300 cd/m

brightness (Initial) 200 cd/m (typ.) (typ.) 500 cd/m (typ.) (typ.) (typ.)

Dimming Yes (Can be adjusted on the menu screen, xAscender Studio settings.

*There are some minor variations in the backlight brightness.

Backlight life time 20,000 hours or more (Note 2) 40,000 hours or more (Note 2)

Touch switch Analog resistive film type Capacitive type

Touch

switch Touch switch operating 1.5 N or less

Life time 1 million times or more (Note 3)

RAM 512 MB 512 MB 1 GB 1 GB 2 GB 2 GB

Memory Flash memory 4 GB 4 GB 4 GB 4 GB 8 GB 8 GB

space Project memory 240 MB

User memory 512 MB

Clock function Yes

Accuracy RTC ±100 ppm or less (at +25 °C +77 °F) (Note 4)

RTC /

Backup Backup range Clock back up

Backup function / 48h with super capacitor backup 3 months with lithium batteries (secondary batteries)

period (at +25 °C +77 °F) (Note 5) (at +25 °C +77 °F) (Note 5)

Other Buzzer

Notes: 1) On the LCD panel, bright spots (points always lit) or black spots (points always unlit) may appear, or the uneven brightness, flickers or

crosstalk (appearance of unintended shades in the area no graphic or part is arranged) may occur depending on the operating conditions.

Note that these phenomena are resulted from the basic characteristics of LCD panel not defects or failures of the product.

2) Time of continuous operation until the brightness of the backlight reaches 50% of the rated value when the surrounding air temperature is

+25 °C +77 °F

3) The touch position may shift due to aging variation. If the touch position has shifted greatly, please adjust it.

4) At +25 °C +77 °F: less than 260 seconds per month. On systems prone to clock error, set the correct time on a regular basis.

5) Must be charged for 48 hours. When the battery is fully charged, it ensures a period of 48 hours of data backup.

Interface specifications

Ethernet port communication specifications

Standard model Advanced model

Type 4.3 inch 7 inch 10.1 inch 5 inch 7 inch 10.1 inch 15.6 inch 21.5 inch

Item Part No. AWHS1R043 AWHS1R070 AWHS1R101 AWHA1C050 AWHA1C070 AWHA1C101 AWHA1C156 AWHA1C215

Number of communication

ports 1 port 2 ports 3 ports

Interface 100BASE-TX / 10BASE-T

Baud rate 100 Mbps / 10 Mbps, Auto negotiation (Note 2)

Connecter shape RJ-45 (Note 3)

Cable total length 100 m 328.084 ft (500 m 1,640.42 ft when using a repeater) (Note 4)

Communication cable UTP cable (Category 5 or higher)

Number of web client

simultaneous connections Max. 4

Communication method Full-duplex / Half-duplex

Communication protocol TCP/IP, UDP/IP

DNS Name server support

DHCP Correspondence of automatic IP address acquisition

FTP server / client Server function: Transfer file / Client function: Transfer data and file

HTTP server / client Server function: Customer web / Client function: Web browser

SNTP Correspondence of time setting function

Notes: 1) Ethernet is a registered trademark of FUJIFILM Business Innovation Corp. and Xerox Corp.

2) Switching between different speeds is done automatically by auto negotiation function.

3) Be careful not to apply excessive static electricity to the metal parts of the connector.

4) T he maximum length of the cable is 100 m 328.084 ft in accordance with the standards, but depending on the operating environment, a ferrite

core may be installed to reduce noise. May be required. It is also recommended that the hub be installed near the control panel and that it be

used at 10 m 32.808 ft or less.

13

Page14

WH

SPECIFICATIONS

Interface specifications

Serial port communication specifications (Same for both standard and advanced models)

Item Type RS-232C RS-422 / RS-485

Communication standard Conforms to RS-232C (Non insulation type) Conforms to RS-422 / RS-485 (Non insulation type)

Number of communication

ports 1 port *Can be switched with xAscender Studio

Conditions for Baud rate 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200 bit/s (Note 1)

communication Data bits 7 bits / 8 bits

with external Parity none / even / odd

devices Stop bit 1 bit / 2 bit

Transmission distance Max. 15 m 49.213 ft (for advanced model: Max. 15 m 49.213 ft)

(Total length) (Baud rate: 19,200 bps) Max. 500 m 1,640.42 ft (Baud rate: 115.2 kbps)

Terminal resistance No termination (Note 2)

Connector D-Sub 9 pins (Note 3) (Connector supplied with advanced model)

Notes: 1) Communication conditions depend on the communications state of PLCs or other slave devices. Please check with the actual devices when

some commercial devices with RS-485 interface are connected. The number of connected devices, transmission distance, and transmission

speed may be different according to using transmission line.

2) When connected to the termination, it is recommended that a 120Ω, 1/2W or better termination resistor be connected between the communi-

cation lines.

3) Use standard commercially available 9-pin D-sub male connector.

USB port specifications

Standard model Advanced model

Type 4.3 inch 7 inch 10.1 inch 5 inch 7 inch 10.1 inch 15.6 inch 21.5 inch

Item Part No. AWHS1R043 AWHS1R070 AWHS1R101 AWHA1C050 AWHA1C070 AWHA1C101 AWHA1C156 AWHA1C215

Number of ports 1 port 1 port 2 ports

USB specifications USB Host

Electrical specifications Complies with USB 2.0

Connector shape USB Type A (Note 1)

Transmission speed 480 Mbps (High speed mode)

Maximum current Max. 500 mA

Notes: 1) Take care of handling of the connector not to add an excessive static electricity on the metal part of the connector.

2) The format of the external memory should be in FAT32 or FAT. The max number of files inside external memory depends on the type of

formatting. (Supports up to 32 GB capacity.)

• FAT32: Max. 65,535 files

• FAT: Max. 512 files

SD memory card specifications

Standard model Advanced model

Type 4.3 inch 7 inch 10.1 inch 5 inch 7 inch 10.1 inch 15.6 inch 21.5 inch

Item Part No. AWHS1R043 AWHS1R070 AWHS1R101 AWHA1C050 AWHA1C070 AWHA1C101 AWHA1C156 AWHA1C215

Support media SD memory card, SDHC memory card (Note 1)

Supported format Conforms to SD standard (Note 2)

standard (Please format with a format software for SD memory cards.)

Notes: 1) Industrial or business use SD memory cards (SLC type) are recommended. Check the operating temperature range of the SD memory card

before use.

2) T he format of the external memory should be in FAT32 or FAT. The max number of files inside external memory depends on the type of

formatting. (Supports up to 32 GB capacity.)

• FAT32: Max. 65,535 files

• FAT: Max. 512 files

14

Page15

WH

DIMENSIONS (Unit: mm in) The CAD data can be downloaded from our website.

AWHS1R043 / AWHS1R070 / AWHS1R101 Standard model AWHA1C050 Advanced model

L

X (Display) 147 5.787

109 4.291

H Y (Display) 107 65.8

4.213 2.591

52 8 136 5.354

2.047 0.315

A

D T 96

3.780 Panel cutout dimensions

B Panel cutout dimensions

Part No. A B L H X Y D T

AWHS1R043 136 5.354 96 3.780 147 5.787 107 4.213 96.4 3.795 55.2 2.173 29 1.142 5 0.197

AWHS1R070 176 6.929 136 5.354 187 7.362 147 5.787 155.5 6.122 88 3.465 29 1.142 5 0.197

AWHS1R101 271 10.669 186 7.323 282 11.102 197 7.756 224.3 8.831 126.8 4.992 28 1.102 6 0.236

(Tolerance (except T): ±1 mm ±0.039 in

T tolerance: ±0.5 mm ±0.020 in )

AWHA1C070 / AWHA1C101 / AWHA1C156 / AWHA1C215 Advanced model

L

X (Display)

H Y (Display)

A

D T

B Panel cutout dimensions

Part No. A B L H X Y D T

AWHA1C070 176 6.929 136 5.354 187 7.362 147 5.787 152.6 6.008 91.6 3.606 45 1.772 8 0.315

AWHA1C101 271 10.669 186 7.323 282 11.102 197 7.756 217.9 8.579 136.6 5.378 52 2.047 8 0.315

AWHA1C156 411 16.181 256 10.079 422 16.614 267 10.512 345.5 13.602 195 7.677 56 2.205 8 0.315

AWHA1C215 541 21.299 336 13.228 552 21.732 347 13.661 478 18.819 269.5 10.610 56 2.205 8 0.315

(Tolerance (except T): ±1 mm ±0.039 in

T tolerance: ±0.5 mm ±0.020 in )

15

Page16

PRECAUTIONS FOR PROPER USE

Information security precautions • When using this product on a system where a PC is

When use this product you might receive damage as listed connected, make sure that checking and cleaning of

below. infection by computer virus or malicious program is

(1) Information leakage or outflow through this product performed periodically.

(2) F raudulent operation of this product by a malicious third • I t has the ability to use unencrypted communications.

party (FTP, HTTP, SMTP, PLC communications, etc.). Please

(3) O bstructing or stopping this product by a malicious third make sure that a third party cannot easily connect to the

party network used by this product.

Sufficient measures, including the following measures, • U se HTTPS when accessing this product through a

should be taken at your own risk to prevent such damages. web browser. Also, be sure to close all browsers after

accessing it.

■Data storage • Do disable the functions of the services you don't use.

• Do not storage of personal information on this product. (SNMP, NTP, VNC, DHCP, Corvina Cloud, etc.)

• Be sure to log out when you have completed the

■Password necessary setup operations.

• Please be sure to change the password since it is set to • S NMP is assumed to be used for testing purposes. It

the default value at the time of purchase. Do not use the should be disabled during operation. Furthermore, it is

default password. recommended that the product be used in an environment

• Please be responsible for managing your password so that has VPN (Virtual Private Network) or leased line

that it is not known to any third party and do not forget it. network.

If you forget your internal password, there is no way for

you to reset it. You must return the product to us and we ■Transfer / Disposal / Repair

will return it to you in its factory condition. • If the product is to be disposed of, transferred, repaired,

• Please make sure that your password is at least 8 or otherwise transferred to a third party, important

characters long and contains a combination of upper information may also be recorded on the product and on

and lower case letters, numbers and symbols so that a the external recording media used. At customer's risk,

third party cannot guess your password. please handle it with care, such as erasing it.

• D o not use the same password as your user name. Do

not use the same password as the one you are using ■Installation

elsewhere. • On the back of the unit, there are interfaces that affect

• Please change your password on a regular basis. its operation, such as power supply, external storage

media, and communication connectors. Please make

■Networks sure to install the unit in a manner that does not allow

• Use this product on a network where safety is secured unauthorized parties to touch it.

by using a firewall. ■Exemption

• The Company shall not be responsible for any information

security problems or damages that may occur to you

in the event that you fail to comply with the above

precautions in using this product.

Please contact ..........

Industrial Device Business Division

7-1-1, Morofuku, Daito-shi, Osaka 574-0044, Japan

industrial.panasonic.com/ac/e/

©Panasonic Corporation 2022

No.CE-WH-1-4 January, 2022 Specifications are subject to change without notice.