1/8ページ

Download(283.4Kb)

Low Profile Swing-Lock Bd.-to-Wire for Power (UL/CSA Certified)

Features

[SnapBee (TM)]

Low Profile [Swing-Lock] Wire-to-Board Connector for Power (UL, C-UL Standard Compliant)

1. Reinforced swing lock design

2. Header lock improves plug retention

3. Highly reliable contact design

4. Insertion guide keys prevent misalignment

5. Solder wicking prevention

6. Case disengagement prevention

7. Cost effective

Document Information

| Document Title | Hirose Electric DF57 Series |

|---|---|

| Document Type | Product Catalog |

| File size | 283.4Kb |

| Company | IIDA ELECTRONICS (Documents List) |

Documents related to this company

Document Contents

Page1

Low Profile “Swing-Lock” Board to Wire Connector for Power

DF57 Series (Compliant with UL, C-UL standards)

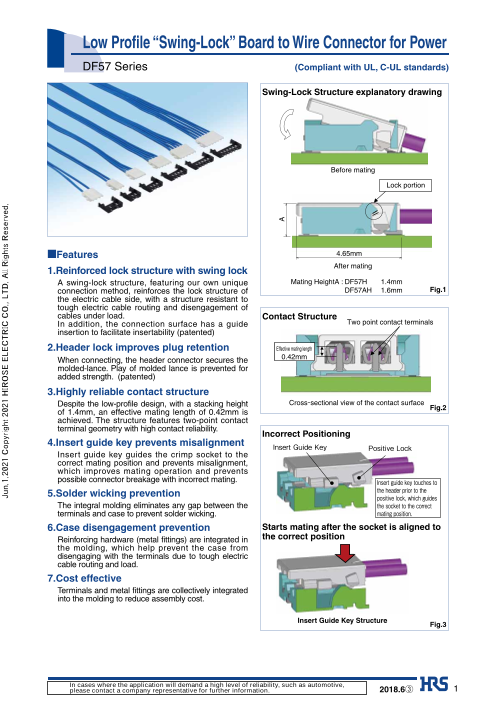

Swing-Lock Structure explanatory drawing

Before mating

Lock portion

■Features 4.65mm

1.Reinforced lock structure with swing lock After mating

A swing-lock structure, featuring our own unique Mating HeightA : DF57H 1.4mm

connection method, reinforces the lock structure of DF57AH 1.6mm Fig.1

the electric cable side, with a structure resistant to

tough electric cable routing and disengagement of

cables under load. Contact Structure

In addition, the connection surface has a guide

insertion to facilitate insertability (patented)

2. Header lock improves plug retention

When connecting, the header connector secures the

molded-lance. Play of molded lance is prevented for

added strength. (patented)

3.H ighly reliable contact structure

Despite the low-profile design, with a stacking height

of 1.4mm, an effective mating length of 0.42mm is Fig.2

achieved. The structure features two-point contact

terminal geometry with high contact reliability.

Incorrect Positioning

4. Insert guide key prevents misalignment Insert Guide Key Positive Lock

Insert guide key guides the crimp socket to the

correct mating position and prevents misalignment,

which improves mating operation and prevents

possible connector breakage with incorrect mating. Insert guide key touches to

5. Solder wicking prevention the header prior to the positive lock, which guides

The integral molding eliminates any gap between the the socket to the correct

terminals and case to prevent solder wicking. mating position.

6.C ase disengagement prevention Starts mating after the socket is aligned to

Reinforcing hardware (metal fittings) are integrated in the correct position

the molding, which help prevent the case from

disengaging with the terminals due to tough electric

cable routing and load.

7. Cost effective

Terminals and metal fittings are collectively integrated

into the molding to reduce assembly cost.

Insert Guide Key Structure Fig.3

In cases where the application will demand a high level of reliability, such as automotive,

please contact a company representative for further information. 2018.6③ 1

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

A

Page2

DF57 Series●Low Profile “Swing-Lock” Board to Wire Connector for Power

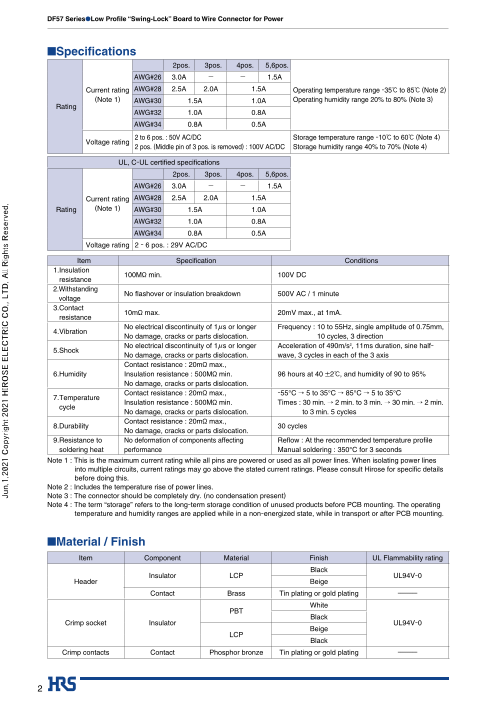

■Specifications

2pos. 3pos. 4pos. 5,6pos.

AWG#26 3.0A _ _ 1.5A

Current rating AWG#28 2.5A 2.0A 1.5A Operating temperature range -35ç to 85ç (Note 2)

(Note 1) AWG#30 1.5A 1.0A Operating humidity range 20% to 80% (Note 3)

Rating

AWG#32 1.0A 0.8A

AWG#34 0.8A 0.5A

2 to 6 pos. : 50V AC/DC Storage temperature range -10ç to 60ç (Note 4)

Voltage rating

2 pos. (Middle pin of 3 pos. is removed) : 100V AC/DC Storage humidity range 40% to 70% (Note 4)

UL, C-UL certified specifications

2pos. 3pos. 4pos. 5,6pos.

AWG#26 3.0A _ _ 1.5A

Current rating AWG#28 2.5A 2.0A 1.5A

Rating (Note 1) AWG#30 1.5A 1.0A

AWG#32 1.0A 0.8A

AWG#34 0.8A 0.5A

Voltage rating 2 - 6 pos. : 29V AC/DC

Item Specifi cation Conditions

1. Insulation

100Mø min. 100V DC

resistance

2.W ithstanding

No fl ashover or insulation breakdown 500V AC / 1 minute

voltage

3. Contact

10mø max. 20mV max., at 1mA.

resistance

No electrical discontinuity of 1µs or longer Frequency : 1 0 to 55Hz, single amplitude of 0.75mm,

4.Vibration

No damage, cracks or parts dislocation. 10 cycles, 3 direction

No electrical discontinuity of 1µs or longer Acceleration of 490m/s2, 11ms duration, sine half-

5.Shock

No damage, cracks or parts dislocation. wave, 3 cycles in each of the 3 axis

Contact resistance : 20mø max.,

6.Humidity Insulation resistance : 500Mø min. 96 hours at 40 ±2ç, and humidity of 90 to 95%

No damage, cracks or parts dislocation.

Contact resistance : 20mø max., -55°C → 5 to 35°C → 85°C → 5 to 35°C

7. Temperature

Insulation resistance : 500Mø min. Times : 30 min. → 2 min. to 3 min. → 30 min. → 2 min.

cycle

No damage, cracks or parts dislocation. to 3 min. 5 cycles

Contact resistance : 20mø max.,

8.Durability 30 cycles

No damage, cracks or parts dislocation.

9. Resistance to No deformation of components affecting Refl ow : A t the recommended temperature profi le

soldering heat performance Manual soldering : 350°C for 3 seconds

Note 1 : This is the maximum current rating while all pins are powered or used as all power lines. When isolating power lines

into multiple circuits, current ratings may go above the stated current ratings. Please consult Hirose for specifi c details

before doing this.

Note 2 : Includes the temperature rise of power lines.

Note 3 : The connector should be completely dry. (no condensation present)

Note 4 : The term “storage” refers to the long-term storage condition of unused products before PCB mounting. The operating

temperature and humidity ranges are applied while in a non-energized state, while in transport or after PCB mounting.

■Material / Finish

Item Component Material Finish UL Flammability rating

Black

Insulator LCP UL94V-0

Header Beige

Contact Brass Tin plating or gold plating ---------

White

PBT

Black

Crimp socket Insulator UL94V-0

Beige

LCP

Black

Crimp contacts Contact Phosphor bronze Tin plating or gold plating ---------

2

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

Page3

DF57 Series●Low Profile “Swing-Lock” Board to Wire Connector for Power

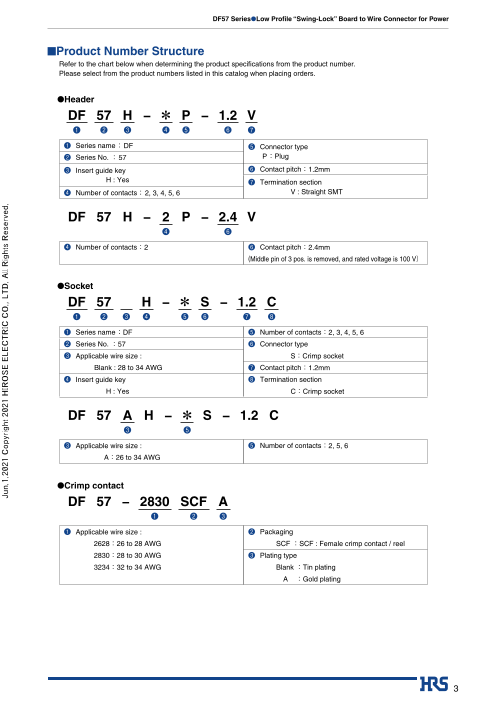

■Product Number Structure

Refer to the chart below when determining the product specifications from the product number.

Please select from the product numbers listed in this catalog when placing orders.

●Header

DF 57 H − * P − 1.2 V

❶ ❷ ❸ ❹ ❺ ❻ ❼

❶ Series name : DF ❺ Connector type

❷ Series No. : 57 P : Plug

❸ Insert guide key ❻ Contact pitch:1.2mm

H : Yes ❼ Termination section

❹ Number of contacts: 2, 3, 4, 5, 6 V : Straight SMT

DF 57 H − 2 P − 2.4 V

❹ ❻

❹ Number of contacts:2 ❻ Contact pitch:2 .4mm

(Middle pin of 3 pos. is removed, and rated voltage is 100 V)

●Socket

DF 57 H − * S − 1.2 C

❶ ❷ ❸ ❹ ❺ ❻ ❼ ❽

❶ Series name :DF ❺ Number of contacts:2, 3, 4, 5, 6

❷ Series No. :57 ❻ Connector type

❸ Applicable wire size : S:Crimp socket

Blank : 28 to 34 AWG ❼ Contact pitch:1.2mm

❹ Insert guide key ❽ Termination section

H : Yes C:Crimp socket

DF 57 A H − * S − 1.2 C

❸ ❺

❸ Applicable wire size : ❺ Number of contacts:2, 5, 6

A:26 to 34 AWG

●Crimp contact

DF 57 − 2830 SCF A

❶ ❷ ❸

❶ Applicable wire size : ❷ Packaging

2628:26 to 28 AWG SCF :SCF : Female crimp contact / reel

2830:28 to 30 AWG ❸ Plating type

3234:32 to 34 AWG Blank :Tin plating

A :Gold plating

3

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

Page4

DF57 Series●Low Profile “Swing-Lock” Board to Wire Connector for Power

■Header(SMT)

A

B

Contact No.1 P=1.2

Vacuum area

C

0.25

Above image is 3 pos.

Recommended PCB layout

(Thickness : 1.0mm)

[Specifi cation number] **

(21) : Tin plated, color : black

(23) : Tin plated, color : beige

(51) : Gold plated, color : black

Unit : mm

Part No. HRS No. No. of contacts A B C

DF57H-2P-1.2V(**) 666-0104-7 ** 2 4.1 1.2 2.5

DF57H-3P-1.2V(**) 666-0105-0 ** 3 5.3 2.4 3.7

DF57H-4P-1.2V(**) 666-0106-2 ** 4 6.5 3.6 4.9

DF57H-5P-1.2V(**) 666-0107-5 ** 5 7.7 4.8 6.1

DF57H-6P-1.2V(**) 666-0108-8 ** 6 8.9 6.0 7.3

Note 1 : Embossed tape reel packaging (5,000 pcs/reel).

Note 2 : The crossed-shaded area is a no conductive trace area.

A

B

Contact No.1

Recommended PCB layout

(Thickness : 1.0mm)

Vacuum area

C

0.25

Unit : mm [Specifi cation number] **

Part No. HRS No. No. of contacts A B C (21) : Tin plated, color : black

DF57H-2P-2.4V(**) 666-0109-0 ** 2 5.3 2.4 3.7 (23) : Tin plated, color : beige

4

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

4.35 4.35

1.4 4.1 1.4 4.1

2.225 2.225

1.55 1.55

Page5

DF57 Series●Low Profile “Swing-Lock” Board to Wire Connector for Power

●Packaging Specification

DF57H-2P-1.2V(**)

DF57H-3P-1.2V(**) 4±0.1

DF57H-2P-2.4V(**) 2±0.1 8±0.1 E E-E

D ED-D D

DIRECTION OF UNREELING

DF57H-4P-1.2V(**)

DF57H-5P-1.2V(**) 2.125±0.3 4±0.1

DF57H-6P-1.2V(**) (CENTER OF 2±0.1 8±0.1 G G-G

VACUUM AREA)

Unit : mm

F F G Part No. No. of contacts H J

F-F DF57H-4P-1.2V(**) 4 16 7.5

DF57H-5P-1.2V(**) 5 16 7.5

DIRECTION OF UNREELING DF57H-6P-1.2V(**) 6 24 11.5

■Crimp socket

[Specifi cation number] **

Above image is 3 pos. Blank : M aterial : PBT, color : white

(08) : M aterial : LCP, color : beige

(15) : M aterial : LCP, color : black

Unit : mm

Part No. HRS No. No. of contacts A B C D E F

DF57H-2S-1.2C(**) 666-0100-6 ** 2 3.5 2.98 2.6 3.2 1.2 1.2

DF57H-3S-1.2C(**) 666-0012-0 ** 3 4.7 4.18 3.8 4.4 2.4 1.2

DF57H-4S-1.2C(**) 666-0101-9 ** 4 5.9 5.38 5.0 5.6 3.6 1.2

DF57H-5S-1.2C(**) 666-0102-1 ** 5 7.1 6.58 6.2 6.8 4.8 1.2

DF57H-6S-1.2C(**) 666-0103-4 ** 6 8.3 7.78 7.4 8.0 6.0 1.2

Note 1 : The quantity is delivered per pack (1,000 pcs.). Order by number of pack.

■Socket for 26 AWG Unit : mm

Part No. HRS No. No. of contacts A B C D E F

DF57AH-2S-1.2C(**) 666-0112-0 ** 2 3.5 2.98 2.6 3.2 1.2 1.4

DF57AH-5S-1.2C(**) 666-0110-0 ** 5 7.1 6.58 6.2 6.8 4.8 1.4

DF57AH-6S-1.2C(**) 666-0111-2 ** 6 8.3 7.78 7.4 8.0 6.0 1.4

Note 1 : The quantity is delivered per pack (1,000 pcs.). Order by number of pack.

[Specifi cation number] **

Blank : M aterial : PBT, color : black

(10) : M aterial : PBT, color : white

(15) : M aterial : LCP, color : black

5

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

16±0.3

H±0.3 7.5±0.1

J±0.1 1.75±0.1 7.375±0.3 1.75±0.1

(CENTER OF

VACUUM AREA)

1

.1 0

.

+

+0 .5 0 0

.5 Ø

1

Ø1

Page6

DF57 Series●Low Profile “Swing-Lock” Board to Wire Connector for Power

■Crimp contact

[Packaging Specifi cation]

Blank : E mbossed tape packaging (40,000 pcs/reel)

(41) : Embossed tape packaging (35,000 pcs/reel)

Part No. HRS No. Packaging Quantity Finish Applicable wire Applicable socket connector

DF57-2628SCF(41) 666-0013-3 41 Reel 35,000 Tin plated

26 to 28 AWG DF57AH-*S-1.2C(**)

DF57-2628SCFA(41) 666-0033-0 41 Reel 35,000 Gold plated

DF57-2830SCF 666-0001-4 Reel 40,000 Tin plated

28 to 30 AWG

DF57-2830SCFA 666-0034-3 Reel 40,000 Gold plated DF57H-*S-1.2C(**)

DF57-3234SCF 666-0016-1 Reel 40,000 Tin plated DF57AH-*S-1.2C(**)

32 to 34 AWG

DF57-3234SCFA Under planning Reel 40,000 Gold plated

Note : Embossed tape reel packaging (40,000 pcs/reel).

Order by number of reels.

●Applicable wire (Tin plated annealed copper wire)

Wire size

Part No. Jacket outer diameter Recommended cable ●Strip length 1.0 to 1.4mm

(Stranded wire conductor)

DF57-2628SCF(41) 26 AWG( 7/Ø0.16mm) UL3302,UL3610

Ø0.88mm max.

DF57-2628SCFA 28 AWG( 7/Ø0.127mm) -----------

DF57-2830SCF 28 AWG( 7/Ø0.127mm) UL1571(Thin wire),

Ø0.5mm ‒ Ø0.63mm

DF57-2830SCFA 30 AWG( 7/Ø0.102mm) UL10584(ETFE wire)

32 AWG( 7/Ø0.08mm)

DF57-3234SCF Ø0.32mm ‒ Ø0.42mm -----------

34 AWG( 7/Ø0.08mm)

Note 1 : When using other than the recommended wire, contact your nearest Hirose sales representative.

Note 2 : The strip length is a reference value. Please make adjustments so fi nished crimps will meet the specifi ed values.

Refer to the crimping quality standards (ATAD-H0404) for details.

BTools

Type Part No. HRS No. Applicable contact

DF57-2628SCF(41)

AP105-DF57-2628S 901-4622-2

DF57-2628SCFA(41)

Applicator AP105-DF57-2830S 901-4618-5 DF57-2830SCF

AP105-DF57-2830SA 901-4645-0 DF57-2830SCFA

AP105-DF57-3234S 901-4629-1 DF57-3234SCF

Press CM-105C 901-0001-0 -----------

Hand crimping tool HT305/DF57-2830HC(Note 2) 902-4635-0 DF57-2830SCF

Contact extraction tool DF-C-PO(B) 550-0179-2 DF57-****SCF(A)

Note 1 : If any trouble has occurred due to tools other than the designated tool, Hirose bears no respoisibility for any trouble.

Note 2 : The compatible wire is limited to UL1571 of thin wire type, 28 to 30 AWG.

6

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

Page7

DF57 Series●Low Profile “Swing-Lock” Board to Wire Connector for Power

BUsage Recommendations

1. Recommended temperature

profi le

10secMAX

MAX 250ç

250

220ç

200

180ç

150

100

0

TIME (sec)

90 to 120sec 60secMAX

PRE-HEATING TIME SOLDERING TIME

The temperature profi les are based on the above conditions.

In individual applications the actual temperature may vary,depending on solder paste type, volume/

thickness and board size/thickness. Consult your solder paste and equipment manufacturer for

specifi c recommendations.

2.Recommended manual soldering Manual soldering : 350ç ± 10ç for 3 seconds

3.R ecommended screen thickness and Thickness : 0.1mm

open area ratio (Pattern area ratio) Open area ratio : 100%

4.Board warpage

Maximum of 0.02mm at the connector center, with both ends of the connector as reference points.

5.Cleaning conditions Cleaning is not recommended. When cleaning, please evaluate as if can deteriorate the

performance including mechanical operation and environmental resistance.

■ When inserting crimp-type (solderless) terminals to crimping (solderless) sockets, to maintain

6.Precautions reliable performance, please do not insert obliquely.

■ DO NOT mate/un-mate non-terminated plugs with non-mounted receptacles.

This may lead to damage or deformation of the contacts.

■Removal of the holding electric cable may cause damage so please be careful.

■ DO NOT apply fl ux to the contact terminals when hand soldering the receptacle to the board.

Wicking of the fl ux into the electrical contact areas may lead to connection failures.

■ Slight discoloration on the insulating materials will not affect form, fit or function of the

connectors.

■ Please refer to the documents "DF57 Series Cable assembly Procedure ETAD-H0421", "Crimp

condition" and "DF57-****SCF(A)(**) Crimp quality standards ATAD-H0404" for the cable

assembly procedures.

■P lease refer to the "DF57H Series Mating/Unmating Operation Instruction Manual (ETAD-H0652)"

for the connector operation.

7

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

TEMPERATURE(ç)

Page8

DF57 Series●Low Profile “Swing-Lock” Board to Wire Connector for Power

7. I nsertion and removal operation

method Mating

① Determine position, fitting ② Insert the cable side ③ Push the contact portion side

the external form

Un-mating

① Engage lever ② Pull up and release the ③ T he reinforced lock is also released

simple lock and the un-mating is complete

8. Mating compatibility

DF57H DF57

Header

DF57H DF57 DF57H DF57

Socket

Mating compatibility Y Y N Y

Additional guiding

Y N - N

keys

® 2-6-3,Nakagawa Chuoh,Tsuzuki-Ku,Yokohama-Shi 224-8540,JAPAN

TEL: +81-45-620-3526 Fax: +81-45-591-3726

http://www.hirose.com

http://www.hirose-connectors.com

The characteristics and the specifications contained herein are for reference purpose. Please refer to the latest customer drawings prior to use.

8 The contents of this catalog are current as of date of 06/2018. Contents are subject to change without notice for the purpose of improvements.

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.