1/12ページ

Download(605Kb)

Miniature Waterproof Shielded Connectors

1. Ease of shielded termination and connector assembly

2. Protects against water and dust

3. Simplified assembly procedure

4. Bayonet lock

5. Safety standard certified

6. High current rating capacity

Patent TW I314798

Document Information

| Document Title | Hirose Electric LF Series (waterproof) |

|---|---|

| Document Type | Product Catalog |

| File size | 605Kb |

| Company | IIDA ELECTRONICS (Documents List) |

Documents related to this company

Document Contents

Page1

Miniature Waterproof Shielded Connectors

LF Series

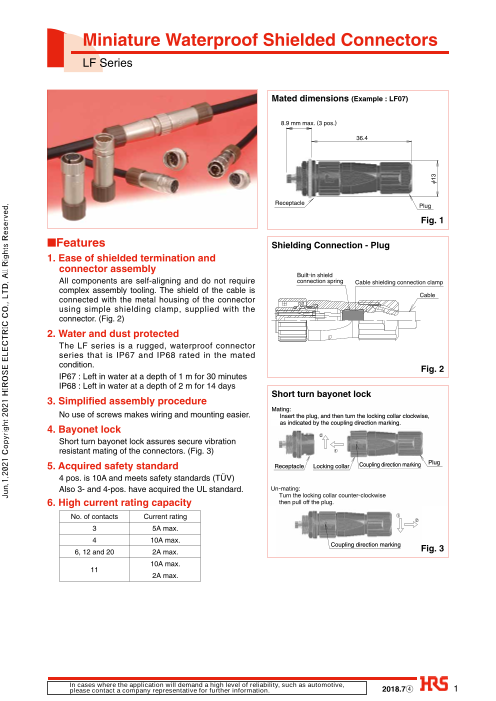

Mated dimensions (Example : LF07)

8.9 mm max. (3 pos.)

36.4

Receptacle

Plug

Fig. 1

■Features Shielding Connection - Plug

1. Ease of shielded termination and

connector assembly

Built-in shield

All components are self-aligning and do not require connection spring Cable shielding connection clamp

complex assembly tooling. The shield of the cable is

Cable

connected with the metal housing of the connector

using simple shielding clamp, supplied with the

connector. (Fig. 2)

2. Water and dust protected

The LF series is a rugged, waterproof connector

series that is IP67 and IP68 rated in the mated

condition. Fig. 2

IP67 : Left in water at a depth of 1 m for 30 minutes

IP68 : Left in water at a depth of 2 m for 14 days

Short turn bayonet lock

3. Simplified assembly procedure

Mating:

No use of screws makes wiring and mounting easier. Insert the plug, and then turn the locking collar clockwise,

as indicated by the coupling direction marking.

4. Bayonet lock

2

Short turn bayonet lock assures secure vibration

resistant mating of the connectors. (Fig. 3) 1

5. Acquired safety standard Receptacle Locking collar Coupling direction marking Plug

4 pos. is 10A and meets safety standards (TÜV)

Also 3- and 4-pos. have acquired the UL standard. Un-mating:

Turn the locking collar counter-clockwise

6. High current rating capacity then pull off the plug.

No. of contacts Current rating 1

2

3 5A max.

4 10A max.

Coupling direction marking

6, 12 and 20 2A max. Fig. 3

10A max.

11

2A max.

In cases where the application will demand a high level of reliability, such as automotive,

please contact a company representative for further information. 2018.7④ 1

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

Ø13

Page2

LF Series●Miniature Waterproof Shielded Connectors

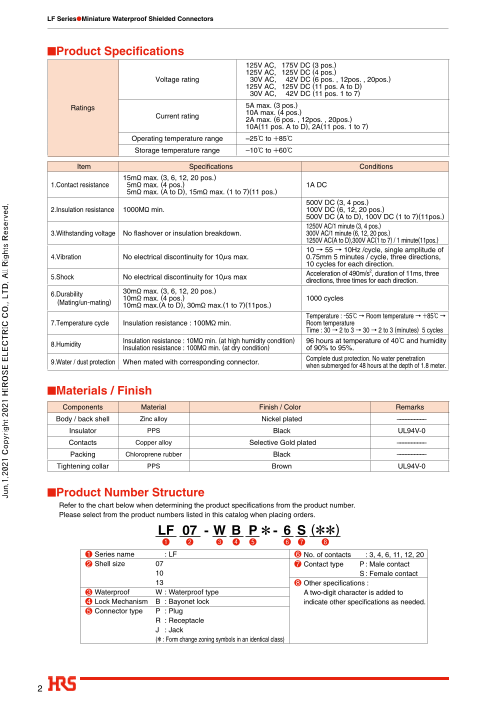

■Product Specifi cations

125V AC, 175V DC (3 pos.)

125V AC, 125V DC (4 pos.)

Voltage rating 30V AC, 42V DC (6 pos. , 12pos. , 20pos.)

125V AC, 125V DC (11 pos. A to D)

30V AC, 42V DC (11 pos. 1 to 7)

Ratings 5A max. (3 pos.)

10A max. (4 pos.)

Current rating

2A max. (6 pos. , 12pos. , 20pos.)

10A(11 pos. A to D), 2A(11 pos. 1 to 7)

Operating temperature range –25ç to +85ç

Storage temperature range –10ç to +60ç

Item Specifi cations Conditions

15mø max. (3, 6, 12, 20 pos.)

1.Contact resistance 5mø max. (4 pos.) 1A DC

5mø max. (A to D), 15mø max. (1 to 7)(11 pos.)

500V DC (3, 4 pos.)

2.Insulation resistance 1000Mø min. 100V DC (6, 12, 20 pos.)

500V DC (A to D), 100V DC (1 to 7)(11pos.)

1250V AC/1 minute (3, 4 pos.)

3.Withstanding voltage No fl ashover or insulation breakdown. 300V AC/1 minute (6, 12, 20 pos.)

1250V AC(A to D),300V AC(1 to 7) / 1 minute(11pos.)

10 → 55 → 10Hz /cycle, single amplitude of

4.Vibration No electrical discontinuity for 10µs max. 0.75mm 5 minutes / cycle, three directions,

10 cycles for each direction.

2

Acceleration of 490m/s , duration of 11ms, three

5.Shock No electrical discontinuity for 10µs max

directions, three times for each direction.

6.Durability6. 30mø max. (3, 6, 12, 20 pos.)

10mø max. (4 pos.) 1000 cycles(Mating/un-mating) 10mø max.(A to D), 30mø max.(1 to 7)(11pos.)

Temperature : -55ç → Room temperature → +85ç →

7.Temperature cycle Insulation resistance : 100Mø min. Room temperature

Time : 30 → 2 to 3 → 30 → 2 to 3 (minutes) 5 cycles

Insulation resistance : 10Mø min. (at high humidity condition) 96 hours at temperature of 40ç and humidity

8.Humidity

Insulation resistance : 100Mø min. (at dry condition) of 90% to 95%.

Complete dust protection. No water penetration

9.Water / dust protection When mated with corresponding connector.

when submerged for 48 hours at the depth of 1.8 meter.

■Materials / Finish

Components Material Finish / Color Remarks

Body / back shell Zinc alloy Nickel plated ––––––––––

Insulator PPS Black UL94V-0

Contacts Copper alloy Selective Gold plated ––––––––––

Packing Chloroprene rubber Black ––––––––––

Tightening collar PPS Brown UL94V-0

■Product Number Structure

Refer to the chart below when determining the product specifications from the product number.

Please select from the product numbers listed in this catalog when placing orders.

LF 07 - W B P * - 6 S (**)

❶ ❷ ❸ ❹ ❺ ❻ ❼ ❽

1 Series name : LF 6 No. of contacts : 3, 4, 6, 11, 12, 20

2 Shell size 07 7 Contact type P : Male contact

10 S : Female contact

13 8 Other specifications :

3 Waterproof W : Waterproof type A two-digit character is added to

4 Lock Mechanism B : Bayonet lock indicate other specifications as needed.

5 Connector type P : Plug

R : Receptacle

J : Jack

(* : Form change zoning symbols in an identical class)

2

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

Page3

LF Series●Miniature Waterproof Shielded Connectors

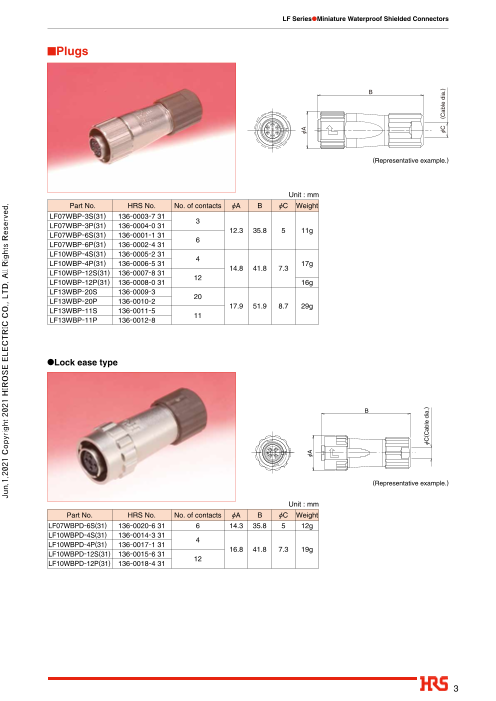

■Plugs

B

(Representative example.)

Unit : mm

Part No. HRS No. No. of contacts ØA B ØC Weight

LF07WBP-3S(31) 136-0003-7 31

3

LF07WBP-3P(31) 136-0004-0 31

12.3 35.8 5 11g

LF07WBP-6S(31) 136-0001-1 31

6

LF07WBP-6P(31) 136-0002-4 31

LF10WBP-4S(31) 136-0005-2 31

4

LF10WBP-4P(31) 136-0006-5 31 17g

14.8 41.8 7.3

LF10WBP-12S(31) 136-0007-8 31

12

LF10WBP-12P(31) 136-0008-0 31 16g

LF13WBP-20S 136-0009-3

20

LF13WBP-20P 136-0010-2

17.9 51.9 8.7 29g

LF13WBP-11S 136-0011-5

11

LF13WBP-11P 136-0012-8

●Lock ease type

B

(Representative example.)

Unit : mm

Part No. HRS No. No. of contacts ØA B ØC Weight

LF07WBPD-6S(31) 136-0020-6 31 6 14.3 35.8 5 12g

LF10WBPD-4S(31) 136-0014-3 31

4

LF10WBPD-4P(31) 136-0017-1 31

16.8 41.8 7.3 19g

LF10WBPD-12S(31) 136-0015-6 31

12

LF10WBPD-12P(31) 136-0018-4 31

3

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

ØA

ØA

ØC(Cable dia.)

ØC (Cable dia.)

Page4

LF Series●Miniature Waterproof Shielded Connectors

■Receptacles

●Front panel mount type・Solder Type

C

D

E

F(HEX)

(Representative example.)

Unit : mm

Part No. HRS No. No. of contacts ØA ØB C D ØC E F Weight

LF07WBR-3P 136-1003-2

3 16.55

LF07WBR-3S 136-1004-5

10.3 13 7.65 1M9∞0.75 11 4g

LF07WBR-6P 136-1001-7 15.05

6

LF07WBR-6S 136-1002-0 15.25

LF10WBR-4P 136-1005-8

4 19.05 6g

LF10WBR-4S 136-1006-0

12.8 15.3 7.75 M11∞0.75 13

LF10WBR-12P 136-1007-3 5g

12 17.25

LF10WBR-12S 136-1008-6 6g

LF13WBR-20P 136-1009-9 9g

20 17.25

LF13WBR-20S 136-1010-8 10g

15.9 18.3 7.75 M14∞0.75 17

LF13WBR-11P 136-1011-0 9g

11 19.05

LF13WBR-11S 136-1012-3 10g

●Front panel mount type・Through hole Type

C

D

E

F(HEX)

(Representative example.)

Unit : mm

Part No. HRS No. No. of contacts ØA ØB C D E F Weight

LF13WBR-20SD 136-1017-7 20 15.9 18.3 17.5 7.75 M14∞0.75 17 9g

4

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

ØB ØB

ØA ØA

Page5

LF Series●Miniature Waterproof Shielded Connectors

■Receptacles

●Rear panel mount type・Solder Type

D(HEX) C

E

(Representative example.)

Unit : mm

Part No. HRS No. No. of contacts ØA ØB C D E Weight

LF10WBRB-4P 136-1118-4 4 19.05

LF10WBRB-12P 136-1013-6 12.8 18.3 17 M14∞0.75 10g

12 17.25

LF10WBRB-12S 136-1014-9

LF13WBRB-20S 136-1018-0 20

15.9 21.5 19.25 20 M17∞0.75 16g

LF13WBRB-11S 136-1019-2 11

●Rear panel mount type ・ Through hole Type

D(HEX) C

E

(Representative example.)

Unit : mm

Part No. HRS No. No. of contacts ØA ØB C D E Weight

LF10WBRB-12PD 136-1015-1

12 12.8 18.3 17.5 17 M14∞0.75 9g

LF10WBRB-12SD 136-1016-4

■Jacks

C

(Representative example.)

Unit : mm

Part No. HRS No. No. of contacts ØA ØB C ØD Weight

LF07WBJ-3P 136-2003-8

3

LF07WBJ-3S 136-2004-0

10.3 11.5 36.3 5 11g

LF07WBJ-6P 136-2001-2

6

LF07WBJ-6S 136-2002-5

LF10WBJ-4P 136-2005-3

4

LF10WBJ-4S 136-2006-6

12.8 13.8 42.4 7.3 16g

LF10WBJ-12P 136-2007-9

12

LF10WBJ-12S 136-2008-1

LF13WBJ-20P 136-2009-4 29g

20

LF13WBJ-20S 136-2010-3 30g

15.9 16.9 52.4 8.7

LF13WBJ-11P 136-2011-6 29g

11

LF13WBJ-11S 136-2012-9 30g

5

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

ØB

ØA

ØA

ØA

ØB

ØB

ØD (Cable dia.)

Page6

LF Series●Miniature Waterproof Shielded Connectors

■CAP

●For Receptacles

B

(Representative example.)

Unit : mm

Part No. HRS No. Applicable connector ØA B Weight

LF07WBR-6P

LF07WBR-6S

LF07WBR-C 136-3008-7 12.3 4g

LF07WBR-3P

LF07WBR-3S

LF10WBR-4P

LF10WBR-4S

LF10WBR-12P

LF10WBR-12S

LF10WBR-C 136-3001-8 LF10WBRB-4P 14.8 5g

LF10WBRB-12P

8.8

LF10WBRB-12S

LF10WBRB-12PD

LF10WBRB-12SD

LF13WBR-20P

LF13WBR-20S

LF13WBR-11P

LF13WBR-C 136-3003-3 LF13WBR-11S 17.9 7g

LF13WBR-20SD

LF13WBRB-20S

LF13WBRB-11S

6

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

ØA

Page7

LF Series●Miniature Waterproof Shielded Connectors

BApplicable tools

Unit : mm

Description Part No. HRS No. LF series Applicable cable dia.

Manual cable HR10A-TC-02 150-0041-2 5 (Note)

clamp crimp LF-TC-01 150-0234-6 7.3 · 8.7

(Representative example.) Note : Applicable cable dia. is only 5mm for LF series.

BSolder termination fixture

(Representative example.) (Representative example.)

Part No. HRS No. Applicable connectors

LF07BP-T01 150-0232-0 LF07WBP-**

LF07BJ-T01 150-0233-3 LF07WBJ-**

LF10BP-T01 150-0235-9 LF10WBP-**

LF10BJ-T01 150-0236-1 LF10WBJ-**

LF13BP-T01 150-0237-4 LF13WBP-** Note : It is applicable regard less of given

LF13BJ-T01 150-0238-7 LF13WBJ-** alphabets or Numbers shown at *.

BPanel Cutout Unit : mm

Alignment guide

Shell size A B Weight

LF07WBR-** Ø9.05 8.1

LF10WBR-** Ø11.05 10.2

0.7 to 2

LF13WBR-**

Ø14.05 13.1

LF10WBRB-**

+0.05

B 0

LF13WBRB-** Ø17.05 16.1 0.7 to 4.8

BContact position arrangement and specifications

Shell size LF07 LF10 LF13

9 1

1

B C 2 3 4 5

6 1 4 8 10 2

Contact arrangement 3 1

1

5 2 A D

6 7 8 9 10

7 12 11 3 11 12 13 14 15

2 4 3 3 2 6 1

2 3 4 16 17 18 19

5 4 5 6 7 20

No. of contacts 3 6 4 12 11 20

4 7

Withstanding voltage 1250V AC 300V AC 1250V AC 300V AC AC300V

AC1250V AC300V

4 7

Current rating 5A 2A 10A 2A 2A

10A 2A

Insulation resistance 1000Mø

4 7

Contact resistance 15mø 5mø 15mø 15mø

5mø 15mø

4 7

Solder pot inner diameter 1.15mm 0.8mm 1.7mm 0.8mm 0.8mmØ1.7 Ø0.8

Note 1 : The contact configuration as viewed from the female contact connector mating side.

Note 2 : The ▼ symbol indicates polarizing key position.

Note 3 : Withstanding voltages are test voltage values.

7

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

.0

5

+0 0A

Page8

LF Series●Miniature Waterproof Shielded Connectors

□Termination and Assembly Instructions

The connectors are delivered with pre-assembed condition and the disassembly as shown No.1.

No. Illustration Operation

1 Solder termination fixture

Plug disassembly

1 Plug 1 Insert the plug into securely held solder

termination fixture as shown.

Fixture Part No. Applicable connector

Locking collar LF07BP-T01 LF07WBP-6S,6P,3S,3P

LF10BP-T01 LF10WBP-4S,4P,12S,12P

Insertion direction LF13BP-T01 LF13WBP-20S,20P,11S,11P

2 Body / insulator assembly

2 Loosen the backshell turning it counter

Backshell clockwise and remove it from the body/

insulator assembly.

Note

Note Vice fixed ban

When removing, assembling and wiring, be

Vice A

sure to use a solder termination fixture.

A Detail view Retaining ring Directly fixing the locking collar in place with

a vice etc.. could lead to damage,

Vice deformation or lacuna of retaining ring.

1 Solder termination fixture

Jack Disassembly

Jack 1 Insert the jack into the securely held solder

termination fixture as shown.

Fixture Part No. Applicable connector

LF07BJ-T01 LF07WBJ-6S,6P,3S,3P

Insertion direction LF10BJ-T01 LF10WBJ-4S,4P,12S,12P

LF13BJ-T01 LF13WBJ-20S,20P,11S,11P

Body / insulator assembly 2 Loosen the backshell turning it2

counterclockwise.

Backshell

Note

When removing, assembling and wiring, be

Note Vice fixed ban

sure to use a solder termination fixture.

Vice

Directly fixing the body in place with a vice

etc.. could lead to damage or deformation.

Vice

Backshell Connector Assembly

2 1 1 Apply a coating of Loctite 7649

(Manufactured by Henkel Japan, Ltd,) primer

to the threaded sections of the backshell and

the tightening collar. Completely dry the

coated surfaces.

Threaded section Threaded section

Notes

(1) Drying time at room temperature is

approximately 30 to 70 seconds.

(2) Ensure sufficient ventilation of the area at

time of drying.

(3) Take necessary steps to protect the coated

Tightening collar surfaces from contamination.

Backshell Strain relief collar Thread the tightening collar, strain relief collar,

2 Tightening collar 2

seal bushing and the backshell over the cable

as illustrated.

Note

Threading the components may not be

Cable preparation end Gasket Cable possible after the cable-end finishing process.

8

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

Page9

LF Series●Miniature Waterproof Shielded Connectors

No. Illustration Operation

Cable preparation

3 1 Stripping dimensions 1 Strip the cable’s outer jacket to the dimensions

A Cable outer jacket illustrated in the table 1.

Table 1. Stripping Dimensions Notes

No. of Conductors A mm

(1) Exercise caution not to damage the shielding

3

8 to 9

6 mesh.

4 13 to 14 Any damage to the cable’s outer jacket may

Shielding mesh (2)12 14 to 15

affect the waterproof performance of the

22 to 23 (No.A to D)

11

23 to 24 (No.1 to 7) assembled connector.

20 23 to 24

Shielding mesh Cable outer jacket

Wires 2 Fold back the shielding mesh over the cable’s2

outer jacket assuring that it is uniform on its

diameter.

Shielding mesh

4 to 5mm

(Folded back)

Wires Cable outer jacket

Stripping dimensions

3 Strip the wires to the dimensions illustrated in

3 Cable outer jacket

the Table 2.

Table 2. Stripping Dimensions

B Wires NoteNo. of Conductors B mm

3 2.5±0.5 When stripping the wires exercise caution not

6 2±0.5 to damage it’s insulation, folded over

4 3±0.5 shielding mesh or cable’s outer jacket.

12 2±0.5

3±0.5 (No.A to D) It may cause deffects in insulation,

11

2±0.5 (No.1 to 7) conduction, and waterproof performance.

Conductors 20 2±0.5

4 Soldering

1 Soldering conditions

Soldering iron tip temperature: 350±10ç

Soldering time: within 5 sec.

Notes

(1) Assure that the solder compound is

sufficiently melted on the soldering iron tip.

(2) When applying, make sure that the solder will

flow correctly at all the contact surfaces

between the conductor and the contact.

C 2 – 1 6, 12, 11(No.1 to 7), 20 Conductors2 – 1 Wire

Table 3 Heat shrink tubing Dimensions

(1) Place a heat-shrink tubing (inside diameter of

Insulator No. of No. of contacts C mm 1.1 mm min.) over every other wire.

Conductors

Contact Perform the soldering of the contact and the

6 1 to 6 4

(2) conductor, with the wire’s insulation touching

1 to 9 4

12 the contact as shown.

10 to 12 6 After soldering, slide the heat shrink tubing

1 to 4 6

Heat-shrink tubing 11 (3) over the soldered joint and shrink it. The 5 to 7 4 tubing should touch the insulator as shown.

1 to 5,16 to 20 4

20 6 to 15 6

Insulator

Insulator wall – 2 3, 4, 11(No.A to D) Conductors

2 2– 2

(1) Perform the soldering of the contact and the

conductor, with the wire’s insulation touching

Insulator Contact Contact Wire insulation the contact as illustrated.

Insulator wall (2) When soldering, to maintain the insulation

between adjacent contacts. Make sure that

the wire’s insulation remains below the edge

Wire insulation of the insulator’s wall 0.5 mm min., as

illustrated.

Solder 0.5 mm min.

9

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

Page10

LF Series●Miniature Waterproof Shielded Connectors

No. Illustration Operation

4 3 D Cable outer jacket 3 After the soldering, keep a distance of D

between the contact end and the cable’s

Table 4. Wire Dimensions

outer jacket as illustrated.

No. of Conductors D mm

Note

3

6 to 7

6 The distance of D is required in order to

Shielding mesh 4 10 to 11 assure correct assembly of the backshell.

(Folded back) 12 13 to 14

11

18 to 19

20

Solder termination fixture Crimping of the Shielding Clamp

5 1

Body / insulator assembly 1 After completion of the soldering operations

carefully remove (holding on the locking collar)

the body/insulator assembly from the solder

termination fixture.

Note

Exercise caution not to damage or deform the

Soldered joints solder joints.

2 Wrap the folded over shielding mesh with 5 to

2 Cable outer jacket

6mm wide copper tape to assure that it will

Cable outer jacket

Wires Copper tape

not become loose.

Apply the copper tape so that the shielding

mesh does not protrude from under it.

Note

After wrapping the copper tape, the tape

Shielding mesh 5 to 6mm

Copper tape should overlap itself by 2mm max.

3 Insert the “U” shaped shielding clamp over the

3

copper tape as shown on the illustration.

Cable outer jacket

Copper tape It is critical that the overlap of the copper tape

Ground clamp 1±0.5mm is located inside the shielding clamp as shownCable outer jacket

on the illustration.

Copper tape

Note

When the end of the copper tape wrapping is

positioned at the open side of the ground

Wires Shielding clamp fitting, the end portion of the copper tape

Shielding mesh wrapping will no longer be covered by the

ground fitting when the ground fitting is

Overlap of the copper tape crimped.

4 Using commercially available pliers bend the

4

open ends of the shielding clamp as illustrated,

Commercially assuring that it stays in place. The dimension

available pliers of E. between opposing edges of the shielding

clamp is necessary to assure correct final

E crimp.

Table 5

Shell size E

LF07 5mm max.

LF10

Shielding clamp 7mm max.LF13

Overlap of the copper tape

10

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

2 mm

max.

Page11

LF Series●Miniature Waterproof Shielded Connectors

No. Illustration Operation

Crimping tool 5 Both sides of the shielding clamp must be

5 5 Forming cavity placed in the forming cavity of the tool

(as shown on the illustration) and crimped

over the cable by closing the tool completely.

Applicable Shielding clamp

Crimping tool Forming cavity cable diameter

diameter after crimping

5.3 5mm 5.3mm to5.5mm

HR10A-TC-02

7.0 ––– –––

7.9mm to

7.9 7.3mm 8.1mm

LF-TC-01

9.1 8.7mm 9.1mm to9.3mm

Connector Assembly

1 , 2 Locktite area

6 Wiring side 1 to 2 threaded portion 1 Place the body/insulator assembly in the

applicable solder termination fixture.

For plug assembly

Fixture Part No. Applicable connector

LF07BP-T01 LF07WBP-6S,6P,3S,3P

LF10BP-T01 LF10WBP-4S,4P,12S,12P

LF13BP-T01 LF13WBP-20S,20P,11S,11P

For jack assembly

Body/insulator assembly Fixture Part No. Applicable connector

LF07BJ-T01 LF07WBJ-6S,6P,3S,3P

Threaded section

Backshell LF10BJ-T01 LF10WBJ-4S,4P,12S,12P

LF13BJ-T01 LF13WBJ-20S,20P,11S,11P

2 Coat the thread section of the body/insulator

assembly with Loctite 263 compound

(manufactured by Henkel Japan, Ltd.) or

equivalent, tightening it with a torque

specified in the table 6.

Notes

Wrench width : D (1) The applied loctite should not protrude out further

than the wiring side 1 to 2 threaded section. If it

Table 6 (Recommend tightening torgue) does, it may affect waterproof performance and

Shell size Tightening torque Wrench width locking. Please remove any protruding loctite

LF07 1N·m to 1.5N·m 10mm with a cloth or cotton swab. etc.

LF10 1N·m to 1.5N·m 13mm (2) It is critical that the cable itself will not turn or

LF13 1.5N·m to 2N·m 16mm twist during this operation.

It may cause breakage at the soldered area.

3 Slide forward the gasket and insert it in

3 , 4

Gasket the backshell until fully seated.

Strain relief collar 4 Slide forward the strain relief collar and insert

it in the backshell, making sure that the

opposing protrusions fit inside the

corresponding grooves, as shown on the

illustration.

Note

Groove Protrusion It is critical that the protrusions are inside the

Tightening collar corresponding grooves.

It may cause breakage, when a tightening collar is assembled.

5 5 Verify that the Locktite 7649 primer

Threaded section

(or equivalent) on the threaded sections of the

Tightening collar

backshell and tightening collar are dry.

Apply the Locktite 263 compound to the

tightening collar’s threaded section and attach

it to the backshell.

11

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

5.3

7.0

Page12

LF Series●Miniature Waterproof Shielded Connectors

No. Illustration Operation

6 6 Remove the connector from the solder6 Tightening collar termination fixture, holding it by the locking

collar. Do not pull on the cable.

It may cause breakage.

Recommended tightening torgue

Wrench width

Shell size Tightening torque Wrench width

LF07 0.8N·m to 1N·m 10mm

LF10 0.7N·m to 1N·m 14mm

LF13 1 N·m to 1.5 N·m 16mm

Confirmation of Waterproof Performance

7

After connector assembly procedure is completed,

compress air in to the connector from the mating

side under 17.6 kPa for 30 seconds check that no

air leaks out of the connector.

□Cable Specifications (Reference)

No. of contact 3 pos. 4 pos. 6 pos. 12 pos. 20 pos. 11 pos.

Material Tin plated soft copper wire

Size (mm) Ø0.18 Ø0.26 Ø0.16 Ø0.16 Ø0.16 Ø0.26 Ø0.16

Construction 20 /Ø0.18 mm dia. 20 /Ø0.26 mm dia. 7 /Ø0.16 mm dia. 7 /Ø0.16 mm dia. 7 /Ø0.16 mm dia. 26 /Ø0.26 mm dia. 7 /Ø0.16 mm dia.

Size (AWG) 20 AWG 16 AWG 26 AWG 26 AWG 26 AWG 16 AWG 26 AWG

Sectional area 0.5 1.25 0.14 0.14 0.14 1.25 0.14

Diameter (mm) Ø0.98 Ø1.5 Ø0.48 Ø0.48 Ø0.48 Ø1.5 Ø0.48

Diameter (mm) Ø1.5 (Standard) Ø2.1 (Standard) Ø0.88 (Standard) Ø0.9 (Standard) Ø0.9 (Standard) Ø2.1 (Standard) Ø0.95 (Standard)

Thickness (mm) 0.26 0.3 0.2 0.21 0.21 0.3 0.24

Material Tin plated soft copper wire

Density 85% 80% or more 85% 80% or more 80% or more 80% or more

Diameter (mm) Ø3.6 Ø5.5 Ø3.4 Ø4.2 Ø5.1 Ø6.7

Diameter (mm)

Ø5±0.2 Ø7.3±0.2 Ø5±0.2 Ø7.3±0.2 Ø8.7±0.2 Ø8.7±0.2

Remarks : The cable satisfies required specifications for UL specification.

Notes : The cable pull and twisting strength, waterproof tightness and other characteristics may differ, depending on the cable structure,

please confirm before the use.

® 2-6-3,Nakagawa Chuoh,Tsuzuki-Ku,Yokohama-Shi 224-8540,JAPAN

TEL: +81-45-620-3526 Fax: +81-45-591-3726

http://www.hirose.com

http://www.hirose-connectors.com

The characteristics and the specifications contained herein are for reference purpose. Please refer to the latest customer drawings prior to use.

12 The contents of this catalog are current as of date of 07/2018. Contents are subject to change without notice for the purpose of improvements.

Jun.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

Jacket Shield Insulator Conductor