種類豊富に取り揃えています。

基板外観検査装置 Sherlockシリーズのご紹介です。

Sherlock-3D-1000S

Sherlock-300I

Sherlock-300F

Sherlock-300B

・Sherlockシリーズの特長

・オプションソフト

・装置仕様

このカタログについて

| ドキュメント名 | 基板外観検査装置 Sherlockシリーズ 総合カタログ(英語版) |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 2.2Mb |

| 登録カテゴリ | |

| 取り扱い企業 | 株式会社レクザム (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログ(基板外観検査装置 Sherlockシリーズ 総合カタログ(英語版))の内容

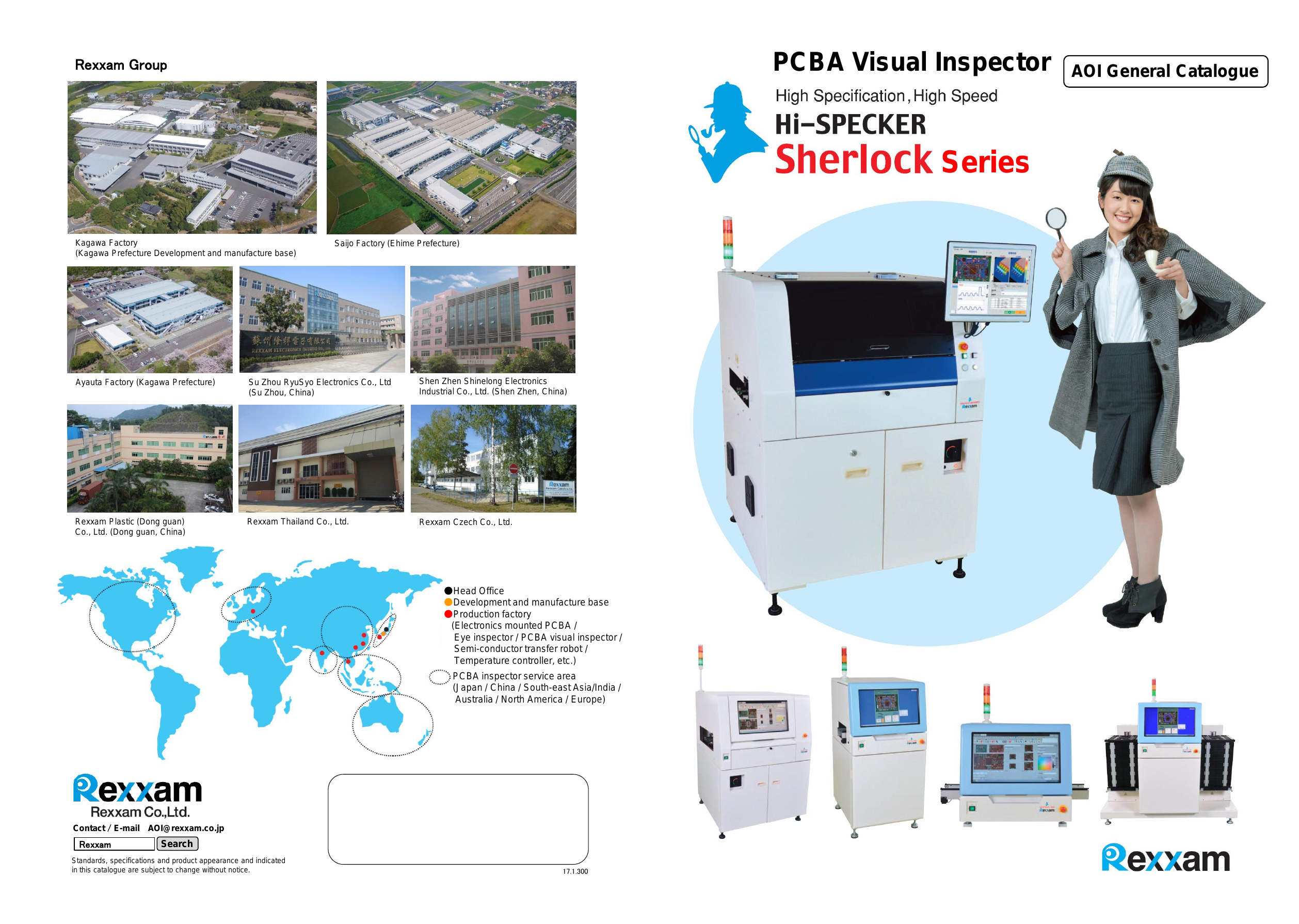

Page 1:Rexxam GroupContact/E-mail AOI@rexxam.co.jpStandards, specifications and product appearance and indicatedin this catalogue are subject to change without notice.PCBA Visual InspectorSeries17.1.300●Head Office●Development and manufacture base●Production factory(Electronics mounted PCBA /Eye inspector / PCBA visual inspector /Semi-conductor transfer robot /Temperature controller, etc.)PCBA inspector service area(Japan / China / South-east Asia/India /Australia / North America / Europe)Rexxam SearchAOI General CatalogueKagawa Factory(Kagawa Prefecture Development and manufacture base)Saijo Factory (Ehime Prefecture)Su Zhou RyuSyo Electronics Co., Ltd(Su Zhou, China)Shen Zhen Shinelong ElectronicsIndustrial Co., Ltd. (Shen Zhen, China)Ayauta Factory (Kagawa Prefecture)Rexxam Thailand Co., Ltd. Rexxam Czech Co., Ltd.Rexxam Plastic (Dong guan)Co., Ltd. (Dong guan, China)

Page 2:●High level of 2D inspection such as solderinspection and character recognition can beperformed by installing RGB lighting and warnwhite LED lighting just as Sherlock-300/500L.7) 2D inspection is also availableData of soldercan be obtainedImage of telecentric laserData omissiondue to shade6) Equipped a telecentric laser●Solder and micro components beside tallcomponents can be inspected by reducing theshade due to masses of light.QFPInspection frames and parameter can be set by one click.●Automatic data creation function for major components such as chips and QFPs to support the teachingoperation even if there is no library data.●Inspection data is created automatically simply by selecting the type of component.●Time for the data creation can be shortened to less than half compared with the ordinary way.5) Automatic inspection settingCross-section profile(Amount of floating is visible)Cross section isdisplayed simply bytracing the arbitrarypositionRotate 3D image3D image2D imageSimple displayswitch between2D and 3DCorresponding part is enlarged by selecting inspection item●3D image makes visual check easy by rotating and rescaling to see the condition of the component from different angle.Image of Multi-scan●High accuracy imaging of 20mm height is available (measurable) with the 12μm resolution.●Multiple scan, maximum of 4 times, can be performed according to the height of objects.●High accuracy inspection of height is also available even though the large components mounted PCBAsuch as electrolytic capacitor.Model with 24μm12μm : Sherlock-3D-1000S●Enables the inspection of micro components by imaging with the industry-leading resolution of 12μm.(185×135mm PCBA)(185×135mm PCBA)Model with 2M cameraImaging frequency : 88 timesReduced by80%Sherlock-3D-1000SImaging frequency : 16 times●Inspection speed is improved by enlarging the visual field angle so as to decrease the imaging frequency.2) 12M camera (resolution of 12μm) is mountedSherlock-3D-1000S●相较于对元件高度只能进行疑似判定的2维检查,这是通过实测让定量检查成为可能的3维方式。●采用灯泡色LED照明与RGB照明的2D检查也同时可行。●能获知2D检查难以检出的元件或引脚的漂起、焊锡等的体积。1) High-speed inspection (3D 2D)●Inspection speed 5,000㎟/sec (@12μm lens)●High speed inspection equivalent to 2D inspection3) Multi-scan procedure has achieved the high-accuracy repeatability14) Simple visual judgement with 3D imagePCBA image taken by Sherlock-3D-1000S with RGB lighting.2Typical line laserScreen for the detailed paramenter setting●3D system enables the quantitative inspection by actualmeasurement in comparison with 2D system whichinspects the height of parts spuriously.●3D-inspection detects the floating of components andleads, and the volume of solder etc. which areundetectable in 2D inspection.●Also achieved 2D inspection by both warm white LEDlighting and RGB lighting.Screen for the component type selectionLarge sizePCBMedium sizePCBIn-lineBig/smallcomponents

Page 3:Realize high productivity andlabor-saving by multiple operation1 operator for 1 unit●Compact, excellent in stability, and suitable for multiple-unit layout.●Simple and intuitive by touch panel operation withoutkeyboard and mouse.●Visual check can be performed by enlarging theinspection objects on 21.5" large touch panel.3) Simple inspection●Compact desktop type for easy installation.●Exclusive stand is available as an option.2) Compact body●Inspection speed : 5,000㎟/sec (@18.7μm lens)1) High speed inspectionImage of placement of Sherlock-300I●Keeps high production rate by allowing visual check judgment ofmultiple equipments in distant place.3) Viewer software (Optional)●Easy installation to the existing line such as the inspection ofPCBA before reflow process.2) Slim body (Width 620mm)●Inspection speed 5,000㎟/sec (@18.7μm lens)1) Applicable to high-speed lineHeight measurement image3) Height measurement (Optional)●Available of inspecting 45mm height part fromthe surface of board with our originally designedlens unit which has excellent depth of field.●Rich line up of lens magnification are providedfor the inspection from small size to the bigsize components.2) Both tall and small components are inspectable●7,500㎟/sec (@18.7μm lens)1) High speed inspectionSherlock-500L●Possible to mount a point heightmeasurement function.●The floating of component canbe inspected by measuring theheight at a point by laser.Sherlock-300F3) Optimization and labor-saving21.5” touch panel display●Compact equipment integrating loader and unloader which firstappeared in the industry.●Passed and rejected PCBAs are sorted automatically withoutoperators.●Automatic sorting allows a single operator to operate multiple units.●Available of multiple operation .※)Placing of a conveyor recommended in between Sherlock-300I and reflow oven.3 4Large sizePCBMedium sizePCBIn-lineHeightmeasurementMedium sizePCBIn-line Slim bodyMedium sizePCBDesk top CompactMedium sizePCBCompactbatch-lineLabor-saving1) Compact batch-line2) Compact bodySherlock-300I620mmChip mounter Mounter for varianttypes of componentsReflow ovenSolder printing machineSherlock-300B

Page 4:1) Intuitive operation by touch paneloperationNavigation information and its correspondingarea are indicated with different colors.Pre-installed libraryB) Navigation modeThe teaching procedure is navigated by displayingthe next recommended operation contents and areaon the screen.A) Pre-installed libraryUsing pre-installed part data simplifies theprogramming and reduces the time forteaching to approximately one-third.(Comparing to our previous model)2) Adopting a telecentric lens developedby RexxamFeaturesSherlock-500L/300 Series●All operations can be performed on thetouch panel display.●Zoom in/out the screen image, select and move thedata by intuitive operation with your fingertips.Image of a bridge between leadsImage of telecentric lens21.5" touch panel display●Effective in detection of bridges and solder ballsbetween components and leads.Schematic diagramof RGB lightingSchematic diagram ofwarm LED lightingComponent inspection: Comparison of images with different lighting3) RGB LED lighting warm white LED lightingA) RGB LightingAdapted to solder inspection by irradiating the RGBlighting from different steps and recognizing 3D shapethrough the color distribution of inspection objects.Solder inspection: image with RGB lightingSoldered correctly Image with RGB LEDlighting5 6Schematic diagramof solder filletUnsoldered Image with warm whiteLED lighting4) Helpful teaching support toolsRejectionrangePassrangeB) Warm white LED lightingRemarkable improvement of color inspection withwarm white LED.Sherlock-300F Sherlock-300BSherlock-500L Sherlock-300IC) HistogramThe threshold to become the pass standard can be set without question based on the distribution ofscore and the measured value by every inspection item by tallying the test results.Display of histogramThreshold

Page 5:Sherlock-3D-1000S Sherlock-500L Sherlock-300I Sherlock-300F Sherlock-300BEditor ○* ○ ○ ○ ○Manager ○ ○ ○ ○ ○Repair ○ ○ ○ ○ ○SPC ○ ○ ○ ○ ○Viewer - ○ ○ ○ ○MODELOptionalSoftware●The latest teachingdata is automaticallyacquired.Solder printingmachineMounter forcomponentsSoftware to display the information of rejectedcomponents and record the reason of rejection.●The past inspection history and repair historycan be easily browsed and managed by specifyinga serial number.●Possible to connect a bar-code reader.Inspection history is displayed by using serial code.●Reasons of rejection input can be tabulated withSPC (see SPC chapter of below).4) Repair ~Repair support software~SherlockManager1) Editor ~Off-line teachig software~2) Viewer ~Remote visual check software~3) Manager ~Centralized management system~Software to automatically synchronize the data, library and inspection history between machines and Editor.●This system always allows the latest teaching data to edit and inspect.●Modificated data is only overwritten through Manager to shorten the time of data transfer.This software allows creation and editing of inspection data on other PC than the one on the main unit whilekeeping the operation of main unit.The data can be created in a same mannerwith the main unit. (Partially limited)On-line equipmentOff-line system●Upload inspection history●Modification ofteaching data●Data tuning●Teaching data is automaticallyuploaded to the server .Optional software在线机EDITOR● Correspandence table of optional software5) SPC ~Inspection status statistical software~This software provides the information helpful for theprocess improvement.●It tabulates the rejection by equipment, model, date,circuit name, contents of rejection, and etc.●Checking the contents of rejection and the processin real time leads to the early detection of abnormalityin process.Screen for tabulation of inspection result by model* Sherlock-3D-1000S requires exclusive optional software.On-line equipment7 8Chip mounter Reflow ovenOn-line equipment在线机Inspection datahistoryEven if on-line machine isunder the operation, dataediting is available by off-lineteaching system separatelyEdited inspection dataInspection with theedited inspection dataInspect PCBASoftware to perform visual check on the remotely-positioned PC without handling the main unit.●Visual check of multiple units is possible on one PC by switching the screen.Edit inspection dataSolder printingmachineChip mounter Mounter forcomponentsReflow oven< Schematic diagram of Centralized management system >

Page 6:Sherlock-300I Sherlock-300F Sherlock-300B○ ○ ○- - -50mm(W)×50mm(D) to330mm(W)×250mm(D)50mm(W)×50mm(D) to330mm(W)×250mm(D)50mm(W)×80mm(D) to330mm(W)×250mm(D)0.5 to 2.0mm 0.5 to 2.0mm 0.5 to 2.0mm1kg 1kg 1kg25mm(Resolution:12.4μm/pixel)30mm(Resolution:18.7μm/pixel)25mm(Resolution:12.4μm/pixel)30mm(Resolution:18.7μm/pixel)25mm(Resolution:12.4μm/pixel)30mm(Resolution:18.7μm/pixel)70mm 70mm 20mm12.4μm/pixel18.7μm/pixel(Selected before shipment)12.4μm/pixel18.7μm/pixel(Selected before shipment)12.4μm/pixel18.7μm/pixel(Selected before shipment)0402(Resolution:12.4μm/pixel)0603(Resolution:18.7μm/pixel)0402(Resolution:12.4μm/pixel)0603(Resolution:18.7μm/pixel)0402(Resolution:12.4μm/pixel)0603(Resolution:18.7μm/pixel)5,000mm2/s(※in case of resolution:18.7μm/pixel)5,000mm2/s(※in case of resolution:18.7μm/pixel)5,000mm2/s(※in case of resolution:18.7μm/pixel)Missing parts, displacement, defective standing,polarity, foreign objects, wrong parts, inversion,OCR (character recognition)Missing parts, displacement, defective standing,polarity, foreign objects, wrong parts, inversion,OCR (character recognition)Missing parts, displacement, defective standing,polarity, foreign objects, wrong parts, inversion,OCR (character recognition)Excess, Insufficient, unsoldered,bridges, solder ballExcess, insufficient, unsoldered,bridges, solder ballExcess, insufficient, unsoldered,bridges, solder ball25.4×13.5mm(Resolution:12.4μm/pixel)38.3×20.3mm(Resolution:18.7μm/pixel)25.4×13.5mm(Resolution:12.4μm/pixel)38.3×20.3mm(Resolution:18.7μm/pixel)25.4×13.5mm(Resolution:12.4μm/pixel)38.3×20.3mm(Resolution:18.7μm/pixel)6mm(Resolution:12.4μm/pixel)10mm(Resolution:18.7μm/pixel)6mm(Resolution:12.4μm/pixel)10mm(Resolution:18.7μm/pixel)6mm(Resolution:12.4μm/pixel)10mm(Resolution:18.7μm/pixel)±50μm ±50μm ±50μm2M Pixel 2M Pixel 2M PixelRGB warm white LED RGB warm white LED RGB warm white LEDOptical system with the object sidetelecentric lensOptical system with the object sidetelecentric lensOptical system with the object sidetelecentric lensRight to left/left to right(selected before shipment)Right to left Right to leftHigh rigidity biaxial driving High rigidity biaxial driving High rigidity biaxial drivingAir clamp Air clamp Air clampAutomatic Automatic Automatic910±60mm - -Front Front Front21.5" touch panel display 21.5" touch panel display 21.5" touch panel displayWindows 7 Professional 64bitJapanese/English (selected before shipment)Windows 7 Professional 64bitJapanese/English (selected before shipment)Windows 7 Professional 64bitJapanese/English (selected before shipment)8GB 8GB 8GBConformance to SMEMAstandard - -10 to 35℃/30 to 80%RH (no condensation) 10 to 35℃/30 to 80%RH (no condensation) 10 to 35℃/30 to 80%RH (no condensation)-10 to 60℃/30 to 80%RH(no condensation) -10 to 60℃/30 to 80%RH(no condensation) -10 to 60℃/30 to 80%RH(no condensation)AC100 to 240V ±10%(single phase)50/60HzAC100 to 240V ±10%(single phase)50/60HzAC100 to 240V ±10%(single phase)50/60HzCompressed air :0.5MPaAir consumption :5Nℓ/minCompressed air :0.5MPaAir consumption :5Nℓ/minCompressed air :0.5MPaAir consumption :5Nℓ/minW620×D758×H1,294mm*in case of the pass line 900mmW620×D758×H594mm W1,496×D786×H1,328mm154kg 92kg 252kgSherlock-3D-1000S Sherlock-500LM size ○ ○L size ○ ○Dimensions50mm(W)×50mm(D) to510mm(W)×460mm(D)50mm(W)×50mm(D) to510mm(W)×460mm(D)0.3 to 4.0mm 0.3 to 4.0mm3kg 3kgUpper side 30mm 45mmUnder side 20mm 45mmHorisontal resolution:24μm(3D)、12μm(2D)Height resolution:12μm8.7μm/pixel13.7μm/pixel18.7μm/pixel(Selected before shipment)06030402(Resolution:8.7、13.7μm/pixel)0603(Resolution:18.7μm/pixel)5,000mm2/s (3D 2D)7,500mm2/s(※in case of resolution:18.7μm/pixel)ComponentinspectionMissing parts, displacement, defective standing,polarity, foreign objects, wrong parts, inversion,OCR (character recognition), floating of lead,floating of partsMissing parts, displacement, defective standing,polarity, foreign objects, wrong parts, inversion,OCR (character recognition)Solder inspectionExcess, insufficient, unsoldered, bridges,solder ball, volume of solderExcess, insufficient, unsoldered,bridges, solder ball49mm (width of scan) 17.8×17.8mm(Resolution:8.7μm/pixel) 28.1×28.1mm(Resolution:13.7μm/pixel) 38.3×38.3mm(Resolution:18.7μm/pixel)5mm 3mm(Resolution:8.7μm/pixel) 5mm(Resolution:13.7μm/pixel) 10mm(Resolution:18.7μm/pixel)±7μm ±50μm12M Pixel 4M PixelRGB warm white LED RGB warm white LEDOptical system with both side telecentric lensOptical system with the object sidetelecentric lensRight to Left/Left to right(selected before shipment)Right to left/left to right(selected before shipment)Ball screw biaxial driving High rigidity biaxial drivingAir clamp Air clampAutomatic Automatic925±45mm 920±50mmFront Front/back (selected before shipment)17" touch panel display 21.5" touch panel displayOSWindows 7 Professional 64bitJapanese/English (selected before shipment)Windows 7 Professional 64bitJapanese/English (selected before shipment)Memory 32GB 8GBConformance to SMEMAstandard Conformance to SMEMAstandard10 to 35℃/30 to 80%RH (no condensation) 10 to 35℃/30 to 80%RH (no condensation)-10 to 60℃/30 to %RH(no condensation) -10 to 60℃/30 to 80%RH(no condensation)AC200 to 240V ±10%(single phase)50/60HzAC100 to 240V ±10%(single phase)50/60HzCompressed air :0.5MPaAir consumption :5Nℓ/minCompressed air :0.5MPaAir consumption :5Nℓ/minW985×D1,100×H1,400mm*in case of the pass line 900mmW920×D927×H1,336mm*in case of the pass line 900mm354kg 290kgMonitorPCPCBAclamping unitWidth adjustment fortransferring conveyorInspection speedMain inspectionitemsImaging rangeDepth of fieldMaximum weight of PCBAHeight limit ofPCBA(Clearance)ResolutionPasslineReference position for PCBAwidthMinimum componentsto be inspected (JIS)Weight (excluding PC)ModelInterface between equipmentsEnvironment conditions for operationEnvironment conditions for storagePower supplyCompressed air consumptionDimensions of main unit(excluding protruding portion)Repeatability of positioningCameraLightingStructure of imaging unitFlow direction of PCBADriving system of imaging unitPCBAs to beinspectedThickness of PCBA9 10Specifications※Standards, specifications and product appearance indicated in this catalogue are subject to change without notice.※Numbers in the specification are based on the internal regulations of Rexxam.