1/3ページ

ダウンロード(4.2Mb)

HDA測定装置は、インジェクターの特性を総合的に解析します!

メーヴァルト(MOEHWALD)社は1973年にラルフ・メーワルト氏によって設立され、ディーゼル噴射システム用部品のテストの関するライセンス契約を1990年にロバートボッシュと結び、ボッシュ製インジェクションテストベンチの販売を開始しました。

1999年にボッシュグループの傘下に入り、ボッシュグループの中でボッシュのテスト計測技術を使用した噴射システム用テストベンチの外販を行うことができる唯一の会社です。

その他、ガソリン用テストベンチも取り扱います。

近年は燃料電池用測定装置も開発しております。

このカタログについて

| ドキュメント名 | MOEHWALD / インジェクター噴射量・噴射率計測ユニット |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 4.2Mb |

| 取り扱い企業 | 株式会社シーケービー (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

Moehwald GmbH

Michelinstrasse 21

D-66424 Homburg/Germany

Contact: Gerd Scherer

Phone: +49 6841 707 311

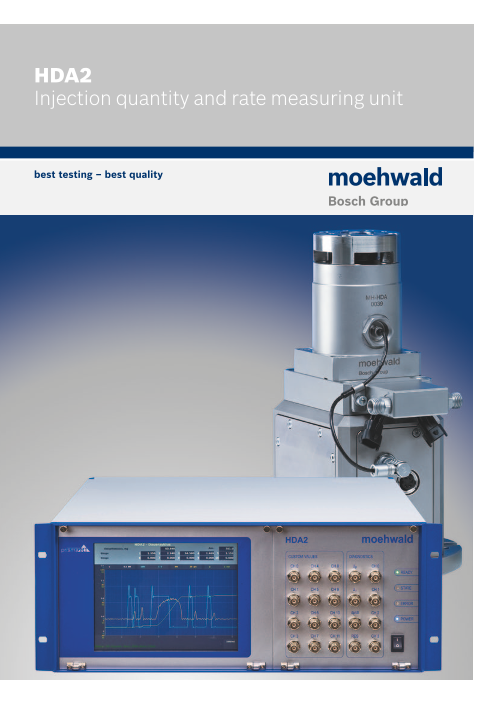

E-Mail: g.scherer@moehwald.de HDA2

www.moehwald.de

Injection quantity and rate measuring unit

best testing – best quality

Technical Data

Measurement HDA-500 HDA-5000 HDA-25000

Injection frequency 30 – 3100 1/min 30 – 3100 1/min 30 – 3100 1/min

Mass measuring resolution ~ 0.01 mg * <0.5 mg * <1 mg * (<0.4 mg * at 40 °C)

Mass measuring repeatability 0 – 16: < 0.075 5 – 400: < 2 5 – 600: 3

(mg/injection) 16 – 60: < 0.1 > 400: 0.2 % of > 600: 0.5 % of

60 – 200: < 0.2 reading reading

> 200: < 0.5

Total mass injected per cycle 0,1 – 500 mg 1 – 5000 mg 1 – 25000 mg

Aquisition frequency 100 kHz 100 kHz 100 kHz

Bandwidth of injection signal

(adjustable by digital filter parameter) ≤ 10 kHz ≤ 10 kHz ≤ 4 kHz

Minimum delay

between 2 partial injections 30 µs 100 µs 100 µs

Number of injections per cycle 1 – 10 1 – 10 1 – 10

Back pressure

(adjustable py parameters) 5 – 95 bar 5 – 95 bar 5 – 250 bar

Cooling circuit flow 100 l/h at 40 °C 100 l/h at 40 °C 200 l/h at 40 °C

Number of cycle measurements

with statistic values 2 – 10000 2 – 10000 2 – 10000

Automatic injection detection yes yes yes

Automatic injection timing

measurement for energizing and

hydraulic injection signal yes yes yes

Timing error of energizing timing ≤ 1 µs *** ≤ 1 µs *** < 1 µs ***

Timing error of hydraulic timing ≤ 10 µs *** ≤ 10 µs *** ≤ 10 µs ***

Calibrated pressure range of pressure sensor 0 – 100 bar (abs) 0 – 100 bar (abs) 0 – 280 bar (abs)

Calibrated temperature range

of pressure sensor 20 – 160 °C ** 20 – 160 °C ** 20 – 160 °C **

Synchronization via 1/rev. pulse or

rotary encoder yes yes yes

* Dependent on the compressibility of the test medium

** Standard, for cold tests –40 up to +160°C

*** Dependent on the rising time of the signal – typical 0,1 µs for hydraulic injection

© All rights reserved by Moehwald GmbH, including the right to file in-

dustrial property rights. We reserve all rights of disposal such as copying

and distribution rights. Subject to technical modifications and errors.

This document is a schematic representation and not an operating

manual. There may be some differences in illustrations compared to the

operating manual. Please refer to the operating manual with regard to

the proper use of the system.

Page2

2 | HDA2 Injection quantity and rate measuring unit HDA2 Injection quantity and rate measuring unit | 3

Special features and operating principle Components

The HDA measurement device enables a comprehensive analysis of injector characteristics.

The injected mass and the injection rate shape are determined with a high sample rate and recorded. HDA2

measuring

By analog input of the injector energizing signals in the HDA electronics an extended timing analysis of computer

the injection cycle can be performed.

If additionally e.g. the rail pressure signal is supplied, the interaction of the injection system and the

complete system is visible. A multiplicity of curves and measuring values are stored in the result data for

each recorded injection cycle, which are available for an extensive investigation of the injector.

Special features Operating principle

Standard measurement range up to 500 mg with the The HDA measurement head consists of a closed

HDA-500, 5000 mg with the HDA-5000 respectively measurement chamber of constant volume filled with

25000 mg with the HDA-25000 test medium. An injection into the closed chamber

Flexible adaptation capability using type-specific volume increases the chamber pressure. The pres-

injector adapters sure increase depends on the compressibility of the

Automatic evaluation of up to 10 partial injections test medium. By the direct measurement of the

Automatic injection timing analysis of up to 10 partial sound velocity in the test medium, the influences

injections (power on / power off response time, etc.) of temperature, density, and compressibility are

Medium-independent measuring principle detected. Therefore the unit can be used with diffe- Measuring computer HDA2 19˝ Measuring head

Robust design, no moving parts, no wear rent test media without the involvement of HDA2 measuring computer is downward compatible Measurement chamber with high-precision,

Measurement computer as 19˝rack, 4 RU medium equations that are generally imprecise. to HDA1 system. Existing HDA measuring heads can temperature-compensated pressure sensor

Dimensions of measurement head of the HDA-500 be used without any problems. Ultrasonic sensor

enable installation at a cylinder head Dual Core i7 CPU Safety pressure limiting valve

Installation space and hydraulic connections of the Tempered stainless Real time operating system (based on Linux) Drainage valve

Injector

HDA-500 are compatible with EMI2/ E MI21 steel chamber 10.1˝ Touch display Amplifier electronics

Up to 10 kHz bandwidth for the injection rate signal Cooling channels 6 ADC channels, ± 10 V, with 100 kHz sampling Ultrasonic evaluation electronics

Pressure control

Real-time acquisition of all measured values valve Pressure sensor rate, of which 4 can be used for user-specific tasks Geometrical compatible to the EMI

Control at the unit itself, or remote control 0 – 100 bar 3 analogue channels ± 10 V, 100 kHz (chamber Counterpressure is generated by the test sample

Open host interface-DLL for remote control of the unit Path of ultrasonic Drainage valve pressure, chamber temperature, pressure rate) itself (no nitrogen supply needed)

Optional first-shot measurement capability Calibration independent of the measuring head

Broad temperature range from –40 °C to 160 °C Ultrasonic (replaceable)

Two freely usable analog input channels sensor

±10 V, 100 kHz (control, rail pressure)

Back presssure is generated by the test sample Evaluation

itself (no nitrogen supply needed) electronic

Synchronous acquisition of injector control,

rail pressure and injection rate

HDA HDA-500 HDA-5000 HDA-25000

measuring with stiff with large

head clamping engine

fixture for injector

truck injectors

Page3

Moehwald GmbH

Michelinstrasse 21

D-66424 Homburg/Germany

Contact: Lukas Übelacker

Phone: +49 6841 707 510 NEW

E-Mail: L.uebelacker@moehwald.de HDA2

www.moehwald.de

Injection quantity and rate measuring unit

best testing – best quality

Technical Data

Measurement HDA-500 HDA-5000 HDA-25000

Injection frequency 30 – 3100 1/min 30 – 3100 1/min 30 – 3100 1/min

Mass measuring resolution ~ 0.01 mg * <0.5 mg * <1 mg * (<0.4 mg * at 40 °C)

Mass measuring repeatability 0 – 16: < 0.075 5 – 400: < 2 5 – 600: 3

(mg/injection) 16 – 60: < 0.1 > 400: 0.2 % of > 600: 0.5 % of

60 – 200: < 0.2 reading reading

> 200: < 0.5

Total mass injected per cycle 0,1 – 500 mg 1 – 5000 mg 1 – 25000 mg

Acquisition frequency 100 kHz 100 kHz 100 kHz

Bandwidth of injection signal

(adjustable by digital filter parameter) ≤ 10 kHz ≤ 10 kHz ≤ 4 kHz

Minimum delay

between 2 partial injections 30 µs 100 µs 100 µs

Number of injections per cycle 1 – 10 1 – 10 1 – 10

Back pressure

(adjustable py parameters) 5 – 95 bar 5 – 95 bar 5 – 245 bar

Cooling circuit flow 100 l/h at 40 °C 100 l/h at 40 °C 200 l/h at 40 °C

Number of cycle measurements

with statistic values 2 – 10000 2 – 10000 2 – 10000

Automatic injection detection yes yes yes

Automatic injection timing

measurement for energizing and

hydraulic injection signal yes yes yes

Timing error of energizing timing ≤ 1 µs *** ≤ 1 µs *** < 1 µs ***

Timing error of hydraulic timing ≤ 10 µs *** ≤ 10 µs *** ≤ 10 µs ***

Calibrated pressure range of pressure sensor 0 – 100 bar (abs) 0 – 100 bar (abs) 0 – 280 bar (abs)

Calibrated temperature range

of pressure sensor 20 – 160 °C ** 20 – 160 °C ** 20 – 160 °C **

Synchronization via 1/rev. pulse or

rotary encoder yes yes yes

* Dependent on the compressibility of the test medium

** Standard, for cold tests –40 up to +160°C

*** Dependent on the rising time of the signal – typical 0,1 µs for hydraulic injection

© All rights reserved by Moehwald GmbH, including the right to file in-

dustrial property rights. We reserve all rights of disposal such as copying

and distribution rights. Subject to technical modifications and errors.

This document is a schematic representation and not an operating

manual. There may be some differences in illustrations compared to the

operating manual. Please refer to the operating manual with regard to

the proper use of the system.