1/11ページ

Download(974.5Kb)

AYAHA HYBRID WOVEN FABRIC <for CFRTP/FRTP> ver.2022

Product Catalog

AYAHA HYBRID WOVEN FABRIC <for CFRTP/FRTP> ver.2022

Movie

Document Information

| Document Title | AYAHA HYBRID WOVEN FABRIC <for CFRTP/FRTP> ver.2022 |

|---|---|

| Document Type | Product Catalog |

| File size | 974.5Kb |

| Category | |

| Company | AYAHA CORPORATION (Documents List) |

Documents related to this company

Document Contents

Page1

Full Pages For Download

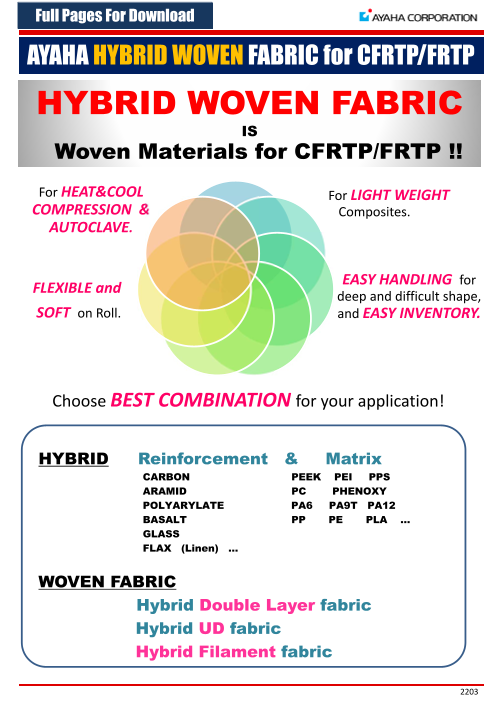

AYAHA HYBRID WOVEN FABRIC for CFRTP/FRTP

HYBRID WOVEN FABRIC

IS

Woven Materials for CFRTP/FRTP !!

For HEAI&CWWL For LIGHI WEIGHI

CWMPRESSIWN & Composites.

AUIWCLAVE.

EAST HANDLING for

FLEXIBLE and

deep and difficult shape,

SWFI on Roll. and EAST INVENIWRT.

Choose BESI CWMBINAIIWN for your application!

HYBRID Reinforcement & Matrix

CARBON PEEK PEI PPS

ARAMID PC PHENOXY

POLYARYLATE PA6 PA9T PA12

BASALT PP PE PLA …

GLASS

FLAX (Linen) …

WOVEN FABRIC

Hybrid Double Layer fabric

Hybrid UD fabric

Hybrid Filament fabric

2203

Page2

AYAHA HYBRID WOVEN FABRIC for CFRTP/FRTP

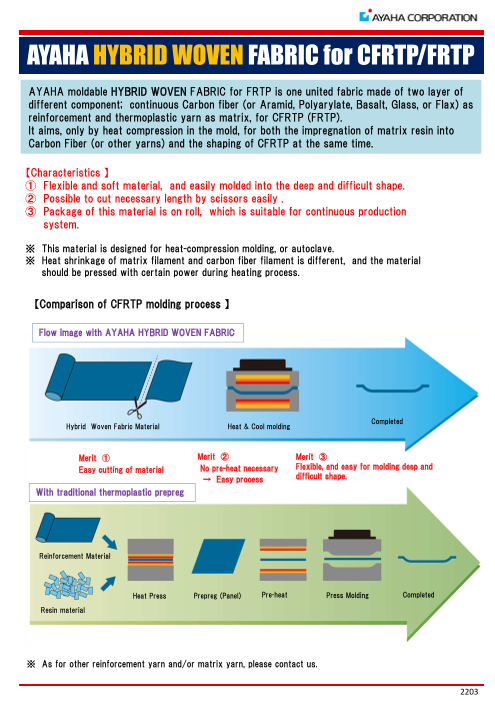

AYAHA moldable HYBRID WOVEN FABRIC for FRTP is one united fabric made of two layer of

different component; continuous Carbon fiber (or Aramid, Polyarylate, Basalt, Glass, or Flax) as

reinforcement and thermoplastic yarn as matrix, for CFRTP (FRTP).

It aims, only by heat compression in the mold, for both the impregnation of matrix resin into

Carbon Fiber (or other yarns) and the shaping of CFRTP at the same time.

【Characteristics 】

① Flexible and soft material, and easily molded into the deep and difficult shape.

② Possible to cut necessary length by scissors easily .

③ Package of this material is on roll, which is suitable for continuous production

system.

※ This material is designed for heat-compression molding, or autoclave.

※ Heat shrinkage of matrix filament and carbon fiber filament is different, and the material

should be pressed with certain power during heating process.

【Comparison of CFRTP molding process 】

Flow image with AYAHA HYBRID WOVEN FABRIC

Completed

Hybrid Woven Fabric Material Heat & Cool molding

Merit ① Merit ② Merit ③

Easy cutting of material No pre-heat necessary Flexible, and easy for molding deep and

→ Easy process difficult shape.

With traditional thermoplastic prepreg

Reinforcement Material

Heat Press Prepreg (Panel) Pre-heat Press Molding Completed

Resin material

※ As for other reinforcement yarn and/or matrix yarn, please contact us.

2203

Page3

AYAHA HYBRID WOVEN FABRIC for CFRTP/FRTP

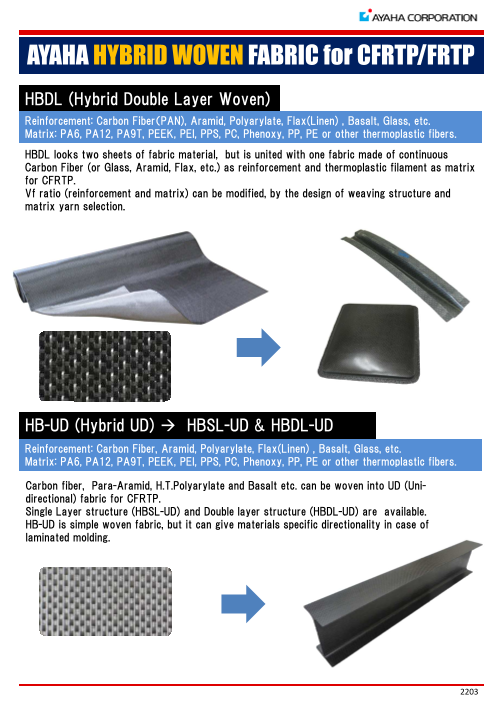

HBDL (Hybrid Double Layer Woven)

Reinforcement: Carbon Fiber(PAN), Aramid, Polyarylate, Flax(Linen) , Basalt, Glass, etc.

Matrix: PA6, PA12, PA9T, PEEK, PEI, PPS, PC, Phenoxy, PP, PE or other thermoplastic fibers.

HBDL looks two sheets of fabric material, but is united with one fabric made of continuous

Carbon Fiber (or Glass, Aramid, Flax, etc.) as reinforcement and thermoplastic filament as matrix

for CFRTP.

Vf ratio (reinforcement and matrix) can be modified, by the design of weaving structure and

matrix yarn selection.

HB-UD (Hybrid UD) HBSL-UD & HBDL-UD

Reinforcement: Carbon Fiber, Aramid, Polyarylate, Flax(Linen) , Basalt, Glass, etc.

Matrix: PA6, PA12, PA9T, PEEK, PEI, PPS, PC, Phenoxy, PP, PE or other thermoplastic fibers.

Carbon fiber, Para-Aramid, H.T.Polyarylate and Basalt etc. can be woven into UD (Uni-

directional) fabric for CFRTP.

Single Layer structure (HBSL-UD) and Double layer structure (HBDL-UD) are available.

HB-UD is simple woven fabric, but it can give materials specific directionality in case of

laminated molding.

2203

Page4

AYAHA HYBRID WOVEN FABRIC for CFRTP/FRTP

HYBRID DOUBLE LAYER WOVEN for COMPOSITES

NATURAL FLAX YARN & THERMOPLASTIC YARN

HBDL FYPLA T-701

FLAX YARN & PLA YARN

Hybrid woven fabric, made of natural FLAX yarn as a reinforcement,

and biodegradable PLA yarn as matrix.

Both are carbon-neutral and nature-friendly materials.

HBDL FYPP T-701

FLAX YARN & PP YARN

Hybrid woven fabric, made of natural FLAX yarn as a reinforcement,

and low density general-purpose PP yarn as matrix.

It is a material aiming to both carbon-neutral and light-weight.

2203

Page5

AYAHA HYBRID WOVEN FABRIC for CFRTP/FRTP

Hybrid Filament Fabric (HBFIL)

Hybrid filament fabric is woven from special hybrid filament yarn

made of two materials with different melting points.

By proper thermoforming this hybrid filament fabric in the mold,

resin with a lower melting point in the yarn melt into a matrix, and

resin with a higher melting points remains as reinforcement yarn.

This is a developed product aimed at creating FRTP products that

express the resin properties of matrix and the physical properties

of reinforcement including mechanical strength.

There are the following combinations.

Glass roving & PP GF & PP

Glass roving & PA6 GF & PA6

Carbon fiber & Phenoxy CF & PX

Polypropylene & Polyethylene PP & PE

Polyester & Low-melting-point polyester PET & CoPET

2203

Page6

AYAHA HYBRID WOVEN FABRIC for CFRTP/FRTP

Hybrid Filament Fabric (HBFIL)

【GF & PP】

Glass Roving & Polypropylene

【GF & PA6】

Glass Roving & PA6

Special flat shaped hybrid filaments consisting of glass

roving inside and PP (or PA6) filament outside, is

made into woven fabrics, without twist, of plain, twill,

or double layer weave.

This fabric shows good impregnation properties and

Cross section image* can be thermoformed in a short time.

GF & PP type is a "stampable fabric" , which has

strength of glass roving, lightweight property of

polypropylene, and flexibility of woven fabric.

Thermoforming with approx. 200~220℃

temperature is required.

GF & PA6 type is has better heat resistance.

Thermoforming with approx. 220~240℃

temperature is required.

Glass roving & PP

HBFIL GF&PP T-201 plain weave

HBFIL GF&PP T-202 twill weave

Glass roving & PA6

HBFIL GF&PA T-201 plain weave

HBFIL GF&PA T-202 twill weave

* Graphic with courtesy of PHP Fibers

2203

Page7

AYAHA HYBRID WOVEN FABRIC for CFRTP/FRTP

Hybrid Filament Fabric (HBFIL)

【CF & PX】

Carbon & Phenoxy (Thermoplastic epoxy)

Phenoxy

Special flat commingled hybrid filament yarn consisting

of 12K carbon fiber and phenoxy yarn is, without twist,

made into woven fabric of plain, twill weave, and UD

sheet.

Carbon Filament

Cross section image

The combination of highly fluid and amorphous

phenoxy resin and 12K carbon fiber enables good

impregnation in a short time by thermoforming.

For thermoforming, approx. 220~240℃ temperature

is required.

(Phenoxy resin, as matrix, is a non-crystalline resin

with a Tg point of 84 ℃, which is used as an adhesive

and is also called a thermoplastic epoxy.)

HBFIL CF&PX T-091 plain weave

HBFIL CF&PX T-092 twill weave

HBFIL-UD CF&PX T-093 UD

2203

Page8

AYAHA HYBRID WOVEN FABRIC for CFRTP/FRTP

Hybrid Filament Fabric (HBFIL)

【PP & PE】

Polypropylene & Polyethylene

Special flat shape hybrid monofilaments with high

tensile PP on the core (inside) and low melting point

PP PE on the sheath (outside), are made into double layer

PE woven fabric.

Cross section image

It has higher strength and higher modulus than general

olefin fibers, and by thermoforming you will get the

product with good impact resistance.

Lightweight material with density of 0.9.

For thermoforming approx. 140℃ temperature is

required.

(Melting point: core 165℃, sheath 120℃)

Color designed fabric is available by inserting colored

yarn.

HBFIL PP&PE T-DL400 double layer weave

HBFIL PP&PE T-DL540 BL02 Blue double layer weave

HBFIL PP&PE T-DL500 BL04 Blue double layer weave

2203

Page9

AYAHA HYBRID WOVEN FABRIC for CFRTP/FRTP

Hybrid Filament Fabric (HBFIL)

【PET & CoPET】

Polyester & Low-melting-point Polyester

High-performance hybrid multi filaments, with

high viscosity polyester on the core (inside) and

low-melting-point polyester on the sheath

(outside), are made into woven fabrics of plain,

PET twill, or double layer weave.

CoPET

Cross section image By thermoforming, it is possible to perform three-

dimensional molding that has both higher rigidity

and modulus than general polyester.

For thermoforming approx. 180~190℃

temperature is required.

(Melting point: core 250 ℃, sheath 180 ℃)

Colored fabric is available by adding colored yarn.

Single Layer HBFIL PET&CoPET T-800 single layer weave, white

HBFIL PET&CoPET T-8CX single layer weave, color

HBFIL PET&CoPET T-DL800 double layer weave, white

HBFIL PET&CoPET T-DL8CX double layer weave, color

(Color code: X = 0: white 1: Yellow 2: Red 3: cyan blue 4: black

※ other color is also available)

Double Layer

2203

Page10

AYAHA HYBRID WOVEN FABRIC for CFRTP/FRTP

HBDL (Hybrid Double Layer) & HB-UD (Hybrid UD)

【HBDL】 HYBRID DOUBLE LAYER Woven Fabric

Thickness

Weight Fabric Width

Fabric Code Structure Reinforcement Matrix Binder Weight Thickness after

Reinforcement/Matrix/Binder Vf Actual/Effect ive

molding

Category Code - - - Type g/㎡ g/㎡ % mm cm mm

HBDL CFPEEK T-001 Double Layer PAN CF3K PEEK - 323 200 / 123 55 0.5 110 / 105 0.2

HBDL CFPEI T-001 Double Layer PAN CF3K PEI - 335 200 / 135 52 0.5 110 / 105 0.2

HBDL CFPPS T-001 Double Layer PAN CF3K PPS - 335 200 / 135 53 0.5 110 / 105 0.2

HBDL CF9N T-001 S10 Double Layer PAN CF3K PA9T S10 329 200 / 115 / 14 50 0.5 110 / 105 0.2

HBDL CF6N T-007 S10 Double Layer PAN CF3K PA6 S10 349 200 / 135 / 14 46 0.5 110 / 105 0.2

HBDL CF6N T-016 S40 Double Layer PAN CF3K PA6 S40 315 200 / 70 / 45 53 0.5 110 / 105 0.2

HBDL CF12N T-005 S10 Double Layer PAN CF3K PA12 S10 324 200 / 110 / 14 48 0.5 110 / 105 0.2

HBDL CF12N T-005 S40 Double Layer PAN CF3K PA12 S40 360 200 / 110 / 50 42 0.6 110 / 105 0.25

HBDL CFPC T-001 Double Layer PAN CF3K PC - 332 200 / 132 50 0.6 110 / 105 0.2

HBDL CFPCFR T-001 Double Layer PAN CF3K PCFR *1 - 332 200 / 132 50 0.6 110 / 105 0.2

HBDL CFPP T-001 M08 Double Layer PAN CF3K PP M08 310 200 / 110 / 12 46 0.6 110 / 105 0.25

HBDL CFPE T-001 X05 Double Layer PAN CF3K PE X05 320 200 / 110 / 10 48 0.7 110 / 105 0.25

HBDL CFPX T-001 Double Layer PAN CF3K Phenoxy - 305 200 / 105 56 0.6 110 / 105 0.2

HBDL KV12N T-001 Double Layer Para-ARAMID(HM) PA12 - 267 157 / 110 50 0.5 110 / 105 0.2

HBDL GLPEI T-201 Double Layer GLASS (75 1/0) PEI - 597 362 / 235 43 0.6 110 / 105 0.3

HBDL FYPLA T-701 Double Layer FLAX (Natural) PLA - 617 306 / 311 46 1.3 100 / 100 0.4

HBDL FYPP T-701 Double Layer FLAX (Natural) PP - 980 512 / 468 41 2.3 100 / 100 0.8

【HBDL-UD】 HYBRID DOUBLE LAYER UD Woven Fabric

HBDL-UD CF6N T-001 Double Layer-UD PAN CF3K PA6 - 303 200 / 103 56 0.5 110 / 105 0.2

【HBSL-UD】 HYBRID SINGLE LAYER UD Woven Fabric

HBSL-UD CFPEEK T-001 Single Layer-UD PAN CF3K PEEK - 174 100 / 74 50 0.3 110 0.1

HBSL-UD CFPEI T-001 Single Layer-UD PAN CF3K PEI - 165 100 / 65 52 0.3 110 0.1

HBSL-UD CFPPS T-001 Single Layer-UD PAN CF3K PPS - 165 100 / 65 53 0.3 110 0.1

HBSL-UD CFPC T-001 Single Layer-UD PAN CF3K PC - 165 100 / 65 50 0.3 110 0.1

HBSL-UD CFPCFR T-001 Single Layer-UD PAN CF3K PCFR *1 - 165 100 / 65 50 0.3 110 0.1

HBSL-UD CF12N T-001 S10 Single Layer-UD PAN CF3K PA12 S10 163 100 / 55 / 8 48 0.3 110 / 105 0.1

HBSL-UD CF12N T-051 S40 Single Layer-UD PAN CF12K PA12 S40 362 192 / 110 / 60 40 0.7 110 / 105 0.2

HBSL-UD KV12N T-301 Single Layer-UD Para-ARAMID(HM) PA12 - 154 100 / 54 56 0.3 110 0.15

HBSL-UD VCPET T-401 Single Layer-UD H.T. Polyarylate PET/Co-PET - 191 83 / 108 43 0.6 110 0.15

Remarks: Above figures are representat ive one , and not guaranteed .

Thickness after mold ing is approximate figure . It may change depend ing on mold ing method and cond it ions.

*1 PCFR : Polycarbonate , F lame-retardant

【Reference Data】

【REINFORCEMENT】 【MATRIX】

Reinforcement Density Matrix properties Melting point Tg point Density

Carbon Fiber (PAN) 1.76 ~ 1.8 PA 6 (Polyamide 6) 220℃ 50℃ 1.14

E-Glass 2.55 PA 9T (Polyamide 9T) 265℃ 120℃ 1.14

PA 12 (Polyamide 12) 176℃ 47℃ 1.02

Para-ARAMID (HM) 1.45

PEEK(Polyetheretherketone) 343℃ 143℃ 1.30

H.T. Polyarylate 1.41

PEI (Polyetherimide) - 217℃ 1.27

FLAX 1.45

PPS (Polyphenylenesulfide) 285℃ 91℃ 1.34

PC (Polycarbonate) - 145~150℃ 1.20

PCFR (Polycarbonate, Flame-retardant) - 150℃ 1.20

Phenoxy (Thermoplastic Epoxy) - 84℃ 1.18

PP (Polypropylene) 167℃ ‐20℃ 0.91

PE (Polyethylene) 132℃ ‐120℃ 0.96

PLA (Polylactic acid) 170℃ 57℃ 1.25

2203

Page11

AYAHA HYBRID WOVEN FABRIC for CFRTP/FRTP

HYBRID FILAMENT Woven Fabric

Fabric Thickness

Fabric Code Yarn Weave Structure Weight Vf Thickness

Width after molding

Category Code Core&Seath - - g/㎡ % mm cm mm

【HBFIL GF & PP】

HBFIL GF&PP T-201 Glass Roving & PP Plain Hybrid x Hybrid 554 41 0.8 110 0.3

HBFIL GF&PP T-202 Glass Roving & PP Twill Hybrid x Hybrid 554 41 0.7 110 0.3

【HBFIL GF & PA6】

HBFIL GF&PA6 T-201 Glass Roving & PA6 Plain Hybrid x Hybrid 563 46 0.7 110 0.3

HBFIL GF&PA6 T-202 Glass Roving & PA6 Twill Hybrid x Hybrid 563 46 0.7 110 0.3

【HBFIL CF & PX】

HBFIL CF&PX T-091 Carbon Fiber & Phenoxy Plain Hybrid x Hybrid 297 48 0.3 110 0.2

HBFIL CF&PX T-092 Carbon Fiber & Phenoxy Twill Hybrid x Hybrid 323 48 0.3 110 0.2

HBFIL-UD CF&PX T-093 Carbon Fiber & Phenoxy UD Hybrid x Hybrid 175 48 0.2 110 0.1

【HBFIL PP & PE】

HBFIL PP&PE T-DL400 PP & PE Double Layer, Twill Hybrid x Hybrid 400 65 1.2 125 0.5

HBFIL PP&PE T-DL540 BL02 *1 PP & PE Double Layer, Twill Hybrid x Regular mix 540 71 1.7 126 0.65

HBFIL PP&PE T-DL500 BL04 *1 PP & PE Double Layer, Twill Hybrid x Regular mix 500 66 1.3 124 0.55

*1: Other colors can be prepared.

【HBFIL PET & CoPET】

HBFIL PET&CoPET T-800 White PET & CoPET Plain Hybrid x Hybrid 221 73 0.3 110 0.2

HBFIL PET&CoPET T-8C2 Red *1 PET & CoPET Plain Hybrid x Regular Color 221 87 0.3 110 0.2

HBFIL PET&CoPET T-DL800 White PET & CoPET Double Layer, Plain Hybrid x Hybrid 403 73 0.7 110 0.4

HBFIL PET&CoPET T-DL8C2 Red *1 PET & CoPET Double Layer, Plain Hybrid x Regular Color 403 80 0.7 110 0.4

*1: Other colors can be prepared.

【HYBRID FILAMENT】

Core/Sheath Std. Molding

Core/Sheath Melting point Total Density

Ratio temperature

HBFIL GF & PP - / 165℃ 41% / 59% 200~220℃ 1.65

HBFIL GF & PA6 - / 215℃ 46% / 54% 240~260℃ 1.84

HBFIL CF & PX - /Amorphous 48% / 52% 220~240℃ 1.54

HBFIL PP & PE 165℃ / 120℃ 65% / 35% 120~140℃ 0.9

HBFIL PET & CoPET 250℃ / 160℃ 73% / 27% 170~180℃ 1.38

HYBRID Woven for FRP

Fabric Code Structure Reinforcement Weight (g/㎡) Thickness (mm) Fabric Width (cm)

HBWV CFBAS T-F01 HB3/3 Twill PAN CF3K &BASALT 290 0.30 110

WOVEN BASALT T-F51 2/2 Twill BASALT 100% 300 0.30 110

Remarks: Above figures are representative one, and not guaranteed.

Thickness after molding is approximate figure. It may change depending on molding method and conditions.

【Contact】 【Sales Rep. EUROPE】

AYAHA Corporation, R&D Dept. ITOCHU Deutschland GmbH

T.Tomiyori Carsten Gifhorn

3-6-14 Minami-Honmachi, Chuo-ku, Osaka ,541-0054,JAPAN Brandstwiete 1, 20457 Hamburg, GERMANY

TEL : +81-6-6282-1081 FAX : +81-6-6252-7757 TEL: +49-40-41529-130 Fax: +49-40-41529-108

E-Mail : t_tomiyori@ayaha.co.jp E-mail : carsten.gifhorn@itochu-hamburg.de

URL : http://www.ayaha.co.jp/kogyo/products/frtp_en.html ITOCHU Deutschland GmbH www.itochu.de

2203