1/2ページ

Download(294.4Kb)

Specification - AYAHA HYBRID WOVEN FABRIC ver.2022

Product Catalog

Specification - AYAHA HYBRID WOVEN FABRIC ver.2022

Movie

Document Information

| Document Title | Specification - AYAHA HYBRID WOVEN FABRIC ver.2022 |

|---|---|

| Document Type | Product Catalog |

| File size | 294.4Kb |

| Category | |

| Company | AYAHA CORPORATION (Documents List) |

Documents related to this company

Document Contents

Page1

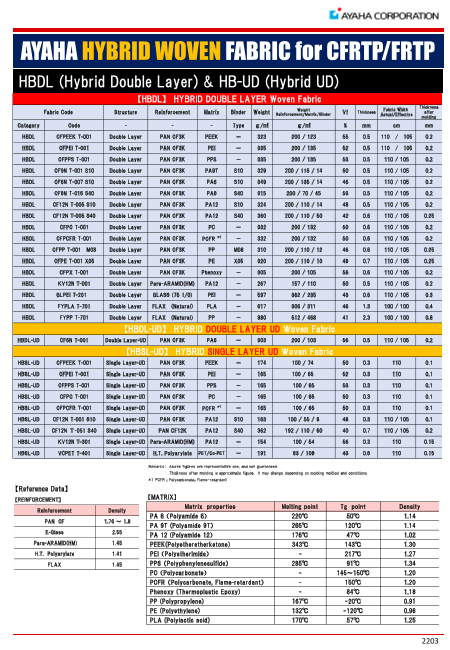

AYAHA HYBRID WOVEN FABRIC for CFRTP/FRTP

HBDL (Hybrid Double Layer) & HB-UD (Hybrid UD)

【HBDL】 HYBRID DOUBLE LAYER Woven Fabric

Thickness

Weight Fabric Width

Fabric Code Structure Reinforcement Matrix Binder Weight Vf Thickness after

Reinforcement/Matrix/Binder Actual/Effective

molding

Category Code - - - Type g/㎡ g/㎡ % mm cm mm

HBDL CFPEEK T-001 Double Layer PAN CF3K PEEK - 323 200 / 123 55 0.5 110 / 105 0.2

HBDL CFPEI T-001 Double Layer PAN CF3K PEI - 335 200 / 135 52 0.5 110 / 105 0.2

HBDL CFPPS T-001 Double Layer PAN CF3K PPS - 335 200 / 135 53 0.5 110 / 105 0.2

HBDL CF9N T-001 S10 Double Layer PAN CF3K PA9T S10 329 200 / 115 / 14 50 0.5 110 / 105 0.2

HBDL CF6N T-007 S10 Double Layer PAN CF3K PA6 S10 349 200 / 135 / 14 46 0.5 110 / 105 0.2

HBDL CF6N T-016 S40 Double Layer PAN CF3K PA6 S40 315 200 / 70 / 45 53 0.5 110 / 105 0.2

HBDL CF12N T-005 S10 Double Layer PAN CF3K PA12 S10 324 200 / 110 / 14 48 0.5 110 / 105 0.2

HBDL CF12N T-005 S40 Double Layer PAN CF3K PA12 S40 360 200 / 110 / 50 42 0.6 110 / 105 0.25

HBDL CFPC T-001 Double Layer PAN CF3K PC - 332 200 / 132 50 0.6 110 / 105 0.2

HBDL CFPCFR T-001 Double Layer PAN CF3K PCFR *1 - 332 200 / 132 50 0.6 110 / 105 0.2

HBDL CFPP T-001 M08 Double Layer PAN CF3K PP M08 310 200 / 110 / 12 46 0.6 110 / 105 0.25

HBDL CFPE T-001 X05 Double Layer PAN CF3K PE X05 320 200 / 110 / 10 48 0.7 110 / 105 0.25

HBDL CFPX T-001 Double Layer PAN CF3K Phenoxy - 305 200 / 105 56 0.6 110 / 105 0.2

HBDL KV12N T-001 Double Layer Para-ARAMID(HM) PA12 - 267 157 / 110 50 0.5 110 / 105 0.2

HBDL GLPEI T-201 Double Layer GLASS (75 1/0) PEI - 597 362 / 235 43 0.6 110 / 105 0.3

HBDL FYPLA T-701 Double Layer FLAX (Natural) PLA - 617 306 / 311 46 1.3 100 / 100 0.4

HBDL FYPP T-701 Double Layer FLAX (Natural) PP - 980 512 / 468 41 2.3 100 / 100 0.8

【HBDL-UD】 HYBRID DOUBLE LAYER UD Woven Fabric

HBDL-UD CF6N T-001 Double Layer-UD PAN CF3K PA6 - 303 200 / 103 56 0.5 110 / 105 0.2

【HBSL-UD】 HYBRID SINGLE LAYER UD Woven Fabric

HBSL-UD CFPEEK T-001 Single Layer-UD PAN CF3K PEEK - 174 100 / 74 50 0.3 110 0.1

HBSL-UD CFPEI T-001 Single Layer-UD PAN CF3K PEI - 165 100 / 65 52 0.3 110 0.1

HBSL-UD CFPPS T-001 Single Layer-UD PAN CF3K PPS - 165 100 / 65 53 0.3 110 0.1

HBSL-UD CFPC T-001 Single Layer-UD PAN CF3K PC - 165 100 / 65 50 0.3 110 0.1

HBSL-UD CFPCFR T-001 Single Layer-UD PAN CF3K PCFR *1 - 165 100 / 65 50 0.3 110 0.1

HBSL-UD CF12N T-001 S10 Single Layer-UD PAN CF3K PA12 S10 163 100 / 55 / 8 48 0.3 110 / 105 0.1

HBSL-UD CF12N T-051 S40 Single Layer-UD PAN CF12K PA12 S40 362 192 / 110 / 60 40 0.7 110 / 105 0.2

HBSL-UD KV12N T-301 Single Layer-UD Para-ARAMID(HM) PA12 - 154 100 / 54 56 0.3 110 0.15

HBSL-UD VCPET T-401 Single Layer-UD H.T. Polyarylate PET/Co-PET - 191 83 / 108 43 0.6 110 0.15

Remarks: Above figures are representative one, and not guaranteed.

Thickness after molding is approximate f igure. It may change depending on molding method and conditions.

*1 PCFR : Polycarbonate, Flame-retardant

【Reference Data】

【REINFORCEMENT】 【MATRIX】

Matrix properties Melting point Tg point Density

Reinforcement Density

PA 6 (Polyamide 6) 220℃ 50℃ 1.14

PAN CF 1.76 ~ 1.8

PA 9T (Polyamide 9T) 265℃ 120℃ 1.14

E-Glass 2.55

PA 12 (Polyamide 12) 176℃ 47℃ 1.02

Para-ARAMID(HM) 1.45 PEEK(Polyetheretherketone) 343℃ 143℃ 1.30

H.T. Polyarylate 1.41 PEI (Polyetherimide) - 217℃ 1.27

FLAX 1.45 PPS (Polyphenylenesulfide) 285℃ 91℃ 1.34

PC (Polycarbonate) - 145~150℃ 1.20

PCFR (Polycarbonate, Flame-retardant) - 150℃ 1.20

Phenoxy (Thermoplastic Epoxy) - 84℃ 1.18

PP (Polypropylene) 167℃ ‐20℃ 0.91

PE (Polyethylene) 132℃ ‐120℃ 0.96

PLA (Polylactic acid) 170℃ 57℃ 1.25

2203

Page2

AYAHA HYBRID WOVEN FABRIC for CFRTP/FRTP

HYBRID FILAMENT Woven Fabric

Fabric Thickness

Fabric Code Yarn Weave Structure Weight Vf Thickness

Width after molding

Category Code Core&Seath - - g/㎡ % mm cm mm

【HBFIL GF & PP】

HBFIL GF&PP T-201 Glass Roving & PP Plain Hybrid x Hybrid 554 41 0.8 110 0.3

HBFIL GF&PP T-202 Glass Roving & PP Twill Hybrid x Hybrid 554 41 0.7 110 0.3

【HBFIL GF & PA6】

HBFIL GF&PA6 T-201 Glass Roving & PA6 Plain Hybrid x Hybrid 563 46 0.7 110 0.3

HBFIL GF&PA6 T-202 Glass Roving & PA6 Twill Hybrid x Hybrid 563 46 0.7 110 0.3

【HBFIL CF & PX】

HBFIL CF&PX T-091 Carbon Fiber & Phenoxy Plain Hybrid x Hybrid 297 48 0.3 110 0.2

HBFIL CF&PX T-092 Carbon Fiber & Phenoxy Twill Hybrid x Hybrid 323 48 0.3 110 0.2

HBFIL-UD CF&PX T-093 Carbon Fiber & Phenoxy UD Hybrid x Hybrid 175 48 0.2 110 0.1

【HBFIL PP & PE】

HBFIL PP&PE T-DL400 PP & PE Double Layer, Twill Hybrid x Hybrid 400 65 1.2 125 0.5

HBFIL PP&PE T-DL540 BL02 *2 PP & PE Double Layer, Twill Hybrid x Regular mix 540 71 1.7 126 0.65

HBFIL PP&PE T-DL500 BL04 *2 PP & PE Double Layer, Twill Hybrid x Regular mix 500 66 1.3 124 0.55

【HBFIL PET & CoPET】

HBFIL PET&CoPET T-800 White PET & CoPET Plain Hybrid x Hybrid 221 73 0.3 110 0.2

HBFIL PET&CoPET T-8C2 Red *2 PET & CoPET Plain Hybrid x Regular Color 221 87 0.3 110 0.2

HBFIL PET&CoPET T-DL800 White PET & CoPET Double Layer, Plain Hybrid x Hybrid 403 73 0.7 110 0.4

HBFIL PET&CoPET T-DL8C2 Red *2 PET & CoPET Double Layer, Plain Hybrid x Regular Color 403 80 0.7 110 0.4

*2: Other colors can be prepared.

【HYBRID FILAMENT】

Core/Sheath Std. Molding

Core/Sheath Melting point Total Density

Ratio temperature

HBFIL GF & PP - / 165℃ 41% / 59% 200~220℃ 1.65

HBFIL GF & PA6 - / 215℃ 46% / 54% 240~260℃ 1.84

HBFIL CF & PX - /Amorphous 48% / 52% 220~240℃ 1.54

HBFIL PP & PE 165℃ / 120℃ 65% / 35% 120~140℃ 0.9

HBFIL PET & CoPET 250℃ / 160℃ 73% / 27% 170~180℃ 1.38

HYBRID Woven for FRP

Fabric Code Structure Reinforcement Weight (g/㎡) Thickness (mm) Fabric Width (cm)

HBWV CFBAS T-F01 HB3/3 Twill PAN CF3K &BASALT 290 0.30 110

WOVEN BASALT T-F51 2/2 Twill BASALT 100% 300 0.30 110

Remarks: Above figures are representative one, and not guaranteed.

Thickness after molding is approximate figure. It may change depending on molding method and conditions.

2003

【Contact】 【Sales Rep. EUROPE】

AYAHA Corporation, R&D Dept. ITOCHU Deutschland GmbH

T.Tomiyori Carsten Gifhorn

3-6-14 Minami-Honmachi, Chuo-ku, Osaka ,541-0054,JAPAN Brandstwiete 1, 20457 Hamburg, GERMANY

TEL : +81-6-6282-1081 FAX : +81-6-6252-7757 TEL: +49-40-41529-130 Fax: +49-40-41529-108

E-Mail : t_tomiyori@ayaha.co.jp E-mail : carsten.gifhorn@itochu-hamburg.de

URL : http://www.ayaha.co.jp/kogyo/products/frtp_en.html URL : https://www.itochu.de/

2203