1/4ページ

Download(441.8Kb)

Benchtop, turnkey system for rapid synthesis of high-quality Graphene

Document Information

| Document Title | nanoCVD-8G |

|---|---|

| Document Type | Product Catalog |

| File size | 441.8Kb |

| Category | |

| Company | Thermocera Japan Ltd. (Documents List) |

Documents related to this company

Document Contents

Page1

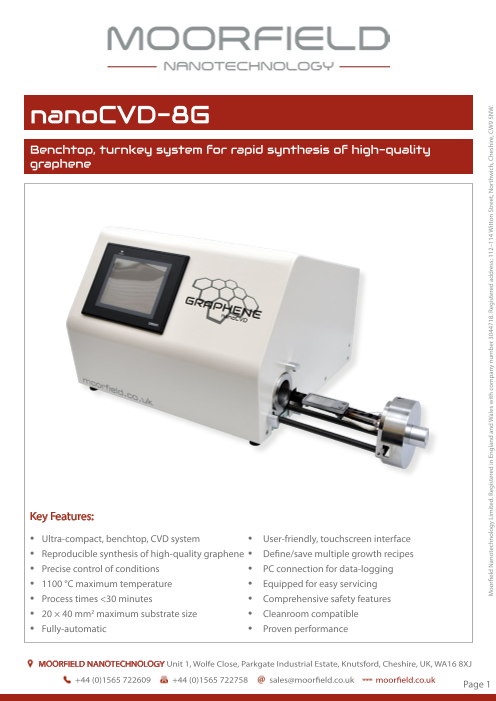

nanoCVD-8G

Benchtop, turnkey system for rapid synthesis of high-quality

graphene

Key Features:

• Ultra-compact, benchtop, CVD system • User-friendly, touchscreen interface

• Reproducible synthesis of high-quality graphene • Define/save multiple growth recipes

• Precise control of conditions • PC connection for data-logging

• 1100 °C maximum temperature • Equipped for easy servicing

• Process times <30 minutes • Comprehensive safety features

• 20 × 40 mm2 maximum substrate size • Cleanroom compatible

• Fully-automatic • Proven performance

MOORFIELD NANOTECHNOLOGY Unit 1, Wolfe Close, Parkgate Industrial Estate, Knutsford, Cheshire, UK, WA16 8XJ

+44 (0)1565 722609 +44 (0)1565 722758 sales@moorfield.co.uk moorfield.co.uk Page 1

Moorfield Nanotechnology Limited. Registered in England and Wales with company number 3044718. Registered address: 112–114 Witton Street, Northwich, Cheshire, CW9 5NW.

Page2

nanoCVD-8G

System Description:

Developed in collaboration with academic partners, the nanoCVD-8G is designed for the high-

throughput production of high-quality graphene for R&D and pilot-scale applications. Synthesis is via the

well-established chemical vapour deposition (CVD) route. This method allows for rapid production, and,

in contrast to approaches such as mechanical exfoliation (i.e., the “sticky-tape method”), is also scalable

making it promising for future commercialisation of graphene-based technologies.

Technology:

The system contains a low thermal-mass heater stage onto which film or foil substrates can be placed.

The stage slides into a small volume, cold-walled reaction chamber, which is sealed during process

operation, and is designed for uniform heating over areas up to 20 x 40 mm2. The maximum setpoint

temperature is 1100 °C, and temperatures can be set and controlled with a resolution of 1 °C. The unit

is capable of high heating/cooling rates, if required, allowing for complete growth cycles <30 minutes.

Such efficient operation also results in minimised resource usage (e.g., in terms of power and process

gases).

Process gases are controlled via mass-flow controllers (MFCs). The standard configuration is equipped

for 3 process gases: argon, methane and hydrogen. The system is capable of operating in flow-rate or

pressure control modes. Automatic pressure control is possible throughout the range 0-20 Torr. Pressure

measurement is by capacitance manometer, with pumping by rotary or scroll-type backing pumps.

The nanoCVD-8G allows for graphene synthesis via a wide variety of CVD schemes, including, but not

limited to, those based on metal substrates and using methane as feedstock gas that are known to

provide high-quality material.

Control System:

The unit is fitted with industrial-grade PLC electronics. User operation is via a 5” touchscreen HMI

mounted on the front panel. Users are able to define, store and run multiple ‘recipes’ via flexible, but

easy-to-use, touchscreen software. Online data-logging and recipe upload/download to a PC is possible

via the provided NanoConnect software.

Screenshots from the touchscreen HMI software through which all user operation of the nanoCVD-8G is carried out.

MOORFIELD NANOTECHNOLOGY Unit 1, Wolfe Close, Parkgate Industrial Estate, Knutsford, Cheshire, UK, WA16 8XJ

+44 (0)1565 722609 +44 (0)1565 722758 sales@moorfield.co.uk moorfield.co.uk Page 2

Moorfield Nanotechnology Limited. Registered in England and Wales with company number 3044718. Registered address: 112–114 Witton Street, Northwich, Cheshire, CW9 5NW.

Page3

nanoCVD-8G

nanoCVD-8G Graphene:

Graphene samples synthesised using a nanoCVD-8G have been characterised using Raman spectroscopy,

high magnetic field transport, and electron and optical microscopies. The graphene produced was

shown to be monolayer, have high quality with low intrinsic doping, and macroscopic uniformity.

Transistor devices show high charge carrier mobilities, 3300 cm2/(V∙s) at 1.4 K and 2773 cm2/(V∙s) at room

temperature. Hall bar devices at high magnetic fields indicated the half integer quantum Hall effect

(unique to monolayer graphene). Such observations provide strong evidence for the exceptional quality

of the material that can be produced using the nanoCVD-8G.

For full results, see reference 1.

Characterisation indicating high-quality, defect-free graphene produced using a nanoCVD-8G. Left: Raman spectrum. Right:

Longitudinal resistivity and Hall conductance data indicating half integer quantum Hall effect unique to monolayer graphene

(data taken from reference 1).

Graphene produced with the nanoCVD-8G has found

multiple applications:

• Optoelectronics: As electrodes for flexible and

transparent touch sensors, and in photovoltaic

devices.

• Biosensors: Functionalisation of graphene surfaces

has allowed for detection of specific proteins using

electrical transport techniques.

• CVD growth mechanisms: Given its rapid heating/ A flexible and transparent

cooling abilities and cold-walled design, the touch sensor fabricated from

nanoCVD-8G and its graphene have allowed for graphene made using a

nanoCVD-8G. Taken from reference 1.

detailed studies of CVD synthesis.

• Fundamental transport: Investigation of exotic

physics in graphene with low intrinsic doping, such as the quantum Hall effect over large areas, and

high charge carrier mobilities.

MOORFIELD NANOTECHNOLOGY Unit 1, Wolfe Close, Parkgate Industrial Estate, Knutsford, Cheshire, UK, WA16 8XJ

+44 (0)1565 722609 +44 (0)1565 722758 sales@moorfield.co.uk moorfield.co.uk Page 3

Moorfield Nanotechnology Limited. Registered in England and Wales with company number 3044718. Registered address: 112–114 Witton Street, Northwich, Cheshire, CW9 5NW.

Page4

nanoCVD-8G

References:

1. Bointon, T. H., et al. “High Quality Monolayer Graphene Synthesized by Resistive Heating Cold Wall Chemical Vapor

Deposition” Adv. Mater. 2015 DOI: 10.1002/adma.201501600

2. Neves, A. I. S., et al. “Transparent Conductive Graphene Textile Fibers” Sci. Rep. 2015 DOI: 10.1038/srep09866

3. Lupina, G., et al. “Residual Metallic Contamination of Transferred Chemical Vapor Deposited Graphene” ACS Nano 2015

DOI: 10.1021/acsnano.5b01261

System Requirements—Standard Configuration:

• Substrates: Typically foils/films of various metals.

• Process gases: 25 psi supplies of methane, hydrogen and argon.

• Service gas: Dry inert (e.g., nitrogen or argon), 60–80 psi supply.

• Power: Single-phase 230 V, 50 Hz, 10 A.

• Exhaust extraction.

Applications: Distributed By:

• Fundamental research.

• Education.

• Product R&D.

moorfield.co.uk

nanoCVD.co.uk

MOORFIELD NANOTECHNOLOGY Unit 1, Wolfe Close, Parkgate Industrial Estate, Knutsford, Cheshire, UK, WA16 8XJ

+44 (0)1565 722609 +44 (0)1565 722758 sales@moorfield.co.uk moorfield.co.uk Page 4

Moorfield Nanotechnology Limited. Registered in England and Wales with company number 3044718. Registered address: 112–114 Witton Street, Northwich, Cheshire, CW9 5NW.