1/4ページ

Download(873.4Kb)

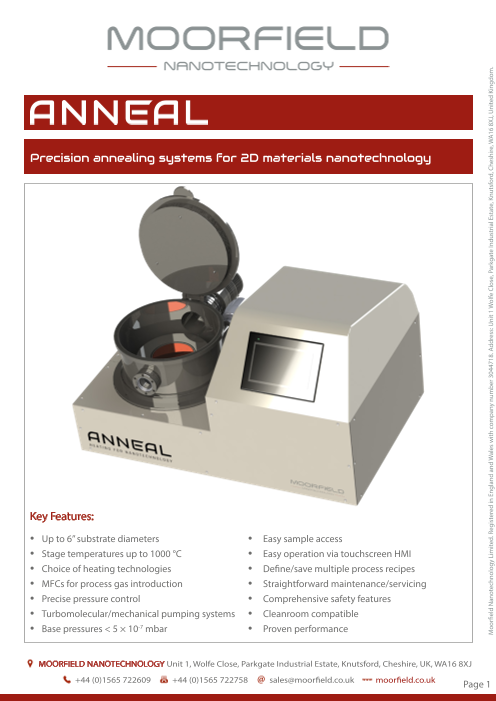

Precision annealing systems for 2D materials nanotechnology

High-temperature vacuum annealing for planar substrates, up to 1000C, with precision gas and pressure control-all in a benchtop package.

Movie

Document Information

| Document Title | ANNEAL |

|---|---|

| Document Type | Product Catalog |

| File size | 873.4Kb |

| Category | |

| Company | Thermocera Japan Ltd. (Documents List) |

Documents related to this company

Document Contents

Page1

Precision annealing systems for 2D materials nanotechnology

Key Features:

• Up to 6” substrate diameters • Easy sample access

• Stage temperatures up to 1000 °C • Easy operation via touchscreen HMI

• Choice of heating technologies • Define/save multiple process recipes

• MFCs for process gas introduction • Straightforward maintenance/servicing

• Precise pressure control • Comprehensive safety features

• Turbomolecular/mechanical pumping systems • Cleanroom compatible

• Base pressures < 5 × 10-7 mbar • Proven performance

MOORFIELD NANOTECHNOLOGY Unit 1, Wolfe Close, Parkgate Industrial Estate, Knutsford, Cheshire, UK, WA16 8XJ

+44 (0)1565 722609 +44 (0)1565 722758 sales@moorfield.co.uk moorfield.co.uk Page 1

Moorfield Nanotechnology Limited. Registered in England and Wales with company number 3044718. Address: Unit 1 Wolfe Close, Parkgate Industrial Estate, Knutsford, Cheshire, WA16 8XJ, United Kingdom.

Page2

Overview:

ANNEAL systems from Moorfield are optimised for the thermal treatment of 2D materials and wafers

under controlled atmospheres. Substrates are supported face-up on stage-top platens that are situated

centrally inside a stainless-steel high-vacuum chamber fitted with appropriate heat shielding and a

shuttered viewport. Heating is via a heat source located beneath the platen. Maximum temperatures up

to 1000 °C are possible—depending on the heating technology used (see below).

Heat Source Technologies:

ANNEAL systems can be fitted with a variety of heat source technologies, with choice being dependent

on the application—particularly required operation temperature, ramp rates and oxygen resistance.

Standard options are detailed below:

Quartz lamp: This technology uses quartz lamps to generate IR radiation. A cost-effective means of

heating for substrate temperatures up to 500 °C, and compatible with most atmospheres.

Carbon-carbon composite (CCC): Where substrate temperatures above 500 °C are required, CCC elements

are used. Suitable for heating up to 1000 °C.

SiC-coated CCC: When high temperatures and oxygen resistance are required, CCC elements are coated

with a resistant layer of SiC.

For all technologies, the heat source is located immediately below the substrate platen and optimised for

uniform and rapid heating. Substrate platens are constructed from, aluminium or inconel (other materials

available) to allow for best thermal transmission.

All heat sources are powered by an onboard supply, with the output being matched to the technology

fitted. A thermocouple located in the platen (K-type as standard) allows for accurate temperature

monitoring. PLC electronics allow users to achieve setpoint temperatures with a resolution of 1 °C.

Additional thermocouples can also be fitted, e.g., for checking substrate surface temperatures during

operation.

MOORFIELD NANOTECHNOLOGY Unit 1, Wolfe Close, Parkgate Industrial Estate, Knutsford, Cheshire, UK, WA16 8XJ

+44 (0)1565 722609 +44 (0)1565 722758 sales@moorfield.co.uk moorfield.co.uk Page 2

Moorfield Nanotechnology Limited. Registered in England and Wales with company number 3044718. Address: Unit 1 Wolfe Close, Parkgate Industrial Estate, Knutsford, Cheshire, WA16 8XJ, United Kingdom.

Page3

Above: Heating stages fitted in ANNEAL systems. Left: Quartz lamp stage with water-cooled enclosure and extra

thermocouple. Middle: Quartz lamp stage, platen removed. Right: CCC-element stage for 1000 ° C substrate temperatures.

Gas and Pressure:

Results of annealing processes are sensitive to atmospheric conditions. For some processes, low-vacuum

may be sufficient. For this, the systems are fitted with rotary- or scroll-type backing pumps. For minimised

contamination, units can be equipped with turbomolecular pumping systems that enable base pressures

better than 5×10-7 mbar. ANNEAL systems can also be equipped with process gases.

Gas introduction: The systems can be fitted with up to 3 mass flow controllers (MFCs) for process gas

introduction. Typical gases are Ar, O2, N2 and H2. Flexible MFC full scale flow rates.

Pressure measurement: As standard, ANNEAL systems are equipped with wide-range pressure

measurement. But for accurate monitoring, capacitance manometers can be fitted.

Automatic pressure control: Where stabilised pressures are needed, automatic pressure control (APC)

packages are available. Resolutions to 0.1 mTorr are possible based on feedback loops between

capacitance manometer readings and MFC flow rates (upstream control).

Where gas introduction is present, the system includes a throttle valve between the chamber and the

pumping system that closes to a low-conductance position to protect turbomolecular pumps from gas

loads.

User Control:

All ANNEAL tools are fitted with high-stability, industrial-grade PLC electronics that interface to a

7” touchscreen HMI. Easy-to-use software allows for system setup and operation via a menu-driven

interface.

Users are able to run system hardware in manual or automatic modes. For manual operation, individual

components are operated as and when required. For automatic operation, users first define multi-stage

recipes. With a recipe selected and started, the system then operates all hardware as instructed until the

process end.

As standard, recipe definition includes the ability to program setpoint temperatures, hold times and

ramp rates. Depending on configuration, gas flow rates and APC pressures may also be defined.

The systems are also supplied with IntelliNet PC software for data-logging, offline recipe definition/

storage and system diagnostics.

MOORFIELD NANOTECHNOLOGY Unit 1, Wolfe Close, Parkgate Industrial Estate, Knutsford, Cheshire, UK, WA16 8XJ

+44 (0)1565 722609 +44 (0)1565 722758 sales@moorfield.co.uk moorfield.co.uk Page 3

Moorfield Nanotechnology Limited. Registered in England and Wales with company number 3044718. Address: Unit 1 Wolfe Close, Parkgate Industrial Estate, Knutsford, Cheshire, WA16 8XJ, United Kingdom.

Page4

Above: Screenshots from the touchscreen HMI software for ANNEAL system user control..

Technical Specification:

Chamber: 270 mm ID stainless-steel chamber with hinged lid, Viton o-rings, and various hardware ports.

Safety interlocks: Water and vacuum levels.

Pumping group: Rotary or dry backing pump; optional Edwards EXT75DX turbomolecular pump;

Pressure measurement: Edwards wide-range gauge and optional capacitance manometer.

Heated substrate stages: Various types depending on requirements (see above); up to 6” diameters.

Gas introduction: Up to 3 Horiba STEC MFCs. Throttle valve for pumping system protection. Optional

upstream APC via flow rate modulation.

Control system: PLC electronics with 7” colour touchscreen HMI for user operation. Optional IntelliNet PC

software for data-logging.

Weight: Approximately 40 kg; dependant on configuration.

Size: 750 mm (w) × 500 mm (d) × 400 mm (h).

System Requirements:

• Service gas: Dry compressed air, nitrogen or argon, 60–80 psi supply

• Process gases: 25 psi supplies, 99.99% purity or better

• Vent gas: N2, 0.5 bar

• Power: Single-phase 230 V, 50 Hz, 13 A Distributed By:

• Chilled water: 18–20 °C, 3 L/min, pressure < 4 bar

• Exhaust extraction

Applications:

• Graphene and 2D materials

• Semiconductor film processing

• Device annealing

• Education

• Product development

• Pilot-level/batch production

MOORFIELD NANOTECHNOLOGY Unit 1, Wolfe Close, Parkgate Industrial Estate, Knutsford, Cheshire, UK, WA16 8XJ

+44 (0)1565 722609 +44 (0)1565 722758 sales@moorfield.co.uk moorfield.co.uk Page 4

Moorfield Nanotechnology Limited. Registered in England and Wales with company number 3044718. Address: Unit 1 Wolfe Close, Parkgate Industrial Estate, Knutsford, Cheshire, WA16 8XJ, United Kingdom.