1/4ページ

Download(3.2Mb)

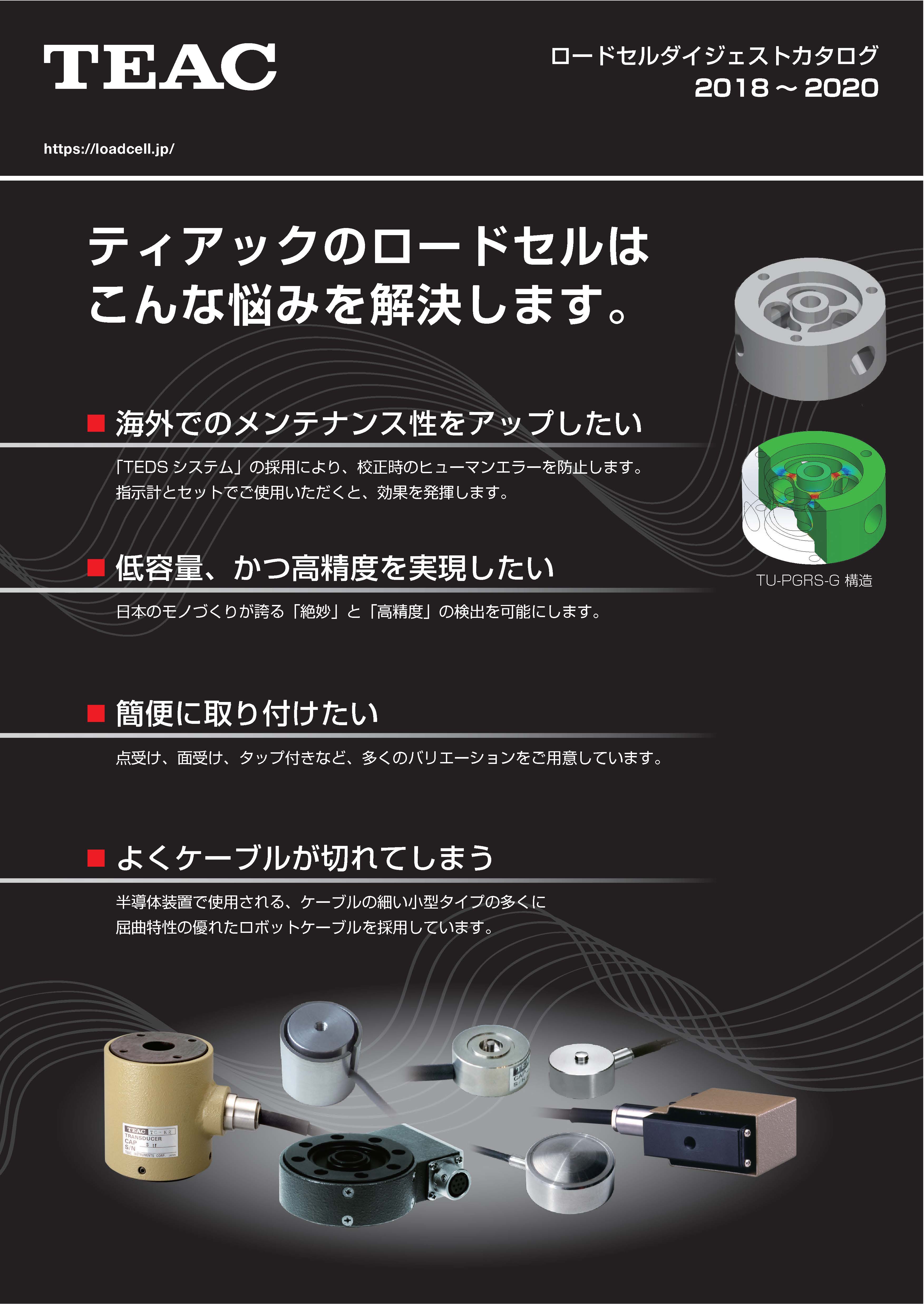

teac load cells provide solutions for force measurements

Semiconductor technology is essential for many consumer products, such as appliances.

teacs highly accurate force measurement allows the handling of delicate micro parts.

measuring and monitoring the force of a wafer prober

managing polishing force on the wafer polishing machine

force management during bonding of the wire bonding machine

to control the loading pressure of SMT placement equipment

checking variation in fluid weight of residual quantity detecting

Movie

Document Information

| Document Title | Load Cell Digest Catalog |

|---|---|

| Document Type | Product Catalog |

| File size | 3.2Mb |

| Category | |

| Company | TEAC CORPORATION (Documents List) |

Documents related to this company

Document Contents

Page1

Other Related Products Load Cell Digest Catalog

2017 - 2018

Digital Indicator

http://loadcell.jp/en/

Static Strain Comparison Waveform

*Supports remote sense functions.

Offers 5 different functions: displays static strain, dynamic strain, analog data

value, digital data value and used as a signal conditioner. TEAC’s load cells provide

solutions for force measurements.

Portable Digital Indicator

■ Eliminates confusing configuration steps

Graphical displays allow you to see numeric values or waveforms as you easily

monitor and record your measurements. TEAC load cells and indicators utilizing TEDS perform

auto-calibration and eliminates manual settings and human errors.

Digital Indicator ■ Measures a variety of ranges accurately

A variety of compact, precision and reliable

CF load cells are ready to use.

Card

Waveform Data storage Static Strain Comparison Hold Touch screen

Supports a variety of hold functions, digital and waveform display and recording

measured value, it's the high-end indicator with high-performance.

The TD series are used in fabrication, as well as quality control and advanced ■ Ease of Use

analysis.

The TEDS function of both load cell and indicator

Signal provides plug and play operation

Conditioner

■ Designed to prevent cable breaking

Plug-in

connection

The optimal conditioner equipped with all the functions needed to detect the TEAC’s load cell and cables are designed to be

appropriate current or voltage to load cells for measurement and control. resistance to mechanical stress.

Company names and product names in this document are the trademarks or registered trademarks of their respective owners.

TEAC EUROPE GmbH. Features and specifications are subject to change without notice.Precaution : To ensure safe handling and operation, read the Instruction Manual before use.

Bahnstrasse 12, 65205 Wiesbaden-Erbenheim, Germany TEAC Data Recorder Products Distributed by:

Tel.: +49-(0)611-7158-362

Fax: +49-(0)611-7158-392

Email: ipd-sales@teac.eu

https://teac.eu/en/

Copyright© 2017 TEAC CORPORATION. All rights reserved.

1117 ISD-077

Page2

TEAC’s strain gauge based load cells Glossary

TEAC’s many years of experience and expertise have developed load cells that have Rated Capacity / R.C. Insulation Resistance

High-responsiveness, High-accuracy and High-stability. The maximum capacity (load) that the load cell will be DC resistance between the load cell electrical circuit and

subjected to its specification. the load cell body.

Safe overload Compensated temperature range

The maximum load that can be applied without permanent Temperature ranges by which the rated output and the

Indicators and characteristic change (damage) to the load cell. zero balance are compensated to meet specifications.Load cells Signal conditioner Maximum safe overload Operating temperature range

The limiting load that can be used without causing Temperature range that the load cell within the stated

damage or breaking. specifications.

Rated Output / R.O. Safe temperature range

The value subtracted the non-load output from the output The temperature range which can be used without

resulted by applying the rated load. That is expressed in permanent characteristic change (damage) to the load

the output per applied voltage. (mv/V) cell.

All combinations of

load cells and Non-Linearity Temperature effect on zero

indicator are available. Maximum deviation of a calibration curve to a specified The rated output shift at no-load due to a change in

straight line (reference curve, which is determined by ambient temperature. That is expressed as %R.O. per 10

connecting the no-load output and the rated load output). degrees.

TEAC offers a wide variety of strain based load cells, indicators , signal Measured when increasing calibration load.

conditioner, amplifiers and accessories to support your system without delay. Temperature effect on output

Hysteresis The output shift due to a change in ambient temperature.

Maximum difference in output produced in the same load That is expressed as %R.O. per 10 degrees.

when the load increasing or decreasing (between no-load

and rated capacity). That is expressed as %R.O. Static strain

What is TEDS? Static strain is a measure of deformity in non-dynamic Non-Repeatability conditions. By recording and managing the amount of

Maximum difference in outputs when calibration loads are static strain in the no-load state, it is possible to identify

applied repeatedly under the same conditions and load cell defects and other problems through plastic

TEAC sensors and indicators support IEEE 1451.4 TEDS. ambient. That is expressed as %R.O. deformity.

TEDS compatible sensors store specific information that contain the model name, serial number,

sensitivity and calibration information in its memory. This provides an automatic way to identify the Maximum Excitation Robot cable

sensor and program the indicator which eliminates any set up errors. The maximum voltage that the load cell can be A cable used in moving applications such as industrial

continuously subjected to and keep within its specification. robots and has excellent characteristics such as bending

resistance, twist resistance, oil resistance and chemical

Products with TEDS Input/output terminal resistance resistance.TEDS Advantages Resistance between the input (or output) terminals under

Tension/ TC-BSR(T)-G the output terminals opened with no load.■ Connecting or changing sensors saves time.

Compression type TC-SR(T)-G■ Eliminates confusing configuration steps.

TU-QR(T)-G TC-MR(T)-G■ Eliminates the need to remember or have on hand

calibration data since it is read from the sensor. TU-MXR2(T)-G Tension type The static strain makes it easier to check load-cells for plastic deformation.

TU-CR(T)-G

■ Eliminates scaling and calibration errors. TT-FR(T)-G

Compression type The strain gauge based load cell produces the value of load and weight by generating strain within the elastic

■ Gives a secure solution for your measurement. Indicators

TC-AR(T)-G region on the sensing element.

TC-FR(T)-G TD-280T When the sensing element is undergoing permanent deformation, the load cell will not only fail to perform within

TC-KR(T)-G TD-275T specified parameters, but it may also cause failure of the load cell and critical damage to the whole system.

Each TEDS sensor Reading TC-XR(T)-G TD-260T Since indicators can show the input signal as microstrain, it is possible to check and monitor a load cell's TD-700T

contains specific TC-LPR(T)-G condition accurately.

information. TC-NSR(T)-G

TD-01

TC-NSRSP(T)-G Load cell defect causes

TC-USR(T)-G

TC-MFSR(T)-G Impact

Overload from

dropping

*Model number enables you to know TEDS-compliant sensors. For management

Ex)TU-QR (T) -G RoHS compliant load cell

conditions

TEDS compliant

Extended

load

TEAC has various TEDS load cells and indicators for performing reliably and accurately in a variety of industries.

For more information http://loadcell.jp/en/teds.html When static strain is displayed any plastic deformation of a load cell is easier to check.

Page3

TEAC’s load cells are used in a variety of industries

TC-MFSR(T)-G

Semiconductor technology is essential for many consumer products, such as appliances.

TEAC’s highly accurate force measurement allows the handling of delicate micro parts.

■ Measuring and monitoring the force of a wafer prober

■ Managing polishing force on the wafer polishing machine TC-SR(T)-G

■ Force management during bonding of the wire bonding machine TC-SR

■ To control the loading pressure of SMT placement equipment

■ Checking variation in fluid weight of residual quantity detecting

TC-USR(T)-G

Load cell indicator

and signal conditioner

Digital Indicator for load cells Signal Conditioner TC-NSR(T)-G

TD-700T TC-11

-For semiconductor TC-NSRSP(T)-G

Load cells suitable for semiconductor production process

Rated Capacity[N] Rated Output Non-Linearity Dimension

Model Type (Diameter) TEDS RobotCable

0.5 1 2 5 10 20 50 100 200 500 1k 2k 5k 10k 20k 50k 100k 200k 1000k [mV/V] [% R.O.] [mm]

TC-MFSR(T)-G Compression 1.0 0.5 φ12 TC-BSR(T)-G

TC-SR(T)-G Compression 1.0 1 φ12~φ20

TC-SR Compression 1.0 1 φ25

TC-USR(T)-G Compression 0.5(~10N) 0.3(2N/5N)

0.75(20N~) 0.1 φ17~φ34

TC-NSR(T)-G Compression 0.75 1 φ20

TC-NSRSP(T)-G Compression 1.3 0.2 φ20 TU-QR(T)-G

TC-BSR(T)-G Compression 1.0(10kN) 1.0(10, 50kN)1.5(20, 50kN) 2.0(20kN) φ21~φ22

TU-QR(T)-G Tension/Compression 0.5 0.5 φ28

TU-PGRS Tension/Compression 2.0 0.03 φ58~φ118

TU-PGRS

Load cell LINEUP

Page4

Performing reliably and accurately in a variety of industries

TEAC’s many years of experience and expertise in the measurement instruments industries TC-KR(T)-G

allows us to provide a variety of reliable, robust and accurate load cells.

Let us help you select the right load cell for your application, contact TEAC today.

Application of load cells in production process

■ Control a critical force in process of press-fitting, press-forming and so on.

■ Measuring or managing of the force on universal testing machine.

TU-PGRS

■ Measuring frictional force of sliding parts at products inspection.

■ Managing quantity or weight of tanks and hoppers.

TC-WAR-G

Load cell indicators

TC-AR(T)-G

Digital Indicator for load cells

-For maPonrtable Diguital Indicatfor actTuD-280TTD-01 ring

Load cells suitable for various production process TU-BR-G

Rated Capacity[N] Rated Non-Linearity Dimension

Model Type Output (Diameter) TEDS RobotCable

20 50 100 200 300 500 1k 2k 3k 5k 10k 20k 30k 50k 100k 200k 300k 500k 1000k [mV/V] [% R.O.] [mm]

TC-KR(T)-G Compression 1.0 0.5 φ40~φ100

Tension/

TU-PGRS Compression 2.0 0.03 φ58~φ118

TC-WAR-G Compression 2.0 0.15(~20k)0.1(50k~) φ60~φ116 TC-XR(T)-G

TC-AR(T)-G Compression 2.0 0.15(~30k)0.1(50k~) φ60~φ120

TU-BR-G Tension/ W60~74Compression 3.0 0.05 D60~90

TC-XR(T)-G Compression 1.0 0.5 φ62~φ100

TU-GR-G Tension/ 0.05(~200k)Compression 2.0 0.15(500k~) φ105~φ460

TU-GR-G

Load cell LINEUP