1/752ページ

ダウンロード(80.8Mb)

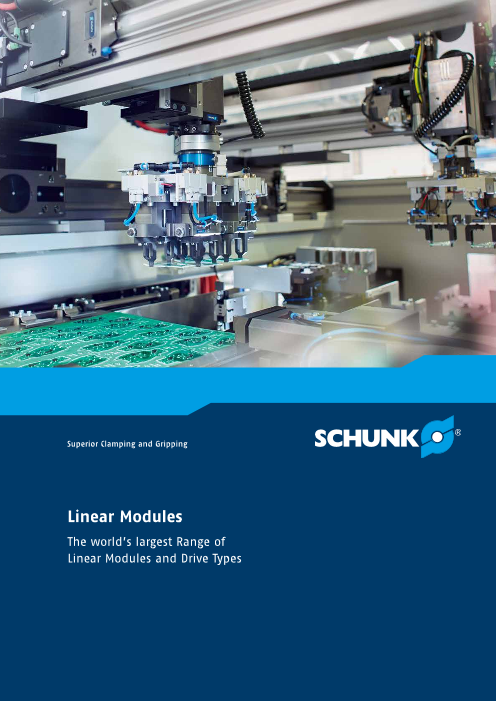

Linear Modules The world's largest Range of Linear Modules and Drive Types

製品カタログ

このカタログについて

| ドキュメント名 | Linear Modules The world's largest Range of Linear Modules and Drive Types |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 80.8Mb |

| 取り扱い企業 | シュンク・ジャパン株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

Title

S uperior Clamping and Gripping

Linear Modules

The worldʼs largest Range of

Linear Modules and Drive Types

Page2

Familienseite_Broschuere_2016-11_EN.pdf

Superior Clamping and Gripping

Jens Lehmann stands for safe, precise gripping and holding.

As a brand ambassador of the SCHUNK team,

the No. 1 goalkeeper represents our global competence

leadership for gripping systems and clamping technology.

The top performance of SCHUNK and Jens Lehmann are

characterized by dynamics, precision, and reliability.

For more information visit our website:

schunk.com/lehmann

Jens Lehmann

Familienseite_Broschuere_2016-11_EN.pdf

Familienseite_Broschuere_2016-11_EN.pdf

Familienseite_Broschuere_2016-11_EN.pdf

Page3

Familienseite_Broschuere_2016-11_EN.pdf

Henrik A. Schunk, Kristina I. Schunk, brand ambassador Jens Lehmann, and Heinz-Dieter Schunk

Top Performance in the Team

SCHUNK is the world’s No. 1 for gripping systems and As a competence leader, we recognize and develop

clamping technology – from the smallest parallel gripper standards with a large potential for the future, which

to the largest chuck jaw program. will drive the rapid progress in many industries.

In order to boost efficiency, SCHUNK customers have Our customers profit from the expert knowledge, the

bought more than 2,000,000 precision toolholders, experience, and the team spirit of more than 2,700

1,000,000 SCHUNK grippers, and 100,000 lathe chucks employees in our innovative family-owned company.

and stationary workholding systems so far.

The Schunk family wishes you improved end results with

This makes us proud and motivates us to attain new top our quality products.

performances.

Heinz-Dieter Schunk Henrik A. Schunk Kristina I. Schunk

Familienseite_Broschuere_2016-11_EN.pdf

Familienseite_Broschuere_2016-11_EN.pdf

Familienseite_Broschuere_2016-11_EN.pdf

Page4

PotenziPaolete_nAzltiaPrloeKPt_aeAotnatlzetlaoinargzlKe_iPa_moltAeaitte_lRtonaAgezrlK_tgiamiasrleKtiaet_aRlrAot_eagl2tgl_ao0imsrg1Kt_7eiatm-Rrt0_aie2tlRgo_0igeE1s_gt7Nemi-s.r0p_ti2etd2R_rf0_eE12gN70is-.1p0t7ed2-rf0_E2_0NE1.p7Nd-.0fp2d_fEN.pdf

SuSpuSSepuurSepipuroeiepror rierCio rolCriaro lm CarClm lapCamlipanipmgnpi ginpan ginagn dn aga dn Gna drGdni pr dGGip rrGipinpripignpiginpngigng

I It It ’tIs’ st’ s’ ts tit imitmiemee te tot oot uo uu ssuesesee

y y oy oy ouuourru r mr m amaaccahchchiihninnieen’e’se’ssf’fusfuulflul ll pl plpo opotteotenetnenttnitaiaitlai!la!ll!l!

WiWthiW tsWhui tispWhtuhe ipsr tsiuheoupr rspie oucerropir oimceorr rpimc ocorponm mcoeopnpmoetosnpn,et oefsnin,nt efstdisn, ,fpt difsoni ,np tdfedoi npt pedtoino tapetleionsan tileitnsain ailytnslios aiy unilonsr uy miyonro ua myucro rham ucminrha aemicnc hhaeinc inheei n e

whwehrwew hryheweo eryuhero e wuy ry eowo uyu olow duwu oll doeuwu allodlesdut al lseldetax aesplestxe tapec stxet xpc teptoe xe ctfpcoti ten t fcotditon f tdifhoni net dfhmdi net .htmdhe .etmhme..m.

MakMe afukeMll Mafuukaslekl M eufo uasfleu kly eloul ufsu erysl eolm ufoa rsfyc e mohy uoianrufc erhmy’ oimsan upcaerho’c msihtn epiaenoc’ethsti’e aispnl opet–tio’ae st ln e p–tnoi tat ilea n–l t –i a l –

withw tihthew tweihtxihete hwetn hxtisehtiehv eene xtes hptixverteno e dsnpxiusvrtiocevtd ne pups rpiocvrtrdeo tp udfpocurlrtocit otpdfo upflrociottrfm topffrl oioSolrCmit oHf roUSfolrNCimoHKm U.fSrN CoSHKCm.UH NUSKNCH.KU. NK.

SCHUSNCKH, UtNhSCKeSH ,Cc UtHohNmUeKSN p,CcK eHot,htm UeteNhnp Keceoe ,tc m etolhnempaeced pct eolertnm eafcnodpecre elrtge eralfnieodpacrep edgri e nrlfierogp af rpods gyiren rsrigt perf iopsmpyrip nsgt igaenr imngspy dps yit anesngtme dsm y ast naedmn d s and

clamcplianmg pctelianclmhga nmpteoicpnllohigangn mgtyoe, p ltccoeihnagcnhgyo, n tnlceooaclgwonhyg n, no yoc,opa lwcoenagn ony u, po npcewoa nt wnho u penop eopf nutweh lnul e o p upf ouptethl nelte h npu etfopui atf leutl hnloplet foip ayftouelo tnlouelt frnpi ay tooilat uoel rfno ytfio ayulo rou fr y our

procepsrsoincegps smrpoinracogecc hsmespisinrnasoeicgncsh e gmiasn nsmaeidcnsah gcpai hrnmoiedndas e ucpashcr notianidnoe undpsc rptaoirnodondudc ceuptsicrsoteindcose u.np scR srptoeirocsdoe.nu csR ecspesrds soce.uoc secRs.e stRs dc e ousdsc.u teRsc ec od csuotcse t s c osts

by cobmy bcionbminyb gcyi on acmiconbcmbguyi rbnacaiciotncemiug,n rbfgali cetnaecxicu,nic brfgual ertaaxe cwti,cbe uof,ll erfak xlwpetiebxioe,il rbecfkel pew xmi oweibacrokelcerp hkm iiwpenaicoicenrch kgemip n wmiaienciacthgheci hnwm iiinatihgcnh gw i niwtihnit gh w ith

dynadmyinca pmdryodincdy aupnmcraotdmidcoy iunpcca rpatomiurodoitnucdo cmupaticuraottitndoio munanc uat.ituoiotnmon ma. tuaitotoinom.na.tion.

SCHUSNCHKU SNCySHKnC UHeSrNUySgnKNCyHe K S–rU ygS NnwyKen –hr eSge rywygn yh –e e –rvwgne wy hre ye–hvtne hwr nieynh vtegehv nrifenyi rtetgyshvt fetihinortigynst egthfto ihiftgnisete gsrtt. ohftgioetegsr.t ethtoehgre.ert.her.

With WSCitHhU WSNCKWiHt hSUity NhSnCK WeSH rCSiUgtHyhyNnU, K eSNy rCKoSgHy uySUn, y bNeynerKoegn urySeg ,yb fynyi,eto e nyfuroreg oufybim, et b yn feosreonufmpei tbfe iefrstri unofpremro fecim rtosi uo fmsrprou pecmporein morseirupo npcroto esncmr oefiormnporotm pscn o fenrmnoemtpnso t fsnr oefrmnotm s from

our inounro vinaontuoiovru veiran ftinaoivmounevroi al fvyiatna-imvntoeioiwv lvefyna- fmetoaidwvmi lecyni o-lfeyamod-mw opcinwaolyenm-dyeop dacwaon cnmdoye mptdahan pcendao yrn m teayhsp nueaad lnrnt e dtyohs futae haln ter dep or seftu hrsalfuet p lcortte flor syaffu e alpctt e ploryef erafce tplcyet lryf ectly

harmhoanrimzehodanh riamznretmodehnr opiainzlreatimzeyder o podinlf a itgznyeert riodepfr lp iagnilynrat ieogypr fpos gyilfna rsigtyper iopsmpyfip nsgt igaenr imngspy dps yitcaneslngtame dmsm y cpaslita naemdgmn pdctseli naclmhgna ndmpteo icpnllohigangn mgtyoe. plt coeihngcnhgyo. nt leoclgohygn. yo.l ogy.

The mThoere m TShoCTHrehe Uem SN CmoKTHrh,oe Uetr NheS mCKe SH ,oCm UtHrheNoUe rKSNe ,CmK Het,ho fUtfreNhiec Kem ie ,m fontfrhitoec eir te mni fseftio.f cfiritec i nse.tfn fiittc ites .nist. it is.

PotenziPaolete_nAzltiaPrloeKPt_aeAotnatlzetlaoinargzlKe_iPa_moltAeaitte_lRtonaAgezrlK_tgiamiasrleKtiaet_aRlrAot_eagl2tgl_ao0imsrg1Kt_7eiatm-Rrt0_aie2tlRgo_0igeE1s_gt7Nemi-s.r0p_ti2etd2R_rf0_eE12gN70is-.1p0t7ed2-rf0_E2_0NE1.p7Nd-.0fp2d_fEN.pdf

Potenziale_AltarKatalog_mitRegister_2017-02_EN.pdf

Potenziale_AltarKatalog_mitRegister_2017-02_EN.pdf

Potenziale_AltarKatalog_mitRegister_2017-02_EN.pdf

Potenziale_AltarKatalog_mitRegister_2017-02_EN.pdf

Potenziale_AltarKatalog_mitRegister_2017-02_EN.pdf

Potenziale_AltarKatalog_mitRegister_2017-02_EN.pdf

Potenziale_AltarKatalog_mitRegister_2017-02_EN.pdf

Potenziale_AltarKatalog_mitRegister_2017-02_EN.pdf

Potenziale_AltarKatalog_mitRegister_2017-02_EN.pdf

Potenziale_AltarKatalog_mitRegister_2017-02_EN.pdf

Page5

PotenziaPleo_tAenltazPiraKoleate_tanAlzoltiPga_orleKmte_ainAtRazltlieoagrleKi_s_amtAetairltl_Rao2rgeK0_g1amis7tati-te0lRor2_ge_2_gE0misN1tie7t.Rpr-_0de2fg0_is1Et7eN-r.0_p2d_0fE17N-.0p2d_fEN.pdf

I tI It’ Its ’ts’ s’t s ti tmitimimee eet to tot oou u ususesesee

y y oy oy uoouurur rm r m maacaachchchihniininene’ee’s’s’fssfufuflulu llp l p oppotootetetnenentntitaitailai!la!l!l!

WitWhi WtshuiW tpsheui trsphiuoe spru iecoprorie mocrroip ocmor npmceopnmotepsn,oe tfnsin,et fsdni, nt pfsdi,on ftpdieno npdtteo ipnateoltsinta eitlnisa tyilinsoa iulynsro iyumnor a yumcorh uamircn hameci nhaecinh ein e

whwerhwee hyrwoeh ruye o wryueo wyuo lowduu olweduao lldsuet al ldes xtal pestaex sceptxe eptcoxte pctftioen c tfdtoi nttfodhin eftdimhn etd.hm eth.me.m.

GrippGirnigpG psriyinpsgGtpe risminypgspt iesanymngsdts es aymsntsde a m nsd a nd

clamcplianmgc lpatiemncghpla nitmneogclpho itgneygoc h l–otne gtocyhl oe–ng opytleh o–regf etyphc e–telr yftpe hecert lfpye ectrlfye ctly

adjusatdejdua sidtnejtudaes drtipenjuldtase ytir enpmdtle airyknp etmlesa aryyp komleausay kymeosua ky eosu y ou

a chaam cphaiao mcnh paini moc hntpea ironmn pts ei normnf t pesin rom tfde spu rormcoft isdpv uoirtocfy td.pi uvr iocttdyi.vu i cttyi.v i ty.

We caWlel icWta SelCl HcWiatU elSNl CcKiHat UlSly CNinHtKe U SrSNCgyHKynU. eSNrygKny eS.rygnye.rgy.

Let’s Lheat’vsLe eh taa’ sLvl eohto a’ksv lewho aohv kele orw eoa hk tle howreoeh k pet wohrtehe tenphrtoeita etplhnso etti eapnlost tieanlst ials

in yoiunr ymoinua cry hoimniun arye comshu iarnrc mehs iah nacierdhesdi naheernieds. daheriedn d.heidnd. en.

Jens LehJemnasn LneJehnms aLneJenhnmsa Lnenhmann

PotenziaPleo_tAenltazPiraKoleate_tanAlzoltiPga_orleKmte_ainAtRazltlieoagrleKi_s_amtAetairltl_Rao2rgeK0_g1amis7tati-te0lRor2_ge_2_gE0misN1tie7t.Rpr-_0de2fg0_is1Et7eN-r.0_p2d_0fE17N-.0p2d_fEN.pdf

Potenziale_AltarKatalog_mitRegister_2017-02_EN.pdf

Potenziale_AltarKatalog_mitRegister_2017-02_EN.pdf

Potenziale_AltarKatalog_mitRegister_2017-02_EN.pdf

Potenziale_AltarKatalog_mitRegister_2017-02_EN.pdf

Potenziale_AltarKatalog_mitRegister_2017-02_EN.pdf

Potenziale_AltarKatalog_mitRegister_2017-02_EN.pdf

Potenziale_AltarKatalog_mitRegister_2017-02_EN.pdf

Potenziale_AltarKatalog_mitRegister_2017-02_EN.pdf

Page6

SCHUNK No. 1 Products for higher Productivity … ... in your Automated Handling System ... in your Automated Handling System ... in your Automated Assembly

Discover new

potential now:

schunk.com/machine-potential No.1 unique more 500 standard combination than combinations options

And order the SCHUNK Synergy poster The new PGN-plus-P, the world-proven gripper

by telephone +49-7133-103-2256 on the market – Now NEW with permanent

for line and room gantries from SCHUNK modular assembly system

lubrication in the multi-tooth guidance the modular system 180% better gripping force – mass ratio

100% 90% faster gripper EPG – The powerful electronic gripper for small up 20 tons load cycle increase change components with integrated electronicsto handling greater Universal rotary module SRU-plus 20-S, Quick-change system SWS – fully

magnetic li ing technology 25% gripping forcethe new benchmark in top performance automatic gripper change within seconds

MPG-plus – The most powerful pneu-

matic miniature gripper in the market

... for your Automated Machine Loading ... in your Machining Center ... in your Automated Assembly 110 picks per minute

PPU-E – The fastest pick & place unit

in the market, PPU-P with 90 picks/min

... in your Lathe

... in your Service Robotics Application

Future handling

6 degrees of freedom

Powerball lightweight arm LWA 4P

The lightweight arm with the world’s most

compact performance. Used on mobile platforms

... in your Lathe ... in your Machining Center

60 seconds jaw change 75,000 customized 0.3 mm shank suitable for all Lathe chucks and solutions diameter less than 3 µ run-out accuracy 100% SCHUNK toolholders

... for your Automated Machine Loading Hydraulic expansion technology for tool mini sets a benchmark -R with unique patented polygonal -SVL tool extension – 90% less set-up or workpiece clamping in micro machining clamping technology optimized interfering contours and super-slimcosts

with , due to set-up

300% better 100% during processing time 100% encapsu- 3 80 bar coolant-proof or more years of experience in surface quality control lated less than µ run-out accuracy up to peripheral coolant than 35 hydraulic expansion

– innovative hydraulic expansion 4,000 Nm clamping force block centric clamping vise KSK -SVL super-slim tool extension Versatile clamping range with intermediate technology. , the original. With 29 interfaces, toolholders, for lathes and turning/milling centers moment load KSP plus with jaw monitoring fully functional in harsh environments optimized interfering contours sleeves GZB-S versatile, with 3 µ run-out accuracy

Robot coupling NSR-A for

pallet handling – space-saving and

1,200 standard extremely exible 30% 20 5 -sided up chuck jaws more productivity mm height workpiece machining to 85,000 2,000 Nm torque µ permanent run-out RPM with Ø 32 mm 0 accuracy

The world’s largest chuck jaw program Automated machine loading with the new SCHUNK NSE mini – the pneumatic in one set-up – magnetic -S predestined for for large volume cutting, boring, , perfect vibration damping,

for every chuck type gripper PGN-plus-P with spindle interface GSW quick-change pallet system in a very at design clamping technology high-speed cutting reaming, and threads resulting in up to 50% longer service life

Page7

SCHUNK No. 1 Products for higher Productivity … ... in your Automated Handling System ... in your Automated Handling System ... in your Automated Assembly

Discover new

potential now:

schunk.com/machine-potential No.1 unique more 500 standard combination than combinations options

And order the SCHUNK Synergy poster The new PGN-plus-P, the world-proven gripper

by telephone +49-7133-103-2256 on the market – Now NEW with permanent

for line and room gantries from SCHUNK modular assembly system

lubrication in the multi-tooth guidance the modular system 180% better gripping force – mass ratio

100% 90% faster gripper EPG – The powerful electronic gripper for small up 20 tons load cycle increase change components with integrated electronicsto handling greater Universal rotary module SRU-plus 20-S, Quick-change system SWS – fully

magnetic li ing technology 25% gripping forcethe new benchmark in top performance automatic gripper change within seconds

MPG-plus – The most powerful pneu-

matic miniature gripper in the market

... for your Automated Machine Loading ... in your Machining Center ... in your Automated Assembly 110 picks per minute

PPU-E – The fastest pick & place unit

in the market, PPU-P with 90 picks/min

... in your Lathe

... in your Service Robotics Application

Future handling

6 degrees of freedom

Powerball lightweight arm LWA 4P

The lightweight arm with the world’s most

compact performance. Used on mobile platforms

... in your Lathe ... in your Machining Center

60 seconds jaw change 75,000 customized 0.3 mm shank suitable for all Lathe chucks and solutions diameter less than 3 µ run-out accuracy 100% SCHUNK toolholders

... for your Automated Machine Loading Hydraulic expansion technology for tool mini sets a benchmark -R with unique patented polygonal -SVL tool extension – 90% less set-up or workpiece clamping in micro machining clamping technology optimized interfering contours and super-slimcosts

with , due to set-up

300% better 100% during processing time 100% encapsu- 3 80 bar coolant-proof or more years of experience in surface quality control lated less than µ run-out accuracy up to peripheral coolant than 35 hydraulic expansion

– innovative hydraulic expansion 4,000 Nm clamping force block centric clamping vise KSK -SVL super-slim tool extension Versatile clamping range with intermediate technology. , the original. With 29 interfaces, toolholders, for lathes and turning/milling centers moment load KSP plus with jaw monitoring fully functional in harsh environments optimized interfering contours sleeves GZB-S versatile, with 3 µ run-out accuracy

Robot coupling NSR-A for

pallet handling – space-saving and

1,200 standard extremely exible 30% 20 5 -sided up chuck jaws more productivity mm height workpiece machining to 85,000 2,000 Nm torque µ permanent run-out RPM with Ø 32 mm 0 accuracy

The world’s largest chuck jaw program Automated machine loading with the new SCHUNK NSE mini – the pneumatic in one set-up – magnetic -S predestined for for large volume cutting, boring, , perfect vibration damping,

for every chuck type gripper PGN-plus-P with spindle interface GSW quick-change pallet system in a very at design clamping technology high-speed cutting reaming, and threads resulting in up to 50% longer service life

Page8

SCHUNK No. 1 Products for higher Productivity … ... in your Automated Handling System ... in your Automated Handling System ... in your Automated Assembly

Discover new

potential now:

schunk.com/machine-potential No.1 unique more 500 standard combination than combinations options

And order the SCHUNK Synergy poster The new PGN-plus-P, the world-proven gripper

by telephone +49-7133-103-2256 on the market – Now NEW with permanent

for line and room gantries from SCHUNK modular assembly system

lubrication in the multi-tooth guidance the modular system 180% better gripping force – mass ratio

100% 90% faster gripper EPG – The powerful electronic gripper for small up 20 tons load cycle increase change components with integrated electronicsto handling greater Universal rotary module SRU-plus 20-S, Quick-change system SWS – fully

magnetic li ing technology 25% gripping forcethe new benchmark in top performance automatic gripper change within seconds

MPG-plus – The most powerful pneu-

matic miniature gripper in the market

... for your Automated Machine Loading ... in your Machining Center ... in your Automated Assembly 110 picks per minute

PPU-E – The fastest pick & place unit

in the market, PPU-P with 90 picks/min

... in your Lathe

... in your Service Robotics Application

Future handling

6 degrees of freedom

Powerball lightweight arm LWA 4P

The lightweight arm with the world’s most

compact performance. Used on mobile platforms

... in your Lathe ... in your Machining Center

60 seconds jaw change 75,000 customized 0.3 mm shank suitable for all Lathe chucks and solutions diameter less than 3 µ run-out accuracy 100% SCHUNK toolholders

... for your Automated Machine Loading Hydraulic expansion technology for tool mini sets a benchmark -R with unique patented polygonal -SVL tool extension – 90% less set-up or workpiece clamping in micro machining clamping technology optimized interfering contours and super-slimcosts

with , due to set-up

300% better 100% during processing time 100% encapsu- 3 80 bar coolant-proof or more years of experience in surface quality control lated less than µ run-out accuracy up to peripheral coolant than 35 hydraulic expansion

– innovative hydraulic expansion 4,000 Nm clamping force block centric clamping vise KSK -SVL super-slim tool extension Versatile clamping range with intermediate technology. , the original. With 29 interfaces, toolholders, for lathes and turning/milling centers moment load KSP plus with jaw monitoring fully functional in harsh environments optimized interfering contours sleeves GZB-S versatile, with 3 µ run-out accuracy

Robot coupling NSR-A for

pallet handling – space-saving and

1,200 standard extremely exible 30% 20 5 -sided up chuck jaws more productivity mm height workpiece machining to 85,000 2,000 Nm torque µ permanent run-out RPM with Ø 32 mm 0 accuracy

The world’s largest chuck jaw program Automated machine loading with the new SCHUNK NSE mini – the pneumatic in one set-up – magnetic -S predestined for for large volume cutting, boring, , perfect vibration damping,

for every chuck type gripper PGN-plus-P with spindle interface GSW quick-change pallet system in a very at design clamping technology high-speed cutting reaming, and threads resulting in up to 50% longer service life

Page9

SCHUNK No. 1 Products for higher Productivity … ... in your Automated Handling System ... in your Automated Handling System ... in your Automated Assembly

Discover new

potential now:

schunk.com/machine-potential No.1 unique more 500 standard combination than combinations options

And order the SCHUNK Synergy poster The new PGN-plus-P, the world-proven gripper

by telephone +49-7133-103-2256 on the market – Now NEW with permanent

for line and room gantries from SCHUNK modular assembly system

lubrication in the multi-tooth guidance the modular system 180% better gripping force – mass ratio

100% 90% faster gripper EPG – The powerful electronic gripper for small up 20 tons load cycle increase change components with integrated electronicsto handling greater Universal rotary module SRU-plus 20-S, Quick-change system SWS – fully

magnetic li ing technology 25% gripping forcethe new benchmark in top performance automatic gripper change within seconds

MPG-plus – The most powerful pneu-

matic miniature gripper in the market

... for your Automated Machine Loading ... in your Machining Center ... in your Automated Assembly 110 picks per minute

PPU-E – The fastest pick & place unit

in the market, PPU-P with 90 picks/min

... in your Lathe

... in your Service Robotics Application

Future handling

6 degrees of freedom

Powerball lightweight arm LWA 4P

The lightweight arm with the world’s most

compact performance. Used on mobile platforms

... in your Lathe ... in your Machining Center

60 seconds jaw change 75,000 customized 0.3 mm shank suitable for all Lathe chucks and solutions diameter less than 3 µ run-out accuracy 100% SCHUNK toolholders

... for your Automated Machine Loading Hydraulic expansion technology for tool mini sets a benchmark -R with unique patented polygonal -SVL tool extension – 90% less set-up or workpiece clamping in micro machining clamping technology optimized interfering contours and super-slimcosts

with , due to set-up

300% better 100% during processing time 100% encapsu- 3 80 bar coolant-proof or more years of experience in surface quality control lated less than µ run-out accuracy up to peripheral coolant than 35 hydraulic expansion

– innovative hydraulic expansion 4,000 Nm clamping force block centric clamping vise KSK -SVL super-slim tool extension Versatile clamping range with intermediate technology. , the original. With 29 interfaces, toolholders, for lathes and turning/milling centers moment load KSP plus with jaw monitoring fully functional in harsh environments optimized interfering contours sleeves GZB-S versatile, with 3 µ run-out accuracy

Robot coupling NSR-A for

pallet handling – space-saving and

1,200 standard extremely exible 30% 20 5 -sided up chuck jaws more productivity mm height workpiece machining to 85,000 2,000 Nm torque µ permanent run-out RPM with Ø 32 mm 0 accuracy

The world’s largest chuck jaw program Automated machine loading with the new SCHUNK NSE mini – the pneumatic in one set-up – magnetic -S predestined for for large volume cutting, boring, , perfect vibration damping,

for every chuck type gripper PGN-plus-P with spindle interface GSW quick-change pallet system in a very at design clamping technology high-speed cutting reaming, and threads resulting in up to 50% longer service life

Page10

SCHUNK customized Gripping Systems

Components and Systems

SCHUNK Gripping Technology

From the standard Component

to the customized Gripping System

More than 30 years of gripping expertise is the basis for the world’s largest standardized

gripping technology product range, with more than 4,000 components and an average of

2,000 standard and customized gripping systems per year.

Components Gripping Systems

Standard Customized Standard Customized

Components Components Gripping Systems Gripping Systems

From standard components Solution composed of several

further developed in accordance SCHUNK components, of which

with customer requirements at least one is further de-

to exclusive customized new veloped or newly developed

developments. specifically for the customer.

SCHUNK Grippers

Examples: Examples:

Rotary Modules

Modular Assembly Automation

Linear Modules

Wafer Grippers

made of laser-forming material

with SCHUNK LGP gripper

Connecting Rod Handling

Robot Accessories

Line and Room Gantries

Pick & Place Units

Compact Vises

for sheet metal machining,

pneumatically actuated

Aluminum Foil Handling

Gripping Hands

Packaging Grippers

High-speed grippers according Solution composed of several

to legal, hygienic, and SCHUNK standard components Modular and

Lightweight Arms production specifications for robots and gantries Mobile Gripping Systems

10

Page11

SCHUNK customized Gripping Systems

Your added value

From the standard Component to the

customized Gripping System

Solution Expertise

Standard Standard Components Customized Standard Ready-for-Use, customized

Components Modified Specifically Components Gripping Systems Gripping Systems

for the Customer

Customer added Value

1 Y our AdvantageJust Expert

• Over 30 years of experience in gripping technology

Contact Person for a Solution • Over 12,000 implemented gripping systems for a wide

from one Source range of industries

• Modular design with perfectly coordinated standard

For smooth communications, a personal contact person components

is available to you from the start of the project until • Complete accuracy of fit due to standardized interfaces

completion. Your contact person is the interface between • Shorter project lead times due to standardized

you and the individuals involved in the project and ensures systems

that information is exchanged smoothly.

• Reliable implementation processes and planning

From planning to continued support after the conclusion security without extra project costs

of the project, SCHUNK guarantees that your project will be • Functional assemblies fitted on request or ready for

handled cooperatively and efficiently. use

• Time savings due to the perfect solution from a single

source

11

Page12

SCHUNK customized Gripping Systems

Project Management

All inclusive!

SCHUNK customized Gripping Systems.

Take Advantage of our Experience.

More than 12,000

The analysis of complex processes and the comprehensive

implemented solutions analysis of parts and products of our customers leads SCHUNK

to develop effective and customized gripping systems.

speak for themselves. The visualization of automated processes requires maxi-

mum precision – we use state-of-the art technology for 2D

Consistent and comprehensive project management and 3D visualizations and 3D simulations. Our components

is an important part of the SCHUNK philosophy. and configurations contain decisive performance potential

Our approach is systematic and individually adapted for the cost effectiveness of your process chain. We exhaust

to your project; each step is traceable and documented. this potential. Entirely for your benefit.

Consulting Project p lanning Engineering

Imple-

mentation Service

12

Page13

SCHUNK Gripping Systems

Axle System Application Solutions

Automated Handling of Conrods Handling of ground Parts in the

Machining Process

Task Task

Move conrods using a transfer system. Wear parts must be loaded, unloaded and transported.

SCHUNK solution SCHUNK solution

8 SCHUNK lifting/rotary and gripping units are mounted on SCHUNK linear modules type HSB in combination with SCHUNK

a horizontal SCHUNK linear axis with 8 slides to move the universal grippers PGN-plus with a jaw quick-change system

workpieces on in a cycle. BSWS remove a fully ground part from the toolholder and

then loads the clamping device with a rough part.

Finish-machined parts are placed on a pallet,

raw parts are gripped from the pallet.

SCHUNK products SCHUNK products

X-axis (horizontal) 2 x B140-ZSS Z-axis (vertical) 8 x SLE 32-125 X-axis (Horizontal) D240-ZSS Z-axis (vertical) B180-SSS

Toothed belt drive Pneumatic lifting unit Toothed belt axis Spindle axis

Linear module Linear module lifting unit Linear module Linear module

BSWS

SRU-plus PZN-plus Jaw quick- PGN-plus

Swivel unit Centric gripper change system Universal gripper

13

013_EN.indd 13 26.05.17 10:31

Page14

SCHUNK Modular Assembly Automation

Product Overview

100% Flexibility

from the Modular System.

Design an infinite number of applications for micro part handling and

assembly automation with the SCHUNK modular assembly system. An

incredible variety of automation solutions can be realized with just a

few standard modules from the SCHUNK modular system.

Rotary Modules

Cutting edge technology for rotary movements.

More than 600 available components.

Variable from 180° to infinite rotation.

RM-F RM-W RST-D

ERD ERS

i F or further product information please visit

schunk.com/rotary-modules

SCHUNK Grippers

The most extensive gripper

portfolio in the world with NEW

over 2,550 pneumatic and

electric components.

MPG-plus MPG KGG PGN-plus-P

NEW

MPZ PZN-plus SWG PWG-plus GAP EGP PGN-plus-E

i For further product information please visit schunk.com/schunk-grippers

1144 14

Page15

SCHUNK Modular Assembly Automation

Product Overview

Linear Modules

More than 450 pneumatic and electric

components with up to 7,000 mm stroke.

The most comprehensive program on the

market.

LM CLM

KLM

NEW

ELP HLM

ELB ELM

ELS PMP

Beta Delta

i F or further product information please

visit schunk.com/linear-modules

SCHUNK Pillar Assembly System

100% flexible. Achieves a virtually infinite

number of possibilities for combining compo-

nents. Pillars up to 1,000 mm long.

Media feed-through VEH

SOE AMEH/AMDH AMEV/AMDV APEH/APDH STG/STR

i For further product information please visit schunk.com/pillar-assembly-system

15

Page16

SCHUNK ELP Linear Module

The new benchmark innovation in production automation.

With integrated electronics and 24 V Linear Direct Drive.

Easy! Long service life!

The SCHUNK ELP is the easiest electric linear module on The SCHUNK ELP is practically wear-free and is therefore robust,

the market to adjust, and therefore the new technologi- with a long service life.

cal benchmark for use in production automation.

• No shock absorbers to be damaged or require replacing.

• Ready for operation in only two work steps!

Adjust end positions mechanically with a screw and the • Plannable maintenance cycles.

speed of extension and retraction using rotary switches

on the side. ... and you’re done!

• Automatic adjustment of speed depending on Compact and convenient!

extension weight. The control and power electronics are directly integrated

• No shock absorber adjustment is necessary - into the module.

the drive automatically regulates the brake process. • Less space required in the control cabinet.

• Simple control via binary signals such as pneumatic • The ELP module can be decentrally controlled via a

valves, meaning no mechatronics expertise is necessary. fieldbus distributor or directly via digital signals.

Alternative

Adaptable

Intelligent Step 1:

Mechanical end

position adjustment

Step 2:

Adjustment of speed of extension and

retraction using rotary switch

Further information on

SCHUNK ELP:

Unique auto-learn function!

Speed adjustment in 2 - 5 strokes.

schunk.com/ELP

16

Page17

Ready for operation in

only 2 work steps!

Automated Automated

Handling Handling

Mobile Gripping

Systems

Lathe Automated Machine Loading Machining Modular Assembly

Center Automation

Superior Clamping and Gripping –

It’s time to use your machine’s full potential!

With superior components, find potentials in your machine, where you would

least expect to find them. SCHUNK Synergy – the perfectly harmonized interplay of

gripping systems and clamping technology turns our customers into productivity

champions.

17

Page18

018_019_EN_01.pdf

Linear Modules

The worldʼs largest Range of Linear Modules and

Drive Types

The diversity of the linear modules from SCHUNK provides the Reasons to use SCHUNK linear modules:

most extensive range of linear technology for high-speed

assembly automation from one source, as well as for any • Simple commissioning and system integration

kind of process automation handling. Designed as compact

modular systems, all sorts of modules can be combined into • High-speed modules for high-performance assembly

a complete system. Whether you need individual • Highest precision and outstanding repeat accuracy

components, pick & place units, or fully pre-assembled

multi-axis systems, SCHUNK offers the complete portfolio. • Economic gantry solutions from the modular system

This cutting-edge technology “Made by SCHUNK” is only • Compact pick & place units for high-speed use

possible through our continuous innovative strength and

• The worldʼs most extensive pneumatic

decades of experience derived from individual customer

and electric program.

applications.

18

018_019_EN_01.pdf

018_019_EN_01.pdf

018_019_EN_01.pdf

Page19

Contents

018_019_EN_02.pdf

Linear Modules

Contents

Page

Pneumatic Components 28

Electric Components 173

Pick & Place Units 511

Gantry Solutions 573

Check-lists 608

Accessories 618

SCHUNK Contact 742

SCHUNK Service 742

Subsidiaries/Distribution Partners 744

Catalog Order 746

Plants 748

Fax Order 750

19

018_019_EN_02.pdf

018_019_EN_02.pdf

018_019_EN_02.pdf

Page20

Linear Modules

Product Overview

Pneumatic Components | Page 29

Pneumatic Components | Page 32 Pneumatic Components | Page 54 Pneumatic Components | Page 86

HLM Stroke Module CLM Compact Slide LM Universal Linear

• 25 mm up to 150 mm effective stroke • 14 mm to 150 mm effective stroke Module

• Up to 482 N driving force • Up to 482 N driving force • 25 mm to 450 mm effective stroke

• 4 sizes 25 to 200 • 6 sizes 8 to 200 • Up to 753 N driving force

• Optionally available with rod lock • Optionally available with rod lock • 5 sizes 25 to 300

• Optionally available with up to 2 inter-

mediate positions and with rod lock

Pneumatic Components | Page 126 Pneumatic Components | Page 158

KLM Linear Module PMP Gantry Axis

• 25 mm to 300 mm effective stroke • Up to 3,700 mm effective stroke

• Up to 753 N driving force • Up to 250 N driving force

• 4 sizes 25 to 300 • 2 sizes 16 and 25

• Optionally available with intermediate • Optionally available with bellow for

position, dust cover, and rod lock increasing the degree of protection

Electric Components | Page 173

Electric Components | Page 182 Electric Components | Page 198 Electric Components | Page 214

ELP Compact Linear Module ELM Compact Linear Module ELB Compact Linear Module

• Up to 200 mm effective stroke • Up to 260 mm effective stroke • Up to 125 mm effective stroke

• Unique auto-learn function • Up to 100 N driving force • 140 N driving force

• Direct replacement of a • 0.05 mm repeat accuracy • 0.01 mm repeat accuracy

pneumatic version with digital control • 2 sizes 23 and 37 • Absolute path measuring system

• Commissioning in just 2 steps • Optionally available with rod lock and • Optionally available with rod lock and

• Maintenance-free weight compensation weight compensation

Electric Components | Page 226 Electric Components | Page 238 Electric Components | Page 250

LDH Short-stroke Module LDK Stroke Module LDN Universal Linear

• Up to 200 mm effective stroke • Up to 400 mm effective stroke Module

• Up to maximum 52 N driving force • Up to 185 N driving force • Up to 2,700 mm effective stroke

• 0.01 mm repeat accurracy • 0.01 mm repeat accurracy • Up to 205 N driving force

• Absolute path measuring system • Absolute path measuring system • 0.01 mm repeat accuracy

• Optionally available with parking brake • Optionally available with parking break • Absolute path measuring system

or supported version • Optionally with parking break, in a

supported version, and with long slides

20