1/616ページ

ダウンロード(124.5Mb)

このカタログについて

| ドキュメント名 | RotaryModules Cutting-Edge Technology for Rotational Movement |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 124.5Mb |

| 取り扱い企業 | シュンク・ジャパン株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

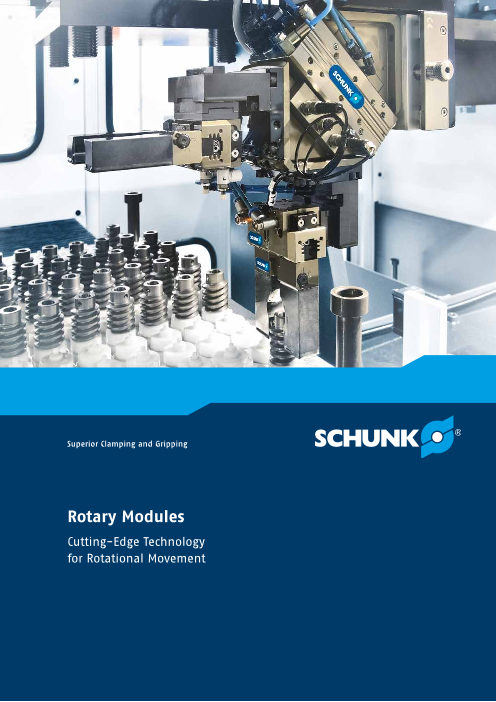

Page1

Title Page

S uperior Clamping and Gripping

Rotary Modules

Cutting-Edge Technology

for Rotational Movement

Page3

Rotary Modules

Cutting-Edge Technology

for Rotational Movement

SCHUNK GmbH & Co. KG

Spann- und Greiftechnik

Bahnhofstr. 106 - 134

D-74348 Lauffen/Neckar

Tel. +49-7133-103-2503

Fax +49-7133-103-2189

grippingsystems@de.schunk.com

www.schunk.com

www.youtube.com/SCHUNKHQ

www.twitter.com/SCHUNK_HQ

www.facebook.com/SCHUNK.HQ

Page4

Familienseite_BroschuereohneRegister_2015-08_EN.pdf

Superior Clamping and Gripping

Jens Lehmann stands for precise gripping, and safe holding.

As a brand ambassador of the SCHUNK team,

the No. 1 goalkeeper represents our global competence

leadership for clamping technology and gripping systems.

The top performance of SCHUNK and Jens Lehmann are

characterized by dynamics, precision, and reliability.

For more information visit our website:

www.gb.schunk.com/Lehmann

Jens Lehmann

FamilienseiteF_aBmriolisecnhsueeitree_oBhrnoesRcheugeisrteeorh_n2e0R15e-g0i8st.einrd_d2 0 1158-08_EN.pdf 06.08.15 15:03

Familienseite_BroschuereohneRegister_2015-08_EN.pdf

Familienseite_BroschuereohneRegister_2015-08_EN.pdf

Page5

Familienseite_BroschuereohneRegister_2015-08_EN.pdf Familienseite_KatalogemitRegister_2015-08_EN.pdf

Henrik A. Schunk, Kristina I. Schunk, brand ambassador Jens Lehmann, and Heinz-Dieter Schunk

Top Performance in the Team

SCHUNK is the world’s No. 1 for clamping technology and As a competence leader, we recognize and develop

gripping systems – from the smallest parallel gripper to standards with a large potential for the future, which

the largest chuck jaw program. will drive the rapid progress in many industries.

In order to boost efficiency, SCHUNK customers have Our customers profit from the expert knowledge, the

bought more than 2,000,000 precision toolholders, experience, and the team spirit of more than 2,300

1,000,000 SCHUNK grippers, and 100,000 lathe chucks employees in our innovative family-owned company.

and stationary workholding systems so far.

Superior Clamping and Gripping The Schunk family wishes you improved end results with

This makes us proud and motivates us to attain new top our quality products.

Jens Lehmann stands for precise gripping, and safe holding. performances.

As a brand ambassador of the SCHUNK team,

the No. 1 goalkeeper represents our global competence

leadership for clamping technology and gripping systems.

The top performance of SCHUNK and Jens Lehmann are

characterized by dynamics, precision, and reliability.

For more information visit our website: Heinz-Dieter Schunk Henrik A. Schunk Kristina I. Schunk

www.gb.schunk.com/Lehmann

Jens Lehmann

FamilienseiteF_aBmriolisecnhsueeitree_oBhrnoesRcheugeisrteeorh_n2e0R15e-g0i8st.einrd_d2 0 1158-08_EN.pdf 06.08.15 15:03 FamilienseiteF_aKmailtiaelnosgeeimtei_tRKeagtaislotegre_m20itR15e-g0i8st.einrd_d2 0 1159-08_EN.pdf 06.08.15 15:04

Familienseite_BroschuereohneRegister_2015-08_EN.pdf

Familienseite_KatalogemitRegister_2015-08_EN.pdf

Familienseite_BroschuereohneRegister_2015-08_EN.pdf

Familienseite_KatalogemitRegister_2015-08_EN.pdf

Page6

Potenziale_AltarKatalog_mitRegister_2015-08_EN.pdf

Superior Clamping and Gripping

I t’s time to use

y our machine’s full potential!

With superior components, find potentials in your machine

where you would least expect to find them.

Make full use of your machine’s potential –

with the extensive product portfolio from SCHUNK.

SCHUNK, the competence leader for clamping technology and

gripping systems, can now open up the full potential of your

processing machines and production processes. Reduce costs

by combining accurate, flexible workpiece machining with

dynamic production automation.

SCHUNK Synergy – when everything fits together.

With SCHUNK Synergy, you benefit from superior components from

our innovative family-owned company and the result of a perfectly

harmonized interplay of clamping technology and gripping systems.

The more SCHUNK, the more efficient it is.

Potenziale_AltarKatalog_mitRegister_2015-08_EN.pdf

Potenziale_AltarKatalog_mitRegister_2015-08_EN.pdf

Potenziale_AltarKatalog_mitRegister_2015-08_EN.pdf

Page7

Potenziale_AltarKatalog_mitRegister_2015-08_EN.pdf Potenziale_AltarKatalog_mitRegister_2015-08_EN.pdf

Superior Clamping and Gripping

I t’s time to use

y our machine’s full potential!

With superior components, find potentials in your machine

where you would least expect to find them.

Make full use of your machine’s potential –

with the extensive product portfolio from SCHUNK.

SCHUNK, the competence leader for clamping technology and

gripping systems, can now open up the full potential of your

processing machines and production processes. Reduce costs

by combining accurate, flexible workpiece machining with

dynamic production automation. Clamping technology and

gripping systems – the perfectly

adjusted interplay makes you

SCHUNK Synergy – when everything fits together. a champion in terms of productivity.

With SCHUNK Synergy, you benefit from superior components from We call it SCHUNK Synergy.

our innovative family-owned company and the result of a perfectly

harmonized interplay of clamping technology and gripping systems. Let’s have a look where the potentials

The more SCHUNK, the more efficient it is. in your machines are hidden.

Jens Lehmann

Potenziale_AltarKatalog_mitRegister_2015-08_EN.pdf Potenziale_AltarKatalog_mitRegister_2015-08_EN.pdf

Potenziale_AltarKatalog_mitRegister_2015-08_EN.pdf

Potenziale_AltarKatalog_mitRegister_2015-08_EN.pdf

Potenziale_AltarKatalog_mitRegister_2015-08_EN.pdf

Potenziale_AltarKatalog_mitRegister_2015-08_EN.pdf

Page8

SCHUNK No. 1 Products for higher Productivity … ... in your Automated Handling System

Discover new ... in your Automated Handling System

potential now:

www.gb.schunk.com/machine-potential

Order the SCHUNK Synergy poster

by telephone +49-7133-103-2256

up 20 tons load to handling

Magnetic li ing technology

... in your Lathe

... for your Automated Machine Loading

... in your Lathe

60 seconds better jaw change 300% surface quality

Lathe chucks and – innovative hydraulic expansion

toolholders, for lathes and turning / milling centers

1,200 standard chuck jaws

The world’s largest chuck jaw program

for every chuck type

Page9

... in your Automated Handling System

No.1 unique more 500 standard than combinations

PGN-plus-P, Generation Permanent, the

only gripper with multi-tooth guidance for line and room gantries from

and permanent lubrication the modular system

100% faster gripper cycle increase 90% change

Universal rotary module SRU-plus 20-S, SWS Quick-change system – fully

the new benchmark in top performance automatic gripper change within seconds

... for your Automated Machine Loading

... for your Automated Machine Loading ... in your Machining Center

300 kg load capacity

NSR Robot coupling

for pallet handling – space-saving and

extremely exible 90% less set-up costs

with , due to set-up

100% during processing timecontrol

KSP plus Clamping force

block with jaw monitoring

30% more productivity 20 mm height

Automated machine loading with PGN-plus-P, NSE mini – the pneumatic

Generation Permanent grippers with GSW Spindle quick-change pallet system in a thin design

interface

Page10

... in your Automated Handling System

... in your Machining Center ... in your Automated Assembly

75,000 customer-specific mm shank solutions 0.3 diameter

less set-up Hydraulic expansion technology for tool

mini sets a benchmark

or workpiece clamping in micro machining

costs

, due to set-up

during processing time 100% encapsu- 3 µ run-out lated less than accuracy

KSK Centric clamping vise -SVL Super-slim tool extension

fully functional in harsh environments optimized interfering contours

5 -sided up workpiece machining to 85,000 rpm

in one set-up – Magnetic -S predestined for

in a thin design clamping technology high-speed cutting

Page11

... in your Automated Assembly

combination

options

SCHUNK Modular assembly system

180% better gripping greater force – mass ratio 25% gripping force

EGP – The powerful electronic gripper for small MPG-plus – The most powerful pneu-

components with integrated electronics matic miniature gripper in the market

110 picks per minute

PPU-E – The fastest pick & place unit

... in your Automated Assembly in the market, PPU-P with 90 picks/min

... in your Service Robotics Application

Future handling

6 degrees of freedom

Powerball lightweight arm LWA 4P

The lightweight arm with the world’s most

compact performance. Used on mobile platforms.

less than 3 µ run-out accuracy 100% suitable for all SCHUNK toolholders

-R with unique patented polygonal -SVL Tool extension –

clamping technology optimized interfering contours and super-slim

up 80 bar coolant-proof or more years of experience in to peripheral coolant than 35 Hydraulic expansion

-SVL Super-slim tool extension Versatile clamping range with GZB-S technology. , the original, is versatile,

Intermediate sleeves with 29 interfaces and 3 µ run-out accuracy

2,000 Nm torque 0 µ permanent run-out with Ø 32 mm accuracy

for large volume cutting, boring, , perfect vibration damping,

reaming, and threads resulting in up to 50% longer service life

Page12

SCHUNK customized Gripping Systems

Components and Systems

SCHUNK Gripping Systems

From the standard Component

to the customized Gripping System

More than 30 years of gripping competence is the basis for the world’s largest standardized

gripping technology product range with more than 4,000 components and for an average of

2,000 standard and customized gripping systems per year.

Components Gripping Systems

Standard Customized Standard Customized

Components Components Gripping Systems Gripping Systems

From standard components Solution composed of several

further developed in accordance SCHUNK components, of which

with customer requirements at least one is further de-

to exclusive customized new veloped or newly developed

developments. specifically for the customer.

SCHUNK Grippers

Examples: Examples:

Rotary Modules

Modular Assembly Automation

Linear Modules

Wafer Grippers

made of laser-forming material

with SCHUNK LGP gripper

Connecting Rod Handling

Robot Accessories

Line and Room Gantries

Pick & Place Units

Compact Vises

for sheet metal machining,

pneumatically actuated

Aluminum Foil Handling

Gripping Hands

Packaging Grippers

High-speed grippers according Solution composed of several

to legal, hygienic, and SCHUNK standard components Modular and

Lightweight Arms production specifications for robots and gantries Mobile Gripping Systems

11

10

Page13

SCHUNK customized Gripping Systems

Your added value

From the standard Component to the

customized Gripping System

Solution Expertise

Standard Standard Components Customized Standard Ready-for-Use, customized

Components Modified Specifically Components Gripping Systems Gripping Systems

for the Customer

Customer added Value

1 Y our AdvantageJust Expert

• Over 30 years of experience in gripping technology

Contact Person for a Solution • Over 12,000 implemented gripping systems for a wide

from one Source range of industries

• Modular design with perfectly coordinated standard

For smooth communications, a personal contact person components

is available to you from the start of the project until • Compete accuracy of fit due to standardized interfaces

completion. Your contact person is the interface between you • Shorter project lead times due to standardized systems

and the individuals involved in the project and ensures that

information is exchanged smoothly. • Reliable implementation processes and planning security

without extra project costs

From planning to continued support after the conclusion • Functional assemblies fitted on request or ready for use

of the project, SCHUNK guarantees that your project will be • Time savings due to the perfect solution from a single

handled cooperatively and efficiently. source

11

10

Page14

SCHUNK customized Gripping Systems

Project Management

All inclusive!

SCHUNK customized Gripping Systems.

Take Advantage of our Experience.

More than 12,000 The analysis of complex processes and the comprehensive

analysis of parts and products of our customers leads SCHUNK

implemented solutions to develop effective and customized gripping systems.

The visualization of automated processes requires maximum

speak for themselves. precision – we use state-of-the art technology for 2D and

3D visualizations and 3D simulations. Our components

Consistent and comprehensive project management is and configurations contain decisive performance potential

an important part of the SCHUNK philosophy. for the cost effectiveness of your process chain. We exhaust

Our approach is systematic and individually adapted to your this potential.

project; each step is traceable and documented. Entirely for your benefit.

Consulting Project planning Engineering Implementation Service

13

12

Page15

SCHUNK customized Gripping Systems

Examples

Loading gantry for Handling of

Machining Center Aluminum Rims

Task Task

Loading and unloading of machining centers with To provide a loading gantry for a machining center.

unfinished and finished aluminum parts.

SCHUNK solution

SCHUNK solution Loading of the machine with unfinished/finished parts is

The aluminum blanks of the aluminum rims are finish machined achieved with a SCHUNK pneumatic rotary unit with double

in several steps. The blanks are gripped from the conveyor belt grippers. This significantly reduces the cycle time.

with a modified SCHUNK PFH 2-finger long-stroke gripper and

inserted into the machining center. After the initial machining

the finished part is removed and the next unfinished part

is inserted immediately. The grippers also feature special SCHUNK products

plastic inserts on the gripper fingers.

SCHUNK products

X-axis (horizontal) D240-ZSS Z-axis (vertical) D240-SSS

Linear module Delta, Linear module Delta,

toothed-belt axis spindle axis

PFH SRU-plus PGN-plus

2-finger long-stroke gripper Rotary unit Universal gripper

13

12

Page16

Rotary Modules

Rotary Modules

SCHUNK Rotary and Swivel Units –

Cutting Edge Technology for rotational Movements.

The rotary module product line from SCHUNK offers Strong arguments

a complete spectrum of compact rotary and swivel for rotary modules from SCHUNK:

units for every handling task – for fast and easy

integration. • Pneumatic or electric modules

Hose-free media feed-through guarantees reliable • Short swiveling times starting at 0.16 seconds

performance and minimizes interference contours.

Monitoring capabilities by sensors and multiple • Fast and easy integration

mounting options for all modules increase the flexibi- • Lockable intermediate position

lity of every automated production process. A prere-

quisite for this cutting edge technology, which is • Continuously adjustable end positions

“Made in Germany”, is our never-ending innovative

potential.

14

Page17

TABLE OF CONTENTS

Rotary Modules

Contents

Page

Product Overview 16

SCHUNK Rotary Modules, pneumatic 22

Vane Swivel Units 22

Swivel Units 62

Swivel Heads 196

Swivel Fingers 264

Rotary Indexing Tables 286

Lift and Turn Units 304

SCHUNK Rotary Modules, electric 318

Rotary Units 318

Drives M 400

Accessories 448

SCHUNK Contact 606

SCHUNK Service 606

Subsidaries / Distribution Partners 608

Plants 610

Catalog Order 611

Fax Order 612

15

Page18

Product Overview

Rotary Modules

Product Overview

Vane Swivel Units | Page 22

Vane Swivel Units | Page 24 Vane Swivel Units | Page 42

SFL Vane Swivel Unit RM-W

• Axial force 10 N to 50 N Universal Vane Swivel Unit

• Torque 0.1 Nm to 3.6 Nm • 4 sizes 50 to 310

• 3 sizes 25 to 64 • High torque up to 22 Nm

• Compact module for light turning • Angle of rotation optionally 90° or 180°

tasks up to 180° • Standardized mounting holes for

integration in the modular system

Swivel Units | Page 62

Swivel Units | Page 64 Swivel Units | Page 84 Swivel Units | Page 112

SRU-mini RM-F SRU-plus

Miniature Swivel Unit Flat Swivel Unit Universal Swivel Unit

• 4 sizes 8 to 14 • Freely adjustable angle of rotation • Axial force 255 N to 11,000 N

• Optionally with patented speed • Optionally with center position • High torque up to 115 Nm

damping for maximum cycle frequency • 6 unit sizes 6 to 21 • 8 unit sizes 20 to 63

• Optionally with media feed-through • Standardized mounting holes for • Selectable angle of rotation,

• Angle of rotation optionally 90° or 180° integration in the modular system 90° or 180°

• Locked center position possible

Swivel Heads | Page 196

Swivel Heads | Page 198 Swivel Heads | Page 244

SRH-plus SKE

Universal Swivel Head Miniature Swivel Head

• Torque 3 Nm to 69.9 Nm • 90° swivel head

• Integrated media feed-through and • Low weight and compact dimensions

capability of transmitting digital signals • Standardized interfaces to

• 7 unit sizes, 20 to 60, with 180° angle many grippers of the RH series

of rotation

• Modular design with many options

16

Page19

Rotary Modules

Product Overview

Swivel Fingers | Page 264

Swivel Fingers | Page 266

GFS

Universal Swivel Fingers

• Axial force 330 N to 3,300 N

• Torque 0.64 Nm to 10 Nm

• 4 unit sizes 16 to 40

• For turning of workpieces

Rotary Indexing Tables | Page 286

Rotary Indexing Tables

Page 288

RST-D

Rotary Indexing Table

• Pitch 4, 6, 8, 12

• 3 sizes 60, 87 and 134

• Optionally with rotary feed-through

• Right, left or pendulum operation

via controller possible

Lift and Turn Unit | Page 304

Lift and Turn Unit | Page 306

DRL

Compact Lift and Turn Unit

• For highly dynamic and yet smooth

Pick & Place operations

• Up to 90 cycles per minute

• Angle of rotation optionally 90° or 180°

17

Page20

Rotary Modules

Product Overview

Rotary Units | Page 318

Rotary Units | Page 322 Rotary Units | Page 344 Rotary Units | Page 360

PR Universal Rotary Unit PRH Miniature Rotary Unit ERD Torque Motor

• Axial force 345 N to 895 N • Torque 1.5 Nm to 6.8 Nm • Torque 0.4 Nm to 1.2 Nm

• High torque 3.6 Nm to 142 Nm • Endlessly turning • Integrated air and electrical

• 3 unit sizes 70 to 110 • 6 unit sizes feed-through

• Complete integration of the control, • Integrated electronics with • 3 unit sizes 4, 8, 12

regulation, and power electronics, SCHUNK Motion Protocol (SMP) • SIL-2 certified absolute

including different interfaces stroke measuring system

Rotary Units | Page 376 Rotary Units | Page 392

ERS Torque Motor ERM

• High torque from 2.5 Nm to 10 Nm Heavy Load Rotary Module

• High axial force 2,500 N to 10,000 N • Modular drive concept for

• 3 unit sizes 135 to 210 adaptation of servo motors

• 2 controller variants – SCHUNK MCS12 • Integrated media feed-through

controller (48 V) or standard controller • Center bore for cable feed-through

system (560 V, Bosch or Siemens)

M Drives | Page 400

Drives | Page 402 Drives | Page 426

PDU Compact Drive PSM Drive

• Nominal torque 0.19 Nm to 142 Nm • Nominal torque 0.19 Nm to 142 Nm

• 3 unit sizes 70 to 110 • 3 unit sizes 70 to 110

• With integrated precision gears • Complete integration of the control,

• Complete integration of the control, regulation, and power electronics,

regulation, and power electronics, including different interfaces

including different interfaces

18