1/8ページ

ダウンロード(846.3Kb)

BioFlo 320 – Universal controller for cell culture and microbiology research

製品カタログ

このカタログについて

| ドキュメント名 | BioFlo 320 – Universal controller for cell culture and microbiology research |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 846.3Kb |

| 登録カテゴリ | |

| 取り扱い企業 | エッペンドルフ株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

The Smarter Solution

BioFlo® 320 – Universal controller for cell culture and microbiology research

Page2

2 BioFlo® 320

Page3

BioFlo® 320 3

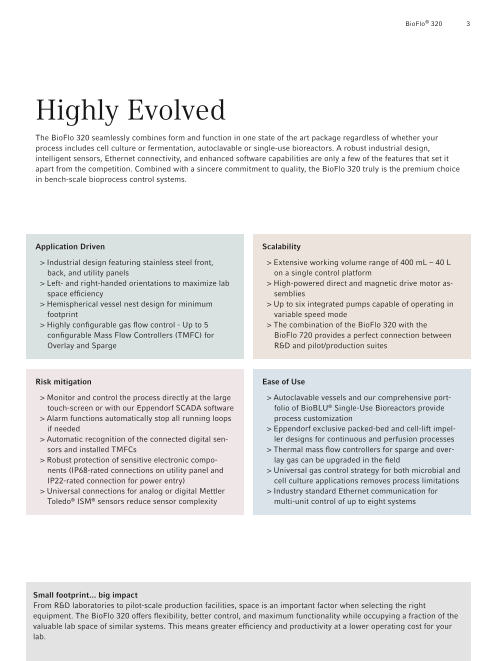

Highly Evolved

The BioFlo 320 seamlessly combines form and function in one state of the art package regardless of whether your

process includes cell culture or fermentation, autoclavable or single-use bioreactors. A robust industrial design,

intelligent sensors, Ethernet connectivity, and enhanced software capabilities are only a few of the features that set it

apart from the competition. Combined with a sincere commitment to quality, the BioFlo 320 truly is the premium choice

in bench-scale bioprocess control systems.

Application Driven Scalability

> Industrial design featuring stainless steel front, > Extensive working volume range of 400 mL – 40 L

back, and utility panels on a single control platform

> Left- and right-handed orientations to maximize lab > High-powered direct and magnetic drive motor as-

space efficiency semblies

> Hemispherical vessel nest design for minimum > Up to six integrated pumps capable of operating in

footprint variable speed mode

> Highly configurable gas flow control - Up to 5 > The combination of the BioFlo 320 with the

configurable Mass Flow Controllers (TMFC) for BioFlo 720 provides a perfect connection between

Overlay and Sparge R&D and pilot/production suites

Risk mitigation Ease of Use

> Monitor and control the process directly at the large > Autoclavable vessels and our comprehensive port-

touch-screen or with our Eppendorf SCADA software folio of BioBLU® Single-Use Bioreactors provide

> Alarm functions automatically stop all running loops process customization

if needed > Eppendorf exclusive packed-bed and cell-lift impel-

> Automatic recognition of the connected digital sen- ler designs for continuous and perfusion processes

sors and installed TMFCs > Thermal mass flow controllers for sparge and over-

> Robust protection of sensitive electronic compo- lay gas can be upgraded in the field

nents (IP68-rated connections on utility panel and > Universal gas control strategy for both microbial and

IP22-rated connection for power entry) cell culture applications removes process limitations

> Universal connections for analog or digital Mettler > Industry standard Ethernet communication for

Toledo® ISM® sensors reduce sensor complexity multi-unit control of up to eight systems

Small footprint... big impact

From R&D laboratories to pilot-scale production facilities, space is an important factor when selecting the right

equipment. The BioFlo 320 offers flexibility, better control, and maximum functionality while occupying a fraction of the

valuable lab space of similar systems. This means greater efficiency and productivity at a lower operating cost for your

lab.

Page4

4 BioFlo® 320

Application Driven

Designed for cGMP environments

The next generation of our BioFlo 320 bioprocess control system combines the benefits of a classical industrial design

with the power of our improved BioFlo control software.

Developed to be used in cGMP regulated environments, Emerson® and Eppendorf have partnered to develop seamless

communication between the DeltaVTM distributed control system and the BioFlo 320 bioprocess control system. Our open

communication protocol exposes controller information allowing it to be integrated into broader features and functions

of the DeltaV platform, simplifying tech transfer, scale-up, and recipe sharing in bioprocess research and process

development.

Four universal connections Control up to eight

for analog or digital Mettler units from a single

High-powered direct Toledo ISM sensors user interface

and magnetic drive

motor assemblies;

capable of clockwise

and counterclockwise

rotation

Interchangeable

Ultra-compact design TMFC drawers for

with vessel nest for sparge and overlay

minimum footprint; gas flexibility

left- and right-handed

orientations to

maximize lab space

Unique variable/

fixed speed front-

mounted pumps

capable of clockwise

Sixteen and counterclockwise

interchangeable rotation

autoclavable

vessels and the

comprehensive line Industrial, brushed

of BioBLU Single-Use stainless steel panels

Bioreactors provide enhanced

corrosion resistance

Single-use bioreactors: Process control: Vessel material: Autoclavable

0.40 L – 40 L Cell culture or Glass or bioreactors:

Microbiology Single-Use 0.6 L – 10.5 L

Page5

BioFlo® 320 5

Scalability

The perfect connection from R&D to production

Seamless transition of your process from 400 mL to 40 L and beyond. In combination with the BioFlo 720 bioprocess

control system, we designed a bioreactor control platform that supports one of the widest range of single-use solutions,

allowing the scale-up of your process to up to 2,000 L.

The updated and improved BioFlo software ensures a consistent user experience across all BioFlo control systems and

comes with new features to improve your process.

BioBLU® Single-Use Bioreactors

> Compatible with 400 mL – 40 L BioBLU Single-Use

Bioreactors, including the BioBLU 5p, the first single-use

bioreactor to utilize the exclusive packed-bed impeller

> Built-in optical pH sensor technology

> Vessel and exhaust heat blanket connections provide pre-

cise temperature control and exhaust gas treatment

> Bench-scale single-use bioreactors specifically designed

for microbial fermentation

> Rigid-walled, stirred-tank design provides many advan-

tages over single-use bag design

> Eliminates potential for tears, pits, and folds during instal-

lation

> Single-layer polymer removes both uncertainty for leach-

able and extractable data and the need for unnecessary

preventative actions, like pre-process media wash

Application flexibility

> Suitable for the use in all labs, from academia through > Scale-up and scale-down modeling

pilot-scale production > Suspension or adherent cultures

> Batch, fed-batch, perfusion, and continuous processes > Micro-aerobic, anaerobic, exothermic

> Universal control for mammalian, stem cell, insect, fermentation processes

microbial, plant, and algae cultures > Specialized impellers for low-shear

> Secreted product, vaccine, and monoclonal antibody and zero-shear process needs

production > Food and beverage

> Biofuels research and manufacturing > Fine chemical processes

Page6

6 BioFlo® 320

Risk Mitigation

Monitoring and control of critical system parameters

Parallel processing is key to efficiently optimizing a process or to producing reproducible results. Eight units of the

BioFlo 320 bioprocess control system can be connected to each other and controlled by a single unit. The control

software gives valuable insights into all processes, such as current process parameters, and the lifetime of connected

digital sensors.

Monitoring the controller and the process is key to successful

process development. The BioFlo 320 software features

screens, designed to provide you with the status of both.

> Alarm functions automatically inform about the status of the

process, with automatic loop shutdown if needed

> Receive alarm notifications via email or text message di-

rectly to your mobile device

> The diagnostic screen provides information on the hardware

status and upcoming maintenance

Intelligent Sensors

> Integrated Mettler Toledo Intelligent Sensor Management (ISM) platform

> Universal connections for up to four analog or digital (ISM) sensors

> pH: analog or digital (ISM)

> DO: analog or digital (ISM)

> Optical DO: digital (ISM)

> Redox: analog or digital (ISM)

> CO2: digital (ISM)

> Real-time sensor diagnostics anticipate sensor failure

Full integration of bioprocess software and data into

Emerson’s DeltaVTM system

Eppendorf and Emerson have collaborated to integrate Emerson’s DeltaV™ distributed control system

(DCS) with the BioFlo 320 bioprocess control system.

> Full integration of bioprocess software and data into Emerson's DeltaV system

> Simplified tech-transfer, scale-up, and recipe sharing in bioprocess research

> Manage data and use the same automation systems throughout the product

development process, from bioprocess research to manufacturing

Page7

BioFlo® 320 7

Ease of Use

Advanced software making life easier

The new release of the BioFlo software ensures a consistent user experience across all BioFlo control systems and

comes with new features to improve your process. Develop your process with the BioFlo 320 and seamlessly scale-up

from 50 L – 2,000 L with the BioFlo 720 bioprocess controller. New software features such as the Auto Calibrate and

Scale Up Assist function simplify your process, mitigate risk, and help to save time.

Auto Calibrate

> Automated calibration for all attached DO sensors

at once

> DO sensors can be run through an automatic

calibration sequence reducing touch time and

ensuring consistency

> User specifies calibration scheme, process condi-

tions, and zero-point method (electronic or N2)

> System completes calibration when slope stabi-

lizes

Parallel Control

> Control eight units from a single user interface

> Automatic gas mixing algorithms for simplified

control (4-gas, 3-gas, O2 enrichment, N2

enrichment)

> Ten-point cascade feature for sophisticated con-

trol strategies

> Built-in elapsed fermentation timer for batch

management

> Trend display with up to twelve process values

within a single view

Scale Up Assist

> Scale Up modeling software for the calculation of

important process parameters

> The integrated Scale Up Assist of the BioFlo

software calculates all parameters based on either

constant P/V or constant tip speed

> Up to 3 different vessel sizes can be selected from

> The software contains vessel specific data from the

Eppendorf vessel portfolio and the

ThermoTM Scie ntific HyPerformaTM 5:1 Single-Use

Bioreactors (SUBs).

Page8

Technical Data

BioFlo 320 Specifications

Control Station

Dimensions (W x D x H) 40.6 x 40.6 x 66.0 cm (16 in x 16 x 26 in)

Net weight 32 kg (70 lb)

Touchscreen 38.1 cm (15 in) projected capacitive touchscreen

Communication 2 x USB (software updates, serial communication)

Ethernet (SCADA, IP Network)

3 x Analog Input/Output (defined as 4 – 20 mA or 0 – 5 V or 0 – 10 V)

Utility Connection Requirement

Electrical IEC (with regional plug types) 100 – 120/208 – 240 VAC, 50/60 Hz, 2270 VA, Single Phase

Water Stainless steel quick-connect 10 psig (0.69 barg)

Gas supply (Air, O2, N2, CO2) Push-connect Autoclavable Single-use

10 psig (0.69 barg) 6 psig (0.44 barg)

Exhaust 0.5 psig (0.035 barg)

Operating conditions 10 – 30 °C, up to 80 % RH, non-condensing

Agitation

Direct drive 1 L, 3 L: 25 – 1500 rpm

5 L, 10 L: 25 – 1200 rpm

Magnetic drive (autoclavable vessels) 1 L, 3 L, or 5 L: 10 – 500 rpm

10 L: 10 – 150 rpm

Magnetic drive (single-use vessels) BioBLU 1f: 10 – 1200 rpm; BioBLU 3f: 25 – 1200

BioBLU 1c: 10 – 500 rpm

BioBLU 3c, 5c, 5p, 10c & 14c: 10 – 200 rpm

BioBLU 50c: 10 – 150 rpm

Temperature

Water-jacketed 5 °C above coolant to 55 °C above ambient (80 °C max)

Stainless steel dish-bottom 5 °C above coolant to 65 °C above ambient (90 °C max; 85 °C max for 10 L)

Single-use 5 °C above ambient to 40 °C (60 °C max for BioBLU 1)

Sensor type PT100

Gas supply

Sparge 1, 3, or 4 TMFC; ring or micro-sparger

Overlay 1 TMFC; headspace addition

Sensors Communication Control range

pH Analog or digital Mettler Toledo ISM 2 – 12

Optical pH Digital (Presens) 6 – 8

DO Analog or digital Mettler Toledo ISM 0 – 200 %

Optical DO Digital Mettler Toledo ISM 0 – 200 %

Redox Analog or digital Mettler Toledo ISM (-)2000 mV – (+)2000 mV

CO2 Digital Mettler Toledo ISM 0 – 100 %

Pumps Pump Head Variable Speed Fixed Speed

Pumps 1, 2, & 3 Watson-Marlow 114DV 5 – 25 rpm 25 rpm (0 – 100 % Duty Cycle)

Pump 4 Watson-Marlow 314D 20 – 100 rpm 100 rpm (0 – 100 % Duty Cycle)

External pumps 1 & 2 Watson-Marlow 120U/DV 0.1 – 200 rpm N/A

Specifications subject to change.

Your local distributor: www.eppendorf.com/contact

Eppendorf SE · Barkhausenweg 1 · 22339 Hamburg · Germany

eppendorf@eppendorf.com · www.eppendorf.com

www.eppendorf.com/BioFlo320

Mettler Toledo® and ISM® are registered trademarks of Mettler Toledo AG, Switzerland. Watson-Marlow® is a registered trademark of Watson-Marlow Limited, UK. Emerson® is

a registered trademark of Emerson Electric Co., USA. DeltaV™ is a trademark of Emerson Electric Co., USA. Thermo ScientificTM and HyPerformaTM are trademarks of Thermo

Fisher Scientific Inc, USA. Eppendorf®, the Eppendorf Brand Design, and BioBLU® are registered trademarks of Eppendorf SE, Germany. DASware® is a registered trademark

of DASGIP Information and Process Technology GmbH, Germany. BioFlo® and BioCommand® are registered trademarks of Eppendorf, Inc., USA. All rights reserved, including

graphics and images. Copyright © 2022 by Eppendorf SE.

Order No.: AN00111020/GB5/0.5T/0422/EBC/STEFF · Carbon neutrally printed in Germany