Page1

SPEC-TTS1B103F3381RS1-廣登-1.0.xls

NTC Thermistor TTS Type

Edition:TTS1B103F3381RS1

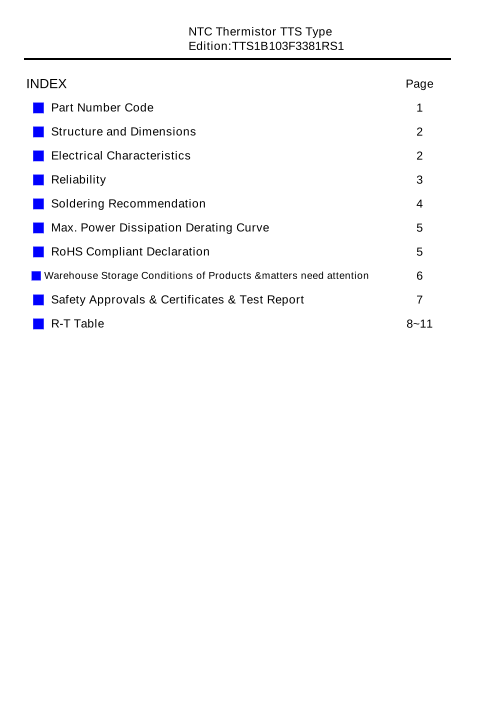

INDEX Page

■ Part Number Code 1

■ Structure and Dimensions 2

■ Electrical Characteristics 2

■ Reliability 3

■ Soldering Recommendation 4

■ Max. Power Dissipation Derating Curve 5

■ RoHS Compliant Declaration 5

■ Warehouse Storage Conditions of Products &matters need attention 6

■ Safety Approvals & Certificates & Test Report 7

■ R-T Table 8~11

Page2

SPEC-TTS1B103F3381RS1-廣登-1.0.xls

NTC Thermistor TTS Type

Edition:TTS1B103F3381RS1 Page 1

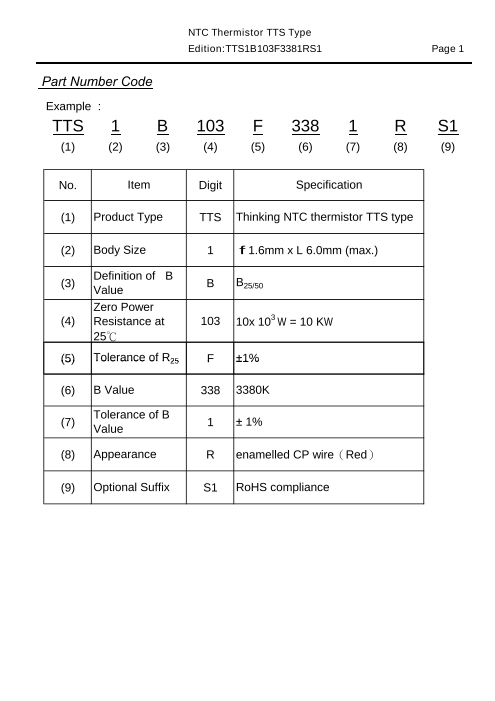

Part Number Code

Example :

TTS 1 B 103 F 338 1 R S1

(1) (2) (3) (4) (5) (6) (7) (8) (9)

No. Item Digit Specification

(1) Product Type TTS Thinking NTC thermistor TTS type

(2) Body Size 1 f 1.6mm x L 6.0mm (max.)

(3) Definition of B

Value B B25/50

Zero Power

(4) Resistance at 103 10x 103 W = 10 KW

25℃

(5) Tolerance of R25 F ±1%

(6) B Value 338 3380K

(7) Tolerance of B

Value 1 ± 1%

(8) Appearance R enamelled CP wire(Red)

(Test (Test ConditTiohnersm :istorTesmt u st be

(9) Optional Suffix S1 RoHS compliance

(Test ThermistorTesmt u st be

(Test

ThermistorTesmt u st be

NTC Thermistor TTS Type

Edition:TTS1B103F3381RS1 Page 2

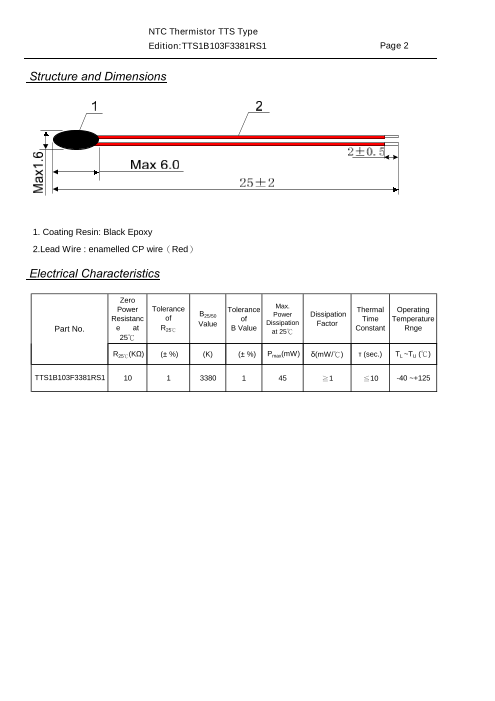

Structure and Dimensions

Dis3c f Dm L31 . ±d p T3m.5a

1. Coating Resin: Black Epoxy

2.Lead Wire : enamelled CP wire(Red)

Electrical Characteristics

Zero

Power Tolerance Tol ax. ing

Resistanc of B erance M

25/50 of Power Dissipation Thermal Operat

Part No. e at alue Dissipation

R V ctor Time Temperature

25℃ B Value Fa

at 25℃ Constant Rnge

25℃

R25℃(KΩ) (± %) (K) (± %) Pmax(mW) δ(mW/℃) τ (sec.) TL ~TU (℃)

TTS1B103F3381RS1 10 1 3380 1 45 ≧1 ≦10 -40 ~+125

Dis3c f Dm L31 . ±d p

(Test ThermistoTrest must

Page4

SPEC-TTS1B103F3381RS1-廣登-1.0.xls

NTC Thermistor TTS Type

Edition:TTS1B103F3381RS1 Page 3

Reliability

Item Standard Test conditions / Methods Specifications

Gradually applying the force specified and keeping the

unit fixed for 10±1 sec.

Tensile Strength Terminal diameter Force

of Terminals IEC60068-2-21 (mm) (Kg) No visible damage

d≦0.25 0.10

0.25<d≦0.3 0.25

0.3<d≦0.5 0.50

Hold specimen and apply the force specified below to

each lead. Bend the specimen to 90°, then return to the

original position. Repeat the procedure in the opposite

Bending direction.

Strength of IEC60068-2- 21 Terminal diameter Force No visible damage

Terminals (mm) (Kg)

d≦0.25 0.050

0.25<d≦0.3 0.125

0.3<d≦0.5 0.250

At least 95% of terminal

Solderability IEC60068-2-20 245 ± 3 ℃ , 3 ± 0.3 sec electrode is covered by

new solder

Resistance to No visible damage

Soldering Heat IEC60068-2-20 260 ± 3 ℃ , 10 ± 1 sec

∣△R25/R25∣≦3 %

High No visible damage

Temperature IEC60068-2-2 125 ± 5 ℃ , 1000 ± 24 hrs

Storage ∣△R25/R25∣≦5 %

Damp Heat, No visible damage

Steady State IEC 60068-2-78 40 ± 2 ℃ , 9 0 ~ 95 % RH , 1000 ± 24hrs

∣△R25/R25∣≦3%

The conditions shown below shall be repeated 5 cycles

Step Temperature (℃) Period (minutes)

Rapid Change of

Temperature IEC60068-2-14 1 -40 ± 5 No visible damage

30 ± 3

∣△R 3 %

2 Room temperature 5 ± 3 25/R25∣≦

3 125 ± 5 30 ± 3

4 Room temperature 5 ± 3

Max. No visible damage

Power IEC60539-1 4.26.3 25 ± 5 ℃, Pmax. , 1000 ± 24 hrs

Dissipation ∣△R25/R25∣≦ 5 %

NTC Thermistor TTS Type

Edition:TTS1B103F3381RS1 Page 4

No break out OK

Soldering Recommendation

No break out OK

No break out OK

█ Wave Soldering Profile

Preheating Soldering Cooling

260℃ max.

Note 2

Note 3

130±20℃

Note 1

Tamb

t

30~90sec <1sec <10sec

Time

Note 1 : (1~3)℃/sec

Note 2 : Approx. 200℃/sec

Note 3 : 5℃/sec Max

█ Recommended Reworking Conditions with Soldering Iron

Item Conditions

Temperature of Soldering Iron-tip 360℃ (max.)

Soldering Time 3 sec (max.)

Distance from Thermistor 10 mm (min.)

Temperature

NTC Thermistor TTS Type

Edition:TTS1B103F3381RS1 Page 5

Max. Power Dissipation Derating Curve

PTa

P 100%

max

0

TL 0 25 TU

Ambient temperature (℃)

Note: TL = Minimum operating temperature(℃)

TU = Maximum operating temperature (℃)

For example:

Ambienttemperature(Ta)=55℃

Maximum operating temperature(Tu)=100℃

PTa=(Tu-Ta)/(Tu-25)×Pmax=60% Pmax

RoHS Compliant Declaration

We hereby declare the components delivered to your company

are compliant with RoHS Directive 2015/863/EU

Install and use

1. Use this product within the specified temperature r ange.

2. Higher temperature may cause deterioration of the characteristics or the material quality of this product.

3. Do not melt the solder in resin head, when you solder this product. If you melt the solder in resin head,

it has possibility that the break of wire, short and insulation damage.

4. Do not touch the resin head directly by solder iron. It may cause the melt of solder in resin head.

5. At least away from resin head 10mm above when lead dividing.

6. In case you cut the lead wire of this product less than 10mm from resin head,

the heat of melted solder at lead wire edge is propagated easily to the resin head along the lead wire.

7. Radius of lead bending should be more than 1mm when lead bending.

Holding element by side lead wire is recommended when lead wire is bent or cut.

8. Do not apply an excessive force to the lead. Otherwise, it may cause junction between lead and element to break or crack.

9. The ceramic element of this product is fragile, and care must be taken not to load an excessive press-force

or not to give a shock at handling. Such forces may cause cracking or chipping.

10. If you mold by resin this product, please evaluate the quality of this product before you use it.

Warehouse Storage Conditions of Products

To keep solderability of product from declining, the following storage condition is recommended.

1. Storage condition:

Temperature -10℃ to +40℃

Humidity less than 75%RH (not dewing condition)

2. Storage term:

Use this product within 1 year after delivery by first-in and first-out stocking system.

3. Handling after unpacking:

After unpacking, reseal product promptly or store it in a sealed container with a drying agent.

4. Storage place:

Do not store this product in corrosive gas (Sulfuric acid gas, Chlorine gas, etc.) or in direct sunlight.

Warn and note item

This product is designed for application in an ordinary environment (normal room temperature, humidity and atmospheric pressure).

Do not use under the following conditions because all of these factors can deteriorate the product characteristics or cause failures and burn-out.

1. Corrosive gas or deoxidizing gas (Chlorine gas, Hydrogen sulfide gas, Ammonia gas, Sulfuric acid gas, Nitric oxide gas, etc.)

2. Volatile or flammable gas

3. Dusty conditions

4. Under vacuum, or under high or low pressure

5. Wet or humid locations; soak in the liquid or wash with liquid

6. Places with salt water, oils, chemical liquids or organic solvents and do not use directly with quick-drying glue.

7. Strong vibrations

8. Other places where similar hazardous conditions exist

9. Be sure to provide an appropriate fail-safe function on your product to prevent secondary damages

that may be caused by the abnormal function or the failure of our product.

Restriction of Weapon and Military End-Use

Thinking has established and implemented the fundamental policy on none of our product should be used or sold,

through any channels, for use in the design, development, production, utilization, maintenance or operation of,

or otherwise contribution to any weapons (Weapons of Mass Destruction [nuclear, chemical or biological weapons or missiles]

or conventional weapons) or goods or systems specially designed or intended for military

end-use or utilization by military end-users.

Page8

SPEC-TTS1B103F3381RS1-廣登-1.0.xls

NTC Thermistor TTS Type

Edition:TTS1B103F3381RS1 Page 6

Certificates

(1) IATF 16949 certificate

(2) ISO 9001 certificate

Test Report

(1) RoHS test report

Page9

SPEC-TTS1B103F3381RS1-廣登-1.0.xls

R - T Table

Part No. : TTS1B103F3381RS1 R25=10KΩ ±1%

B25/50 = 3380 K ± 1%

Temperature Rmax. Rnor. Rmin. Temperature Tol.

(℃) (KΩ) (KΩ) (KΩ) (℃)

-40 199.814 192.074 184.616 -0.73 0.73

-39 189.146 181.919 174.950 -0.71 0.72

-38 179.017 172.270 165.761 -0.70 0.71

-37 169.448 163.151 157.072 -0.69 0.71

-36 160.435 154.557 148.878 -0.68 0.70

-35 151.958 146.469 141.164 -0.68 0.70

-34 143.988 138.861 133.903 -0.67 0.69

-33 136.493 131.702 127.067 -0.67 0.69

-32 129.440 124.963 120.628 -0.66 0.68

-31 122.799 118.613 114.558 -0.66 0.68

-30 116.539 112.625 108.831 -0.65 0.67

-29 110.635 106.974 103.424 -0.65 0.67

-28 105.062 101.637 98.3143 -0.64 0.66

-27 99.7979 96.5940 93.4837 -0.64 0.65

-26 94.8238 91.8261 88.9143 -0.63 0.65

-25 90.1215 87.3164 84.5902 -0.62 0.64

-24 85.6748 83.0497 80.4970 -0.62 0.63

-23 81.4687 79.0119 76.6215 -0.61 0.63

-22 77.4896 75.1901 72.9515 -0.60 0.62

-21 73.7247 71.5722 69.4756 -0.59 0.61

-20 70.1621 68.1470 66.1832 -0.59 0.61

-19 66.7906 64.9040 63.0643 -0.58 0.60

-18 63.5997 61.8332 60.1097 -0.58 0.59

-17 60.5794 58.9251 57.3103 -0.57 0.59

-16 57.7202 56.1709 54.6577 -0.56 0.58

-15 55.0131 53.5619 52.1438 -0.56 0.57

-14 52.4496 51.0902 49.7611 -0.55 0.57

-13 50.0217 48.7481 47.5021 -0.54 0.56

-12 47.7216 46.5282 45.3602 -0.54 0.56

-11 45.5420 44.4237 43.3285 -0.53 0.55

-10 43.4761 42.4280 41.4011 -0.53 0.54

-9 41.5173 40.5349 39.5718 -0.52 0.54

-8 39.6593 38.7385 37.8352 -0.51 0.53

-7 37.8965 37.0333 36.1860 -0.51 0.52

-6 36.2233 35.4140 34.6193 -0.50 0.52

-5 34.6345 33.8757 33.1303 -0.49 0.51

-4 33.1253 32.4139 31.7146 -0.49 0.50

-3 31.6911 31.0241 30.3681 -0.48 0.50

-2 30.3277 29.7023 29.0869 -0.47 0.49

-1 29.0310 28.4447 27.8674 -0.47 0.48

0 27.7973 27.2476 26.7060 -0.46 0.48

1 26.6230 26.1077 25.5997 -0.45 0.47

2 25.5049 25.0218 24.5454 -0.44 0.46

3 24.4398 23.9871 23.5403 -0.44 0.45

4 23.4250 23.0006 22.5818 -0.43 0.45

5 22.4576 22.0600 21.6673 -0.42 0.44

6 21.5351 21.1626 20.7945 -0.42 0.43

7 20.6552 20.3064 19.9614 -0.41 0.42

8 19.8157 19.4890 19.1658 -0.40 0.41

9 19.0144 18.7086 18.4059 -0.39 0.41

10 18.2494 17.9632 17.6797 -0.38 0.40

11 17.5189 17.2511 16.9858 -0.38 0.39

12 16.8211 16.5707 16.3223 -0.37 0.38

13 16.1545 15.9203 15.6880 -0.36 0.37

14 15.5174 15.2986 15.0813 -0.35 0.37

15 14.9084 14.7040 14.5009 -0.34 0.36

16 14.3262 14.1354 13.9457 -0.34 0.35

17 13.7695 13.5914 13.4143 -0.33 0.34

18 13.2370 13.0709 12.9056 -0.32 0.33

19 12.7277 12.5729 12.4187 -0.31 0.32

20 12.2404 12.0962 11.9524 -0.30 0.31

21 11.7741 11.6398 11.5060 -0.29 0.31

22 11.3278 11.2029 11.0783 -0.29 0.30

23 10.9006 10.7845 10.6686 -0.28 0.29

24 10.4916 10.3838 10.2761 -0.27 0.28

25 10.1000 10.0000 9.90000 -0.26 0.27

26 9.73224 9.63227 9.53237 -0.27 0.28

27 9.37971 9.27991 9.18025 -0.28 0.30

28 9.04175 8.94223 8.84291 -0.29 0.31

29 8.71769 8.61856 8.51970 -0.31 0.32

30 8.40692 8.30827 8.20996 -0.32 0.33

31 8.10884 8.01077 7.91309 -0.33 0.34

32 7.82288 7.72547 7.62850 -0.34 0.35

33 7.54852 7.45183 7.35564 -0.35 0.37

34 7.28522 7.18933 7.09399 -0.37 0.38

35 7.03251 6.93747 6.84303 -0.38 0.39

36 6.78991 6.69578 6.60228 -0.39 0.40

37 6.55698 6.46380 6.37130 -0.40 0.42

38 6.33330 6.24110 6.14963 -0.41 0.43

39 6.11844 6.02727 5.93686 -0.43 0.44

40 5.91203 5.82192 5.73260 -0.44 0.45

41 5.71370 5.62467 5.53647 -0.45 0.47

42 5.52309 5.43516 5.34810 -0.46 0.48

43 5.33986 5.25306 5.16716 -0.48 0.49

44 5.16369 5.07804 4.99330 -0.49 0.50

45 4.99428 4.90978 4.82623 -0.50 0.52

46 4.83133 4.74800 4.66563 -0.52 0.53

47 4.67456 4.59240 4.51124 -0.53 0.54

48 4.52371 4.44273 4.36276 -0.54 0.56

49 4.37852 4.29872 4.21996 -0.55 0.57

50 4.23875 4.16014 4.08257 -0.57 0.58

51 4.10417 4.02674 3.95038 -0.58 0.59

52 3.97456 3.89831 3.82314 -0.59 0.61

53 3.84971 3.77463 3.70066 -0.61 0.62

54 3.72941 3.65551 3.58272 -0.62 0.63

55 3.61348 3.54075 3.46913 -0.63 0.65

56 3.50173 3.43016 3.35972 -0.65 0.66

57 3.39400 3.32358 3.25430 -0.66 0.67

58 3.29011 3.22083 3.15270 -0.67 0.69

59 3.18990 3.12177 3.05478 -0.69 0.70

60 3.09324 3.02622 2.96037 -0.70 0.71

61 2.99997 2.93406 2.86932 -0.72 0.73

62 2.90995 2.84515 2.78151 -0.73 0.74

63 2.82306 2.75935 2.69681 -0.74 0.76

64 2.73917 2.67654 2.61507 -0.76 0.77

65 2.65816 2.59659 2.53620 -0.77 0.78

66 2.57992 2.51941 2.46006 -0.78 0.80

67 2.50434 2.44487 2.38656 -0.80 0.81

68 2.43132 2.37287 2.31559 -0.81 0.82

69 2.36076 2.30332 2.24705 -0.83 0.84

70 2.29256 2.23611 2.18084 -0.84 0.85

71 2.22663 2.17117 2.11688 -0.85 0.86

72 2.16290 2.10840 2.05508 -0.87 0.88

73 2.10127 2.04773 1.99536 -0.88 0.89

74 2.04166 1.98907 1.93763 -0.90 0.91

75 1.98401 1.93234 1.88183 -0.91 0.92

76 1.92824 1.87748 1.82788 -0.93 0.93

77 1.87428 1.82442 1.77571 -0.94 0.95

78 1.82207 1.77309 1.72525 -0.95 0.96

79 1.77154 1.72342 1.67645 -0.97 0.98

80 1.72263 1.67537 1.62925 -0.98 0.99

81 1.67528 1.62886 1.58358 -1.00 1.01

82 1.62944 1.58385 1.53939 -1.01 1.02

83 1.58506 1.54028 1.49662 -1.03 1.04

84 1.54208 1.49810 1.45523 -1.04 1.05

85 1.50046 1.45727 1.41517 -1.06 1.06

86 1.46015 1.41772 1.37639 -1.07 1.08

87 1.42110 1.37943 1.33885 -1.09 1.09

88 1.38327 1.34234 1.30250 -1.10 1.11

89 1.34661 1.30642 1.26730 -1.12 1.12

90 1.31110 1.27162 1.23321 -1.13 1.14

91 1.27668 1.23790 1.20019 -1.15 1.15

92 1.24332 1.20524 1.16821 -1.17 1.17

93 1.21099 1.17359 1.13722 -1.18 1.19

94 1.17965 1.14291 1.10721 -1.20 1.20

95 1.14927 1.11319 1.07812 -1.21 1.22

96 1.11982 1.08437 1.04994 -1.23 1.23

97 1.09126 1.05644 1.02263 -1.25 1.25

98 1.06357 1.02937 0.99616 -1.26 1.26

99 1.03671 1.00311 0.97051 -1.28 1.28

100 1.01066 0.97766 0.94564 -1.30 1.30

101 0.98540 0.95298 0.92153 -1.31 1.31

102 0.96089 0.92904 0.89815 -1.33 1.33

103 0.93712 0.90582 0.87548 -1.35 1.35

104 0.91405 0.88330 0.85350 -1.37 1.36

105 0.89166 0.86145 0.83218 -1.38 1.38

106 0.86994 0.84026 0.81151 -1.40 1.40

107 0.84886 0.81969 0.79145 -1.42 1.42

108 0.82839 0.79973 0.77199 -1.44 1.43

109 0.80853 0.78037 0.75311 -1.45 1.45

110 0.78924 0.76157 0.73478 -1.47 1.47

111 0.77052 0.74332 0.71700 -1.49 1.49

112 0.75234 0.72560 0.69975 -1.51 1.50

113 0.73468 0.70840 0.68299 -1.53 1.52

114 0.71752 0.69169 0.66673 -1.55 1.54

115 0.70086 0.67547 0.65094 -1.57 1.56

116 0.68467 0.65971 0.63560 -1.58 1.58

117 0.66894 0.64441 0.62071 -1.60 1.59

118 0.65366 0.62953 0.60624 -1.62 1.61

119 0.63880 0.61508 0.59218 -1.64 1.63

120 0.62435 0.60103 0.57853 -1.66 1.65

121 0.61031 0.58738 0.56525 -1.68 1.67

122 0.59665 0.57411 0.55235 -1.70 1.69

123 0.58337 0.56120 0.53981 -1.72 1.70

124 0.57045 0.54865 0.52762 -1.74 1.72

125 0.55788 0.53644 0.51576 -1.76 1.74