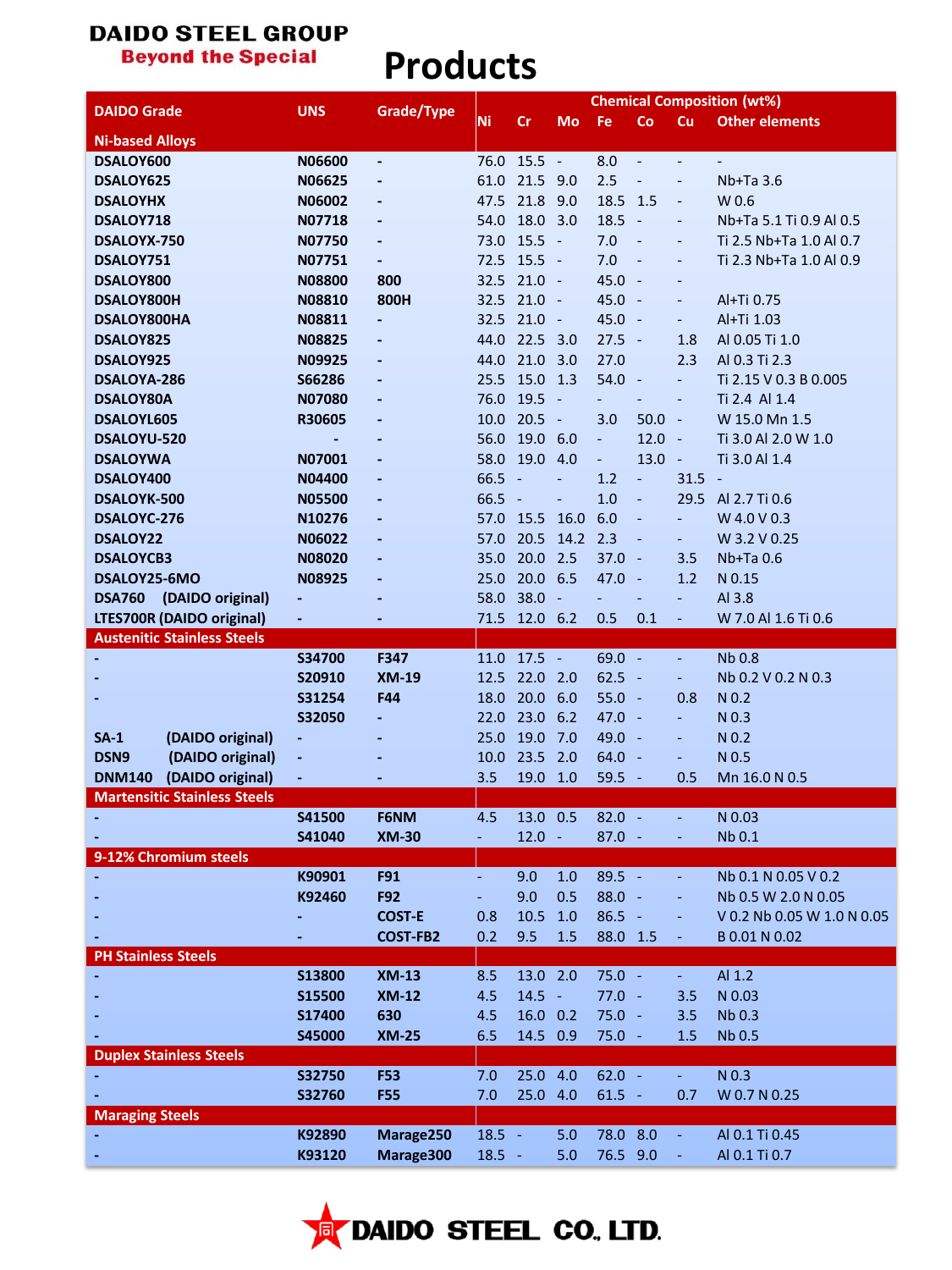

当社が製造可能な材質と寸法範囲の一覧です。

このカタログについて

| ドキュメント名 | 製造可能材質・寸法範囲一覧 |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 295.8Kb |

| 登録カテゴリ | |

| 取り扱い企業 | 大同特殊鋼株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログ(製造可能材質・寸法範囲一覧)の内容

Page 1:ProductsDAIDO Grade UNS Grade/TypeChemical Composition (wt%)Ni Cr Mo Fe Co Cu Other elementsNi-based AlloysDSALOY600 N06600 - 76.0 15.5 - 8.0 - - -DSALOY625 N06625 - 61.0 21.5 9.0 2.5 - - Nb Ta 3.6DSALOYHX N06002 - 47.5 21.8 9.0 18.5 1.5 - W 0.6DSALOY718 N07718 - 54.0 18.0 3.0 18.5 - - Nb Ta 5.1 Ti 0.9 Al 0.5DSALOYX-750 N07750 - 73.0 15.5 - 7.0 - - Ti 2.5 Nb Ta 1.0 Al 0.7DSALOY751 N07751 - 72.5 15.5 - 7.0 - - Ti 2.3 Nb Ta 1.0 Al 0.9DSALOY800 N08800 800 32.5 21.0 - 45.0 - -DSALOY800H N08810 800H 32.5 21.0 - 45.0 - - Al Ti 0.75DSALOY800HA N08811 - 32.5 21.0 - 45.0 - - Al Ti 1.03DSALOY825 N08825 - 44.0 22.5 3.0 27.5 - 1.8 Al 0.05 Ti 1.0DSALOY925 N09925 - 44.0 21.0 3.0 27.0 2.3 Al 0.3 Ti 2.3DSALOYA-286 S66286 - 25.5 15.0 1.3 54.0 - - Ti 2.15 V 0.3 B 0.005DSALOY80A N07080 - 76.0 19.5 - - - - Ti 2.4 Al 1.4DSALOYL605 R30605 - 10.0 20.5 - 3.0 50.0 - W 15.0 Mn 1.5DSALOYU-520 - - 56.0 19.0 6.0 - 12.0 - Ti 3.0 Al 2.0 W 1.0DSALOYWA N07001 - 58.0 19.0 4.0 - 13.0 - Ti 3.0 Al 1.4DSALOY400 N04400 - 66.5 - - 1.2 - 31.5 -DSALOYK-500 N05500 - 66.5 - - 1.0 - 29.5 Al 2.7 Ti 0.6DSALOYC-276 N10276 - 57.0 15.5 16.0 6.0 - - W 4.0 V 0.3DSALOY22 N06022 - 57.0 20.5 14.2 2.3 - - W 3.2 V 0.25DSALOYCB3 N08020 - 35.0 20.0 2.5 37.0 - 3.5 Nb Ta 0.6DSALOY25-6MO N08925 - 25.0 20.0 6.5 47.0 - 1.2 N 0.15DSA760 (DAIDO original) - - 58.0 38.0 - - - - Al 3.8LTES700R (DAIDO original) - - 71.5 12.0 6.2 0.5 0.1 - W 7.0 Al 1.6 Ti 0.6Austenitic Stainless Steels- S34700 F347 11.0 17.5 - 69.0 - - Nb 0.8- S20910 XM-19 12.5 22.0 2.0 62.5 - - Nb 0.2 V 0.2 N 0.3- S31254 F44 18.0 20.0 6.0 55.0 - 0.8 N 0.2S32050 - 22.0 23.0 6.2 47.0 - - N 0.3SA-1 (DAIDO original) - - 25.0 19.0 7.0 49.0 - - N 0.2DSN9 (DAIDO original) - - 10.0 23.5 2.0 64.0 - - N 0.5DNM140 (DAIDO original) - - 3.5 19.0 1.0 59.5 - 0.5 Mn 16.0 N 0.5Martensitic Stainless Steels- S41500 F6NM 4.5 13.0 0.5 82.0 - - N 0.03- S41040 XM-30 - 12.0 - 87.0 - - Nb 0.19-12% Chromium steels- K90901 F91 - 9.0 1.0 89.5 - - Nb 0.1 N 0.05 V 0.2- K92460 F92 - 9.0 0.5 88.0 - - Nb 0.5 W 2.0 N 0.05- - COST-E 0.8 10.5 1.0 86.5 - - V 0.2 Nb 0.05 W 1.0 N 0.05- - COST-FB2 0.2 9.5 1.5 88.0 1.5 - B 0.01 N 0.02PH Stainless Steels- S13800 XM-13 8.5 13.0 2.0 75.0 - - Al 1.2- S15500 XM-12 4.5 14.5 - 77.0 - 3.5 N 0.03- S17400 630 4.5 16.0 0.2 75.0 - 3.5 Nb 0.3- S45000 XM-25 6.5 14.5 0.9 75.0 - 1.5 Nb 0.5Duplex Stainless Steels- S32750 F53 7.0 25.0 4.0 62.0 - - N 0.3- S32760 F55 7.0 25.0 4.0 61.5 - 0.7 W 0.7 N 0.25Maraging Steels- K92890 Marage250 18.5 - 5.0 78.0 8.0 - Al 0.1 Ti 0.45- K93120 Marage300 18.5 - 5.0 76.5 9.0 - Al 0.1 Ti 0.7MaterialsStainlessSteelDuplex StainlessSteelCarbon & Alloy Ni-based AlloyMax. weight(ton) 15 12 18 6Max. Dia 800 (32”) 550 (22”) 1,200 (47”) 500 (20”)Max. Length 10,000 (394”) 5,000 (197”) 8,000 (315”) 3,000 (118”)Max. Width 1,800 (71”) 2,000 (79”) 800 (32”)Min. Thickness 100 (4”) 100 (4”) 100 (4”)Max. Length 6,000 (236”) 6,000 (236”) 3,000 (118”)Max. Dia 3,200 (126”) 2,500 (98”) 3,200 (126”) 2,500 (98”)Min. Thickness 100 (4”) 100 (4”) 100 (4”) 100 (4”)Max. Outer Dia 2,800 (110”) 3,200 (126”) 2,500 (98”)Min. Thickness 100 (4”) 100 (4”) 100 (4”)Max. Thickness 1,500 (59”) 1,500 (59”) 500 (20”)Max. Outer Dia 1,300 (51”) 1,300 (51”)Max. Length 3,000 (118”) 3,000 (118”)MaterialsStainlessSteelDuplex StainlessSteelCarbon & Alloy Ni-based AlloysMax. weight(ton) 5 5 5 5Max. Dia 370 (15”) 370 (15”) 430 (17”) 370 (15”)Min. Dia 90 (4”) 90 (4”) 90 (4”) 90 (4”)Max. Length 9,800 (386”) 9,800 (386”) 9,800 (386”) 6,000 (236”)Max. Width 370 (15”) 430 (15”) 370 (15”)Min. Thickness 60 (2”) 60 (2”) 60 (2”)Max. Length 6,000 (236”) 6,000 (236”) 6,000 (236”)Open Die ForgingShapesCapability(negotiable)(negotiable)(negotiable)(negotiable)(negotiable)GFM ForgingShapesROUND BARFLAT BARDISCRINGPIPEROUND BARFLAT BAREmail: forging@ask.daido.co.jpwww.daido.co.jpOsaka branchKogin Bldg 1-1, Koraibashi 4-chome,Chuo-ku, Osaka, 541-0043,JapanPhone: 81-6-6229-6530Fax: 81-6-6202-8663Tokyo head officeDaido Shinagawa Bldg 6-35, Konan,1-Chome Minato-ku, Tokyo, 108-8478,JapanPhone: 81-3-5495-1277Fax: 81-3-5495-6742MaterialsStainlessSteelDuplex StainlessSteelCarbon & Alloy Ni-based AlloyMax. weight(ton) 15 12 18 6Max. Dia 800 (32”) 550 (22”) 1,200 (47”) 500 (20”)Max. Length 10,000 (394”) 5,000 (197”) 8,000 (315”) 3,000 (118”)Max. Width 1,800 (71”) 2,000 (79”) 800 (32”)Min. Thickness 100 (4”) 100 (4”) 100 (4”)Max. Length 6,000 (236”) 6,000 (236”) 3,000 (118”)Max. Dia 3,200 (126”) 2,500 (98”) 3,200 (126”) 2,500 (98”)Min. Thickness 100 (4”) 100 (4”) 100 (4”) 100 (4”)Max. Outer Dia 2,800 (110”) 3,200 (126”) 2,500 (98”)Min. Thickness 100 (4”) 100 (4”) 100 (4”)Max. Thickness 1,500 (59”) 1,500 (59”) 500 (20”)Max. Outer Dia 1,300 (51”) 1,300 (51”)Max. Length 3,000 (118”) 3,000 (118”)MaterialsStainlessSteelDuplex StainlessSteelCarbon & Alloy Ni-based AlloysMax. weight(ton) 5 5 5 5Max. Dia 370 (15”) 370 (15”) 430 (17”) 370 (15”)Min. Dia 90 (4”) 90 (4”) 90 (4”) 90 (4”)Max. Length 9,800 (386”) 9,800 (386”) 9,800 (386”) 6,000 (236”)Max. Width 370 (15”) 430 (15”) 370 (15”)Min. Thickness 60 (2”) 60 (2”) 60 (2”)Max. Length 6,000 (236”) 6,000 (236”) 6,000 (236”)Open Die ForgingShapesCapability(negotiable)(negotiable)(negotiable)(negotiable)(negotiable)GFM ForgingShapesROUND BARFLAT BARDISCRINGPIPEROUND BARFLAT BAREmail: forging@ask.daido.co.jpwww.daido.co.jpOsaka branchKogin Bldg 1-1, Koraibashi 4-chome,Chuo-ku, Osaka, 541-0043,JapanPhone: 81-6-6229-6530Fax: 81-6-6202-8663Tokyo head officeDaido Shinagawa Bldg 6-35, Konan,1-Chome Minato-ku, Tokyo, 108-8478,JapanPhone: 81-3-5495-1277Fax: 81-3-5495-6742

Page 2:MaterialsStainlessSteelDuplex StainlessSteelCarbon & Alloy Ni-based AlloyMax. weight(ton) 15 12 18 6Max. Dia 800 (32”) 550 (22”) 1,200 (47”) 500 (20”)Max. Length 10,000 (394”) 5,000 (197”) 8,000 (315”) 3,000 (118”)Max. Width 1,800 (71”) 2,000 (79”) 800 (32”)Min. Thickness 100 (4”) 100 (4”) 100 (4”)Max. Length 6,000 (236”) 6,000 (236”) 3,000 (118”)Max. Dia 3,200 (126”) 2,500 (98”) 3,200 (126”) 2,500 (98”)Min. Thickness 100 (4”) 100 (4”) 100 (4”) 100 (4”)Max. Outer Dia 2,800 (110”) 3,200 (126”) 2,500 (98”)Min. Thickness 100 (4”) 100 (4”) 100 (4”)Max. Thickness 1,500 (59”) 1,500 (59”) 500 (20”)Max. Outer Dia 1,300 (51”) 1,300 (51”)Max. Length 3,000 (118”) 3,000 (118”)MaterialsStainlessSteelDuplex StainlessSteelCarbon & Alloy Ni-based AlloysMax. weight(ton) 5 5 5 5Max. Dia 370 (15”) 370 (15”) 430 (17”) 370 (15”)Min. Dia 90 (4”) 90 (4”) 90 (4”) 90 (4”)Max. Length 9,800 (386”) 9,800 (386”) 9,800 (386”) 6,000 (236”)Max. Width 370 (15”) 430 (15”) 370 (15”)Min. Thickness 60 (2”) 60 (2”) 60 (2”)Max. Length 6,000 (236”) 6,000 (236”) 6,000 (236”)Open Die ForgingShapesCapability(negotiable)(negotiable)(negotiable)(negotiable)(negotiable)GFM ForgingShapesROUND BARFLAT BARDISCRINGPIPEROUND BARFLAT BAREmail: forging@ask.daido.co.jpwww.daido.co.jpOsaka branchKogin Bldg 1-1, Koraibashi 4-chome,Chuo-ku, Osaka, 541-0043,JapanPhone: 81-6-6229-6530Fax: 81-6-6202-8663Tokyo head officeDaido Shinagawa Bldg 6-35, Konan,1-Chome Minato-ku, Tokyo, 108-8478,JapanPhone: 81-3-5495-1277Fax: 81-3-5495-6742