1/216ページ

ダウンロード(35.4Mb)

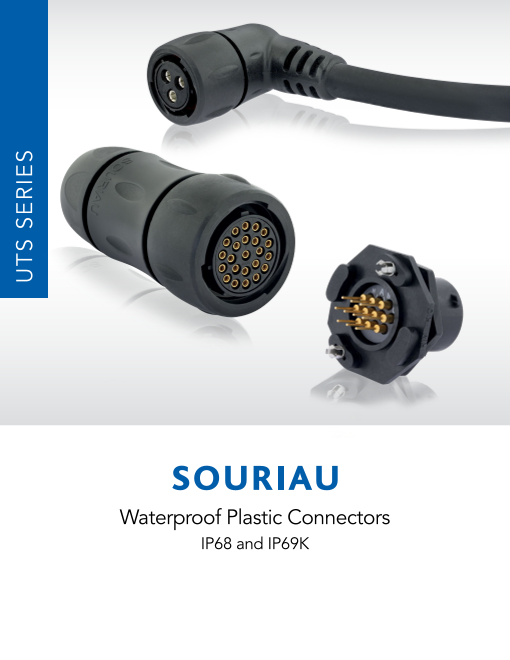

プラスチック製 IP68/69K防水コネクタ

UTSシリーズは、1/3回転バイヨネットカップリングを備えた防水丸形プラスチックコネクタで、クリック音による嵌合確認により、迅速で正しい接続を保証します。

IECおよびUL規格に準拠するよう開発されたTrim Trioは設置者および利用者の安全条件を保証します。

屋外用に最適なコネクタです。

防湿性と紫外線耐性(IP68/69Kシーリングレベル)を備えるUTSシリーズは、屋外で長時間利用することができ、メンテナンスの必要性を低減します。UTS ハイシールタイプでは、嵌合・非嵌合状態であっても、業界最高水準の防水性IP68/IP69Kレベルを維持します。

UTSシリーズは、同じコネクタ内に信号と電源、または銅線と光ファイバーを結合する幅広い種類のレイアウトを提供します。

UTSシリーズはTrim Trioコンタクトを使用し、UTGやUTOシリーズと完全に互換します。その結果、工具やパネルカットアウトを変更することなく、1つのシリーズから別のシリーズに変更することができます。追加費用なしで、製品を簡単かつ迅速にアップグレードできます!

UTSシリーズについてご質問がありますか?または、お見積りが必要ですか?弊社の技術チームおよび営業チームがサポートいたします。

お気軽に service_jpn-itd@eaton.com までお問合せください。

関連メディア

このカタログについて

| ドキュメント名 | 防塵・防水フルプラスチックコネクタ UTSシリーズ |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 35.4Mb |

| 登録カテゴリ | |

| 取り扱い企業 | スリオジャパン株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

Waterproof Plastic Connectors

IP68 and IP69K

UTS SERIES

Page3

UTS Series | Connector

Contents

Overview Contacts

Typical Applications .......................................... 06 Description ....................................................... 162

Features & Benefits .......................................... 07 Contact Plating Selector Guide ........................ 163

Range Overview ............................................... 08 Contact Selector Guide .................................... 164

Layouts ............................................................. 10 Packaging ......................................................... 164

General Technical Characteristics ..................... 12 Crimp Contacts ................................................ 165

#16 Coaxial Contacts ....................................... 167

PCB Contacts ................................................... 168

Fiber Optic Contacts ........................................ 170

Connector

Overmoulded Cable Assembly ........................ 16 Technical Information

2 contacts ......................................................... 20 Tooling .............................................................. 174

2 + ground contacts ......................................... 28 Crimping Instructions ....................................... 176

3 contacts ......................................................... 36 Handle & Interchangeable Heads .................... 178

3 + ground contacts ......................................... 52 Extraction Tools ................................................ 179

4 contacts ......................................................... 60 Overmoulded Cable Assembly Dimensions ..... 179

5 contacts ......................................................... 72 Assembly Instructions ....................................... 180

6 contacts ......................................................... 80 Mated Connector Lengths ............................... 184

Mating Procedure ............................................. 185

6 + ground contacts ......................................... 92

Rated Current & Working Voltage .................... 186

7 contacts ......................................................... 96

UV Resistance ................................................... 187

8 contacts ......................................................... 100 UL94 + UL1977 ................................................. 188

10 contacts ....................................................... 112 IEC 61984 & IP Codes Explained ..................... 191

12 contacts ....................................................... 116 IEC 61140 Explained ........................................ 193

14 contacts ....................................................... 128 What is NEMA Rating ? .................................... 194

15 contacts ....................................................... 132 Ethernet for the Layman ................................... 195

18 contacts ....................................................... 136

19 contacts ....................................................... 140 Appendices

23 contacts ....................................................... 144 #16 Coaxial Contacts/Cabling Notices ............ 200

32 contacts ....................................................... 148 Glossary of Terms ............................................. 201

LC (Fiber Optic) ................................................ 152 Discrimination/Keying Methods ....................... 208

MPO (Fiber Optic) ............................................ 156 Part Number Index ........................................... 209

3

Appendices Technical Information Contacts Connector Overview

Page4

© 2014 SOURIAU - SOURIAU is a registered trademark

UTS SERIES

Page5

UTS Series

Overview

Typical Applications ................................................................................................ 06

Features & Benefits ................................................................................................ 07

Range Overview .................................................................................................... 08

Layouts ................................................................................................................... 10

General Technical Characteristics ........................................................................... 12

5

Page6

UTS Series | Overview

Typical Applications

Energy - Power Off-Road Building Automation & Control

Instrumentation - Measurement Rail

Stage - Light

6

© cachoudesign / Fotolia © krungchingpixs / Fotolia © Vibe Images / Fotolia

© Pinosub / Fotolia © Sergey Milovidov / Fotolia

© Volodymyr Kyrylyuk / Fotolia

Page7

UTS Series | Overview

Features & Benefits

IP68/69k Dynamic Mated & Unmated

WATER Ideal for outdoor and indoor dynamic applications requiring

continuous underwater immersion, routine pressure washing

PROOF and dust protection.

No Degradation Over Time

UV No mechanical deterioration or important variation in colour after

5 years of exposure in natural environment (equivalent exposure

RESISTANT to sun and moisture as per ISO4892) and F1 rated per UL 746C.

qualified & Certified

UL/IEC In accordance with:

- UL 1977 - Certificate ECBT2, File number: E169916

COMPLIANT - CSA C22.2 n°182.3 - Certificate ECBT8, File number: E169916.

1/3 Bayonet Coupling

qUICk With only 1/3 twist of the bayonet coupling system, connectors are

mated with audible "click" and tactile feel to confirm proper mating.

MATINg This mating feature eliminates connection uncertainty and reduces

time and labor during installation.

Mixed Power & Signal Contacts

COST Power supply and signal transmission can be combined in

a unique interconnect solution to reduce system complexity

SAVINgS and minimize component installation cost.

7

Overview

Page8

UTS Series | Overview

Range

UTS Series UTS Standard

Cable Sealed Single Wire

Sealed

Sealed: IP68/69K dynamic Corrosion-proof

UV resistant Plastic housing

UL/IEC compliant

UTS Backshells Contacts Supplied Separately

Cable Sealing

Choice of Crimp Contacts

• Machined

• Stamped and Formed

• Coaxial Plug

PCB Contacts

Double Sealing Fiber Optic

(Wires + Cable)

Contacts Loaded

Screw Termination

grommet Contacts Loaded

Handsolder

Single Wire

Sealed

UTS Sealed Unmated

Flexible conduit

adaptators

Sealed Unmated: IP68/69K dynamic

MIL-C-26482 compatible

Contact us for more information UV resistant

UL/IEC compliant Corrosion-proof

Plastic housing

Overmoulded Cable Assembly

8

Page9

UTS Series | Overview

Overview

UTS Standard Receptacle

Contacts Supplied Separately

UTS Backshells

Square Flange Choice of Crimp Contacts

• Machined

• Stamped and Formed Cable Sealing

• Coaxial

PCB Contacts

Fiber Optic

Threaded Receptacle

Contacts Supplied Separately Double Sealing

(Wires + Cable)

Choice of Crimp Contacts

• Machined

• Stamped and Formed

• Coaxial grommet

In-line PCB Contacts

Fiber Optic Single Wire

Sealed

Contacts Loaded

Jam Nut Flexible conduit

Screw Termination adaptators

PCB

UTS Sealed Unmated

Receptacle

Contact us for more information

UTS PCB Contacts

Stand-offs to allow Metal hold down clips

Contacts Loaded cleaning after - to lock the connector easily on

soldering the PCB and to release stress

on solder joints

Jam Nut Handsolder - suitable for soldering in a

metallic hole

PCB

Pre-assembled PCB contacts

- machined or stamped versions

available

Square Flange - different solder tails lengths

Low profile housing to limit possible

space between panel and PCB - different plating options

9

Overview

Page10

UTS Series | Overview

Layouts (Electrical parameter according to IEC)

Shell Size Contact #16 (Ø 1.6mm) Contact #20 (Ø 1.0mm) Contact #8 (Ø 3.6mm) Hybrid & others

8E2/8D2(1) 8E3/8D3(1)

7A 32V 7A 32V

2 contacts 3 contacts

Page 20 Page 36

8E3A/8D3A(1) 8E98/8D98(1)

7A 50V 7A 50V

8 3 contacts 3 contacts

Page 40 Page 40

8E33/8D33(1) 8E4/8D4(1)*

7A 50V 7A 32V

3 contacts 4 contacts

Page 44 Page 60

106* 102W2 103W3

25A 150V 5A 32V

103 104(3) 10E6(1)/10D6

4 contacts 6 contacts

16A 300V 13A 150V 7A 32V

2xØ2.4 (#12) 3xØ1.6 (#16)

2+ground 4 contacts 6 contacts 2xØ1.0 (#20) 3xØ1.0 (#20)

10 Page 28 Page 68 Page 84 Page 64 Page 80

10E98/10D98 10E7(1)/10D7

7A 50V 7A 50V

6 contacts 7 contacts

Page 88 Page 96

1210*

12E2/12D2 12E3/12D3 12E10/12D10

16A 150V 16A 150V 6A 50V

2 contacts 3 contacts 10 contacts

11 1

1

1

22 2 1

55 5 44 4

12 Page 24 Page 48 Page 112 1 2 5 4

2 5 4

2

124 5 4

1 2 5 4 33 3

12E4/12D4 28(1) (3) 12E8/12D8 12E14/12D14 3

10A 80V 6A 32V 5A 32V 3

16A 300V 3

8 contacts 8 contacts 14 contacts

3+ground 3

Page 52 Page 100 Page 104 Page 128

1: M12, M16 and M20 threaded receptacle available 2: NPT available 3: Discrete wire grommet option * Ethernet compatible: see pages 195 & 196

10

1 1

1

2 2 5 5 4 4

2 5 4

3 3

3

Page11

UTS Series | Overview

Contacts #20: Contacts #16: Contacts #12: Contacts #8:

from AWG 26 to 18 from AWG 30 to 14 from AWG 22 to 12 from AWG 16 to 8

0.13 to 0.93 mm² 0.05 to 2.5 mm² 0.13 to 4 mm² 1.5 to 10 mm²

Shell Size Contact #16 (Ø 1.6mm) Contact #20 (Ø 1.0mm) Contact #8 (Ø 3.6mm) Mixed Power

147(3) 14E18/14D18 142g1(2) 148

14E5/14D5 14E7/14D7 5A 50V 40A 300V 17A 230V

16A 150V 16A 300V 18 contacts 2+ground 8 contacts

4xØ1.6 (#16)+4xØ2.4 (#12)

5 contacts 6+ground

Page 136 Page 32 Page 108

Page 72 Page 92 14E12/14D12

4A 50V

1412(3) 1492(3) 1419 12 contacts

10A 63V 10A 63V 14E19/14D19 4xØ1.6 (#16)+8xØ1.0 (#20)

12 contacts 12 contacts 5A 32V

14 19 contacts

Page 120

Page 116 Page 124 14E15/14D15

Page 140 4A 50V

15 contacts

1xØ1.6 (#16)+14xØ1.0 (#20)

Page 132

18X2M3(2)

1823 18E32/18D32 183g1(2) 32A 300V

9A 63V 4A 32V 32A 300V 5 contacts

23 contacts 32 contacts 3+ground 3xØ1.6 (#16)+2xØ3.6 (#8)

1

1

2 5 4

1

2 5 4

2 3

5 4

3

Page 144 Page 148 Page 56 Pag3e 76

LC

18

Page 152

MPO

Page 156

XXXXXX blue highlighted items: UTS Sealed in Unmated Condition

11

Overview

Page12

UTS Series | Overview

General Technical Characteristics

Materials Environmental Electrical

• Body connector + Backshell: Thermoplastic • Operating temperature: • In accordance with:

from -40°C to +105°C - UL 1977: Certificat ECBT2

• Insert: 40/100/21 per NFF 61-030 File number: E169916

- UTS Standard, UTS Single Wire Sealed, - CSA C22.2 n°182.3: Certificat ECBT8

UTS Screw Termination Contacts: • Flammability rating: File number: E169916

Thermoplastic - UL94 V-0 (all UTS except the Sealed

- UTS Sealed Unmated Handsolder & Unmated version) see page 180

UTS Sealed Unmated with PC Tails - UL94 HB (UTS Sealed Unmated version

Contacts: Elastomer only) see page 180

- I2F3 according to NFF 16101 & NFF 16102

• Nut: Metal • Also see pages 10 & 11

• Salt spray:

• Contacts: See page 161 per EIA-026A ≥500 hours

• Halogen free • UV resistant:

No mechanical degradation or important

• RoHS compliant & conforms to the Chinese variation of colour after 5 years of exposure

standard SJ/T1166-2006 in natural environment (equivalence exposure Mechanical

(Chinese RoHS equivalent) to sun and moisture as per ISO 4892) and

F1 rated per UL 746C • Durability:

250 matings & unmatings per MIL-C-26482

• Sealing:

- UTS Standard: IP68/IP69K dynamic (mated) • Vibration resistance (all UTS versions

- UTS Sealed Unmated version: except UTS Screw Termination contacts):

IP68/IP69K dynamic (unmated) Sinusoidal vibrations per IEC 60512-4 - from

- UTS Single Wire Sealed: IP67/69K (up to 10 to 2000 Hz

IP68 with double sealing backshell)

- UTS Screw Termination Contacts: • Thermal shock:

IP68/IP69K dynamic (mated) 5 cycles 30 min. from -40°C to 105°C per

Note: IP68=10 m underwater during 1 week MIL-STD-1344 method 1003

• Fluid resistance:

- Gas and Oil

- Mineral oil

- Acid bath

- Basic bath

12

Page13

UTS Series | Overview

13

Overview

Page14

© 2014 SOURIAU - SOURIAU is a registered trademark

UTS SERIES

Page15

UTS Series

Connector

Overmoulded Cable Assembly .............................................................................. 16

2 contacts

8E2/8D2: 7A 32V ................................................................. 20

12E2/12D2: 16A 150V ................................................................. 24

2 contacts + ground

103: 16A 300V ................................................................. 28

142G1: 40A 300V ................................................................. 32

3 contacts

8E3/8D3: 7A 32V ................................................................. 36

8E3A/8E98 - 8D3A/8D98: 7A 50V ................................................................. 40

8E33/8D33: 7A 50V ................................................................. 44

12E3/12D3: 16A 150V ................................................................. 48

3 contacts + ground

124 - 12E4/12D4: 16A 300V ................................................................. 52

183G1: 32A 300V ................................................................. 56

4 contacts

8E4/8D4*: 7A 32V ................................................................. 60

102W2: 25A 150V ................................................................. 64

104: 13A 150V ................................................................. 68

5 contacts

14E5/14D5: 16A 150V ................................................................. 72

18X2M3: 32A 300V ................................................................. 76

6 contacts

103W3: 5A 32V ................................................................. 80

106* - 10E6/10D6: 7A 32V ................................................................. 84

10E98/10D98: 7A 50V ................................................................. 88

6 contacts + ground

147 - 14E7/14D7: 16A 300V ................................................................. 92

7 contacts

10E7/10D7: 7A 50V ................................................................. 96

8 contacts

128: 10A 80V ................................................................. 100

12E8/12D8: 6A 32V ................................................................. 104

148: 17A 230V ................................................................. 108

10 contacts

1210* - 12E10/12D10: 6A 50V ................................................................. 112

12 contacts

1412: 10A 63V ................................................................. 116

14E12/14D12: 4A 50V ................................................................. 120

1492: 10A 63V ................................................................. 124

14 contacts

12E14/12D14: 5A 32V ................................................................. 128

15 contacts

14E15/14D15: 4A 50V ................................................................. 132

18 contacts

14E18/14D18: 5A 50V ................................................................. 136

19 contacts

1419 - 14E19/14D19: 5A 32V ................................................................. 140

23 contacts

1823: 9A 63V ................................................................. 144

32 contacts

1832 - 18E32: 4A 32V ................................................................. 148

LC .......................................................................................................................... 152

MPO ...................................................................................................................... 156

Electrical parameters according to IEC * Ethernet compatible see pages 195 & 196

15

Page16

UTS Series | Connector

Overmoulded Cable Assembly

SOURIAU has provided connectors in various applications for more than 90 years and used in the most extreme environments. Conscious

about the difficulty to finding a quick and a reliable harness manufacturer, we began in-house cable assembly production. It allows

customers to reduce the number of suppliers, and to take advantage of the "best in class" quality of the SOURIAU group. Overmoulding

is a process that further enhances the sealing properties of the UTS range, especially over many years of use. Overmoulding provides

the opportunity to change the cable exit from straight to 90 degrees and avoid stress on the cable terminated to the connector. Also, as

the wires are encapsulated inside the molding, a barrier is created which prevents any liquid from entering the equipment through the

connector if the cable jacket is breached.

How to choose the outer jacket material

Please consult us

TPE

Static installation SILICON

Static installation

OUTDOOR FEP

Static installation

(black outer jacket)

PUR PTFE

Static installation

Static or dynamic installation

INDOOR

PVC

Static or dynamic installation

-40°C +80°C Ambient temperature

16

Chemical aggression Cleaner,

Wet Immersed chlorine

UV resistance

Page17

UTS Series | Connector

Overmoulding Description

Thermoplastic or

elastomer insert Compound Cable outer sheath

PVC or PUR

O-ring Overmoulding adapter overmoulding

Connector with cable gland backshell

If cable jacket is breached...

gOOD

...water ingress unhampered, leading to damage.

Overmoulded connector

If cable jacket is breached...

BEST

...prevents water ingress via capillary action.

17

Connector

Page18

UTS Series | Connector

UTS Waterproof Plastic Overmould

HAUTS Standard

Offering Description

Cable

• PVC outer sheath (grey color)

• Wire section 1.5 mm² for #16 contact

• Wire section 0.5 mm² for #20 contact

• 300V

• Unshielded

• Flammability rating IEC (UL1581 Sec.1160)

• Operating temperature: -40°C +70°C

Overmoulding Specifications

PLATINg SALT SPRAY TEMPERATURE* WATERPROOF* MECHANICAL

No plating 500 H -40°C up to + 105°C IP68/IP69K dynamic (mated) 250 matings/unmatings

* With appropriate cable and overmoulding

Example of Customized Cable Assemblies

Overmoulding on Curly Cable Overmoulding with Double Ends Harness for PCB Connection

To define your customized cable assembly, please consult our technical services.

18

Page19

UTS Series | Connector

Cable Information

Range of temperature: Occasional flexing: -5°C up to +70°C

Fixed installation: -40°C up to +80°C

Rated voltage: U0/U: 300/500V

Wire section : Layouts with #16 contact: wire section 1.5 mm²

Layouts with #20 contact: wire section 0.5 mm²

Harmonized reference: H05 VV - F XX

Standardisation of European Cable - DIN VDE 0281/DIN VDE 0282/DIN VDE 0292

Harmonized wire coding system

1 2 3 4 5 6 7 8 9

1. 2. 3. 4. 5. 6. 7. 8. 9.

Basic type Working Insulating Sheath- Special Conductor Number of Protective Conductor

voltage cladding features types conductors conductor cross-

material sectional

H: 03: V: V: H: U: X: Area specified

Harmonized 300/300V PVC PVC Ribbon cable, Single wire Without in mm2

Type separable protective

conductor

A: 05: R: R: H2: Ribbon R: G:

National Type 300/500V Rubber Rubber cable Multi-wire With

non-separable protective

conductor

07: S: N: K:

450/750V Silicone Cloroprene Fine wire

Rubber Rubber (permanently

installed)

J: F:

Glass-filament Fine wire

braiding (flexible)

T: H:

Textile Super fine wire

braiding

Y:

Tinsel strand

Example: Harmonized type, 300/500V, PVC insulating, PVC sheath- cladding, Fine wire, 3x1.5 cross-sectional: H05VVF3x1.5

19

Connector

Page20

UTS Series | Connector

8E2/8D2 (Shell size 8, 2x#20)

Layout

OR OR OR

WITH

Connector Part Numbers

Part number

Contact type Connector type Backshell

Male insert Female insert

Square flange

receptacle Without (Fig.1) UTS08E2P UTS08E2S

Handsolder Without (Fig.7) UTS68E2P UTS68E2S

electrical contacts Plug

loaded Cable gland (Fig.8) UTS6JC8E2P UTS6JC8E2S

see page 23 Jam nut

receptacle Without (Fig.4) UTS78E2P UTS78E2S

M12 threaded receptacle Without (Fig.3) UTS78E2PM12 UTS78E2SM12

Square flange

Without (Fig.2)

receptacle UTS08D2P UTS08D2S

Jam nut receptacle

PCB with stand off and Without (Fig.6) UTS78D2P32 UTS78D2S32

contacts loaded with hold down clips

see page 23 Jam nut receptacle

with stand off and Without (Fig.5) UTS78D2P UTS78D2S

without hold down clip

M12 threaded receptacle Without (Fig.3) UTS78D2PM12 UTS78D2SM12

Possibilities of discrimination/keying methods see page 208 Sealed unmated

Overmoulded Cable Assembly Part Numbers

Wire size Harmonized cable Part number (length: 1m.)*

Overmoulding type Connector type

(mm²) part number (1)

Male plug Female plug

Straight ending Plug 0.5 H05 VV - F 2x0.5 HAUTS0V8E2PST100 HAUTS0V8E2SST100

Right angle ending Plug 0.5 H05 VV - F 2x0.5 HAUTS0V8E2PRA100 HAUTS0V8E2SRA100

(1) Other cable available on demand * Other lengths available on demand

20