1/12ページ

ダウンロード(2.7Mb)

Securing High Quality Drinking Water in Sensitive Facilities - Guidelines

製品カタログ

Prevention in the Drinking Water System

To ensure high quality drinking water until the tapping point in the facility, drinking water distribution must be rethought.While drinking water distribution was considered as maintenance-free until a few years ago, new installation concepts and preventive measures during operation are required today. These measures preventively sustain drinking-water quality in the system, thus ensuring a high level of drinking water hygiene.

このカタログについて

| ドキュメント名 | Securing High Quality Drinking Water in Sensitive Facilities - Guidelines |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 2.7Mb |

| 取り扱い企業 | ジョージフィッシャー株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

Guidelines

Securing High Quality Drinking

Water in Sensitive Facilities

Page2

Preface The first three steps - prevention, monitoring and interven-tion - are prerequisites to secure top grade drinking water.

The focus lies on preventive measures which will sustain-

Certain water ingredients and unfavourable operating con- ably protect the investments made by the property opera-

ditions may cause microbial contamination in drinking wa- tors. Safety risks must be reduced in particular in sensitive

ter systems - an issue which often remains undetected un- facilities, i.e. facilities housing immunocompromised indi-

til the entire system is impaired. Providing high quality viduals.

drinking water in the last few meters to the consumer is a

particular challenge in these facilities.

After reading this brochure you

will be familiar with

• the control cycle comprising the four areas of a holistic

approach to drinking water hygiene: Prevention,

monitoring, intervention and risk assessment;

• vital recommendations for planning, installing and

operating drinking water systems providing top-grade

drinking water in facilities such as:

• School buildings,

• Sports facilities,

• Spas,

• Apartment buildings,

• Temporarily used residential buildings,

Fig 1: • Palaces, castles,

The assessment of energy e ciency calls for a holistic of the facility • Hotels,

• Barracks, correctional facilities,

• Old people’s homes,

At the same time, a responsible use of energy is desired. As • Nursing homes,

a result, facilities are heavily insulated and operated with • Hospitals,

high energy efficiency if possible. A holistic assessment of • Negative examples and how to troubleshoot faults.

the facility comprising both energy efficiency and drinking

water hygiene, however, is only rarely conducted. Since

they are increasingly faced with those two issues, especial- Note:

ly Germany’s property operators are becoming more and Below recommendations are based on our ten-years’ prac-

more aware of problems related to drinking water hygiene tical experience. They are not based on guidelines and

and the risks involved when operating drinking water sys- standards as provided by trade associations, since they of-

tems. ten lack important aspects, are dated and thus are no lon-

ger state of the art. Just to name an example: the 3-litre

In order to achieve long-term success, we need a system- rule calls for the taking of samples only with large volumes

atic approach over the entire useful life of a drinking water of drinking water. Or too insensitive test methods used

system. This approach is based on WHO’s “Water Safety during approval of materials which tone down test results

Plan” and comprises the following four steps: and make selection more difficult.

The following symbols indicate drinking water in hot water

supply lines and cold water supply lines.

1. Prevention cold drinking water

2. Monitoring

3. Intervention hot drinking water

4. Risk Assessment

2

Page3

1. Prevention in the

Drinking Water System

To ensure high quality drinking water until the tapping

point in the facility, drinking water distribution must be re-

thought. While drinking water distribution was considered

as maintenance-free until a few years ago, new installation

concepts and preventive measures during operation are re-

quired today. These measures preventively sustain drink-

ing-water quality in the system, thus ensuring a high level

of drinking water hygiene. The following approaches must

be considered when planning, installing and using drinking

water systems.

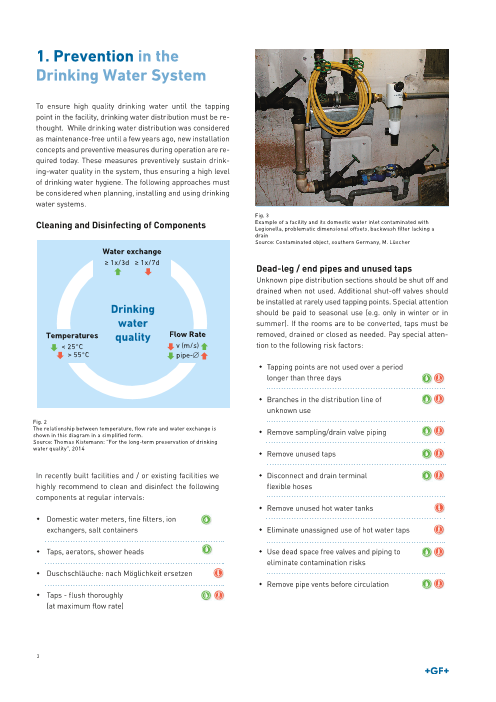

Fig. 3

Cleaning and Disinfecting of Components Example of a facility and its domestic water inlet contaminated with Legionella, problematic dimensional o sets, backwash fi lter lacking a

drain

Source: Contaminated object, southern Germany, M. Lüscher

Water exchange

≥ 1x/3d ≥ 1x/7d

Dead-leg / end pipes and unused taps

Unknown pipe distribution sections should be shut off and

drained when not used. Additional shut-off valves should

be installed at rarely used tapping points. Special attention

Drinking should be paid to seasonal use (e.g. only in winter or in

water summer). If the rooms are to be converted, taps must be

Temperatures quality Flow Rate removed, drained or closed as needed. Pay special atten-

< 25°C v (m/s) tion to the following risk factors:

> 55°C pipe-∅

• Tapping points are not used over a period

longer than three days

• Branches in the distribution line of

unknown use

Fig. 2

The relationship between temperature, fl ow rate and water exchange is

shown in this diagram in a simplifi ed form. • Remove sampling/drain valve piping

Source: Thomas Kistemann: “For the long-term preservation of drinking

water quality”, 2014

• Remove unused taps

In recently built facilities and / or existing facilities we • Disconnect and drain terminal

highly recommend to clean and disinfect the following flexible hoses

components at regular intervals:

• Remove unused hot water tanks

• Domestic water meters, fine filters, ion

exchangers, salt containers • Eliminate unassigned use of hot water taps

• Taps, aerators, shower heads • Use dead space free valves and piping to

eliminate contamination risks

• Duschschläuche: nach Möglichkeit ersetzen

• Remove pipe vents before circulation

• Taps - flush thoroughly

(at maximum flow rate)

3

Page4

Temperatures in the hot and cold water

Temperatures in the drinking water distribution must not

be in the range of 25 to 45 °C, since this temperature range

promotes microbial growth. In addition, the drinking water

distribution concept should ensure that prolonged periods

of stagnation neither occur in the hot water nor the cold

water lines. Furthermore, please note:

• The cold and hot water system requires a

thorough (complete) insulation.

• The regulation of the hot water circulation

system must ensure a uniform heat

distribution.

• At elevated cold water temperatures, we

recommend a cold water circulation or at

least a suitable flushing device.

Fig. 4

Unsuitable sampling valves and fl exible hose used to fi ll the heating (not

allowed), insulation of middle pipe is missing • Monitor the temperatures in the cold and hot

Source: Contaminated facility, southern Germany water, preferably on-line.

This ensures a high level of safety for the

property operator.

Sampling points

• Flush each cold water line at least every 3

For testing drinking water quality, suitable sampling points days or have it flushed automatically with the

should be determined together with the planners. The fol- help of flush valves.

lowing points should be considered:

• Exchange the hot water volume of the tank

Determine sampling points in both the hot as well as in the every day, so that periods of stagnation in the

cold drinking water lines critical temperature range between 25 and 50 °C

can be kept short. The temperature in the tank

• Determine the sampling points in the cold should never fall below 50 °C..

water distribution according to the distribution

concept. • Adjust the dimensions to the current needs

of the user to ensure flow rates of at least

• Pay special attention to rarely use tapping 0.1 m / s at any time.

points and their distribution (washbasin in the

utility room, shower for the caretaker, garden

tap in facilities without garden etc.).

• Install additional sampling valves in rooms

with sensitive use (kitchens, operating theatres,

etc.).

Use angle sampling valves with wash basins to facilitate

sampling without using the wash basin faucets. Sampling

water quality at single-handle mixing valves has proven

problematic, since the grease in the mixing valve may lead

to severe microbial contamination. The disinfection of a

mixing valve would only be possible after it has been disas-

sembled and cleaned beforehand.

4

Page5

Sampling points (minimum level)

exploratory assessment

additional sampling points

as further assessment

measuring point

Fig. 5 Fig. 7

Sampling points in the property, with the sampling points marked in blue Lime and rust deposits form an ideal basis for bacterial growth.

being statutory, however, often insu cient; the cold water at the domestic Source: Watercryst GmbH, Kematen

water inlet and the tapping points ought to be sampled as well.

Source: based on DVGW Bulletin 551

Hard drinking water Dosing water to prevent corrosion

In regions with moderately hard to hard water allow for In many existing facilities, drinking water distribution

lime scale protection since calcium promotes microbial lines are made of galvanized steel. The water is often

growth and lime deposits serve as an optimal habitat for dosed with sulphate or phosphate to prevent corrosion.

bacteria (small dead spaces). Hence, we recommend using Whenever possible, keep this dosage low, as it promotes

an approved descaling device. the growth of bacteria.

• Ion exchangers should be used only in

cold utility rooms which are maintained on Hygiene flushing schedule

a yearly basis.

The easiest method to ensure high quality drinking water is

• Ion exchangers should be used only in the regular flushing of all taps. It is advisable to draw up a

check-list for each room with all the relevant taps. Make

• We recommend using a descaling device sure that the volume of drinking water is exchanged every

in case of high water hardness and high 3 days.

conductivity.

It is advisable to air pulse flush the hot and cold water dis-

tribution once a year as a precautionary measure.

Duct T = 22-28 °C

T = T = TV= K R

10°C 55°C 60°C

Fig. 6 Fig. 8

Duct cross-section with hot water circulation and stagnant cold water that Dosing a 50-year-old galvanized distribution neglecting that a phosphate

heats up to duct temperature after 4-5 hours. dosage breeds bacteria downright.

Source: Technical Report; Focussing on contamination risks in cold drinking Source: Dosing in a contaminated object, southern Germany, M. Lüscher

water, M. Lüscher 2014

5

Page6

Water and air working together: Turbulently, yet controlled

Air bubbles of a precisely The area to be cleaned is revealed Deposits are removed smoothly

predetermined size are on on the boundary surfaces of air and e ciently.

their way. and water.

Fig. 9

Air pulse fl ushing: Flushing with air-water mixture and its e ect

Source: Hamnann air pulse fl ushing

2 Monitoring Test series with new test technologies such as the flow cytom-

etry (https://en.wikipedia.org/wiki/Flow_cytometry) also

of Drinking Water Quality show that bacterial cells are over 90 per cent active in fresh

drinking water supplied from the utilities and still cannot be

The various factors impairing drinking water quality can be detected with the cultivation method. This method, however,

reduced to a minimum when preventive measures are used is still considered the gold standard by all approved laborato-

which help eliminate some of the negative factors ries offering microbiological analysis. As of today, we know

(stagnation, critical temperatures, water exchange). It is that bacterial cells may have a third state of life (viable but

quite difficult to forecast the quality of drinking water non-culturable = VBNC). Bacteria assume this VBNC state

supplied at the domestic water inlet since it is subject to when conditions for growth become unfavourable. If drinking

fluctuations. That is why monitoring the drinking water water conditions change in terms of nutrients, oxygen, and

quality is essential already before commissioning the temperature, bacteria may rapidly grow within hours..

drinking water system and during the operation of the

facility. While in many places the chemical composition of

drinking water will change little over longer periods of

time, there are large seasonal fluctuations with regard to

the bacterial cell counts already noticeable at the domestic

water inlet. By far, the statutory tests for Legionella cannot

ensure drinking water quality, since the time intervals of Microbiological Analyses of Water

twelve or more months are set too much apart. Research Centre EAWAG

Facility assessments of recent years show that 95% of all

bacteria deposit on the surface of drinking water pipes thus 7 %

forming a biofilm (research project of H.C. Flemming 2008).

It has become evident that cavities and niches are preferably

colonized by bacteria. These include:

• Cavities rich of nutrients from grease and rubber Intact

gaskets that are not flushed with water 93 % Permeabilized

• Grease chambers in fittings

• Membranes of solenoid valves (tie rods with water Samples = 69

enclosed) STDEV : T 4.82 %

inw

• Purge sectors in backwashable filters

Fig. 10:

The test series in drinking water applying fl ow cytometry shows that 93 per

cent of the bacteria are active.

Source: St.Kötzsch, Flow Cytometry of Water Samples, 2014

6

Page7

Hence, we recommend the following measures when moni- • When testing for Legionella do not only test

toring drinking water quality: for Legionella pneumophila SG1, but also

for all other serogroups.

• Monitor drinking water temperatures at

various locations in the drinking water • When testing for Legionella in cold drinking

distribution; measure both hot and cold water also test for Pseudomonas aeruginosa,

drinking water. because this bacterium may cause serious

problems in sensitive areas (infestation of

• Monitor drinking water quality and test for wounds).

all bacteria cells at different tapping points

and at regular intervals (at least twice a year).

• Test for Legionella also at cold water taps

and additionally at the domestic water inlet.

Circulation Temperature Profi le at AG Stadelbach

Valve 1 Valve 2 Valve 3 Valve 4 Valve 5 Valve 6 Valve 7 Valve 8 Valve 9

Fig. 11

Temperature profi le over a day, recorded with the LegioTherm system

Source: Temperature monitoring in a nursing home, north-western Switzerland

7

Page8

3 Intervention Thermal Disinfection with Hot Water

Removal of

Before you carry out a thermal disinfection in the hot water

Contaminations distribution, hydraulically calibrate all lines in normal op-

eration. The temperature difference between the tank out-

let and the longest circulation line must not exceed <10 °C.

High bacterial counts or a high number of pathogens evi- The DVGW even calls for a temperature spread as low as

denced through tests of the drinking water are often due to only 5 °C. Furthermore, check the tank volume and the

the neglection of preventive measures frequently aggra- state of the heater required for the increase in tempera-

vated by use “other than the intended use” over longer pe- ture. Carry out the thermal disinfection between 01:00 and

riods, which is to say that water has not been tapped for 04:00 a.m. when water is usually not tapped. We recom-

months or even years. Particularly in existing facilities, mend to hot water flush each line individually in series to

preventive measures must be taken at least for the base- keep the warming up of the duct as low as possible. If you

ment distribution and the risers before taking intervention flush the system with hot water at 75 °C for an extended

measures. The number of interventions should be kept as period, the cold drinking water will heat up within a few

low as possible and should only be seen as a last resort to hours to reach the critical temperature zone, which in turn

ensure top-grade drinking water. In any case, it is impor- will trigger a counter-productive effect - namely microbio-

tant to pay particular attention to a holistic assessment of logical growth in cold water.

the drinking water system. Below we would like to recom-

mend two types of interventions that have proven success-

ful in practice.

Duct T = 22-28 °C

TK= TR= TV=

10°C 55°C 60°C

Fig. 12

The cold water will heat up to 25 °C within a few hours.

Source: Thesis, Cold Water Circulation, A. Meinero

8

Page9

Additionally, flush each tap at 70 °C for three minutes when

carrying out a thermal disinfection with hot water. After you 1. Analyse the drinking water quality (chemically

have informed the consumers accordingly, the cleaning staff and microbiologically)

will be able to support you in doing so in many facilities. 2. Determine the types of wetted materials

3. Determine the hydraulic conditions of cold and

hot water

Chemical Disinfection of 4. Detect critical operating conditions and

Drinking Water Systems connections of the system

5. Determine existing water treatment devices

Microbial contamination in drinking water systems are at the domestic water inlet

usually detected during the periodic sampling and affect 6. Make sure that the drinking water system is

only a part of the installation. If further tests are carried “used as intended” (no stagnation for more

out, the bacterial count might be low, however, the con- than 3 days)

tamination may spread over the entire drinking water dis-

tribution. That is why, an intervention is not only necessary

for the hot, but also for the cold water, since the microbial

contamination is passed on from the cold into the hot wa-

ter. Only if you clean the system prior to the chemical disinfec-

tion, you will achieve the desired long-term effect. As disin-

When carrying out a chemical disinfection, appropriate fectant we recommend using the electro-activated disin-

preventive measures, such as a hydraulic calibration of the fectant Hycleen Des 30. Long-term tests of GF JRG over

lines and periodic flushing, must be taken to protect the more than five years have shown that an electro-activated

entire drinking water distribution. We recommend drawing disinfectant with a proportion of sodium hypochlorite can

up a hygiene schedule prescribing periodic samplings. be used for all materials used in the drinking water system.

When using GF JRG products to dose water according to

Before planning a chemical disinfection, make sure the fol- the German Drinking Water Ordinance, there will be no

lowing points are considered. Your chemical disinfection lifetime limitations of the materials used in the drinking

will only be successful if you observe below guidelines. water system - a fact property operators will clearly benefit

from.

We know from experience that the system should be air

pulse flushed to clean it before you carry out a chemical

disinfection.

9

Page10

4 Risk Assessment The risk assessment of the drinking water system is of par-ticular importance with large facilities, as drinking water

to Secure quality may fluctuate due to various reasons. Property op-

erators are constantly improving this risk assessment and

Drinking Water Quality have developed emergency scenarios in case of impaired

and an Optimum drinking water quality supplied at the domestic water inlet. The disinfection system Hycleen Des 30 is an optimal solu-

Energy E

ciency tion.

A simple schematic shows the property operator how to

The measures taken in the three steps prevention, moni- secure high quality drinking water in four steps.

toring and intervention are prerequisites to secure top

grade drinking water until the tapping points in the facili-

ties. Facility conversions or adjustments made by the utility

companies, however, may require a reassessment of the

measures taken from time to time. This is also true, since

energy and water prices are rising and operating costs are

gaining in importance.

The risk assessment combines and analyses all relevant

parameters. Microbiological analyses and detected tem-

perature values are examined to determine how frequently

temperatures have reached the critical ranges. See an ex-

ample in the illustration below.

Microbiological TWK Analyses

Microbiological TWW Analyses

Temperature in cold water

Temperature in hot water

kitchen

never once a month always

Critical temperature range

10

Contamination potential

low favoured high

Page11

Prevention • Hydraulics of the entire system

• Limescale protection if necessary

• Periodic cold water flush

01

Risik

Assessment 04 02 Monitoring

• Assessment of drinking • Temperature monitoring

water quality on the • Drinking water sampling

basis of various

indicators

03

Intervention • Thermal disinfection

• Chemical disinfection

The advantages of this

control cycle:

• A drinking water system can be operated

efficiently in terms of hygiene.

• It shows where energy costs can be reduced.

• Such a holistic approach to drinking water

quality and thermal energy will gain in

importance for property operators in future.

11

Page12

GF Piping Systems

Worldwide at home

Our sales companies and representatives

ensure local customer support in over 100 countries.

www.gfps.com

Argentina / Southern South America France Middle East Spain / Portugal

Georg Fischer Central Plastics Georg Fischer SAS Georg Fischer Georg Fischer S.A.

Sudamérica S.R.L. 95932 Roissy Charles de Gaulle Cedex Piping Systems (Switzerland) Ltd 28046 Madrid

Buenos Aires, Argentina Phone +33 (0)1 41 84 68 84 Dubai, United Arab Emirates Phone +34 (0) 91 781 98 90

Phone +5411 4512 02 90 Fax. +33 (0)1 41 84 68 85 Phone +971 4 289 49 60 Fax +34 (0) 91 426 08 23

Fax +5411 4512 02 93 fr.ps@georgfi scher.com Fax +971 4 289 49 57 es.ps@georgfi scher.com

gfcentral.ps.ar@georgfi scher.com www.gfps.com/fr gss.ps@georgfi scher.com www.gfps.com/es

www.gfps.com/ar www.gfps.com/int

Germany Sweden

Australia Georg Fischer GmbH Netherlands Georg Fischer AB

George Fischer Pty Ltd 73095 Albershausen Georg Fischer N.V. 11743 Stockholm

Riverwood NSW 2210 Phone +49 (0)7161 302 0 8161 PA Epe Phone +46 (0) 8 506 77 50 0

Phone +61 (0)2 9502 8000 Fax +49 (0)7161 302 25 9 Phone +31 (0) 578 678 222 Fax +46 (0) 8 749 23 70

Fax +61 (0)2 9502 8090 info.de.ps@georgfi scher.com Fax +31 (0) 578 621 768 info.se.ps@georgfi scher.com

australia.ps@georgfi scher.com www.gfps.com/de nl.ps@georgfi scher.com www.gfps.com/se

www.gfps.com/au www.gfps.com/nl

India Switzerland

Austria Georg Fischer Piping Systems Pvt. Ltd. New Zealand Georg Fischer

Georg Fischer Rohrleitungssysteme GmbH 400 076 Powai, Mumbai Georg Fischer Ltd Rohrleitungssysteme (Switzerland) AG

3130 Herzogenburg Phone +91 22 4007 2001 5140 Upper Hutt 8201 Scha hausen

Phone +43 (0) 2782 856 43 0 Fax +91 22 4007 2020 Phone +64 (0) 4 527 9813 Phone +41 (0)52 631 30 26

Fax +43 (0) 2782 856 64 brancho ce@georgfi scher.com Fax +64 (0) 4 527 9834 Fax +41 (0)52 631 28 00

austria.ps@georgfi scher.com www.gfps.com/in nz.ps@georgfi scher.com ch.ps@georgfi scher.com

www.gfps.com/at www.gfps.com/nz www.gfps.com/ch

Indonesia

Belgium / Luxembourg George Fischer Representative O ce Norway Taiwan

Georg Fischer NV/SA 10310 Jakarta Georg Fischer AS Georg Fischer Co. Ltd.

1070 Bruxelles/Brüssel, Belgium Phone +62 21 391 48 62 1351 Rud 24158 New Taipei City

Phone +32 (0)2 556 40 20 Fax +62 21 391 48 63 Phone +47 67 18 29 00 Phone +886 2 8512 2822

Fax +32 (0)2 524 34 26 sgp.ps@georgfi scher.com Fax +47 67 13 92 92 Fax +886 2 8512 2823

be.ps@georgfi scher.com www.gfps.com/sg no.ps@georgfi scher.com tw@georgfi scher.com

www.gfps.com/be www.gfps.com/no www.gfps.com/tw

Italy

Brazil Georg Fischer S.p.A. Philippines Turkey

Georg Fischer Sist. de Tub. Ltda. 20063 Cernusco S/N (MI) George Fischer Representative O ce Georg Fischer Hakan Plastik

04571-020 São Paulo/SP Phone +39 02 921 86 1 1604 Pasig City Boru ve Profi l San. Tic. A.S.

Phone +55 (0)11 5525 1311 Fax +39 02 921 86 24 7 Phone +632 571 2365 59500 Cerkezkoy / Tekirdag

br.ps@georgfi scher.com it.ps@georgfi scher.com Fax +632 571 2368 Phone +90 282 726 64 43

www.gfps.com/br www.gfps.com/it sgp.ps@georgfi scher.com Fax +90 282 726 94 67

www.gfps.com/sg hpsales@hakan.com.tr

Canada Japan www.hakan.com.tr

Georg Fischer Piping Systems Ltd Georg Fischer Ltd Poland

Mississauga, ON L5T 2B2 556-0011 Osaka Georg Fischer Sp. z o.o. United Kingdom / Ireland

Phone +1 (905) 670 8005 Phone +81 (0)6 6635 2691 05 090 Sekocin Nowy George Fischer Sales Ltd

Fax +1 (905) 670 8513 Fax +81 (0)6 6635 2696 Phone +48 (0)22 3131 050 CV2 2ST Coventry, United Kingdom

ca.ps@georgfi scher.com jp.ps@georgfi scher.com Fax +48 (0)22 3131 060 Phone +44 (0) 2476 535 535

www.gfps.com/ca www.gfps.com/jp poland.ps@georgfi scher.com Fax +44 (0) 2476 530 450

www.gfps.com/pl uk.ps@georgfi scher.com

China Korea www.gfps.com/uk

Georg Fischer P iping Systems Ltd Georg Fischer Piping Systems Romania

201319 Shanghai 463-824 Seoul Georg Fischer Rohrleitungssysteme (Elvetia) USA /Caribbean

Phone +86 21 3899 3899 Phone +82 31 8017 1450 3 S.A. SUCURSALA BUCURESTI Georg Fischer LLC

Fax +86 21 3899 3888 Fax +82 31 8017 1454 020257 Bucuresti 92618 Irvine

china.ps@georgfi scher.com kor.ps@georgfi scher.com Phone +40 311 040 492 Phone +1 714 731 88 00

www.gfps.com/cn www.gfps.com/kr Fax +40 212 317 479 Fax +1 714 731 62 01

ro.ps@georgfi scher.com Toll Free 800/854 40 90

Denmark / Iceland Malaysia www.gfps.com/int us.ps@georgfi scher.com

Georg Fischer A/S George Fischer (M) Sdn. Bhd. Sales O ce www.gfpiping.com

2630 Taastrup, Denmark 40460 Shah Alam, Selangor Darul Ehsan Russia

Phone +45 (0) 7022 1975 Phone +60 (0)3 5122 5585 Georg Fischer International

Fax +45 (0) 7022 1976 Fax +60 (0)3 5122 5575 Piping Systems (Switzerland) Ltd Georg Fischer

info.dk.ps@georgfi scher.com my.ps@georgfi scher.com Moscow Representative O ce Piping Systems (Switzerland) Ltd

www.gfps.com/dk www.gfps.com/my 125047 Moscow 8201 Scha hausen/Switzerland

Phone +7 495 258 60 80 Phone +41 (0) 52 631 30 03

Finland Mexico / Northern Latin America Fax +7 495 258 60 81 Fax +41 (0) 52 631 28 93

Georg Fischer AB Georg Fischer S.A. de C.V. ru.ps@georgfi scher.com info.export@georgfi scher.com

01510 Vantaa Apodaca, Nuevo Leon, Mexico www.gfps.com/ru www.gfps.com/int

Phone +358 (0)9 586 58 25 Phone +52 (81) 1340 8586

Fax +358 (0)9 586 58 29 Fax +52 (81) 1522 8906 Singapore

info.fi .ps@georgfi scher.com mx.ps@georgfi scher.com George Fischer Pte Ltd

www.gfps.com/fi www.gfps.com/mx 528 872 Singapore

Phone +65 6747 0611

Fax +65 6747 05 77

sgp.ps@georgfi scher.com

www.gfps.com/sg

The technical data are not binding. They neither constitute expressly 3377 723469 0602

warranted characteristics nor guaranteed properties nor a guaranteed durability. 1e2 ((11021..154)) S MSS

They are subject to modifi cation. Our General Terms of Sale apply.

© G Geeoorrgg F Fiisissccchhheeerr rJ JRJRGG A GAG

Haauuppttssttrtrraaassssseee 1 11333000

CHH--4444555000 S Siisissssaaaccchhh//S/Swwitiitztzezererlrallanandndd

TTeelleeffoonn + +4411 ( (0(0)) ) 6 611 9 97755 2 222 2 222

iinnffoo..jjrjrgg..p.ppsss@@ggeeoorrggffifisissccchhheeerr.rc..cocomom

Prrinintteedd i inin S Swwiititztzzeeerrlrlalaannnddd