1/389ページ

ダウンロード(11.2Mb)

The System for Highly Demanding Applications

Superior purity, outstanding chemical and temperature resistance

このカタログについて

| ドキュメント名 | SYGEF(PVDF) - Product Range |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 11.2Mb |

| 取り扱い企業 | ジョージフィッシャー株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

GF Piping Systems

Product Range International 2016

PVDF

SYGEF

Page2

Introduction

The best choice

for you

Corrosion and chemical resistant

system solutions

Georg Fischer

Georg Fischer focuses on three core businesses: • Microelectronics

GF Piping Systems, GF Automotive and GF Machining • Marine

Solutions. The industrial corporation founded in 1802 • Water & Gas Utilities

headquarters in Switzerland and operates approximately • Water Treatment

130 companies with more than 14 000 employees across 30

countries.

GF Piping Systems is a leading supplier of plastic and metal Global presence

piping systems with global market presence. For the Our global presence ensures customer proximity worldwide.

treatment and distribution of water and chemicals, as well Sales companies in over 26 countries and representatives in

as the safe transport of liquids and gases in industry, we another 80 countries provide customer service around the

have the corresponding jointing technologies, fittings, clock. With 48 production sites in Europe, Asia and the USA

valves, automation products and pipes in our portfolio. we are close to our customers and comply with local

standards. A modern logistics concept with local distribution

centers ensures highest product availability and short

delivery times. GF Piping Systems specialists are always

close by.

Complete solutions provider

Our extensive product range represents a unique form of

product and competence bundling. With over 60 000

products, allied with a broad range of services, we offer

individual and comprehensive system solutions for a

variety of industrial applications. Our automation offering

perfectly fits into our complete system approach and is thus

GF Piping Systems headquarters in Schaffhausen, Switzerland. an integral part of our portfolio. Having the profitability of the

project in focus, we optimize processes and applications that

are integrated into the whole system.

Our market segments Continually setting standards in the market, we directly

Being a strong partner, GF Piping Systems supports its provide our customers with technological advantages. Due

customers in every phase of the project. No matter which to our worldwide network customers benefit directly from

processes and applications are planned in the following over 50 years of experience in plastics.

market segments:

• Building Technology From start to finish, we support our customers as a

• Chemical Process Industry competent, reliable and experienced partner, actively

• Energy contributing the know-how of an industrial company that has

• Food & Beverage / Cooling been successful in the market for over 200 years.

Page3

The system

The System for

Highly Demanding

Applications

Superior purity, outstanding chemical and temperature resistance

We are dedicated to designing, manufacturing and marketing piping systems

for the safe and secure treatment or conveyance of diff erent qualities of water,

liquids and chemicals. Customers rely on our 40+ years experience in Fluoro-

polymers, our state-of-the-art production technology and our global presence

with a worldwide service and training off ering. In close collaboration with

end-customers and based on their high requirements, GF Piping Systems

introduced the SYGEF family – specifi ed PVDF system based on certifi ed raw

material. SYGEF is the optimal choice for highly demanding applications on the

industrial fi eld.

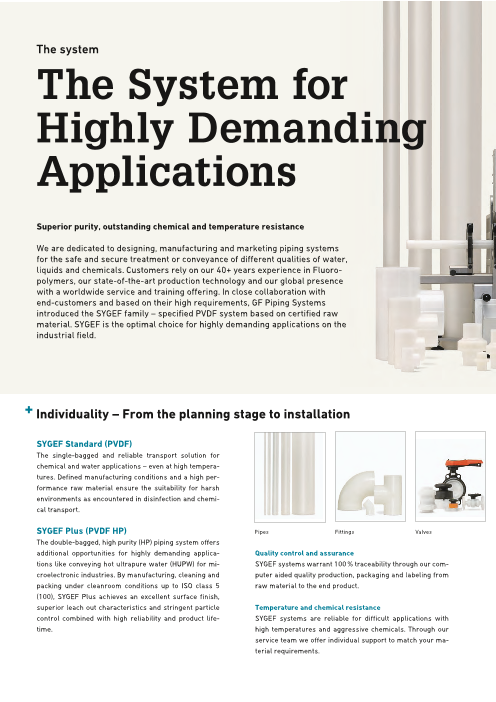

Individuality – From the planning stage to installation

SYGEF Standard (PVDF)

The single-bagged and reliable transport solution for

chemical and water applications – even at high tempera-

tures. Defi ned manufacturing conditions and a high per-

formance raw material ensure the suitability for harsh

environments as encountered in disinfection and chemi-

cal transport.

SYGEF Plus (PVDF HP) Pipes Fittings Valves

The double-bagged, high purity (HP) piping system off ers

additional opportunities for highly demanding applica- Quality control and assurance

tions like conveying hot ultrapure water (HUPW) for mi- SYGEF systems warrant 100 % traceability through our com-

croelectronic industries. By manufacturing, cleaning and puter aided quality production, packaging and labeling from

packing under cleanroom conditions up to ISO class 5 raw material to the end product.

(100), SYGEF Plus achieves an excellent surface fi nish,

superior leach out characteristics and stringent particle Temperature and chemical resistance

control combined with high reliability and product life- SYGEF systems are reliable for diffi cult applications with

time. high temperatures and aggressive chemicals. Through our

service team we off er individual support to match your ma-

terial requirements.

Page4

Main benefi ts

Complete system range

• One-stop-shopping

• Including pipes, fi ttings, valves and automation

• Proven jointing technologies

• Worldwide service: customizing, machine rental

pool, training and sales support

• System lifetime warranty*

Total plastic solution

• Outstanding temperature range

• Excellent chemical resistance and purity

• Extremely smooth surface fi nish

• Rouging- and corrosion-free

• Excellent abrasion resistance

• UV and weather resistant

• No electric conductivity

• Low thermal conductivity

High purity application

• Virgin raw materials

• No additives, stabilizers or pigments

• Outstanding leach-out values

• Fully controlled clean room production

• 100 % traceability and audited

by an independent external company

Technical documentation

Our extensive expertise of more than 50 years is fully docu-

mented in detail in our technical manuals, planning funda-

mentals and application guides.

Training courses and on-site training

We off er a wide range of training courses that provide par-

ticipants an excellent opportunity to gain confi dence in work-

ing with our products and proven jointing technologies.

Automation Jointing technology Customizing and training

Online and mobile calculation tools

Technical support Our numerous online and mobile calculation tools in many

For any successful installation a good technical support is diff erent languages support our customers in confi guring

the key factor. A team of experts is available for individual and commissioning automation products.

assistance all around the world.

CAD library

Customizing The extensive CAD library is the most frequently used

The focus of our worldwide located customizing teams is planning tool. Our online database comprises over 30 000

manufacturing custom parts for special systems. Standard- drawings as well as technical data for our customers. Many

ized processes guarantee the highest level of quality. formats are available.

* Detailed information regarding the warranty can be found under: www.gfps.com – Planning Fundamentals

Page5

Completely controlled process

The SYGEF

High Purity Chain

2 ManufacturingManufacturing of the SYGEF Plus prod- 4

ucts is done in a clean room class 7

(10 000) or better using completely con-

trolled processes. During the complete

production process the inner surface

area of the pipes, fi ttings and valves are

in contact with air up to class 5 (100).

1Raw material Quality controlSYGEF starts the journey with the high- 3 A very detailed and unique QS-

est available quality raw materials. Our system has been implemented to

suppliers provide analytical proof of ensure the highest level of

compliance with the highest specifi ca- quality. It is directly linked to the

tions for every shipment. Once the raw manufacturing of the complete

materials enter our plant, GF performs SYGEF range and includes a

extensive incoming goods inspection. 100 % inspection of every prod-

This assures that only raw materials ful- uct to ensure maximum perfor-

fi lling the strict requirements are re- mance including visual inspec-

leased for production. tion, valve packaging and valve

seat-tests.

Page6

The high purity chain Manufacturing a product that achieves the lowest possible levels of particle contamination, TOC, anionic and cationic

is made up of six links. contamination, ultimate surface fi nish is the result of the rel-

evant links. But it does not stop here. When the

Each one plays its product leaves our state-of-the-art warehouse it is delivered

important role to you in protective packaging.

Finally the installation is supported by the most advanced

and established welding technology in existence. This

technology combined with years of installation training

experience make the most of the product when it is

installed.

4 Cleaning & packing Installation & Highest purity through consistent 6 services

cleaning of all SYGEF Plus products is

With broad selection of system specifi c

achieved in clean rooms up to class 5

state-of-the-art welding equipment GF is

(100), using 18MΩ pure water and spe-

off ering proprietary IR welding technolo-

cial cleaning devices. All products are

gy up to d450mm. Enhanced by industry

packaged under selected and strictly

leading weld bead inspection the highest

monitored process conditions to avoid

quality and most reliable system is en-

contamination. Pipes are capped and

sured. Project support including design,

all SYGEF Plus components are double

installation training and worldwide lo-

bagged with a high quality, certifi ed

cated service centers completing

clean bagging material.

the high purity chain.

5 LogisticsSYGEF products are stored in a sepa-

rate warehouse for pipes, fi ttings and

valves with distribution centers located

worldwide. To avoid damage of SYGEF

pipes GF has designed special wooden

boxes for storage and transportation.

This ensures that the highest possible

quality and safety during transportation

to the customer is ensured.

Page7

High tech factory Ettenheim / Germany

SYGEF Cleanroom

Production

All SYGEF components are

manufactured in the world’s

largest cleanroom factory

for fl uoropolymer products

in Ettenheim

GF Piping Systems played a major role in establishing the relevant

standards SEMI F40, F48 and F57 for polymer component testing. Due

to long experience and continuous improvements SYGEF Plus pipes,

fi ttings and valves are exceeding these requirements to increase our

customers’ yield. SYGEF Plus products are strictly fulfi lling the strong

requirements of the ITRS* roadmap in order to be prepared for upcom-

ing, even more demanding processes in the future.

Fully controlled environment Surface quality

The SYGEF production area includes 5 600m2 cleanroom: Smooth surfaces are achieved due to special equipment de-

4 000m2 class 7 (10 000), 1 000m2 class 6 (1 000) and 600m2 sign, proper tooling material’s selection, mirror fi nish sur-

class 5 (100) in operation. All cleanrooms are continuously face of inner cores and preventive maintenance schedule.

monitored and audited internally and by external companies. Thereby for all SYGEF Plus products the inner surface

The microbiological and specifi ed particle measurements roughness according SEMI F57 is surpassed.

are fully documented with a unique quality assurance (QA)

system.

R Profi l Filter DIN 4768 (RC) Le=0.800 mm

Ultrapure water plant 2.0

Cleaning and rinsing of components with water of impecca-

ble quality assures a constantly high level of cleanliness. 0.0

(μm)

SYGEF Plus products are subject to regular leach-out con-

-2.0

trols. Elementary system impurities like metals, anions and

Taster T1E Lt = 4.80 mm 4.80

TOC** are constantly monitored to exceed SEMI F57 require-

ments to warrant the highest possible system performance

Inner surface roughness measured at a SYGEF Plus T90° equal d250

in use. SDR33 / PN10

Page8

Process expertise Safe and reliable system

Operating staff has in-depth process knowledge and over 40 Quality control is an integral part in every step of the high

years of experience in manufacturing products under strictly purity chain. Therefore each SYGEF Plus component is 100 %

controlled cleanroom conditions. With regular internal train- visually inspected, including overall cleanliness, surface ap-

ings we ensure that our production team keeps always the pearance and imperfections in accordance to internal speci-

highest performance and has the latest insights. All the in- fi cations.

jection molding machines and extrusion lines are developed All mechanical testing takes place in matchless Swiss feder-

by using the latest innovations and technologies. ally accredited lab facility and external certifi cated labs. To-

gether with unsurpassed installation equipment GF Piping

Quality Assurance Systems is superior regarding ovality, internal stress level

The safe delivery to jobsite and traceability of the fi nished and warpage. These key factors are able to infl uence the

product back to the raw material batch are ensured through weld strength which leads to a longer system lifetime and a

completely controlled processes. All relevant data are ar- higher safety.

chived in an internal QA database and electronically avail-

able for statistical researches.

* ITRS: International Technology Roadmap for Semiconductors

** TOC: Total Organic Carbon

Page9

System range

More Than a System

With a constant focus on maximum reliability and safety the SYGEF system assures a sustained

high level of product quality and outstanding performance for high-end applications. By using

certifi ed and completely controlled manufacturing processes the SYGEF products are manufac-

tured according to all relevant specifi cations and these procedures are regularly audited and

evaluated to achieve continuous improvement. Our customers can be assured that their needs are

met or exceeded and that the products comply with all necessary standards.

SYGEF Standard and SYGEF Plus system range

Products d

DN

SDR PN

21 16

Pipes

33 10

Socket fusion fi ttings 16

Butt fusion fi ttings 21 16

(IR and BCF compatible) 33 10

16

Ball valves

10

16 upon request

Diaphragm valves

10

Butterfl y valves 10

16

Check valves

10

Pressure regulating valves 10

Ventilating- and bleed valves 16

Automation

Flanges

Flange seal

Pipe clips

IR fusion machine

BCF fusion machine

Butt fusion machine*

Socket fusion machine

SYGEF Standard SYGEF Plus * Technically possible but not recommended for SYGEF Standard

10 16

15 20

20 25

25 32

32 40

40 50

50 63

65 75

80 90

100 110

100 125

125 140

150 160

200 200

200 225

250 250

250 280

300 315

350 355

400 400

450 450

Page10

System specifi cations

Standards:

SYGEF Standard SYGEF Plus

Material PVDF virgin High Purity PVDF (PVDF-HP)

Color opaque opaque

Density ~1.78 g / cm3 (EN ISO 1183) ~1.78 g / cm3 (EN ISO 1183)

Thermal expansion coeffi cient 0.12–0.18 mm / m K (DIN 53752) 0.12–0.18 mm / m K (DIN 53752)

Thermal conductivity at 23 °C 0.19 W / m K (EN 12664) 0.19 W / m K (EN 12664)

Yield stress at 23 °C > 50 N / mm2 (EN ISO 527) > 50 N / mm2 (EN ISO 527)

Tensile E-modul at 23 °C > 1 700 N / mm2 (EN ISO 527/ASTM D790) ≥ 1 700 N / mm2 (ISO 527/ASTM D790)

Charpy notched impact strength at 23 °C ≥ 8 kJ / m2 (EN ISO 179) ≥ 8 kJ / m2 (EN ISO 179)

Dimensions d16–d315 in accordance to ISO 10931 d20–d450 in accordance to ISO 10931

Temperature rating from -20 °C to 140 °C (-4 °F to 284 °F)

Production - Pipes: extruded - Pipes: extruded

- Fittings: injection moulded / machined - Fittings / Valves: injection moulded /

- Valves: injection moulded (additional oil machined

free treated and paint compatible / silicon - Produced under clean room class

free) 7 (10 000) conditions. Subsequent

assembling, quality inspection and

cleaning is carried out using 18 MΩ pure

water under clean room class 5-6

(100 -1 000) conditions

Surface fi nish Inner surface Ra < 0.5 μm (20μin) Inner surface (PN10/ SDR33):

Compliant to Semi F57 for injection moulded and extruded d ≤ 225 Ra ≤ 0.2 µm (8µin)

components d = 250 Ra ≤ 0.3 µm (12µin)

d280–315 Ra ≤ 0.4 µm (16µin)

d355–450 Ra ≤ 0.65 µm (26µin)

for injection moulded and extruded components

Internal stress Pipes: ≤ 2.5 N / mm2; stress relieved by thermal annealing during manufacturing

Material and product approvals DIBt SEMI F57

FM-4910 listed cleanroom material FM-4910 listed cleanroom material

FDA CFR 21 177.2510 DIBt

USP 25 class VI (physiological non-toxic) FDA CFR 21 177.2510

ASME BPE USP 25 class VI (physiological non-toxic)

ASME BPE

Packing Pipes capped and multiple components Pipes capped and each component

single bagged in a specifi ed bag double bagged in a specifi c inner bag and outer

bag under clean room Class 6

(1 000) conditions

Marking and labeling All components are embossed with a permanent identifi cation during the production

process to ensure full traceability:

- Brand name - Lot No.

- Material - Product description

- Dimensions - Article number

- Pressure rating - Standard and approvals

Approvals / Acceptance:

ISPE I ASME BPE I FM-4910

Page11

Jointing methods

Convincing Welding

Technologies

A diverse range of innovative and intelligent welding solutions is enriched with global training and

service off erings

As a pioneer in the fi eld, GF Piping Systems has always placed a very high priority on developing innova-

tive jointing techniques to fulfi ll specifi c requirements and materials in use. Simplicity in application,

chemical resistance, thermal stability and long-term weld strength are the key drivers in our jointing

technologies. With a global jointing training program, international machine rental and a worldwide

network of service centers, our customers benefi t from our expertise and practical experience.

Welding technology Welding machine Joint cross-section Microscopy

Socket fusion –

the strong connection

The fast and reliable solution to pro-

duce heavy-duty connections, in the

workshop or the fi eld.

Butt fusion –

the economical connection

Economical and fl exible fusion espe-

cially for larger diameters. From

manual machines to full CNC control

with traceability.

IR-Plus (Infrared) fusion –

the fast, clean connection

Fast, repeatable and clean welds via

non-contact heating. Full traceability

of the welding process, with user

guidance.

BCF-Plus fusion –

the smooth connection

Bead and Crevice Free jointing with

the highest weld factor, lowest stress

and completely smooth fusion zone

without any intrusions.

For more information about training courses from GF Piping Systems please contact our local sales companies.

Page12

SYGEF system System up to d450

• Completely controlled processes

Key from raw material to installation• Overall system reliability, purity and safety

• Wide range of pipes, fi ttings, valves,

Products automation and accessories• Stress reduced pipes • SEMI F57 conformity

High purity union

Specially • Special HP design with unique positioning of the sealing

• Defi ned tightening for optimal

deforming of the O-ring

Designed • Crevice and dead space free to avoid bacterial growth

• Full plastic design without metal parts

• In accordance with ASME-BPE

for You High purity diaphragm valves• Maintenance free during temperature

cycles due to full plastic design

• Maximized purity due to minimized

dead legs and manufacturing in

Continuous improvements and new develop- clean room class 5 (100)

ments assure a maximum level of quality to our • Double fl ow rate compared to

customers. The SYGEF Plus system off ers very other diaphragm valves

unique key products which are specially de-

signed by GF Piping Systems to fulfi ll even the Pressure regulating valves (PRV)

highest requirements in segments like Micro-

• Special HP-version with patented elasto-

electronic, Energy and Chemical Process Indus- mer-free piston – no abrasion

try.

• Valve assembly without metal

screws for safer operation

• Compact and intelligent modular

design

• Easy maintenance through replaceable

cartridge

Automated IR welding machine

• Advanced QA/QC technology and

monitored jointing work

• Minimized operator errors by

automated welding process

• Full horizontal freedom for

complex installation

• State-of-the-art, man-machine interface

with user friendly touchscreen display

Ultrasonic fl owmeter

• Noninvasive clamp-on design enables

contamination free fl ow measurement

• Easy to retrofi t – minimum downtime

• Real time monitoring

• Clean solution – no contact with medium

• Economic solution

Page13

Specifi cations

Exceeding Your

Standards of Quality

Technical specifi cations with focus on

pressure, temperature and high purity

attributes

Excellent pressure/temperature performance Sterilization / sanitization / cleaning

SYGEF PVDF is a thermoplastic fl uoropolymer with a melting Due to its outstanding material properties, our SYGEF sys-

point above 175 °C and a wide service temperature range tems are suitable for a broad range of sterilization or clean-

from -20 °C to 140 °C. SYGEF systems are ideal for use in ing methods using steam, hot water, ozone and chemicals.

aggressive chemical or ultrapure water systems since they

are generally considered inert, have high strength and stiff -

ness, and are readily weldable into system components.

Pressure-temperature diagram

T (°F)

2 32 62 92 122 152 182 212 242 272 302

17 240

16 SDR21, PN16

15 220

14 200

13

12 180

11 160

10 140

9

8 120

7 100

6

5 80

4 SDR33, PN10 60

3 40

2

1 20

0 0

-30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

T (°C)

P Permissible pressure in bar, psi C = 1.6

C = 2.0 (recommended by GF)

T Temperature in ˚C (Celsius),

˚F (Fahrenheit)

The pressure/ temperature curve based on medium water, operating temperature of 20°C, valid life

time of 25 years and the design factor of C = 2.0 or C = 1.6 respectively

More information regarding technical specifi cations can be found online in our planning fundamentals: www.gfps.com

P (bar)

P (psi)

Page14

Chemical resistance

For Your

Operational

Safety

Professional material technology

Polyvinylidene fl uoride

(PVDF) – a high quality material

Chemical resistance at 20 °C Partially crystalline Amorphous Stainless steel

(Applications can be very dependent on the concentration) thermoplastics thermoplastics

1.4401 1.4301

Media Chemicals PVDF PE PP PVC-U PVC-C

316 304

HNO < 25 %

3 + o o + + o o

Oxidizing acids 25 % < HNO < 65 %3 + o - o + o o

(HNO , H CrO , H CrO aqueous solution

3 2 4 2 4 + o o o o o o

H SO , etc.)

2 4 H SO < 70%

2 4 + + + + + - -

70 % < H SO < 96 %

2 4 + - - + + - -

HCl < 30 % + + + + + o -

Non oxidizing acids

HF < 40 %

(HCl, HF, etc.) + + + + - o -

40 % < HF < 75 % + + + - - - -

HCOOH < 25 % + + + + + o -

Organic 25 % < HCOOH < tech. pure + + + + - o -

(formic acid, acetic CH COOH < 50 %

3 + + + + + o -

acid, citric acid, etc.) 50 % < CH COOH < tech. pure

3 + + + o - o -

C H OH (COOH)

3 4 3 + + + + + o -

Inorganic (NaOH, KOH, etc.) - + + + o + +

Bases

Organic (amine, imidazole, etc.) - + + o - o o

Salts NaCl, FeCl , FeCl , CaCl , etc.

2 3 2 + + + + + o o

Halogens Chlorine, bromine, iodine, (no fl uorine) o - - o o o -

Aliphatic hydrocarbons + o o + o + +

Fuels / oils

Aromatic hydrocarbons + - - - - + +

Chlorinated hydrocarbons o - - - - o o

Ketones o + + - - + +

Solvents Alcohols + + + o - + +

Esters o o o - - + +

Aldehydes - + + - - + +

Phenols Phenol, Cresol, etc. + + + - - + -

+ resistant o conditionally resistant, please consult us - not resistant

Please note: The above list is only intended as a guideline and does not replace an indepth review of material suitability for the particular application. The

information is based on our experience and is state of the art. These data are general indicators only. In practice, however, other factors such as concentra-

tion, pressure and jointing technology must also be taken into consideration. The technical data are not binding and are not expressly

warranted characteristics of the goods.

Please contact us for help in selecting the right materials.

Page15

The smarter way of automation

Automation

Made Easy

A unique system-based approach that bundles and integrates competencies, knowledge,

best-in-class resources and technologies

With an innovative product portfolio in the fi eld of measurement, control and actuation devices, GF

Piping Systems consistently follows its system approach. The complete solution combines measure-

ment, control and actuation technology together with high quality piping systems and represents a

unique form of product and competence bundling. The system-integrated devices that measure values

such as temperature, pressure and fl ow delivering accuracy, productivity, reliability and safety to

customers in a wide range of industries. Providing the entire range of automation technology from

simple instrument panels to complex measurement installations, GF Piping Systems has not only the

product resources and the technical expertise, but also the global service and support infrastructure

needed to meet the high customer requirements.

ck

edba

PID co

e ntro

itio

n f ller

os

B

s

P atch

alv

e co

V nt

n o Cti on

ectio urn s Mea

n fi t e

r

ti zngs na

ly

A

s Se

nsor

Actuators Pressure regulating

Actu

a

ement

s Transmitters

mete

r

ara

ulti

-p

M

er

ro

ll

l o tr

nn

Co

o

lla

ti

ta

ns

I

Page16

Applications

As Versatile as

Your Applications

Leading applications enabled by safe and reliable systems adapted to fit the needs of highly

demanding industries

GF Piping Systems develops customized best-in-class solutions, aligned to the specific requirements

of our customers in various sectors of industry, enabling profitable operation. With our system

knowledge and product expertise, we support our customers during the planning process, the sus-

tainable realization of the projects and provide valuable added services. Expertise in developing and

producing piping systems, combined with profound industry and market knowledge, based on long-

standing experience, makes GF Piping Systems an uniquely qualified and professional partner for our

customers.

Microelectronics Chemical process industry

Ultrapure water (UPW) is the SYGEF is uniquely equipped to

lifeblood of semiconductor wet provide a broad and versatile

processing. SYGEF Plus system solution for the safe convey-

manufactured out of PVDF high ance of aggressive chemicals in

purity material added with lat- extreme conditions. The excel-

est IR welding technology offers lent life span for temperatures

an industrial benchmark solu- up to 140°C including UV- resis-

tion with excellent leach-out tance even allows outside in-

values and no rouging. stallation.

Energy Water treatment

High voltage direct current With noticeably better water

(HVDC) transmission is used balance compared to steel,

because of its efficiency with SYGEF enables the right water

less power loss. Through its quality for any WT application

thermal resistivity SYGEF sys- like drinking water, industrial

tems are well suited to conduct effluent treatment or filling and

the deionized water in cooling emptying of tanks which are re-

systems to dissipate the gener- quired in manufacturing and

ated heat. Custom solutions of- processing plants to store li-

fered by GF Piping Systems. quid media.

Food & beverage Pharmaceutical

Lighter and corrosion-resistant Down to the lowest pH values

compared to stainless steel the excellent chemical resis-

SYGEF is ideal for the convey- tance of SYGEF provides a high-

ance of food. With FDA conform quality and cost-effective alter-

BCF-welding a smooth and reli- native even to high-performance

able connection is warranted. stainless steel or Titanium al-

Maintenance cycles and life- loys. With BCF welding purest

time are maximized to achieve water conveyance, minimal mi-

highest system efficiency. crobiological growth and endo-

toxin risk is ensured.

Page17

18

Page18

Table of contents

SYGEF Standard 20

SYGEF Plus 280

System-Oriented Fusion Jointing Machines 356

Index 373

19

Page20

SYGEF Standard

SYGEF Standard

Piping systems in PVDF