1/8ページ

ダウンロード(972.6Kb)

Recommendations for the Chemical Disinfection of Drinking Water Installations in Buildings

製品カタログ

Drinking Water Disinfection

このカタログについて

| ドキュメント名 | Recommendations for the Chemical Disinfection of Drinking Water Installations in Buildings |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 972.6Kb |

| 取り扱い企業 | ジョージフィッシャー株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

Recommendations for

the Chemical Disinfection

of Drinking Water

Installations in Buildings

Page2

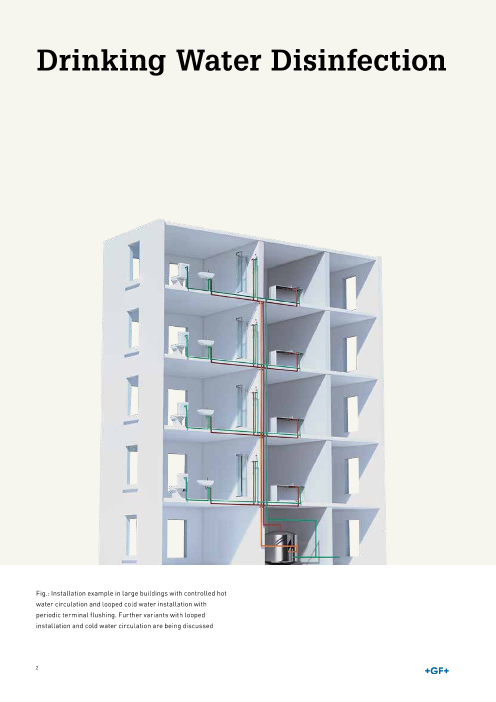

Drinking Water Disinfection

Fig.: Installation example in large buildings with controlled hot

water circulation and looped cold water installation with

periodic terminal flushing. Further variants with looped

installation and cold water circulation are being discussed

2

Page3

Ensuring a Preparations for

High Quality of Conducting a Chemical

Drinking Water Disinfection

Today various disinfectants are used for the chemical 6 steps that you must perform before a chemical

disinfection of drinking water systems. Because of test disinfection

series and experiences from the past 15 years, some

substances have prevailed in terms of their effectiveness;

these substances are listed in the German Drinking Water

Ordinance in the Part 1c. The following explanations are 1 Analyse the drinking water quality

to be understood as recommendation for a chemical (chemically and microbiologically)

disinfection of drinking water systems and as a general

guideline. With contaminated objects we recommend to 2 Determine the type of wetted materials

take the necessary preparatory measures and carry out a

shock disinfection. If required, a continuous disinfection 3 Determine the hydraulic conditions of

should be considered. cold and hot water systems

4 Determine the operating conditions and In heavily contaminated drinking water systems, flushing critical connection points of the system

respectively air pulse flushing can be considered as the

first step. This flushing is carried out to mechanically 5 Determine existing water treatment at

detach and discharge the biofilms. A chemical disinfection domestic water inlet

is often taken into account as an additional measure. 6 Assessment of the „intended use“ of the drinking water installation

If the expert’s risk assessment of the drinking water system

is positive with respect to all six points listed above, both

flushing and chemical disinfection can be carried out.

Section 11 and Part 1c of the German Drinking Water

Ordinance as well as the DVGW Bulletins W 291, W 557, W

229, W 551, W 290 provide a legal basis for these measures.

At the same time, the practical experience of the past years

with regard to effectiveness and material life are taken into

account. Pipe materials, gunmetal valves and elastomeric

gaskets are particularly crucial here, since especially shock

disinfections may lead to water leakage after years of use.

Thus, a number of conditions has to be taken into account

before carrying out a shock disinfection.

3

Page4

Chemical Shock Disinfection

If the preventive measures as described above failed to Material life of the GF JRG product lines is in no way

clean the drinking water system properly, we recommend affected and by shock disinfections (with anolyte neutral)

carrying out a chemical disinfection strictly observing the as described above.

following conditions.

When shock disinfecting JRG valves and systems of the

product lines JRG Sanipex Classic and JRG Sanipex MT, a

sodium hypochlorite disinfectant may be used twice a year

without impairing material life. Restrictions may arise due

to drinking water ingredients and other parameters (pH

value, conductivity), which should be determined in

advance.

Recommendation for a Chemical Shock Disinfection

Designation sodium hypochlorite NaOCI

prepared in situ e.g. Hycleen Des 30

CAS number 7681-52-9

EINECS number 231-668-3

Purity requirements DIN EN 901 Table 1: Type 1 threshold for the contamination

with chlorate (NaClO3): < 5,4 % (m/m) of active chlorine

Permitted addition (free chlorine) max. 50 mg/l max. 100 mg/l

Temperature 5° to 65°C 5° to 65°C

Time max. 24 h max. 16 h

Concentration after completion of the treatment min. 0,1 mg/l free chlorine max. 0,3 mg/l free chlorine

By-products to be observed trihalomethane, bromate

Relevant DVGW Bulletins DVGW W 291, W 296

Note Not comparable with sodium hydroxide solution, which

is prepared using chlorine gas.

Legend:

CAS = Chemical Abstracts Service Registry Number

EINECS = European Inventory of Existing Commercial Chemical Substances

4

Page5

Continuous Chemical Disinfection

The insufficient quality of drinking water at the domestic drinking water system, since the disinfectant is only

water inlet or limitations in the use of the object insufficiently distributed in case of low or irregular water

(reconstruction, conversion, maintenance work) may consumption. In order for the disinfectant to be transported

require a continuous disinfection to ensure a high quality of through the entire system, it is highly recommended to tap

drinking water. Certain incidents leading to microbiologically drinking water at least every three days (72 hours) or to

contaminated drinking water as advised of by the drinking ensure distribution with the help of an automatic flushing.

water suppliers call for timely measures. Depending on the This recommendation applies in particular to objects which

extent of the incident, these measures may take months or are only temporarily or irregularly in use.

years. Details have to be agreed on by the facility operators

and the local Health Department. Before applying other disinfection techniques or

disinfectants, we would advise you to contact GF JRG.

On the basis of our long-term experience with cases in

which a chemical disinfection was unavoidable, we

recommend using a sodium hypochlorite disinfectant

paying special attention to the operating conditions of the

Recommendation for a Continuous Chemical Disinfection

Designation sodium hypochlorite NaOCl

prepared in situ e.g. Hycleen Des 30

CAS number 7681-52-9

EINECS number 231-668-3

Purity requirements DIN EN 901 Table 1: Type 1 threshold for the contamination

with chlorate (NaClO3): <5.4% (m/m) of active chlorine

Permitted addition (free chlorine) max. 1,2 mg/l

Temperature 5° to 65°C

Time continuous

Concentration at each tapping point max. 0,3 mg/l free chlorine

By-products to be observed trihalomethane, bromate

Relevant DVGW Bulletins DVGW W 291, W 296

Note Not comparable with sodium hydroxide solution, which

is prepared using chlorine gas

Legend:

CAS = Chemical Abstracts Service Registry Number

EINECS = European Inventory of Existing Commercial Chemical Substances

5

Page6

Recommendations for the Preparation

of the Disinfectant

In case of contaminated drinking water, preventive measures Furthermore, the Hycleen Des 30 is easy to handle and has

do often not last and particularly in cold drinking water low operating costs of 3 cents per 1000 litres of treated

systems continuous disinfection measures are indispensable. drinking water.

Here, it is important to choose an environmentally friendly

and efficient disinfection technique. The Hycleen Des 30 In future, it will be crucial whether measures such as a

provides a highly effective and easy way to maintain drinking chemical disinfection can be carried out at any time to keep

water quality with a chemical disinfection using an the contamination risk of drinking water as low as possible.

electrochemically activated disinfectant. The disinfectant Only drinking water systems that efficiently combine use

solution is produced in situ out of water and salt through and preventive measures, as the Hycleen Des 30 does, will

diaphragm electrolysis. This process is fully in line with the be able to ensure a high quality of drinking water. Facility

principle of minimization; it features high antibacterial operators will hugely benefit from GF JRG drinking water

efficacy and low environmental impact caused by by- installations and drinking water treatment techniques.

products. The electrochemically activated disinfectant

solution has no negative impact on the service life of the GF

JRG product line.

Fig.: The Hycleen Des 30 disinfection system has been

used for many years and meets the strictest standards for

the quality of drinking water.

6

Page7

Life Cycle Verification When Using

the Hycleen Des 30

Life cycle tests with high chemical and physical stresses The diagram below shows the uniform stabilizer

over several years have shown no lifetime limitations of GF concentration from the inner diameter to the inner

JRG products. The given example of a Sanipex MT pipe aluminum layer. The infrared spectrometer shows the

clearly shows the cross section and the stabiliser distribu- quantitative amount of stabiliser concentration at 1704 cm-1.

tion more than 5 years into the test. The diagram shows the stabiliser concentration of the

inner pipe with a cold water and hot water dosage of

Life Cycle Test for JRG Sanipex MT 16 sodium hypochlorite, with a dose of 3 mg/l free chlorine

being added. After 5 years, there is no evident difference in

For the use of PE-X pipes in drinking water systems, small the stabiliser concentration caused by the different

concentrations of stabilisers are added to the polyethylene. dosages.

The stabilizers ensure that neither water ingredients nor

the temperature damage the PE-X pipe. It is important that

the stabiliser concentration is uniformly distributed over

the entire wall thickness.

2.0

1.5

1.0 = hot water with dosage

= hot water without dosage

= cold water with dosage

= cold water without dosage

0.5

0.0

0 200 400 600 800 1000 1200

distance from inner pipe (µm)

inner diameter

Sources:

German Drinking Water Ordinance Section 11 and Part Ic (http://www.gesetze-im-internet.de/trinkwv_2001/BJNR095910001.html)

DVGW Bulletin W 291; 2000; Cleaning and disinfection of water distribution systems

DVGW Bulletin W 557; 2012; Cleaning and disinfection of drinking water systems

DVGW Bulletin W 229; 2008; Methods for disinfecting drinking water systems with chlorine and hypochlorite

DVGW Bulletin W 551; 2004; Drinking water heating and drinking water pipe systems - Technical measures to prevent the

growth of legionella - planning, construction, operation and maintenance of drinking water installations

DVGW Bulletin W 290; 2005; Drinking Water Disinfection - operational and requirement criteria

7

peak area 1704 cm-1

Page8

GF Piping Systems

Worldwide at home

Our sales companies and representatives

ensure local customer support in over 100 countries.

www.gfps.com

Argentina / Southern South America France Middle East Spain / Portugal

Georg Fischer Central Plastics Georg Fischer SAS Georg Fischer Georg Fischer S.A.

Sudamérica S.R.L. 95932 Roissy Charles de Gaulle Cedex Piping Systems (Switzerland) Ltd 28046 Madrid

Buenos Aires, Argentina Phone +33 (0)1 41 84 68 84 Dubai, United Arab Emirates Phone +34 (0) 91 781 98 90

Phone +5411 4512 02 90 Fax. +33 (0)1 41 84 68 85 Phone +971 4 289 49 60 Fax +34 (0) 91 426 08 23

Fax +5411 4512 02 93 fr.ps@georgfischer.com Fax +971 4 289 49 57 es.ps@georgfischer.com

gfcentral.ps.ar@georgfischer.com www.gfps.com/fr gss.ps@georgfischer.com www.gfps.com/es

www.gfps.com/ar www.gfps.com/int

Germany Sweden

Australia Georg Fischer GmbH Netherlands Georg Fischer AB

George Fischer Pty Ltd 73095 Albershausen Georg Fischer N.V. 11743 Stockholm

Riverwood NSW 2210 Phone +49 (0)7161 302 0 8161 PA Epe Phone +46 (0) 8 506 77 50 0

Phone +61 (0)2 9502 8000 Fax +49 (0)7161 302 25 9 Phone +31 (0) 578 678 222 Fax +46 (0) 8 749 23 70

Fax +61 (0)2 9502 8090 info.de.ps@georgfischer.com Fax +31 (0) 578 621 768 info.se.ps@georgfischer.com

australia.ps@georgfischer.com www.gfps.com/de nl.ps@georgfischer.com www.gfps.com/se

www.gfps.com/au www.gfps.com/nl

India Switzerland

Austria Georg Fischer Piping Systems Pvt. Ltd. New Zealand Georg Fischer

Georg Fischer Rohrleitungssysteme GmbH 400 076 Powai, Mumbai Georg Fischer Ltd Rohrleitungssysteme AG

3130 Herzogenburg Phone +91 22 4007 2001 5140 Upper Hutt 8201 Schaffhausen

Phone +43 (0) 2782 856 43 0 Fax +91 22 4007 2020 Phone +64 (0) 4 527 9813 Phone +41 (0)52 631 30 26

Fax +43 (0) 2782 856 64 branchoffice@georgfischer.com Fax +64 (0) 4 527 9834 Fax +41 (0)52 631 28 00

austria.ps@georgfischer.com www.gfps.com/in nz.ps@georgfischer.com ch.ps@georgfischer.com

www.gfps.com/at www.gfps.com/nz www.gfps.com/ch

Indonesia

Belgium / Luxembourg George Fischer Representative Office Norway Taiwan

Georg Fischer NV/SA 10310 Jakarta Georg Fischer AS Georg Fischer Co. Ltd.

1070 Bruxelles/Brüssel, Belgium Phone +62 21 391 48 62 1351 Rud 24158 New Taipei City

Phone +32 (0)2 556 40 20 Fax +62 21 391 48 63 Phone +47 67 18 29 00 Phone +886 2 8512 2822

Fax +32 (0)2 524 34 26 sgp.ps@georgfischer.com Fax +47 67 13 92 92 Fax +886 2 8512 2823

be.ps@georgfischer.com www.gfps.com/sg no.ps@georgfischer.com tw@georgfischer.com

www.gfps.com/be www.gfps.com/no www.gfps.com/tw

Italy

Brazil Georg Fischer S.p.A. Philippines Turkey

Georg Fischer Sist. de Tub. Ltda. 20063 Cernusco S/N (MI) George Fischer Representative Office Georg Fischer Hakan Plastik

04571-020 São Paulo/SP Phone +39 02 921 86 1 1604 Pasig City Boru ve Profil San. Tic. A.S.

Phone +55 (0)11 5525 1311 Fax +39 02 921 86 24 7 Phone +632 571 2365 59500 Cerkezkoy / Tekirdag

br.ps@georgfischer.com it.ps@georgfischer.com Fax +632 571 2368 Phone +90 282 726 64 43

www.gfps.com/br www.gfps.com/it sgp.ps@georgfischer.com Fax +90 282 726 94 67

www.gfps.com/sg hpsales@hakan.com.tr

Canada Japan www.hakan.com.tr

Georg Fischer Piping Systems Ltd Georg Fischer Ltd Poland

Mississauga, ON L5T 2B2 556-0011 Osaka Georg Fischer Sp. z o.o. United Kingdom / Ireland

Phone +1 (905) 670 8005 Phone +81 (0)6 6635 2691 05 090 Sekocin Nowy George Fischer Sales Ltd

Fax +1 (905) 670 8513 Fax +81 (0)6 6635 2696 Phone +48 (0)22 3131 050 CV2 2ST Coventry, United Kingdom

ca.ps@georgfischer.com jp.ps@georgfischer.com Fax +48 (0)22 3131 060 Phone +44 (0) 2476 535 535

www.gfps.com/ca www.gfps.com/jp poland.ps@georgfischer.com Fax +44 (0) 2476 530 450

www.gfps.com/pl uk.ps@georgfischer.com

China Korea www.gfps.com/uk

Georg Fischer Piping Systems Ltd Georg Fischer Piping Systems Romania

201319 Shanghai 463-824 Seoul Georg Fischer Rohrleitungssysteme (Elvetia) USA /Caribbean

Phone +86 21 3899 3899 Phone +82 31 8017 1450 3 S.A. SUCURSALA BUCURESTI Georg Fischer LLC

Fax +86 21 3899 3888 Fax +82 31 8017 1454 020257 Bucuresti 92618 Irvine

china.ps@georgfischer.com kor.ps@georgfischer.com Phone +40 311 040 492 Phone +1 714 731 88 00

www.gfps.com/cn www.gfps.com/kr Fax +40 212 317 479 Fax +1 714 731 62 01

ro.ps@georgfischer.com Toll Free 800/854 40 90

Denmark / Iceland Malaysia www.gfps.com/int us.ps@georgfischer.com

Georg Fischer A/S George Fischer (M) Sdn. Bhd. Sales Office www.gfpiping.com

2630 Taastrup, Denmark 40460 Shah Alam, Selangor Darul Ehsan Russia

Phone +45 (0) 7022 1975 Phone +60 (0)3 5122 5585 Georg Fischer International

Fax +45 (0) 7022 1976 Fax +60 (0)3 5122 5575 Piping Systems (Switzerland) Ltd Georg Fischer

info.dk.ps@georgfischer.com my.ps@georgfischer.com Moscow Representative Office Piping Systems (Switzerland) Ltd

www.gfps.com/dk www.gfps.com/my 125047 Moscow 8201 Schaffhausen/Switzerland

Phone +7 495 258 60 80 Phone +41 (0) 52 631 30 03

Finland Mexico / Northern Latin America Fax +7 495 258 60 81 Fax +41 (0) 52 631 28 93

Georg Fischer AB Georg Fischer S.A. de C.V. ru.ps@georgfischer.com info.export@georgfischer.com

01510 Vantaa Apodaca, Nuevo Leon, Mexico www.gfps.com/ru www.gfps.com/int

Phone +358 (0)9 586 58 25 Phone +52 (81) 1340 8586

Fax +358 (0)9 586 58 29 Fax +52 (81) 1522 8906 Singapore

info.fi.ps@georgfischer.com mx.ps@georgfischer.com George Fischer Pte Ltd

www.gfps.com/fi www.gfps.com/mx 528 872 Singapore

Phone +65 6747 0611

Fax +65 6747 05 77

sgp.ps@georgfischer.com

www.gfps.com/sg

The technical data are not binding. They neither constitute expressly 37 735 62

warranted characteristics nor guaranteed properties nor a guaranteed durability. e (9.15)

They are subject to modification. Our General Terms of Sale apply.

© Georg Fischer JRG AG

Hauptstrasse 130

CH-4450 Sissach/Switzerland

Telefon +41 (0) 61 975 22 22

info.jrg.ps@georgfischer.com

Printed in Switzerland