1/18ページ

ダウンロード(2.5Mb)

Practice Guide for the Electrofusion Jointing of Larger Diameter Polyethylene Pressure Pipes

製品カタログ

TEPPFA Technical Guidance Document

Contents

1.Introduction

2.Safe and reliable site pre-conditions

3.Quality requirements

4.Installation procedure for Electrofusion socket fittings

5.Saddles

6.Typical failures and root causes

7.Checklist for planning

このカタログについて

| ドキュメント名 | Practice Guide for the Electrofusion Jointing of Larger Diameter Polyethylene Pressure Pipes |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 2.5Mb |

| 取り扱い企業 | ジョージフィッシャー株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

TEPPFA Technical Guidance Document - AGU/2014/01

A Good Practice Guide for the Electrofusion

Jointing of Larger Diameter Polyethylene Pressure

Pipes

Contents

1. Introduction 5. Saddles

2. Safe and reliable site pre-conditions 6. Typical failures and root causes

3. Quality requirements 7. Checklist for planning

4. Installation procedure for Electrofusion socket fittings

1. Introduction

Polyethylene piping systems are being increasingly accepted in larger diameters (above 315 mm) as a result of

their proven performance advantages and the cost e ective installation techniques which can be employed.

Electrofusion (EF) is an important and reliable jointing method for polyethylene pipes and a wide range of EF

fittings approved to EN 12201-3/ EN 1555-3 are o ered in the market.

Usually EF training and certification is only applied to smaller dimensions, the common influencing factors for

good installation practices and the preventive measures to avoid welding failures are often not understood.

This document aims to provide general guidance only, and should be used in conjunction with more detailed

information from the specific pipe, fitting and equipment supplier.

1.1. Objectives of this document

The following guide provides universally valid recommendations for the safe and reliable jointing of large

diameter PE pipes using electrofusion techniques with the intention of preventing installation failures. The code

describes good installation practices independent of fitting design.

1.2. Scope

The Electrofusion jointing of PE pipes and pipe components above dn315mm for buried Gas & Water Utilities

and Sewage and Industrial Water applications.

1.3. Originators

This document was created by the Teppfa Utilities Application Group

1.4. Disclaimer

In the preparation of this document every e ort has been made to o er the most current, and accurate

information. However, to the broadest extent permitted by law, all information published or referenced in this

document is provided without any representation or warranty of any kind either expressed or implied. Changes

and additions to any information contained herein may be made by Teppfa without prior notification.

The Voice of the European Plastic Pipes and Fittings Industry

Page2

Page 2 TEPPFA Technical Guidance Document - AGC/2014/01

2. Safe and reliable site

pre-conditions

The following precautionary measures should be

employed to ensure a healthy and safe working

environment for operatives in the trench and to

generate conditions for secure and reliable jointing,

Figure 2: Pipe end excavated in a suitable length

which in turn safeguard a leak-free operation over

the life span of the piping system. Safety aspects: Storage conditions, handling and

unloading of pipes

2.1. Planning

For an e cient and safe execution all necessary

equipment (machines and tools) and the

corresponding pipe/ fitting components have to be

available on site before the fusion process is

commenced. The planning stage includes ensuring

that the machines, tools and components (fittings)

are available, appropriate, fit for purpose and are

suitable for interactive use (i.e. adapter pins of the

fusion unit and the pin size of the fitting)

• Additional Checklist see chapter 7.

2.2. Site surrounding

Excavation pit and retaining walls

The profile of the excavation or retaining walls

should prevent soil/ ground movements which

could harm the safety of the installer and/or

disturb the later fusion process. National safety

Figure 3 & 4: Safety aspects, e.g. attention is drawn

regulations have to be respected!

when handling floating load on site

Pipe ends have to be excavated in a suitable length

to enable flexibility for ease of alignment. Safety aspects: Electrical power on site

The safety regulations must be complied with and

attention must be paid to the safety provisions and

the operational safety ordinance, particularly if any

work is carried out with electrical voltage over 50

Volt. In general the fusion box shall be placed

outside the trench or the electrical power source

shall be GFCI equipped for outdoor use (symbol:

snowflake). National safety regulations have to be

Figure 1: Retaining walls respected!

The Voice of the European Plastic Pipes and Fittings Industry

Page3

Page 3 TEPPFA Technical Guidance Document - AGC/2014/01

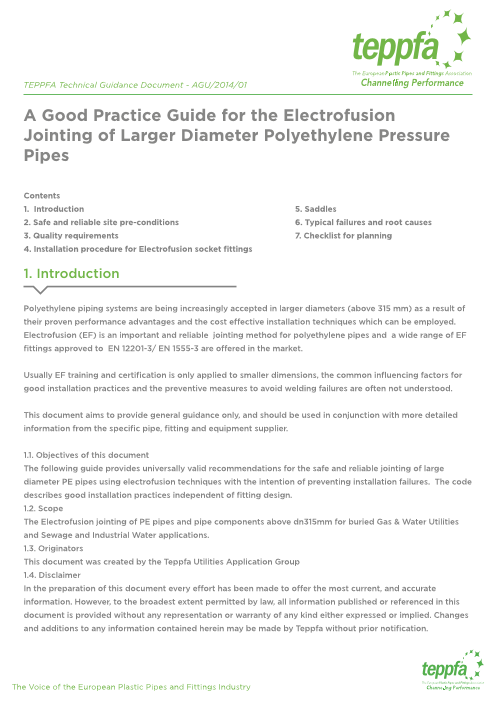

Creating the appropriate working conditions Ensure dry conditions in the working pit

To ensure adequate health and safety conditions In rehabilitation cases, pipelines often contain

for the installers and/ or to guarantee reliable residual water, which steadily flows out at the pipe

conditions for high quality jointing, su cient space ends. Preventive measures (e.g. closing valves,

and dry conditions in the working pit are temporary plungers) shall be taken to stop the flow

important. The application range for Electrofusion into the fusion area before the preparation process

is usually -10°C to +45°C. Make sure by checking starts. For special solutions in rehabilitation please

the installation manual, that installation in the consult your suppliers.

intended temperature range is covered. For

deviations or required additional measures, please 3. Quality requirements

consult the suppliers of the pipe, fitting, tools and

machines. 3.1. Quality control: Incoming goods

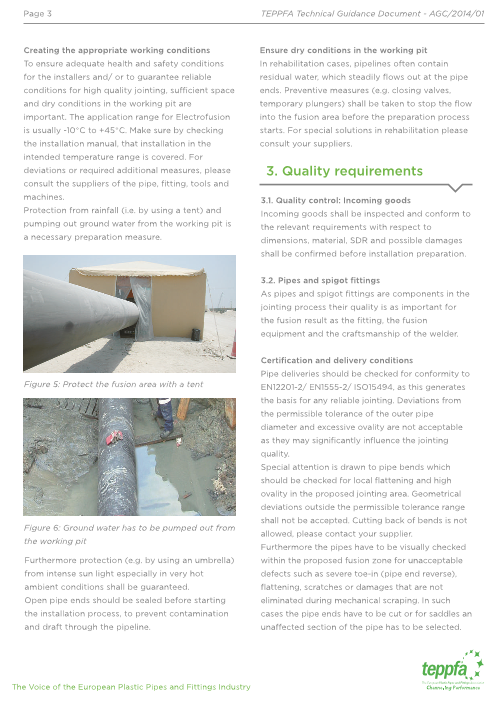

Protection from rainfall (i.e. by using a tent) and Incoming goods shall be inspected and conform to

pumping out ground water from the working pit is the relevant requirements with respect to

a necessary preparation measure. dimensions, material, SDR and possible damages

shall be confirmed before installation preparation.

3.2. Pipes and spigot fittings

As pipes and spigot fittings are components in the

jointing process their quality is as important for

the fusion result as the fitting, the fusion

equipment and the craftsmanship of the welder.

Certification and delivery conditions

Pipe deliveries should be checked for conformity to

Figure 5: Protect the fusion area with a tent EN12201-2/ EN1555-2/ ISO15494, as this generates

the basis for any reliable jointing. Deviations from

the permissible tolerance of the outer pipe

diameter and excessive ovality are not acceptable

as they may significantly influence the jointing

quality.

Special attention is drawn to pipe bends which

should be checked for local flattening and high

ovality in the proposed jointing area. Geometrical

deviations outside the permissible tolerance range

shall not be accepted. Cutting back of bends is not

Figure 6: Ground water has to be pumped out from

allowed, please contact your supplier.

the working pit

Furthermore the pipes have to be visually checked

Furthermore protection (e.g. by using an umbrella) within the proposed fusion zone for unacceptable

from intense sun light especially in very hot defects such as severe toe-in (pipe end reverse),

ambient conditions shall be guaranteed. flattening, scratches or damages that are not

Open pipe ends should be sealed before starting eliminated during mechanical scraping. In such

the installation process, to prevent contamination cases the pipe ends have to be cut or for saddles an

and draft through the pipeline. una

ected section of the pipe has to be selected.

The Voice of the European Plastic Pipes and Fittings Industry

Page4

Page 4 TEPPFA Technical Guidance Document - AGC/2014/01

Appropriate pipe storage, transportation and In areas of high temperatures and heavy sunlight

handling pipes shall be covered by a bright tarpaulin. Heat

accumulation shall be prevented. Pipes shall be

Use appropriate devices for handling of pipes, stored so that changes in temperature will not

e.g. a crane or excavator, tie bar, belts. cause the pipes to move.

Deviations from tolerances and defects may be

caused by in-adequate pipe storage or

transportation. Appropriate pipe storage,

cautious transportation and handling – also from

storage to the working pit - shall be executed in a

way that no excessive ovalisation or damage

(flattening, scratches, cracks) occurs, which could

adversely a

ect the life span of the pipe or the

joint quality.

The ends of pipes which are intended for drinking Figure 7: Protection of pipe against direct sunlight

water systems shall be closed.

Allowable pipe storage times – especially for PE When several di

erent wall thicknesses of pipe

pipes which are not black - have to be confirmed are received, it is recommended that the pipe be

by the pipe supplier. segregated into piles, each pile containing a

single size and pressure rating to minimize

All materials shall be carefully inspected at the sorting of the pipe at a later date. When pipe of

time of delivery and any defects shall be notified di

erent wall thicknesses or pressure ratings

and reported immediately. Pipe shall be have to be stored in the same pile, the pipe with

stockpiled adjacent to the site chosen for jointing the thickest wall shall be placed at the bottom of

the pipe. If the pipe is laid directly on the ground, the pile with pipe of progressively decreasing

the surface shall be level and free of stones and wall thicknesses stacked on top, providing this

debris that might damage the pipe or make the matches the welding sequence. The pile shall be

pipe stack unstable. constructed in a pyramidal, freestanding manner,

with each successive layer having one less pipe

All pipe stacks should be located on firm, flat than the layer below. The bottom layer shall be

ground to evenly support the weight of the pipes braced to prevent movement under the weight

and lifting equipment. Recommended ground of the pipes above. The maximum allowable

conditions are level gravel, sand, snow or grass. stacking height for pipe stored in open yards, in

Where such conditions do not exist or when a stacks of one nominal size, shall not exceed

bed cannot be prepared, the pipe may be placed those given in Table 1.

on planking. This planking shall be evenly spaced For safety and convenience of handling, the

along the pipe length. Care must be taken not to stacking height for pipes shall be limited to six

load the pipe in such a way that will cause flat units or not more than 2.5m, and they shall be

spots. adequately wedged to prevent movement.

The Voice of the European Plastic Pipes and Fittings Industry

Page5

Page 5 TEPPFA Technical Guidance Document - AGC/2014/01

Each level of pipes must be supported by timber

when stored as shown in the example in Figure 9.

Figure 8: shows the maximum level of PE pipes

permitted for each DN/OD size on flat ground

or on recommended planking for loose pipe

storage.

Figure 9: Example of good on-site PE Pipe Packing

Nominal On On

Pipe Flat Recommended and Storage

Size Ground Planking

3.3. EF fittings

Certification and pipe compatibility

315 6 5

Each delivery of EF fittings should be checked for

conformity according to EN12201-3/ EN1555-3/

355 6 5 ISO15494, as this generates the basis for any

reliable jointing.

400 6 4 Additionally the specified pressure ratings (e.g.

PN10, PN16), the pipe compatibility (e.g. SDR11,

SDR26) and the correct voltage (e.g. 40V, 80V) in

450 5 4

combination with the fusion unit has to be checked.

The fusion bar code shall comply with ISO 13950, if

500 4 3 not declared otherwise by the manufacturer.

In addition accredited quality marks, e.g. DVGW,

560 4 3 BSI, KIWA and others guarantee an independent

third party inspection of the products and a

630 3 2 constant high quality level.

Appropriate storage of the EF Fittings

710 3 2 Inadequate transportation and storage can harm the

fusion quality, therefore the fitting should be stored in

800 2 1 its original packaging (i.e. on pallet, in carton box and

PE bag) and handled in accordance with the

manufacturers storage and transportation instructions

Table 3.1.2.3. Number of Permitted Layers of PE (e.g. storage in an up-right orientation as elevated

Pipe for Stacking and Storage ambient temperature can create fitting ovality).

The Voice of the European Plastic Pipes and Fittings Industry

Page6

Page 6 TEPPFA Technical Guidance Document - AGC/2014/01

Store electrofusion fittings in closed rooms or Manufacturer’s information

containers not exposed to UV radiation and e

ects Installation manuals and additional information

of weather. The Allowable storage temperature accompanying the product must be complied with.

range is 0°C to +50°C. Only remove the fitting from Technical information, e.g. data sheets, installation

packaging directly before insertion. manuals for fittings and operation instructions for

fusion boxes and tools are also available, via the

internet. Ensure that the generator and fusion box

have the required power capacity and are

compatible with the fitting being used.

Contact your supplier if in doubt.

3.5. Machinery and preparation tools

Certification

The machinery and accessories have to be

designed according to country specific regulations

and guidelines.

Generators and cables

Figure 10: Transport of EF couplers d1200, packed

For the installation of Electrofusion fittings in field

on individual pallets in horizontal position

applications, it will be necessary to have a reliable

3.4. Welder certification and training source of AC power for the fusion processor to

work properly in supplying the fitting the right

Certification (where applicable) amount of energy.

In some European countries a certification system The common types of generator power control are

for Polyethylene Butt- and/ or Electrofusion Capacitor and Automatic Voltage Regulation

welders is established. Most systems request (AVR). Better welding machine/generator

frequent re-assessment of the welder skills with an performance is provided by Capacitor types as the

o cial re-certification however Butt fusion and current and voltage control are synchronized.

Electrofusion training/ certification is only usually Automatic Voltage Regulation is primarily designed

applied on smaller dimensions. for maintaining consistent voltage supply.

Training on large diameter EF jointing from fitting Generators shall

manufacturer Only supply current to the fusion unit during

The jointing quality in small but even in large the fusion process and not to other machinery.

diameter EF jointing is heavily influenced by Be well maintained and subject to a periodic

adherence to the correct installation procedure. maintenance schedule.

The Utility company/ end client shall require that Provide a nominal voltage in unloaded

only trained and skilled welders are specified. conditions around 230V-240V (48V, 110V,

Therefore, it is the responsibility of the installation 400V).

company to ensure that welders have the proper Keep the nominal voltage stable at

skills for installing the specific type of fitting being 230V±15% (48V, 110V, 400V) during the

used. fusion process under load.

Suppliers may o

er hands-on training for Remain at a stable frequency (50-60Hz)

demonstrating the appropriate installation procedure. under load.

The Voice of the European Plastic Pipes and Fittings Industry

Page7

Page 7 TEPPFA Technical Guidance Document - AGC/2014/01

Provide the required power considering the temperature range (-10°C to +45°C). It should be

following circumstances: requirements of the noted that fusion boxes and fittings with automatic

connected fitting, power e ciency of the temperature compensation are available.

welding unit, use of extension cables,

altitude and ambient temperature and Fusion box cooling times

others (e.g. ≥ 6kVA). Fusion boxes may require cooling times when

fittings with high power consumption are used or

The length of extension cables shall not exceed during high ambient temperatures on site. The use of

50m, they should be rolled out completely and a second fusion box allows a continuous work flow.

have a cross section of at least 2.5 mm2.

Recommended types of Generators may be found Tools

on a positive list, ask your supplier. Generally tools shall be applied only for their intended

use as shown in the instruction manual of the tool

Fusion units manufacturer. For all tools the following requirements

Fusion units according to ISO12176-2 should be must be guaranteed for a proper jointing and to

used to comply with the fusion data recognition respect the health and safety regulations:

and to comply with the necessary health & safety

regulations. Preferably data retrieval units should be Tools should be inspected for any external

used allowing the storage of the actual fusion data damage or defects and any necessary

and permitting a read-out of the data. Ensure that repairs e

ected before use.

adapter plugs, e.g. 4.7 mm are available, if required.

Fusion units shall be calibrated in a regular time. No tools shall damage or contaminate the

fusion areas.

Visual inspection

Regular monitoring of the fusion cable is necessary. After use the tools must be cleaned from

Damaged cables must be replaced. Worn contacts dirt, mud and other debris and checked for

can become hot during the fusion process and damage and defects and stored safely in

should be replaced. their transportation boxes.

Technical inspection approval Cutting tools

According to the information from the Powered cutting tools are commercially available,

manufacturer the fusion equipment must be but the following requirements shall be respected:

regularly inspected in accordance with the

manufacturer’s recommendations by an expert • Only plastic saws or other cutting tools

approved by the manufacturer concerned. suitable for PE should be used.

Appropriate power consumption When chain saws are used contamination

Special requirements for the energy output given from oil/ lubricants must be avoided.

by the fitting manufacturer must be adhered to

(e.g. 90A @ 40V). Ensure a square cut is achieved either by

the design of the cutting tool or with an

Temperature compensation adequate, circumferential marking on the

Equipment shall cover the full intended pipe.

The Voice of the European Plastic Pipes and Fittings Industry

Page8

Page 8 TEPPFA Technical Guidance Document - AGC/2014/01

Tools for Scraping

As the removal of the oxide layer of the pipe is a

critical factor for the fusion quality special attention

has to be given to this process.

To provide reliable and consistent scraping results

mechanical rotary/ window scraping tools shall be

used, whenever possible.

Mechanical scraping tools shall

Be well maintained and subject to a periodic

maintenance schedule, especially with

regards to the wear of the blade

Figure 11: Electrical cutting tool

Tools for Re-Rounding before mechanical Provide a min. swarf removal of >= 0.2mm

scraping/ fusion The condition and the wear of the scraper blade should

be regularly checked, e.g. the swarf thickness with a

Mechanical or hydraulic re-rounding tools/ clamps vernier caliper. Worn blades must be replaced

are commercially available and the following Pipe Estimated Abrasion

requirements must be considered: dimension swarf thickness limit

(mm) (mm) (mm)

• When re-rounding tools/ clamps are used

damage to the pipe surface and any ≥ d315 0.20 - 0.40 ≤ 0.40

contamination of the fusion zone have to be

avoided. ≥ d800 0.40 - 0.60 ≤ 0.80

Re-rounding tools shall be suitable to Table 2: Swarf thickness and abrasion limits

reduce the ovality in the fusion zone <3mm. Abrasives, grinding wheels, or other devices that do

not cleanly remove the oxide layer in an

appropriate way should not be used!

Figure 12: Re-Rounding tool Figure 13: Example of mechanical scraping tool

The Voice of the European Plastic Pipes and Fittings Industry

Page9

Page 9 TEPPFA Technical Guidance Document - AGC/2014/01

Measurement tools (Pi Tape, yard stick) 4.2. Prevent escaping media

Pi Tapes are used to check the compliance of the Fusion with escaping media will negatively influ-

pipe or spigot fitting with the diameter tolerance in ence the jointing quality and is therefore not

the standard (EN12201-2, EN1555-2, ISO15494). permissible!

Clean, state of the art yardsticks are used to mark

the insertion depth of the pipe into the fitting. 4.3. Pre-cleaning of pipes and components

Remove dirt, mud and other debris from the pipe

and other components to reduce the wear on the

mechanical scrapers and cutting tools.

Do not use clothes or rags which may contain oily

or greasy substances.

Clean water can be used, but the pipe components

Figure 14: Example of mechanical scraping tool must be dry and clean before starting the installa-

tion process.

Use a handscraper to deburr the pipe edge.

Figure 17: Checking the outer diameter of the pipe

PE cleaner and tissues where applicable

Use only an appropriate cleaner (e.g. Ethyl-Alcohol

>99.8%) and colourless, lint-free, absorbent,

non-dyed and clean paper towel. Check on a hand

mirror that the cleaning solvent completely evapo-

rates without residues, to guarantee the quality of

Figure 15: Deburr the pipe edge cleaning solvents.

Alignment clamps PE-Marker

Alignment tools are commercially available, either Use recommended markers only which do not

as a stand-alone clamp or combined with a

ect the pipe material.

re-rounding clamps. Functional test of the aligning

result is recommended before use

Pipe support

Pipe supports are used for a simple and 4. Installation procedure for

damage-free movement of pipes. They help to Electrofusion socket fittings

improve pipe alignment and pipe movement with

lower forces to achieve a stress-free installation.

4.1 Prepare working space

Prepare necessary machines, tools and components

for the installation (See checklist in appendix, incl.

SDR compatibility etc.).

Ensure su cient clearance and cleanliness around

Figure 16: Pipe support the pipe in the working area.

The Voice of the European Plastic Pipes and Fittings Industry

Page10

Page 10 TEPPFA Technical Guidance Document - AGC/2014/01

4.2. Prevent escaping media Toe-in of pipe end: Cut-back required if longer than

Fusion with escaping media will negatively influ- inner cold zone of the fitting

ence the jointing quality and is therefore not Check pipe diameters with a Pi tape before and

permissible! after mechanical scraping. Check compliance with

the tolerance specified in the standard (EN12201-2,

4.3. Pre-cleaning of pipes and components EN1555-2, ISO15494).

Remove dirt, mud and other debris from the pipe

and other components to reduce the wear on the

mechanical scrapers and cutting tools. 4.5. Re-Rounding

Do not use clothes or rags which may contain oily Pre-check the ovality with fitting insertion test up

or greasy substances. to 1cm of the cold zone to verify if the assembly is

Clean water can be used, but the pipe components feasible.

must be dry and clean before starting the installa- If not, check ovality of the pipes with a yardstick.

tion process. Pipe ovality (dmax-dmin) in the area of fitting

positioning shall be ≤ 3,0 mm, unless specified

di

erently by the fitting manufacturer.

Do not over-scrape to remove high sides of oval

pipes!

If required apply re-rounding tool/ place re-round-

ing clamp on the pipes immediately outside of the

proposed fitting position. Re-check out of round-

ness of the pipes and reposition the tool, if

required.

Figure 18: Pre-cleaning the pipe

4.4. Pipe cutting and check of pipe diameter

The pipe surfaces have to be visually checked

within the fusion zone for unacceptable defects like

severe toe-in (pipe end reverse), flattening, scratch-

es or damage that will not be eliminated during

mechanical scraping. Where damage is apparent Figure 23: Mechanical Re-Rounding / Figure 24:

the pipe ends should be cut at right angles with Hydraulic Re-Rounding

appropriate pipe cutter and if necessary edges

4.6. Peeling of Multi-Layer Pipes, if applicable

have to be deburred.

Consult your pipe supplier about the tools and

The cutting surfaces of the pipe ends shall be

procedure for removal of the peelable skin and then

smooth and flat.

continue with the procedure.

4.1 Prepare working space 4.7. Mechanical Scraping

Prepare necessary machines, tools and components Measure lengths which must be mechanically

for the installation (See checklist in appendix, incl. scraped (insertion length plus 2 cm or complete

SDR compatibility etc.). Fig. 19 Fig. 20 Fig. 21 Fig. 22 fitting length for slide over installation) with a

Ensure su cient clearance and cleanliness around Toe-in of pipe ends, Marking the cutting position, yardstick on the pipes / components and mark the

the pipe in the working area. Cutting the pipe end / Deburr the pipe end area with a permanent marker.

The Voice of the European Plastic Pipes and Fittings Industry

Page11

Page 11 TEPPFA Technical Guidance Document - AGC/2014/01

Figure 25: Marking the length for peeling Figure 27: Checking the pipe diameter

Scrape the pipes with rotary scraping tool until the 4.8. Cleaning

outer surfaces of the pipes have been removed to The Electrofusion fitting should only be removed

expose a clean, virgin pipe material. Inspect the from its packaging directly before the planned

entire circumference of the scraped areas to ensure jointing process. Avoid touching the fusion zone.

total scraping coverage. Clean pipes only in the scraped area and fittings

internally with an appropriate cleaner (e.g.

Ethyl-Alcohol >99.8%) and colourless, lint-free,

absorbent, non-dyed and clean paper towel. Use

several new paper towels for larger areas and for

each component. Avoid cross-contamination of the

pipes from outside of the scraped zone. Let the

cleaner evaporate.

Avoid possible recontamination of the prepared

Figure 26: Peeling the pipe end surfaces (these should not be touched with bare

Repeated scraping may be necessary, depending hands due to body oils), as this could a

ect the

on actual pipe diameter. Min. chip removal of jointing quality!

approx. 0.2 mm has to beachieved. Ensure the min. Make sure that any possible moisture, dew or frost

allowable pipe diameter given in the table below is is removed.

maintained or consult the fitting manufacturer.

Pipe Pipe Pipe

dn dn, min dn, min s1

355 355,0 354,2

400 400,0 399,2

450 450,0 449,2

500 500,0 499,2

560 560,0 559,2

630 630,0 629,2 Figure 28: Cleaning of the fusion zone / Figure 29:

710 710,0 709,2 Cleaning of the EF coupler

800 800,0 798,4

900 900,0 898,4 4.9. Marking of Insertion depth

1000 1000,0 998,4 Pipe-Pipe-Installation

1200 1200,0 1198,4

1400 1400,0 1399,0 Measure the insertion depths (half-length of the

1600 1600,0 1599,0 fitting) with a yardstick and mark with a permanent

2000 2000,0 1999,0 pen in multiple positions around the circumferences

dn, dn,min according to EN1555, EN12201

1) Min pipe diameter after scraping: dn, minS = dn,min – 2 x chip (according to Table 2) of both pipe ends.

The Voice of the European Plastic Pipes and Fittings Industry

Page12

Page 12 TEPPFA Technical Guidance Document - AGC/2014/01

Integration and Repair fitting length is required on the first pipe, to

For sliding cases, on the first pipe end measure full prevent contamination of the fitting during sliding

fitting length and insertion depth with a yardstick over. Push the fitting completely onto the first pipe

and mark both with a permanent pen in multiple (full fitting length) until the marking is reached.

positions around the circumference. On the second Then install second pipe face to face with first pipe

pipe end measure the half-length of the fitting with without a gap and slide fitting backwards until the

a yardstick and mark with a permanent pen in end aligns with the marking on the second pipe

multiple positions around the circumference. (half-length of the fitting). Check that the distance

between fitting and marking on the first pipe is

equal to half fitting length, to ensure that no gap

has been created between the pipe ends during

insertion.

Figure 30: Measuring the coupler length

Figure 32: Sliding over of the coupler

4.11. Clamping and alignment

All joints prepared for fusion must be stress-free

(no bending, self-loading or misalignment stresses)!

Figure 31: Marking the insertion depth If required use alignment tools or similar measures,

4.10. Pipe insertion to guarantee a stress-free installation.

Insert pipe or spigot end into the Electrofusion

fitting. Leave plastic bag over the other fitting end 4.12. Fusion

to prevent contamination and debris from entering Check compatibility before starting the fusion

the open end. Assembly can be assisted by tapping (Diameter, SDR)

around the face with a plastic hammer at the same Start the fusion process – using a preheating phase,

time. Care should be taken for a low stress if applicable – in accordance with the user manual

installation and do not tilt. Secure pipe and fitting supplied by the specific manufacturers of the fitting

against dislocation. Check that full insertion has and fusion unit.

been achieved up to the markings. Repeat process Fusion parameters are given by a bar code label on

on second pipe end. Check the correct end position the fitting and are automatically converted by the

of the fitting between the marks on both pipe ends. reader wand or scanner of the fusion box. It is

Additional information for Integration and Repair: recommended to use automatic fusion process

Su cient scraping and cleaning for the entire documentation and traceability function, which

The Voice of the European Plastic Pipes and Fittings Industry

Page13

Page 13 TEPPFA Technical Guidance Document - AGC/2014/01

have to be activated at the fusion box. 4.14. Mark fusion parameters

Keep a distance of one meter to the fusion site Mark the relevant fusion parameters (date, joint

during the fusion process for general safety reasons number, fusion time, cooling time and welder

and control and supervise the fusion process. (See name) on the fitting / pipe and in the job site

next chapter “Cooling and quality control of documentation.

fusion”) Electronically processed documentation and

In case of interruption during the fusion process traceability via fusion box is recommended.

(generator, fusion unit break-down), consult the

fitting manufacturer’s installation manual for 5. Saddles

re-heating process.

5.1. Prepare workspace

Prepare all necessary machines, tools and

components for the installation (See checklist in

appendix, incl. SDR compatibility etc.).

Ensure there is su cient clearance and cleanliness

around the pipe in the working area.

5.2. Prevent escaping media

Fusion with escaping media will negatively influence

the jointing quality and is therefore not permissible!

5.3. Pre-cleaning of pipe

Clean the pipes initially by hand to remove dirt, mud

Figure 34: Scanning the fusion bar code and other debris to reduce the wear on the

mechanical scrapers and cutting tools.

Clean water can be used, but the pipe components

4.13. Cooling and quality control of fusion must be dry and clean before starting the installation

During and after the fusion process check the process.

following:

5.4. Re-Rounding / Scratches

• No error message on the fusion unit As flattening, excessive ovality and scratches may

• No melt exudation outside the fitting confines have a negative influence on the fusion quality,

select an appropriate area for the saddle placement.

• No unusual deformations of pipe or fitting The shape of the pipe in the related fusion zone

• Fusion indicators show correct result must comply with the requirements of the fitting

• Fitting remains stress-free and avoid manufacturer.

Check shape of the pipe with fitting curvature or

dislocation until complete cooling time has elapsed similar gauges and compare with the required

Comply with the specific cooling times given by the tolerance given by the fitting manufacturer.

fitting manufacturer, before conducting any If required apply re-rounding tool/ place re-rounding

operations which could cause joint movement e.g clamp on the pipe immediately outside of the

removal of clamps, pressurising the system or proposed fitting position. Re-check out of roundness

carrying out pressure tests. of the pipe and reposition tool, if required.

The Voice of the European Plastic Pipes and Fittings Industry

Page14

Page 14 TEPPFA Technical Guidance Document - AGC/2014/01

5.5. Peeling of Multi-Layer Pipes, if applicable due to body oils), as this could a

ect the jointing

Consult the specific pipe supplier regarding the quality!

tools and procedure for removal of the peelable Make sure that any possible moisture, dew or frost

skin and then continue with procedure. is removed.

5.6. Mechanical Scraping

Measure area which must be mechanically scraped

(fitting area, length and with plus 2 cm) with a

yardstick on the pipe and mark with a permanent

pen. Scrape the pipe with rotary or window scraping

tool or with a hand scraper. Scrape the pipe surface

until the outer “skin” of the pipe has been removed

to expose a clean, virgin pipe material. Inspect the

entire fusion area to ensure total scraping coverage.

Min. swarf removal of 0.2 mm has to be fulfilled.

Figure 39: Cleaning of the scraped area

Fig. 1 Fig. 3

5.8. Clamping of the saddle

The installation manual supplied by the specific

saddle manufacturer should be strictly complied

with as the requirements for clamping/ top-loading

of the saddles and the clamping techniques and

Fig. 3 Fig. 4

procedures for each brand of saddle can vary

significantly. Place saddle in the correct position

and within the prepared pipe area. After clamping

check to confirm that the gaps between saddle and

pipe are within recommended levels.

Figure 35 & 36: Marking the area for scraping

Figure 37: Window scraping tool / Figure 38:

Rotary scraping tool

5.7. Cleaning

The Electrofusion saddle fitting should only be

removed from its packaging immediately before

the planned jointing process and without touching

the fusion zone. Figure 40: Mechanically clamped system

Clean pipes only in the scraped area with Figure 41: Vacuum system

Ethyl-Alcohol (>99.8%) and saddle fusion zone with

colourless, lint-free, absorbent, non-dyed and clean

paper towel. Use several new paper towels for 5.9. Fusion

larger areas and for each component. Avoid Check compatibility before starting the fusion

cross-contamination of the pipes from outside of (dimensions, SDR).

the scraped zone. Let the cleaner evaporate. Start the fusion process in accordance with the user

Avoid all possible recontaminations of the prepared manual supplied by the specific manufacturer of

surfaces (should not be touched with bare hands the fitting and fusion unit.

The Voice of the European Plastic Pipes and Fittings Industry

Page15

Page 15 TEPPFA Technical Guidance Document - AGC/2014/01

Keep a distance of at least one meter away from 6. Typical failures and root causes

the fusion site during the fusion process for general

safety reasons and in order to control and

6.1. Misaligned pipes

supervise the fusion process. (See next chapter

Due to high stresses on the joints, moving wires

“Cooling and quality control of fusion”)

result in overheating and melt flow at the inner or

In case of interruption during the fusion process

outer cold zone. Overheating can cause voids or

(generator, fusion unit break-down), consult the

pipe/ fitting deformation.

fitting manufacturer’s installation manual for the

recommended re-heating process.

5.10. Quality control of fusion

During and after the fusion process check the

following:

• No error message on the fusion unit

• No melt exudation outside the saddle

confines Figure 42: Misalignment

• No unusual deformations of pipe or saddle

• Fusion indicators show correct result

• Fitting remains stress-free and avoid • Use alignment clamps to avoid

dislocation until complete cooling time has misalignment

elapsed

6.2. Pipe joint not centred

5.11. Mark fusion parameters If the pipe is not centered, not properly cut or not

Mark the relevant fusion parameters (date, joint fully inserted into the fitting, melt and wires can

number, fusion time, cooling time and welder cause uncontrolled flow into the pipe gap.

name) on the fitting and in the job site Overheating can cause voids or pipe/ fitting

documentation. Electronically processed deformation.

documentation and traceability is recommended.

• Mark insertion depth and control

5.12. Cooling penetration to avoid

Consider different cooling times for • Use alignment clamp to avoid pipe

leak-tightness-test and tapping. movement

5.13. Leak tightness test

Following the welding of saddles a

leak-tightness-test through the outlet before

tapping the outlet is recommended.

5.14. Tapping Equipment / Tapping under pressure

If separate tapping equipment is used the

installation procedures have to be followed. Special

attention is drawn to tapping of pipes under

pressure. Figure 43: Insu

cient insertion

The Voice of the European Plastic Pipes and Fittings Industry

Page16

Page 16 TEPPFA Technical Guidance Document - AGC/2014/01

Figure 44: Pipe not centered Figure 46: Pipe toe-in

6.4. Insucient peeling

The oxidized surface is not su ciently removed by

mechanical scraping. This will result in insu cient

bonding and leakage may occur.

• Use mechanical scraping tool and control

chip removal frequently to create a

consistent and reliable scraping result.

Figure 45: Pipe not cut properly

6.3. Excessive pipe toe in, pipe scratches,

flattenings

Excessive pipe toe-in may result in melt exudation

into the pipe gap.

Pipe scratches (even minor ones) that are not

peeled o

during mechanical scraping, can result in Figure 47: Insu

cient peeling

poor bonding, as the surface in the scratch is not

prepared (scraped). This can result in the formation

of a leak path.

6.5. Insucient cleaning/ cross contamination

Flattened sections on the pipe locally can increase A contaminating layer prevents the pipe surface

the gap excessively. Flattened pipes do not comply from bonding with the fitting. This may be caused

with the specification and cannot be re-rounded! by body oils, other lubricants or trench

contaminations.

• Cut away the pipe toe-in

• Avoid positions with scratches or flattened • Avoid touching, contaminating fusion areas

sections or apply a second mechanical after peeling

scraping, providing the pipe will remain • Clean pipe surfaces and fittings in the

within the dimensional specification. appropriate way

The Voice of the European Plastic Pipes and Fittings Industry

Page17

Page 17 TEPPFA Technical Guidance Document - AGC/2014/01

Notes

Figure 48: Insu

cient cleaning

6.6. Intended use and operation

Gas and Water according to EN1555, EN12201,

ISO4427, ISO4437 and Industrial applications

according to ISO 15494.

6.7. Pressure test

Pressure test of the piping system should be

conducted in accordance with the national

regulations. Typically a 1.1 x PN test pressure is

applied with medium drinking water. A conditioning

time of minimum 12 hours and a conditioning

pressure of minimum the nominal pressure should

be carried out when filling and conditioning with

water. Make sure that the pipe section is completely

free from air before testing.

Registered Of ce:

Avenue de Cortenbergh 71

1000 Brussels

Belgium

tel: +32 2 736 24 06

fax: +32 2 736 58 82

e-mail: info@teppfa.eu

www.teppfa.eu

All rights including the copyright, on the materials described in

this document rest with The European Plastics Pipes and

Fittings Association (“TEPPFA”), Avenue de Cortenbergh, 71,

B-1000 Brussels (Belgium). This document may not be

reproduced or brought into circulation without the prior written

consent of TEPPFA. Without prior permission in writing from

TEPPFA this document may not be used, in whole or in part, for

the lodging of claims, for conducting proceedings, for publicity

and/or for the benefit or acquisition in a more general sense.

Every e

ort has been made to ensure the accuracy of the

information contained in this document but it is provided for

information purposes only and compliance with the

recommendations does not imply or guarantee performance.

The Voice of the European Plastic Pipes and Fittings Industry

Page18

Page 18 TEPPFA Technical Guidance Document - AGC/2014/01

7. Checklist for planning

Availability Criteria Check

Documents • welder pass

• certificates

• instructions

Generator • in working order

Fusion Box • suitable for the job

Ext. cables • application range

Scraper Tool • valid calibration (EF box, scraper tool)

Cutting Tool • check generator fuel tank is full

Speci

c installation tools • manuals available

Re-Rounding tool • application range

Clamps • application range

Rollers • application range

Cleaning Solvent • sufficient cleaner (e.g. highly pure Ethyl-Alcohol (>99.8%))

Lint free cloth

Marker pen

Yardstick, Pi tape

Handling device • safety on site

Pipes • correct dimensions

Fittings • compatibility, application range, colour

• pressure class, SDR

• Socket • visual aspects

• Saddle • quality aspects

Site installation conditions • clean

• dry

• free from grease

The Voice of the European Plastic Pipes and Fittings Industry