1/568ページ

ダウンロード(7.2Mb)

The best choice for you

Corrosion and chemical resistant system solutions

このカタログについて

| ドキュメント名 | PVC-U - Product Range |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 7.2Mb |

| 取り扱い企業 | ジョージフィッシャー株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

GF Piping Systems

Product Range International 2016

PVC-U

Page2

List of abbreviations

ANSI American National Standard Tg Malleable Iron

ASTM American Society for Testing and d Pipe outside diameter

Materials FM Fusion Method

BS British Standard DN Nominal bore

DIN Deutsche Industrie-Normen PN Nominal pressure at 20°C, water

ISO International Standardization kg Weight in kilograms

Organisation g Weight in grams

ABS Acrylnitril Butadien Styrene SP Standard pack. The figure given

PVC-U Polyvinyl Chloride indicates the quantity of fittings

PVC-C Polyvinyl Chloride chlorinated contained in a standard pack

PP Polypropylene, heat stabilised GP Gross pack. The figure given

PP-N Polypropylene, Random indicates the quantity of fittings

copolymer unpigmented contained in a gross pack

PE Polyethylene G Pipe thread, not pressure tight

PVDF Polyvinylidene fluoride in the thread to ISO 228/1

EPDM Ethylene Propylene Rubber NPT Taper male thread pressure tight in

FPM Fluorine Rubber, e.g. Viton® the thread to ANSI B 1.20.1

NBR Nitrile Rubber R Taper male thread, pressure tight

IIR Butyl Rubber in the thread to ISO 7/DIN 2999/1

CSM Chlore Sulphonyl Polythene, e.g. Rc Taper female thread, pressure tight

Hypalon® in the thread to ISO 7/1

CR Chloroprene Rubber, e.g. Rp Parallel female thread, pressure

Neoprene® tight in the thread to ISO 7/DIN 999/1

PROGEF GF of PP Tr Trapezoid thread

PTFE Polytetrafluorethylene, e.g. Teflon® SC Size of hexagon bolts

UP-GF Unsaturated polyester resin s A/F

glassfibre reinforced e Wall thickness

St Steel AL Number of bolt holes

Ms Brass ® Registered trade-mark

Page3

Introduction

The best choice

for you

Corrosion and chemical resistant

system solutions

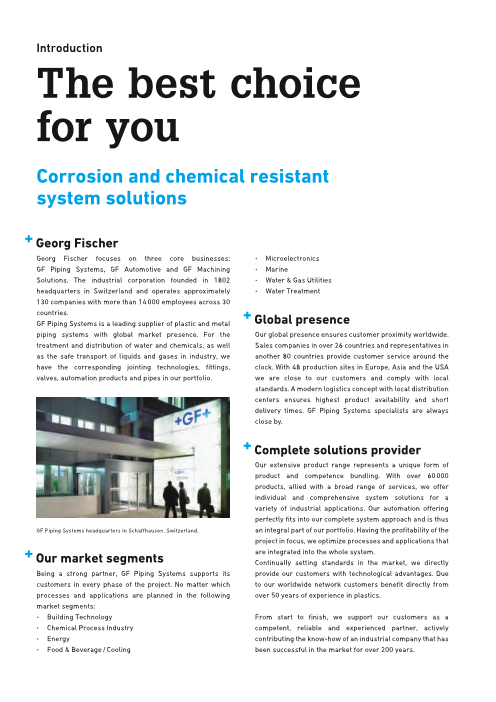

Georg Fischer

Georg Fischer focuses on three core businesses: • Microelectronics

GF Piping Systems, GF Automotive and GF Machining • Marine

Solutions. The industrial corporation founded in 1802 • Water & Gas Utilities

headquarters in Switzerland and operates approximately • Water Treatment

130 companies with more than 14 000 employees across 30

countries.

GF Piping Systems is a leading supplier of plastic and metal Global presence

piping systems with global market presence. For the Our global presence ensures customer proximity worldwide.

treatment and distribution of water and chemicals, as well Sales companies in over 26 countries and representatives in

as the safe transport of liquids and gases in industry, we another 80 countries provide customer service around the

have the corresponding jointing technologies, fittings, clock. With 48 production sites in Europe, Asia and the USA

valves, automation products and pipes in our portfolio. we are close to our customers and comply with local

standards. A modern logistics concept with local distribution

centers ensures highest product availability and short

delivery times. GF Piping Systems specialists are always

close by.

Complete solutions provider

Our extensive product range represents a unique form of

product and competence bundling. With over 60 000

products, allied with a broad range of services, we offer

individual and comprehensive system solutions for a

variety of industrial applications. Our automation offering

perfectly fits into our complete system approach and is thus

GF Piping Systems headquarters in Schaffhausen, Switzerland. an integral part of our portfolio. Having the profitability of the

project in focus, we optimize processes and applications that

are integrated into the whole system.

Our market segments Continually setting standards in the market, we directly

Being a strong partner, GF Piping Systems supports its provide our customers with technological advantages. Due

customers in every phase of the project. No matter which to our worldwide network customers benefit directly from

processes and applications are planned in the following over 50 years of experience in plastics.

market segments:

• Building Technology From start to finish, we support our customers as a

• Chemical Process Industry competent, reliable and experienced partner, actively

• Energy contributing the know-how of an industrial company that has

• Food & Beverage / Cooling been successful in the market for over 200 years.

Page4

Additional Information

Value added services

From planning Chemical resistance

Our specialist teams have decades of experience in the area

support to of chemical resistance. They can offer individual support and

advice in selecting the right material for the corresponding

implementation – system solution. On request, a team will examine and select

the appropriate material for special applications.

our specialists are CAD libra ry

always close by The extensive CAD library is the most frequently used plan-

ning tool at GF Piping Systems. The database comprises over

30 000 drawings and technical data regarding pipes, fittings,

As a leading provider of piping systems in measurement and control technology as well as manual and

plastic and metal, we offer our customers not actuated valves. The big advantage of the CAD library is that

only reliable products, but also a large package the data can be integrated directly in CAD models.

of services. Our support ranges from a compre-

hensive technical manual or the extensive CAD Technical support

library to an international team of experts, who Technical support and material selection are key factors for

work closely together with local sales compa- a successful installation. A team of specialists headquar-

nies. And when it comes to implementing a tered in Switzerland is available to support the GF Piping

project, our customers additionally benefit Systems sales companies around the world. For technical

from a wide range of training courses, either advice or for general information, our customers are

on site or in our modern training centres world- supported individually by the specialist team in the corre-

wide. sponding sales company.

Generating a genuinely individual added v alue Online an d mobile c alculation tools

for our customers is our ultimate goal when Our numerous, multilingual online calculation tools are very

implementing our tailor-made solutions. With useful for configuring and calculating. By means of pres-

our application knowledge and product exper- sure / temperature diagrams, the pressure of liquid media

tise, we support our customers during the recommended for pipes and fittings at various temperatures

planning process, the sustainable realization of can be easily defined. FlowCalc App, the mobile application

the projects and the provision of services. Our of GF Piping Systems, is an on-site planning tool for pipe di-

expertise in developing and producing piping ameter and flow velocity calculation to select the right di-

systems, combined with our profound industry mension of piping systems when no expert is near by.

and market knowledge, based on longstanding

experience, make s us a q ualified and prof es- On-site tr aining

sional partner for our customers. Our experts are available to support our customers locally

and conduct training in diverse fusion and jointing tech-

niques on location. The duration and structure of the training

depends on the project and the system being installed.

Customizi ng

The customizing teams at GF Piping Systems work closely

together around the globe. The focus of these teams is to

manufacture custom parts for special systems. In addition, a

variety of special solutions can be produced in small series.

Standardized processes warrant the highest level of quality

for the individual solutions of our customers.

Page5

Your partner for customized

special solutions

Techn ical manu al Training courses

For our customers, we have documented the extensive GF Piping Systems offers a wide range of training courses

know-how of GF Piping Systems in planning and installing that allow participants to gain confidence in working with

plastic piping systems in our technical manual. This detailed our products and proven jointing technologies. The practical

documentation is available in both printed and digital ver- training is clearly defined, structured and adapted to the

sion. The established reference book is helpful in planning various levels of participants’ experience.

large and small projects.

Page6

PVC-U Piping System

The piping system made of PVC-U material can be used for operating temperatures in the range of 0 °C to +60 °C.

Thanks to outstanding chemical resistance, PVC-U piping systems withstand demanding conditions, particularly

during the transport of aggressive media, such as acids, bases and salts. The PVC-U piping system is used

primarily in the chemical and textile industries, in water treatment and drinking water purification as well as in

vacuum lines.

Pipes Fittings Joining Automation Valves

technology

Essential system properties

• Food and drinking water approvals, proven physiological harmlessness

• First-class solution for aggressive media, such as acids, bases and salts

• Possible compact plant construction using PRO-FIT spigots, sockets, fittings

• Safe and simple joining technologies with low costs for tools and materials

Most important market segments

• Water treatment

• Chemical process industry

• Marine

Technical data

Nominal pressure Up to 16 bar

Temperature range 0 °C to +60 °C

Joining technology Solvent cementing

Standards and guidelines1) ISO, EN ISO, BS, DIN, DVS, JIS

Approvals1) DIBt, GOST-R, DGS (ACS), KIWA, CSTB, IIP, ABS, BV, CCS, DNV, GL, LR, RINA,

RMROS, BSI, LR

1) For additional information about standards, guidelines and approvals, see www.gfps.com

6

Page7

PVC-U product overview

The following table uses metric units of measure.

PN

Products (bar)

16

10

Pipes 6

16

10

Fittings 6

10

Ball valves 16

Butterfly valves 10

6

Check valves 16

Diaphragm valves 10

Pressure regulati 10

Flanges

Gaskets and pipe clips

Automation

The following table uses units of measure based on the BS inch system.

PN

Products (bar)

15 - class E

12 - class D

12 - class T

Pipes 9 - class C

15 - class E

Fittings 9 - class C

Ball valves 16

Butterfly valves 9

Check valves 10

Diaphragm valves 10

Pressure regulating

valves 10

Flanges

Gaskets and pipe clips

Automation

For more information about the system specification of PVC-U, visit www.gfps.com

7

DN d

(mm) (mm)

6

d

(mm) 8

⅜" 10

8 12

½"

10 16

¾" 15 20

1" 20 25

25 32

1 ¼" 32 40

1 ½" 40 50

50 63

2"

65 75

2 ½" 80 90

3" 100 110

100 125

4" 125 140

5" 150 160

150 180

6"

200 200

8" 200 225

10" 250 250

250 280

12"

300 315

14" 355 355

400 400

16"

Page8

Polyvinyl chloride, unplasticized (PVC-U)

PVC-U properties (reference values)

Property Value1 Units Test standard

Density 1.38 g/cm³ EN ISO 1183-1

Yield stress at 23 °C ≥ 54 N/mm² EN ISO 527-1

Tensile e-modulus at 23 °C ≥ 2,700 N/mm² EN ISO 527-1

Charpy notched impact strength at 23 °C ≥ 3 kJ/m² EN ISO 179-1/1eA

Charpy notched impact strength at 0 °C ≥ 2 kJ/m² EN ISO 179-1/1eA

Vicat-heat distortion temperature B/50N ≥ 76 °C ISO 306

Thermal conductivity at 23 °C 0.15 W/m K EN 12664

Water absorption at 23 °C ≤ 0.1 % EN ISO 62

Color 7,011 - RAL

Limiting oxygen index (LOI) 42 % ISO 4589-1

1 Typical characteristics measured at the material should not be used for calculations.

General

Polyvinylchloride (PVC) is one of the most important and oldest plastics. Worldwide consumption of

PVC is exceeded only by PE and PP. PVC was produced for the first time as early as the middle of

the 19th century. But an industrial manufacturing process was not patented until the year 1913.

Nowadays, many industrial applications could not be implemented without PVC, but PVC has also

become irreplaceable in the use of daily products.

PVC is a polymer having approximately 56 % by weight of chlorine. The PVC resin becomes a

processable and usable material only by using additives. The choice of the additives allows a wide

variation of its characteristics and an adjustment to the planned application. There are two classes of

PVC materials. Soft PVC (PVC-P) which is created by adding plasticizers (e.g. phthalates). This type

is not used at GF Piping Systems. Hard PVC, also called unplasticized PVC (PVC-U), is used for

piping system construction.

PVC-U is an amorphous thermoplastic. The properties of PVC-U molded parts are strongly

dependent on the composition of the individual components, but also on the processing. Because of

our 50 years of experience in PVC processing and the continuous advancement of our own

formulation of materials, GF Piping Systems has become a benchmark in the field of PVC-U piping.

Long-term creep strength was tested in long-term tests according to ISO 1167 and calculated

according to ISO 9080. According to ISO 12162, our PVC-U types are classified as MRS 25.

Advantages of PVC-U

• Versatility of use

• Very good chemical and corrosion resistance

• Proven physiological harmlessness and therefore suitable for contact with food

• No influence on drinking water quality

• Biologically inert; no support of microbial growth

• High mechanical tensile strength

• Secure solvent cementing using Tangit

• Use of tin stabilizers for fittings and valves

8

Page9

UV and weather resistance

PVC-U is very weather-resistant. Even longer exposure to direct sunlight, wind and rain does hardly any

damage to the material. Despite its very good weather resistance to ultraviolet radiation, PVC-U loses

some of its impact strength. In extreme applications, it can be advantageous to protect the material from

direct sunlight exposure. Contact your GF Piping Systems representative for suitable protective

measures.

Chemical resistance

PVC-U shows a good resistance against a broad range of media. For detailed information, observe the

comprehensive list of chemical resistance from GF Piping Systems or contact an authorized GF Piping

Systems representative.

Abrasion resistance

As a relatively hard thermoplastic, the resistance of PVC-U against abrasive stress is lower than those

of other pipe materials. For this reason, it is seldom used for applications in the area of solid transport.

Application limits

The application limits of the material on the one hand depend on embrittlement and softening

temperatures and on the other hand on the nature and the expected service life of the application. The

pressure-temperature diagrams give details on application temperatures and pressures.

Combustion behavior

The high chlorine content of PVC-U causes an advantageous combustion behavior. Self-ignition

resulting from temperature influences occurs only at 450 °C. PVC-U burns when exposed to an open

flame, but extinguishes immediately after removing the flame. The oxygen index (LOI) amounts to 42 %

(materials that burn with less than 21 % of oxygen in the air are considered to be flammable).

PVC-U thus also falls in the best flammability class V0 according to UL94, and in the building materials

classes:

• B1 (flame retardant) for pipe wall thicknesses less than 3.2 mm

• B2 (normal flammable) for pipe wall thicknesses greater than 3.2 mm according to DIN 4102-1.

According to the French test method NF P 92-501, PVC-U from GF Piping Systems is tested as M2.

Because the combustion of PVC-U produces hydrogen chloride, which forms a corrosive acid in

connection with water, immediate cleaning of areas susceptible to corrosion is necessary after a fire.

Danger to personnel from hydrochloric acid (HCl) is minimal because its pungent odor allows early

escape from toxic combustion gases, mainly from the odorless carbon monoxide. There are no

restrictions for the choice of firefighting agents.

Electrical properties

PVC-U, like all unmodified thermoplastics, is non-conductive. This means that no electrochemical

corrosion takes place in PVC-U systems. On the other hand, these non-conductive properties have to be

taken into account because an electrostatic charge can develop in the piping. Special attention must be

paid to this fact in environments in which explosive gases may occur. Various methods are available to

prevent the occurrence of electrostatic charges. GF Piping Systems representatives can provide support

in selecting the right one. The specific volume resistance is at least 1,015 Ωcm.

Physiological properties

The PVC-U formulas were developed by GF Piping systems for use with drinking water and food. PVC-

U's physiological harmlessness regarding neutral, acidic and alcoholic foodstuffs, and the non-influence

on drinking water with respect to odor, taste or microbiological effects are not affected and regularly

checked and monitored by neutral institutions in various countries. GF Piping Systems offers PVC-U

systems free from lead and cadmium for your applications in the fields of drinking water or food. The

residual monomer content of vinyl chloride lies below the detection limit of modern analytical methods.

For details regarding existing approvals for applications with drinking water or foodstuffs, please contact

your authorized GF Piping Systems representative.

9

Page10

10

Page11

Table of contents

PVC-U metric 12

PVC-U BS / JIS 284

PVC-U silicon free 419

Electric and pneumatic actuators 473

Solvent cements and tools 481

Spare parts 484

Index 532

11

Page12

12

Page13

PVC-U metric Page

Pipes 16

Fittings 21

Adaptor fittings 32

Threaded fittings 41

Unions 44

Seals 63

Flange adaptors and flanges 66

Branch and tapping saddles 72

Saddles 74

Installation fittings 75

Ball valve type 546 98

Ball valves electric type 107 109

Ball valves electric type 179 117

Ball valves electric type 104 120

Ball valves pneumatic type 230 122

3-Way ball valves type 543 150

3-Way ball valves electric type 167 162

13

Page14

PVC-U metric Page

3-Way ball valves electric type 170 167

3-Way ball valves electric type 189 169

3-Way ball valves pneumatic type 285 171

Metering ball valves type 523 179

Laboratory ball valves type 322 181

Diaphragm valves 182

Diaphragm valves pneumatic 190

Butterfly valves type 567 210

Butterfly valves electric type 145 213

Butterfly valves type 240 217

Lugstyle butterfly valve type 578 220

Lugstyle butterfly valves electric type 146 223

Lugstyle butterfly valves type 243 227

Pressure regulating valves 230

Process control valves 237

Cone check valves 242

Wafer check valves 253

14

Page15

PVC-U metric Page

Angle seat valves 256

Solenoid valves 258

Variable area flow meters 263

Strainers 275

Screen assemblies and Inspection glass 278

Pipe clips 280

15

Page16

Pipes

Pipe PVC-U grey

Series S6,3 SDR13,6 nominal pressure PN16

Model:

• Material: PVC-U, Polyvinylchloride unplasticised DIN 8061

• Colour: RAL 7011 - dark-grey

• Dimension: DIN EN ISO 15493, DIN 8062

• Pipe length: 5m, with plain ends

• Minimum order quantity: 1 length

• DIBT Z-40.23-1 from d20

d Size (NB) PN Code Weight e di

(mm) (inch) (bar) (kg ⁄ m) (mm) (mm)

12 16 161 017 104 0.055 1.0 10.0

16 16 161 017 105 0.090 1.2 13.6

20 16 161 017 106 0.137 1.5 17.0

25 16 161 017 107 0.212 1.9 21.2

32 16 161 017 108 0.342 2.4 27.2

40 16 161 017 109 0.525 3.0 34.0

50 16 161 017 110 0.809 3.7 42.6

63 16 161 017 111 1.290 4.7 53.6

75 2 1∕2 16 161 017 112 1.820 5.6 58.2

90 16 161 017 113 2.610 6.7 76.6

110 16 161 017 114 3.856 8.1 93.8

125 16 161 017 115 4.956 9.2 106.6

140 5 16 161 017 116 6.215 10.3 119.4

160 16 161 017 117 8.109 11.8 136.4

Pipe PVC-U grey

Series S4 SDR9 nominal pressure PN16

Model:

• Material: PVC-U, Polyvinylchloride unplasticised DIN 8061

• Colour: RAL 7011 - dark-grey

• Dimension: DIN EN ISO 15493, DIN 8062

• Pipe length: 5m, with plain ends

• Increased wall thickness for industrial use

• Minimum order quantity: 1 length

• DIBT Z-40.23-1 from d16

d PN Code Weight e di

(mm) (bar) (kg ⁄ m) (mm) (mm)

6 16 161 017 126 0.025 1.0 4.0

8 16 161 017 127 0.035 1.0 6.0

10 16 161 017 128 0.053 1.2 7.6

12 16 161 017 129 0.073 1.4 9.2

16 16 161 017 130 0.123 1.8 12.4

20 16 161 017 131 0.196 2.3 15.4

25 16 161 017 132 0.294 2.8 19.4

32 16 161 017 133 0.482 3.6 24.8

40 16 161 017 134 0.750 4.5 31.0

50 16 161 017 135 1.160 5.6 38.8

63 16 161 017 136 1.820 7.0 49.0

75 16 161 017 137 2.600 8.4 58.2

90 16 161 017 138 3.700 10.0 70.0

110 16 161 017 139 5.560 12.3 85.4

16

Page17

Pipe PVC-U grey

Series S10 SDR21 nominal pressure PN10

Model:

• Material: PVC-U, Polyvinylchloride unplasticised DIN 8061

• Colour: RAL 7011 - dark-grey

• Dimension: DIN EN ISO 15493, DIN 8062

• Pipe length: 5m, with plain ends

• Minimum order quantity: 1 length

• DIBT Z-40.23-1 until d225

d PN Code Weight e di

(mm) (bar) (kg ⁄ m) (mm) (mm)

25 10 161 017 082 0.174 1.5 22.0

32 10 161 017 083 0.276 1.8 28.4

40 10 161 017 084 0.350 1.9 36.2

50 10 161 017 085 0.552 2.4 45.2

63 10 161 017 086 0.854 3.0 57.0

75 10 161 017 087 1.220 3.6 67.8

90 10 161 017 088 1.750 4.3 81.4

110 10 161 017 089 2.610 5.3 99.4

125 10 161 017 090 3.340 6.0 113.0

140 10 161 017 091 4.180 6.7 126.6

160 10 161 017 092 5.470 7.6 144.7

180 10 161 017 093 6.880 8.6 162.8

200 10 161 017 094 8.510 9.6 180.8

225 10 161 017 095 10.800 10.8 203.4

250 10 161 017 096 13.200 11.9 226.2

280 10 161 017 097 16.600 13.4 253.2

315 6 161 017 098 20.900 15.0 285.0

Pipe PVC-U transparent

Series S16.7 SDR34.3

Model:

• Material: PVC-U, Polyvinylchloride unplasticised DIN 8061

• Colour: transparent

• Dimension: DIN EN ISO 15493, DIN 8062

• Pipe length: 5m, with plain ends

• The material used fullfills the requirements of DIN 8061 in all aspects except longterm pres-

sure test

• Minimum order quantity: 1 length

d PN Code Weight e di

(mm) (bar) (kg ⁄ m) (mm) (mm)

50 6 192 017 060 0.422 1.8 46.4

160 6 192 017 080 3.440 4.7 150.6

17

Page18

Pipe PVC-U transparent

Series S25 SDR51

Model:

• Material: PVC-U, Polyvinylchloride unplasticised DIN 8061

• Colour: transparent

• Dimension: DIN EN ISO 15493, DIN 8062

• Pipe length: 5m, with plain ends

• The material used fullfills the requirements of DIN 8061 in all aspects except longterm pres-

sure test

• Minimum order quantity: 1 length

d PN Code Weight e di

(mm) (bar) (kg ⁄ m) (mm) (mm)

63 4 192 017 036 0.532 1.8 59.4

75 4 192 017 037 0.642 1.8 71.4

90 4 192 017 038 0.774 1.8 86.4

110 4 192 017 039 1.160 2.2 105.6

125 4 192 017 040 1.480 2.5 120.0

140 4 192 017 041 1.840 2.8 134.4

160 4 192 017 042 2.410 3.2 153.6

200 4 192 017 044 3.700 4.0 192.0

225 4 192 017 045 4.700 4.5 216.0

250 4 192 017 046 5.650 4.9 240.2

280 4 192 017 047 7.600 5.5 269.0

Pipe PVC-U transparent

Series S6.25 SDR13.5

Model:

• Material: PVC-U, Polyvinylchloride unplasticised DIN 8061

• Colour: transparent

• Dimension: DIN EN ISO 15493, DIN 8062

• Pipe length: 5m, with plain ends

• The material used fullfills the requirements of DIN 8061 in all aspects except longterm pres-

sure test

• Minimum order quantity: 1 length

d PN Code Weight e di

(mm) (bar) (kg ⁄ m) (mm) (mm)

12 16 192 017 104 0.055 1.0 10.0

16 16 192 017 105 0.090 1.2 13.6

20 16 192 017 106 0.137 1.5 17.0

25 16 192 017 107 0.212 1.9 21.2

32 16 192 017 108 0.342 2.4 27.2

40 16 192 017 109 0.525 3.0 34.0

50 16 192 017 110 0.809 3.7 42.6

63 16 192 017 111 1.290 4.7 53.6

18

Page19

Pipe PVC-U transparent

Series S10 SDR21

Model:

• Material: PVC-U, Polyvinylchloride unplasticised DIN 8061

• Colour: transparent

• Dimension: DIN EN ISO 15493, DIN 8062

• Pipe length: 5m, with plain ends

• Minimum order quantity: 1 length

d PN Code Weight e di

(mm) (bar) (kg ⁄ m) (mm) (mm)

25 10 192 017 082 0.174 1.5 22.0

32 10 192 017 083 0.264 1.8 28.4

40 10 192 017 084 0.366 1.9 36.2

50 10 192 017 085 0.552 2.4 45.2

63 10 192 017 086 0.854 3.0 57.0

75 10 192 017 087 1.220 3.6 67.8

90 10 192 017 088 1.750 4.3 81.4

110 10 192 017 089 2.610 5.3 99.4

Pipe PVC-U grey

SDR34.3 nominal pressure PN6

Model:

• Material: PVC-U, Polyvinylchloride unplasticised

• Colour: RAL 7011 - dark-grey

• Dimension: DIN EN ISO 15493, DIN 8062

• Pipe length: 5m, with plain ends

• Minimum order quantity: 1 length

• DIBT Z-40.23-1 until d225

d PN Code Weight e di

(mm) (bar) (kg) (mm) (mm)

50 6 161 017 060 0.422 1.8 46.4

63 6 161 017 061 0.562 1.9 59.2

75 6 161 017 062 0.782 2.2 70.6

90 6 161 017 063 1.130 2.7 84.6

110 6 161 017 064 1.640 3.2 103.6

125 6 161 017 065 2.130 3.7 117.6

140 6 161 017 066 2.650 4.1 131.8

160 6 161 017 067 3.440 4.7 150.6

180 6 161 017 068 4.370 5.3 169.4

200 6 161 017 069 5.370 5.9 188.2

225 6 161 017 070 6.760 6.6 211.6

250 6 161 017 071 8.310 7.3 235.4

315 6 161 017 072 13.200 9.2 296.6

355 6 161 017 073 16.700 10.4 334.2

400 6 161 017 074 21.100 11.7 376.6

19

Page20

Pipe PVC-U grey

SDR51 nominal pressure PN4

Model:

• Material: PVC-U, Polyvinylchloride unplasticised

• Colour: RAL 7011 - dark-grey

• Dimension: DIN EN ISO 15493, DIN 8062

• Pipe length: 5m, with plain ends

• Minimum order quantity: 1 length

d PN Code Weight e di

(mm) (bar) (kg ⁄ m) (mm) (mm)

75 4 161 017 037 0.642 1.8 71.4

90 4 161 017 038 0.774 1.8 86.4

110 4 161 017 039 1.160 2.2 105.6

125 4 161 017 040 1.480 2.5 120.0

140 4 161 017 041 1.840 2.8 134.4

160 4 161 017 042 2.410 3.2 153.6

180 4 161 017 043 3.020 3.6 172.8

200 4 161 017 044 3.700 4.0 192.0

225 4 161 017 045 4.700 4.5 216.0

250 4 161 017 046 5.650 4.9 240.2

280 4 161 017 047 7.110 5.5 269.0

315 4 161 017 048 9.020 6.2 302.6

20