1/12ページ

ダウンロード(584Kb)

One solution protects you twice

The reliable, corrosion-resistant double containment system for highly

diverse industrial applications protects your environment.

このカタログについて

| ドキュメント名 | CONTAIN-IT Plus - System brochure |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 584Kb |

| 取り扱い企業 | ジョージフィッシャー株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

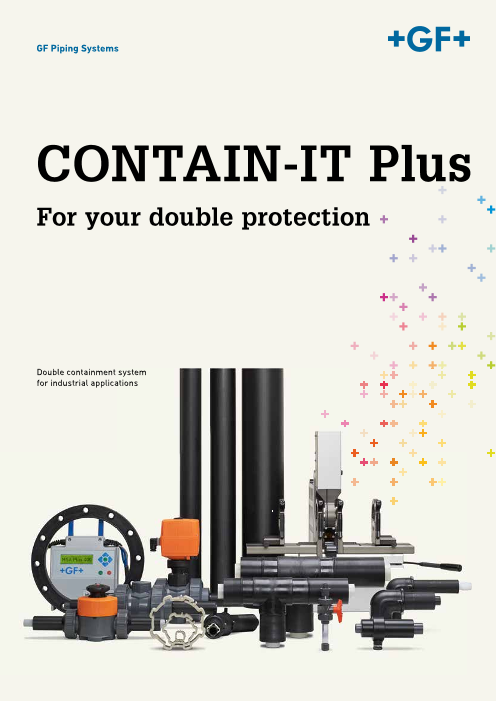

Page1

GF Piping Systems

CONTAIN-IT Plus

For your double protection

Double containment system

for industrial applications

Page2

The system

One solution

protects you twice

The reliable, corrosion-resistant double containment system for highly

diverse industrial applications protects your environment.

We are dedicated to designing, manufacturing and marketing products insuring

greatest possible safety for your employees, whenever environmentally hazard-

ous media need to be conveyed. Customers rely on our 30+ years experience in

double containment, our state-of-the-art production technology and our global

presence with a worldwide service and training off ering. GF Piping Systems

introduced the CONTAIN-IT Plus plastic piping system, which off ers increased

safety to eliminate the accident risk and takes account of the more and more

restrictive legal requirements. In this way we can optimize environmental pro-

tection in this area. CONTAIN-IT Plus warrants a maximum protection, reliability

and performance. It is the ideal and future-oriented choice to minimize personal

and environmental risks for any challenging application on the industrial fi eld.

Individuality - from the planning stage to installation

All you need from

one source

CONTAIN-IT Plus is ideally

adapted to your needs.

Pipes Fittings Valves

We off er more than reliable and innovative products

to our customers. We also supply tailor-made Chemical resistance

solutions from one source. With a comprehensive Our Specialists off er individual support and advice

system solution, GF Piping Systems provides the in selecting the right material for the corresponding

right fi t and quality for many industrial applications requirements of chemical resistance.

and projects worldwide. The variety of pipes,

fi ttings, valves as well as jointing technologies in Static of evidence calculation

the CONTAIN-IT Plus portfolio is as diverse as our While planning containment piping systems the material

customers and their individual challenges. characteristics must be considered in conjunction with

work-related and external eff ects. Such infl uencing factors

can lead to mechanical, thermal and chemical stress. These

stresses and consequences must be calculated.

2

Page3

Main benefi ts

Complete system range

• Simple design for fast and easy assembly

• Available in a number of plastics

(PP, PE, PVDF, PVC-U, PVC-C)

• Includes range of valves and automation

• Worldwide service: Customizing, machine

rental pool, training and sales support

Total plastic solution

• Corrosion-free

• UV and weather resistant

• Good chemical resistance

(choice of material)

• Good temperature resistance

• Smooth internal surface

• Low weight and easy handling

Job safety

• Personnel and environment protection

• Suitable for visual inspection and identifi cation

• Adaptable leak detection system

• System lifetime warranty*

Individuality - from the planning stage to installation

Technical support

Technical support such as material selection is a key factor

for the successful installation. A team of experts is available

for individual support all around the world.

CAD library

The freely available database comprises over 30 000 draw-

ings as well as technical data for our customers.

Diverse formats are available.

Leak detection Jointing technology Customizing and training

Online and mobile calculation tools

Technical documentation Our numerous online and mobile calculation tools, available

Our extensive know-how is fully documented in detail in in many diff erent languages, support our customers in

our technical manuals, planning fundamentals and appli- confi guring and commissioning our products.

cation guides.

Customizing

Training courses and on-site trainings The focus of our worldwide located customizing teams

Off ering a wide range of training courses we provide is manufacturing individual parts for special systems.

participants an excellent opportunity to gain confi dence in Standardized processes guarantee the highest level of quality.

working with our products and proven jointing technologies.

*Detailed information regarding the warranty can be found under: www.gfps.com - Planning Fundamentals

3

Page4

The technique

For highest demands

CONTAIN-IT Plus piping systems are used to minimize risk

to people, environment and equipment. Regulations already Inner pipe EPDM

in eff ect or governmental ordinances can dictate double PVDF coupler

containment systems. GF Piping Systems warrants excellent

performance in the conveyance of corrosive liquids or hazar-

dous media in various applications.

Spacer Outer pipe Termination

PP-H PVC-U, fitting

transparent PVDF / PE100

Elbow 90° ELGEF Ball valve

PVC-U / Pipe Plus ELGEF Plus with pneumatic Manual

PE100 PE100 saddle coupler actuation diaphragm valve

Leak detection

Monitoring pipe

PVC-U, transparent

Innovative double containment solution

Unique jointing method Take “last joint” easy

CONTAIN-IT Plus is based on the principle of the so-called The so-called “last joint”, which occur with every change

initial jointing of the inner pipe. With this technology, the of direction in other systems and which usually have to

inner and outer pipes can be installed separately. This be done blind, do not exist with this method. After jointing

permits laying a double containment pipeline analogous the inner pipe, there is a 30 mm gap between the ends of

to a single pipeline. The DVS guidelines (German Welding the outer pipe. This gap serves to test the inner pipe

Society) which stipulate visual inspection of each joint according to DVS guidelines.

are observed strictly.

Proven installation quality

After the pressure test is successfully completed for the

inner pipe, this gap will be closed with a snap ring. Finally,

an ELGEF Plus coupler or a EPDM coupler is placed over the

ring and the pipe ends, and then fused or screwed down.

4

Page5

Engineering support

Advanced

engineering services

Standard details Heat loss calculations

GF off ers best practice standard details for plastic piping Heat losses can impact your process, even more in specifi c

systems. These rely on own GF solutions, tailored for plastics. applications such as cooling. To design both your system and

We provide you with guidelines for easy and safe transition your process, you need an accurate heat loss calculation,

from metal to plastics and detailed recommendations on which is highly linked to the piping network characteristics.

restraints and thrust blocks based on pipe stress analysis. This is where GF can support you, relying on decades of

experience in plastic piping systems.

Static evidence –

straight length Dynamic mechanical

stress analysis

GF calculates for you the static evidence of your piping

elements, based on single geometries (straight length). Plastics calculations require extensive material know-how

We can also supply a detailed network static calculation. to be reliable, which is a strong asset when working with GF.

We can perform stress analysis in regards to the piping in-

stallation with or without the support system. We also off er

Static evidence for networks you along with this service a warranty statement when using

our products to build on our calculation.

GF calculates for you the static evidence of your piping

network, based on your preliminary drawings, and proposes

improvements. Every calculated evidence is verifi able by 3rd Seismic calculations

parties (PE, TUV…), and our calculations open up to warranty for networks

for the complete installation (when using GF products).

GF verifi es your system compliance to local codes, conduct-

ing seismic calculations and verifying the complete piping

installation. This includes EN 1998, UBC 1997, ASCE 7, 2010,

constant acceleration, acceleration curves…

5

Page6

System range

More than a system

With a constant focus on maximum reliability and safety, the CONTAIN-IT Plus system assures a

sustained high level of product quality and outstanding performance in all applications. The clearly

defined development and manufacturing processes of our worldwide specified systems are carried

out on the basis of all relevant standards and specifications. They are regularly audited and evaluated

to achieve continuous improvement. Certified processes as well as product approvals are part of the

active and sustainable quality management system of GF Piping Systems and make us a reliable

partner. Therefore, with our CONTAIN-IT Plus system range, customers can be assured that their

needs are covered and comply with necessary standards.

CONTAIN-IT Plus system range

Material Products *do

(inner/outer)

PN di

(inner/outer)

10 16

Socket fusion fittings

10 10

10 16

Butt- / IR-fusion fittings

PP-H / PE100 10 10

Ball valve 10 6

Diaphragm valve 10 6

Mechanical joint 10 6

16 16

Butt- / IR-fusion fittings

16 10

PE100 / PE100 Ball valve (Body: PVC-U) 16 6

Ball valve (Body: PP-H) 10 6

Mechanical joint 10 6

10 16

Socket fusion fittings

10 10

PE80 / PE100

Ball valve (Body: PVC-U, PP-H) 10 6

Mechanical joint 10 6

16 16

Socket fusion fittings

16 10

16 16

Butt- / IR-fusion fittings 16 10

PVDF / PE100

10 10

Ball valve 16 6

Diaphragm valve 10 6

Mechanical joint 16 6

16 16

Cemented Socket fittings 16 10

10 10

PVC-U / PE100

Ball valve 16 6

Diaphragm valve 10 6

Mechanical joint 16 6

16 16

Cemented Socket fittings

16 10

PVC-C / PE100 Ball valve 16 6

Diaphragm valve 10 6

Mechanical joint 16 6

Leak detection

*d : dimension of the outer pipe

o

d : dimension of the inner pipe

i

6

20 50

25 50

32 63

40 75

50 90

63 110

75 125

90 140

110 160

125 180

140 200

160 225

200 280

225 315

Page7

Chemical resistance

For your

operational

safety

Our special teams offer individual support and advice in selecting

the right material of inner pipe for the corresponding requirements.

Professional material technology

Chemical resistance at 20 °C Partially crystalline Amorphous Stainless

(Applications can be very dependent on the concentration) thermoplastics thermoplastics Steel

1.4401 1.4301

Media Chemicals PE PP PVDF PVC-U PVC-C

316 304

HNO < 25 %

3 o o + + + o o

Oxidizing Acids 25 % < HNO < 65 %3 o - + o + o o

(HNO3, H2CrO4, H CrO aqueous solution

2 4 o o + o o o o

H2SO4 , etc.) H SO < 70%

2 4 + + + + + - -

70 % < H SO < 96 %

2 4 - - + + + - -

HCl < 30 % + + + + + o -

Non Oxidizing Acids

HF < 40 %

(HCl, HF, etc.) + + + + - o -

40 % < HF < 75 % + + + - - - -

HCOOH < 25 % + + + + + o -

Organic 25 % < HCOOH < tech. pure + + + + - o -

(formic acid, acetic CH COOH < 50 %

3 + + + + + o -

acid, citric acid, etc.) 50 % < CH COOH < tech. pure

3 + + + o - o -

C H OH (COOH)

3 4 3 + + + + + o -

Inorganic (NaOH, KOH, etc.) + + - + o + +

Bases

Organic (amine, imidazole, etc.) + + - o - o o

Salts NaCl, FeCl , FeCl , CaCl , etc.

2 3 2 + + + + + o o

Halogens Chlorine, bromine, iodine, (no fluorine) - - o o o o -

Aliphatic hydrocarbons o o + + o + +

Fuels / Oils

Aromatic hydrocarbons - - + - - + +

Chlorinated hydrocarbons - - o - - o o

Ketones + + o - - + +

Solvents Alcohols + + + o - + +

Esters o o o - - + +

Aldehydes + + - - - + +

Phenols Phenol, Kresol, etc. + + + - - + -

+ resistant o conditionally resistant, please consult us - not resistant

Please note: The above list is only intended as a guideline and does not replace an in-depth review of material suitability for the particular application. The information is based on our

experience and is state of the art. These data are general indicators only. In practice, however, other factors such as concentration, pressure and jointing technology must also be taken

into consideration. The technical data are not binding and are not expressly warranted characteristics of the goods.

Please contact us for help in selecting the right materials.

7

Page8

Jointing methods

Proven technologies

for your installation

Jointing technology Welding machines/tools Joint cross-section

Socket fusion –

the strong connection

The strong, fast and easy solution to produce

heavy-duty connections in the workshop or on fi eld.

Butt fusion –

the economical connection

The economical connection, especially for bigger

diameters. From manual machines to full CNC

control versions including traceability function.

IR- (Infrared) fusion –

the fast, clean connection

The fast, repeatable and clean welding via non-

contact heating. Full traceability of the welding

process with user guideline.

Electrofusion

State-of-the-art semiautomatic technology com-

bined with a low weight make the MSA-Plus

machines perfect for onsite fusion.

Solvent Cementing

The simple and reliable jointing. No machine is

needed, only gap fi lling Tangit cement and a few

simple tools.

8

Page9

Material, application and medium are key criteria for selecting the right jointing technology.

A diverse range of innovative and intelligent welding solutions enriched with global training

and service off erings insure safe connections.

As a pioneer in the fi eld, GF Piping Systems has always been placing a high priority on developing

innovative jointing techniques to fulfi ll specifi c requirements. Simplicity in application, chemical

resistance, thermal stability and long-term weld strength are the key drivers in our jointing technolo-

gies. With a global jointing training program, international machine rental and a worldwide network

of service centers, our customers benefi t from expert know-how and practical experience.

Macro-image Technical characteristics

The pipe end and socket of the fi tting are heated to fusion tem-

perature with contact to a heating bush and a heating spigot.

The fusion areas of the components are heated to fusion

temperature with contact to the heating element and joined

controlled by pressure.

The fusion areas of the components being heated to fusion

temperature without contact to the heating element and

jointed by controlled distance.

The fusion areas of the pipe and electrofusion fi tting overlap

and are welded by resistance wires inside the fi tting

(heating coils) which are heated up by electrical energy.

The solvent cement is applied by a brush on the pipe end and

in the socket of the fi tting. After softening the surfaces, the

pipe is pushed into the socket.

9

Page10

Reference case

Application

Know-how

Sewage treatment plant in Neckarsulm

Treating wastewater in municipal sewage plants involves a removed with the surplus sludge from the secondary sedi-

chemical precipitation process to remove phosphates from mentation basins and conducted to further process steps.

the wastewater. In this process at the sewage plant in Neckar-

sulm, treatment capacity 200,000 PA, iron (III) chloride and For this purpose, two new dosing stations with double-

sodium aluminate are used as precipitating agents. The pre- walled storage tanks were installed in the Neckarsulm

cipitants are metered out and controlled via analyzers in the sewage plant. The storage tank filling pipes, the pipelines

outlet of the activation tanks. The precipitation reaction there- from the tanks to the dosing station and the pipes to the

fore takes place on the way to and in the secondary sedimen- activation tanks, which are often located underground,

tation basins themselves. The difficult to dissolve metal-phos- were installed with the double containment piping system

phorous compounds (iron and aluminum phosphates) are CONTAIN-IT Plus.

10

Page11

Why double containment? conventional fusion machines. The separate jointing of

In hazardous goods designation, iron (III) chloride is inner and outer pipe allows performing a leak test on the

categorized as harmful to health and sodium aluminate as media-conveying pipe prior to closing the outer pipe.

caustic. Responsible companies today demand the highest The fusion joints can be checked as they are made.

level of safety in their plants, building them according to The double containment piping system is therefore

the requirements of Water Resources Act and Technical constructed similarly to a single pipe system.

Rules for Water. Fluids that leak uncontrollably can harm

plant equipment, our environment or people. With the

double containment piping system leaks are contained and

indicated rapidly and reliably by a leak monitoring device.

Leak detection

Leaks are usually monitored with fluid sensors at the

lowest point of the pipeline or in the designated collection Benefits at a glance

tank. The termination fitting, which closes off the

monitoring space between the outer and inner pipe is • Instant leak detection

mounted pressure-resistant with a sealing ring, and

supports connection with a ½“ connection thread. • Legal compliance

Material and jointing technology • Optimal protection of people,

The material PE100 was used for the inner and the outer equipment and our environment

piping. The PE inner pipe is joined with socket fusion

(heating element mandrel) and the containment pipe with • Production safety

electro-socket fusion from our ELGEF Plus program. Both

jointing technologies are standard connections made with • Minimize risk

Sewage treatment plant in Neckarsulm

Germany

11

Page12

GF Piping Systems

Worldwide at home

Our sales companies and representatives ensure

local customer support in more than 100 countries.

www.gfps.com

Argentina / Southern South America France Mexico / Northern Latin America Singapore

Georg Fischer Central Plastics Sudamérica S.R.L. Georg Fischer SAS Georg Fischer S.A. de C.V. George Fischer Pte Ltd

Buenos Aires, Argentina 95932 Roissy Charles de Gaulle Cedex Apodaca, Nuevo Leon 11 Tampines Street 92, #04-01/07

Phone +54 11 4512 02 90 Phone +33 (0) 1 41 84 68 84 CP66636 Mexico 528 872 Singapore

gfcentral.ps.ar@georgfischer.com fr.ps@georgfischer.com Phone +52 (81) 1340 8586 Phone +65 6747 0611

www.gfps.com/ar www.gfps.com/fr Fax +52 (81) 1522 8906 Fax +65 6747 0577

mx.ps@georgfischer.com sgp.ps@georgfischer.com

Australia Germany www.gfps.com/mx www.gfps.com/sg

George Fischer Pty Ltd Georg Fischer GmbH

Riverwood NSW 2210 Australia 73095 Albershausen Middle East Spain / Portugal

Phone +61 (0) 2 9502 8000 Phone +49 (0) 7161 302 0 Georg Fischer Piping Systems (Switzerland) Ltd Georg Fischer S.A.

australia.ps@georgfischer.com info.de.ps@georgfischer.com Dubai, United Arab Emirates 28046 Madrid

www.gfps.com/au www.gfps.com/de Phone +971 4 289 49 60 Phone +34 (0) 91 781 98 90

gcc.ps@georgfischer.com es.ps@georgfischer.com

Austria India www.gfps.com/int www.gfps.com/es

Georg Fischer Rohrleitungssysteme GmbH Georg Fischer Piping Systems Pvt. Ltd

3130 Herzogenburg 400 083 Mumbai Netherlands Sweden

Phone +43 (0) 2782 856 43-0 Phone +91 22 4007 2000 Georg Fischer N.V. Georg Fischer AB

austria.ps@georgfischer.com Fax +91 22 4007 2020 8161 PA Epe 117 43 Stockholm

www.gfps.com/at branchoffice@georgfischer.com Phone +31 (0) 578 678 222 Phone +46 (0) 8 506 775 00

www.gfps.com/in nl.ps@georgfischer.com info.se.ps@georgfischer.com

Belgium / Luxembourg www.gfps.com/nl www.gfps.com/se

Georg Fischer NV/SA Indonesia

1600 Sint-Pieters-Leeuw / Belgium PT Georg Fischer Indonesia Norway Switzerland

Phone +32 (0) 2 556 40 20 Karawang 41371, Jawa Barat Georg Fischer AS Georg Fischer Rohrleitungssysteme (Schweiz) AG

Fax +32 (0) 2 524 34 26 Phone +62 267 432 044 1351 Rud 8201 Schaffhausen

be.ps@georgfischer.com Fax +62 267 431 857 Phone +47 67 18 29 00 Phone +41 (0) 52 631 3026

www.gfps.com/be indonesia.ps@georgfischer.com no.ps@georgfischer.com ch.ps@georgfischer.com

www.gfps.com/id www.gfps.com/no www.gfps.com/ch

Brazil

Georg Fischer Sist. de Tub. Ltda. Italy Philippines Taiwan

04571-020 São Paulo/SP Georg Fischer S.p.A. George Fischer Pte Ltd Georg Fischer Co. Ltd

Phone +55 (0) 11 5525 1311 20063 Cernusco S/N (MI) Representative Office San Chung Dist., New Taipei City

br.ps@georgfischer.com Phone +39 02 921 861 Phone +632 571 2365 Phone +886 2 8512 2822

www.gfps.com/br it.ps@georgfischer.com Fax +632 571 2368 Fax +886 2 8512 2823

www.gfps.com/it sgp.ps@georgfischer.com www.gfps.com/tw

Canada www.gfps.com/sg

Georg Fischer Piping Systems Ltd Japan United Kingdom / Ireland

Mississauga, ON L5T 2B2 Georg Fischer Ltd Poland George Fischer Sales Limited

Phone +1 (905) 670 8005 530-0003 Osaka Georg Fischer Sp. z o.o. Coventry, CV2 2ST

Fax +1 (905) 670 8513 Phone +81 (0) 6 6341 2451 05-090 Sekocin Nowy Phone +44 (0) 2476 535 535

ca.ps@georgfischer.com jp.ps@georgfischer.com Phone +48 (0) 22 31 31 0 50 uk.ps@georgfischer.com

www.gfps.com/ca www.gfps.com/jp poland.ps@georgfischer.com www.gfps.com/uk

www.gfps.com/pl

China Korea USA / Caribbean

Georg Fischer Piping Systems Ltd Georg Fischer Korea Co. Ltd Romania Georg Fischer LLC

Shanghai 201319 Unit 2501, U-Tower Georg Fischer Piping Systems (Switzerland) Ltd 9271 Jeronimo Road

Phone +86 21 3899 3899 120 HeungdeokJungang-ro 020257 Bucharest - Sector 2 92618 Irvine, CA

china.ps@georgfischer.com (Yeongdeok-dong) Phone +40 (0) 21 230 53 80 Phone +1 714 731 8800

www.gfps.com/cn Giheung-gu, Yongin-si, Gyeonggi-do ro.ps@georgfischer.com Fax +1 714 731 6201

Phone +82 31 8017 1450 www.gfps.com/int us.ps@georgfischer.com

Denmark / Iceland Fax +82 31 217 1454 www.gfps.com/us

Georg Fischer A/S kor.ps@georgfischer.com Russia

2630 Taastrup www.gfps.com/kr Georg Fischer Piping Systems (Switzerland) Ltd International

Phone +45 (0) 70 22 19 75 Moscow 125040 Georg Fischer Piping Systems (Switzerland) Ltd

info.dk.ps@georgfischer.com Malaysia Phone +7 495 748 11 44 8201 Schaffhausen/Switzerland

www.gfps.com/dk George Fischer (M) Sdn. Bhd. ru.ps@georgfischer.com Phone +41 (0) 52 631 3003

40460 Shah Alam, Selangor Darul Ehsan www.gfps.com/ru Fax +41 (0) 52 631 2893

Finland Phone +60 (0) 3 5122 5585 info.export@georgfischer.com

Georg Fischer AB Fax +60 (0) 3 5122 5575 www.gfps.com/int

01510 VANTAA my.ps@georgfischer.com

Phone +358 (0) 9 586 58 25 www.gfps.com/my

Fax +358 (0) 9 586 58 29

info.fi.ps@georgfischer.com

www.gfps.com/fi

The information and technical data (altogether “Data”) herein are not binding, unless explicitly confirmed in writing.

The Data neither constitutes any expressed, implied or warranted characteristics, nor guaranteed properties or a guaranteed

durability. All Data is subject to modification. The General Terms and Conditions of Sale of Georg Fischer Piping Systems apply.

700.671.627

GFDO_6386_4b (07.18)

© Georg Fischer Piping Systems Ltd

CH-8201 Schaffhausen/Switzerland, 2018

170106-backcover-A4-industry.indd 1 06.07.2018 15:18:58