1/8ページ

ダウンロード(1.5Mb)

Continuos Development in Close Collaboration with End Users

The GF CNC line incorporates various clever features to simplify the operation of the equipment with

extreme focus on operator safety and ensuring jointing quality and reliability.

These machines work hand in hand with the specialist on the construction site.

For training and after sales service you can rely on the world-wide network of service stations of

GF Piping Systems.

このカタログについて

| ドキュメント名 | CNC Automated Butt Fusion Machine Line |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 1.5Mb |

| 取り扱い企業 | ジョージフィッシャー株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

GF Piping Systems

CNC Automated

Butt-Fusion Machine Line

GF 400 (125 – 400 mm)

GF 500 (200 – 500 mm)

GF 630 (315 – 630 mm)

Page2

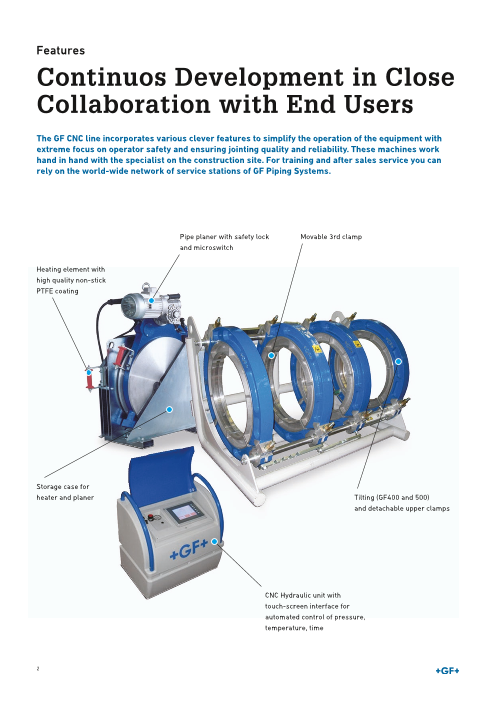

Features

Continuos Development in Close

Collaboration with End Users

The GF CNC line incorporates various clever features to simplify the operation of the equipment with

extreme focus on operator safety and ensuring jointing quality and reliability. These machines work

hand in hand with the specialist on the construction site. For training and after sales service you can

rely on the world-wide network of service stations of GF Piping Systems.

Pipe planer with safety lock Movable 3rd clamp

and microswitch

Heating element with

high quality non-stick

PTFE coating

Storage case for

heater and planer Tilting (GF400 and 500)

and detachable upper clamps

CNC Hydraulic unit with

touch-screen interface for

automated control of pressure,

temperature, time

2

Page3

Benefi ts

Innovative, User-Friendly

and Reliable

The GF CNC machine line is designed for water as well as gas applications,

providing high repetitive accuracy in jointing PE and PP according to the

approved national guidelines or following freely programmable welding

cycles by the operator.

Flexibility

The sliding 3rd clamp of the base machine provides a time

saving, fl exible system for clamping bends and tees without

additional tools. The tilting design of the GF400 & 500 upper

clamps allows quick and easy pipe fi xation, alignment and

removal. Whenever necessary, the upper clamps may also

be removed.

Simplicity

GF CNC hydraulic units incorporate intuitive touch-screen

operator interface, all surrounded by a robust plastic

housing. All hydraulic and electric connections are positioned

on the rear panel and protected by the housing. Only one

mains cable to the generator is required! Oil level control and

refi lling can be easily made without disassembling the unit.

Users safety is assured by a locking mechanism and a micro

switch preventing accidental operation of the planer motor.

Quality

The base machines are equipped with a pull-off mechanism

to separate the pipe ends safely from the heater plate.

Optimised heat distribution on the PTFE coated heater plate

ensures unifi ed heat energy transfer into the pipe ends. By

the use of the automated CNC machines, operator errors can

be minimized and the jointing parameters can be traced.

3

Page4

The system

Innovative and User-friendly

GF 400-500-630 CNC machines are equipped with innovative and user-friendly CNC hydraulic unit.

With a distance measurement device mounted into the base machine all signifi cant movements of the

carriage are supervised during the process. The hydraulic unit is made with a robust inner aluminium

case and protected by a shock adsorbing plastic housing. The hydraulic unit distributes power to the

planer and heating element, which are plugged in with high quality connectors. The mains cable can be

stored on a cable drum to simplify transportation of the unit. Oil level control and refi lling is fast and

easy without dissassembling.

Potentiometer on base machine All connections on rear panel

Oil level check & refi ll CNC Hydraulic unit

The GF CNC machine line performances are focused on safety, operative comfort and reliability of

automated butt-fusion jointing.

GF500 CNC GF400 CNC GF630 CNC

4

Page5

Details

High Quality Fusion Cycles

Through Automated Process

The GF CNC hydraulic control unit is designed to support the operator

during the process with an easy interaction.

GF CNC machines guide the operator from the preparation

to the end of the jointing process by use of symbols and

graphics.

The selection and input of welding and additional data (weld-

ing standard, material, diameter, SDR, operator ID, traceabil-

ity data ISO 12176 - 4) is intuitive and time saving by using

industrially proven touch screen technology.

Touchscreen interface The fusion parameters - pressure, time and temperature -

are automatically calculated, regulated and controlled

according to the selected country specifi c guidelines.

For non standard dimensions 10 free programmable

welding cycles are available.

Various confi guration possibilities, like automatic bead-build

up phase, insertion of GPS coordinates, data input (operator

ID, traceability pipe code...) via barcode scanner are availa-

ble.

USB memory key with cover

The prefered menu language can be chosen from a language

set. The welding reports can be stored on a standard

USB memory key, which is supplied with the machine as well

as the SUVI WIN-WELD software, to be transfered to PC.

Preinstalled socket is provided for connection of barcode

scanner to manage traceability data.

Barcode scanner (Optional)

5

Page6

Accessories

At a Glance

Each welding job is diff erent and requires dedicated accessories to increase

productivity before, during and after the fusion process.

Flange adapter clamping unit

This accessory supports welding of short-end fi ttings (fl ang-

es) to pipes. Depending on the components to be jointed, the

stub-end holder can be fi tted both on the outer clamp or the

sliding 3rd clamp.

Chamfered upper clamps

This accessory is useful for welding short-leg bends having

diameters equal to the maximum available for the machine:

e.g. bend Ø 630 mm with a GF 630 machine.

Set of reduction inserts

For all three machines complete sets of reduction inserts

are available, consisting of 4 narrow and 4 wide half rings of

each dimension. The narrow half rings are generally used to

fi x short-leg fi ttings, while the wide ones enable also easy

re-rounding of pipes.

Hoist unit

For all three machines a complete hoist unit is available,

consisting of frame to be fi xed on the base machine and

swiveling arm, for carrying planer and heating element. A

weight compensator for GF400/500 and an electrical motor

with 2 hoisting speeds for GF 630 are also available.

6

Page7

Technical data

CNC Automated

Butt-Fusion Machine Line

The GF CNC family covers the pipe dimensions from Ø 125 mm to Ø 630 mm

and is built to join pressure pipes for transportation of gas, water and other

fl uids.

Technical data GF 400 GF 500 GF 630

Butt-fusion machine size GF 400 CNC GF 500 CNC GF 630 CNC

Pipe diameter range (mm) 125 – 400 200 – 500 315 – 630

Power supply 3 phase 400V, 50 Hz

Power rating [W] 5.700 6.300 11.000

Mains connector CEI – 16A

Net weight [kg] 205 480 615

Packaging dimension W/D/H [cm] 143 x 137 x 106 180 x 150 x 110 165 x 140 x 135

7

Page8

GF Piping Systems

Worldwide at Home

Our sales companies and representatives

ensure local customer support in over 100 countries

www.gfps.com

Argentina / Southern South America Denmark / Iceland Malaysia Singapore

Georg Fischer Central Plastics Sudamérica S.R.L. Georg Fischer A/S George Fischer (M) Sdn. Bhd. George Fischer Pte Ltd

Buenos Aires, Argentina 2630 Taastrup 40460 Shah Alam, Selangor Darul Ehsan 11 Tampines Street 92, #04-01/07

Phone +54 11 4512 02 90 Phone +45 (0) 70 22 19 75 Phone +60 (0) 3 5122 5585 528 872 Singapore

gfcentral.ps.ar@georgfischer.com info.dk.ps@georgfischer.com Fax +60 (0) 3 5122 5575 Phone +65 6747 0611

www.gfps.com/ar www.gfps.com/dk my.ps@georgfischer.com Fax +65 6747 0577

www.gfps.com/my sgp.ps@georgfischer.com

Australia Finland www.gfps.com/sg

George Fischer Pty Ltd Georg Fischer AB

Riverwood NSW 2210 Australia 01510 VANTAA Mexico / Northern Latin America Spain / Portugal

Phone +61 (0) 2 9502 8000 Phone +358 (0) 9 586 58 25 Georg Fischer S.A. de C.V. Georg Fischer S.A.

australia.ps@georgfischer.com Fax +358 (0) 9 586 58 29 Apodaca, Nuevo Leon 28046 Madrid

www.gfps.com/au info.fi.ps@georgfischer.com CP66636 Mexico Phone +34 (0) 91 781 98 90

www.gfps.com/fi Phone +52 (81) 1340 8586 es.ps@georgfischer.com

Austria Fax +52 (81) 1522 8906 www.gfps.com/es

Georg Fischer Rohrleitungssysteme GmbH France mx.ps@georgfischer.com

3130 Herzogenburg Georg Fischer SAS www.gfps.com/mx Sweden

Phone +43 (0) 2782 856 43-0 95932 Roissy Charles de Gaulle Cedex Georg Fischer AB

austria.ps@georgfischer.com Phone +33 (0) 1 41 84 68 84 Middle East 117 43 Stockholm

www.gfps.com/at fr.ps@georgfischer.com Georg Fischer Piping Systems (Switzerland) Ltd Phone +46 (0) 8 506 775 00

www.gfps.com/fr Dubai, United Arab Emirates info.se.ps@georgfischer.com

Georg Fischer Fittings GmbH Phone +971 4 289 49 60 www.gfps.com/se

3160 Traisen Germany gcc.ps@georgfischer.com

Phone +43 (0) 2762 90300 Georg Fischer GmbH www.gfps.com/int Switzerland

fittings.ps@georgfischer.com 73095 Albershausen Georg Fischer Rohrleitungssysteme (Schweiz) AG

www.fittings.at Phone +49 (0) 7161 302 0 Netherlands 8201 Schaffhausen

info.de.ps@georgfischer.com Georg Fischer N.V. Phone +41 (0) 52 631 3026

Belgium / Luxembourg www.gfps.com/de 8161 PA Epe ch.ps@georgfischer.com

Georg Fischer NV/SA Phone +31 (0) 578 678 222 www.gfps.com/ch

1070 Bruxelles/Brüssel India nl.ps@georgfischer.com

Phone +32 (0) 2 556 40 20 Georg Fischer Piping Systems Pvt. Ltd www.gfps.com/nl Taiwan

be.ps@georgfischer.com 400 083 Mumbai Georg Fischer Co. Ltd

www.gfps.com/be Phone +91 22 4007 2000 Georg Fischer Waga N.V. San Chung Dist., New Taipei City

Fax +91 22 4007 2020 NL-8160 AG Epe Phone +886 2 8512 2822

Brazil branchoffice@georgfischer.com Phone +31 (0) 578 678 378 Fax +886 2 8512 2823

Georg Fischer Sist. de Tub. Ltda. www.gfps.com/in waga.ps@georgfischer.com www.gfps.com/tw

04571-020 São Paulo/SP www.waga.nl

Phone +55 (0) 11 5525 1311 Italy United Kingdom / Ireland

br.ps@georgfischer.com Georg Fischer S.p.A. Norway George Fischer Sales Limited

www.gfps.com/br 20063 Cernusco S/N (MI) Georg Fischer AS Coventry, CV2 2ST

Phone +39 02 921 861 1351 Rud Phone +44 (0) 2476 535 535

Canada it.ps@georgfischer.com Phone +47 67 18 29 00 uk.ps@georgfischer.com

Georg Fischer Piping Systems Ltd www.gfps.com/it no.ps@georgfischer.com www.gfps.com/uk

Mississauga, ON L5T 2B2 www.gfps.com/no

Phone +1 (905) 670 8005 Georg Fischer TPA S.r.l. USA / Caribbean

Fax +1 (905) 670 8513 IT-16012 Busalla (GE) Poland Georg Fischer LLC

ca.ps@georgfischer.com Phone +39 010 962 47 11 Georg Fischer Sp. z o.o. 9271 Jeronimo Road

www.gfps.com/ca tpa.ps@georgfischer.com 05-090 Sekocin Nowy 92618 Irvine, CA

www.gfps.com/it Phone +48 (0) 22 31 31 0 50 Phone +1 714 731 88 00

China poland.ps@georgfischer.com Fax +1 714 731 62 01

Georg Fischer Piping Systems Ltd Japan www.gfps.com/pl us.ps@georgfischer.com

Shanghai 201319 Georg Fischer Ltd www.gfps.com/us

Phone +86 21 3899 3899 530-0003 Osaka Romania

china.ps@georgfischer.com Phone +81 (0) 6 6341 2451 Georg Fischer Piping Systems (Switzerland) Ltd Georg Fischer Central Plastics LLC

www.gfps.com/cn jp.ps@georgfischer.com 020257 Bucharest - Sector 2 Shawnee, OK 74801

www.gfps.com/jp Phone +40 (0) 21 230 53 80 Phone +1 (405) 273 63 02

Chinaust Plastics Corp. Ltd. ro.ps@georgfischer.com gfcentral.ps@georgfischer.com

Songlindian, Zhuozhou city, Korea www.gfps.com/int www.centralplastics.com

Hebei province, China, 072761 Georg Fischer Korea Co. Ltd

Phone +86 312 395 2000 Unit 2501, U-Tower Russia International

Fax +86 312 365 2222 120 HeungdeokJungang-ro Georg Fischer Piping Systems (Switzerland) Ltd Georg Fischer Piping Systems (Switzerland) Ltd

chinaust@chinaust.com (Yeongdeok-dong) Moscow 125040 8201 Schaffhausen/Switzerland

www.chinaust.com.cn Giheung-gu, Yongin-si, Gyeonggi-do Phone +7 495 748 11 44 Phone +41 (0) 52 631 3003

Phone +82 31 8017 1450 ru.ps@georgfischer.com Fax +41 (0) 52 631 2893

Fax +82 31 217 1454 www.gfps.com/ru info.export@georgfischer.com

kor.ps@georgfischer.com www.gfps.com/int

www.gfps.com/kr

The technical data are not binding. They neither constitute expressly

warranted characteristics nor guaranteed properties nor a guaranteed durability.

They are subject to modification. Our General Terms of Sale apply.

700.671.550

PCOM_9200_4a (09.16)

© Georg Fischer Piping Systems Ltd

CH-8201 Schaffhausen/Switzerland, 2016