1/12ページ

ダウンロード(1.9Mb)

Butterfly Valves From GF - Right Choice

The wide range of innovative valves and continual developments in modularity and

multifunctionality accentuate GF Piping Systems’ role as a leading system supplier.

The versatile butterfly valves feature not only great flexibility in how they can be used but also

a high level of quality and durability.

Aligned with the individual requirements of our customers, the valves are reliable,

efficient and economical in use, thus providing you with sustainable added value.

このカタログについて

| ドキュメント名 | Butterfly Valves Overview |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 1.9Mb |

| 取り扱い企業 | ジョージフィッシャー株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

GF Piping Systems

Our System Solution

Overview

Butterfly Valves

Page2

Benefi ts

Butterfly Valves From GF –

Right Choice

The wide range of innovative valves and continual developments in modularity and multifunctionality

accentuate GF Piping Systems’ role as a leading system supplier. The versatile butterfl y valves feature

not only great fl exibility in how they can be used but also a high level of quality and durability. Aligned

with the individual requirements of our customers, the valves are reliable, effi cient and economical in

use, thus providing you with sustainable added value.

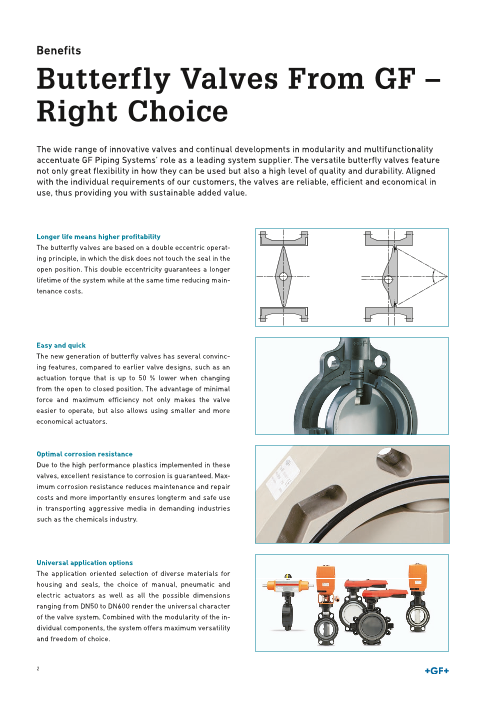

Longer life means higher profi tability

The butterfl y valves are based on a double eccentric operat-

ing principle, in which the disk does not touch the seal in the

open position. This double eccentricity guarantees a longer

lifetime of the system while at the same time reducing main-

tenance costs.

Easy and quick

The new generation of butterfl y valves has several convinc-

ing features, compared to earlier valve designs, such as an

actuation torque that is up to 50 % lower when changing

from the open to closed position. The advantage of minimal

force and maximum effi ciency not only makes the valve

easier to operate, but also allows using smaller and more

economical actuators.

Optimal corrosion resistance

Due to the high performance plastics implemented in these

valves, excellent resistance to corrosion is guaranteed. Max-

imum corrosion resistance reduces maintenance and repair

costs and more importantly ensures longterm and safe use

in transporting aggressive media in demanding industries

such as the chemicals industry.

Universal application options

The application oriented selection of diverse materials for

housing and seals, the choice of manual, pneumatic and

electric actuators as well as all the possible dimensions

ranging from DN50 to DN600 render the universal character

of the valve system. Combined with the modularity of the in-

dividual components, the system off ers maximum versatility

and freedom of choice.

2

Page3

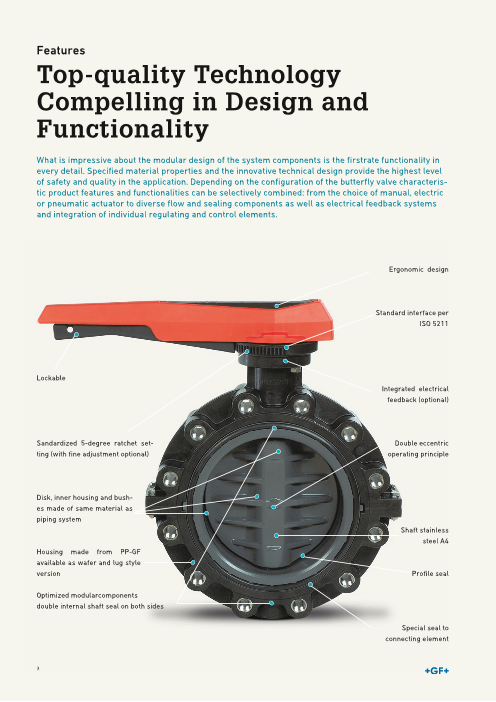

Features

Top-quality Technology

Compelling in Design and

Functionality

What is impressive about the modular design of the system components is the fi rstrate functionality in

every detail. Specifi ed material properties and the innovative technical design provide the highest level

of safety and quality in the application. Depending on the confi guration of the butterfl y valve characteris-

tic product features and functionalities can be selectively combined: from the choice of manual, electric

or pneumatic actuator to diverse fl ow and sealing components as well as electrical feedback systems

and integration of individual regulating and control elements.

Ergonomic design

Standard interface per

ISO 5211

Lockable

Integrated electrical

feedback (optional)

Sandardized 5-degree ratchet set- Double eccentric

ting (with fi ne adjustment optional) operating principle

Disk, inner housing and bush-

es made of same material as

piping system

Shaft stainless

steel A4

Housing made from PP-GF

available as wafer and lug style

version Profi le seal

Optimized modularcomponents

double internal shaft seal on both sides

Special seal to

connecting element

3

Page4

At a glance

Build on High Performance

and Versatility

When GF Piping Systems developed the various butterfl y valves and their individual system compo-

nents, the customary claim to a high level of quality and innovation were in the foreground, but highest

priority was given to customer focus. The custommade approach and individual character of the system

solutions, targeted to the specifi c requirements and application environments of customers, grant

maximum fl exibility, in addition to decisive added value. By focusing on the users in the planning,

consulting and implementation phases, GF Piping Systems convinces their customers not only with their

competence and expertise, but also with their indepth knowledge of the market and industry, based on

extensive experience.

Systematic quality Modular product range

The numerous certifi cations according to customary stand- A wide selection of diff erent materials and dimensions

ards and international standards as well as approvals for allows confi gurating your system to the particular applica-

various applications are evidence to the high quality, safety tion and medium. A versatile system that provides an ideal

and reliability of the system product range. solution for every application.

Standards: In every detail

• DIN / EN / ISO / BS / ASTM / JIS (only wafer-style) / ANSI The quality of a butterfl y valve is largely determined by the

Approvals: quality of the individual components. Dedicated system

• DIBt / ACS / TA Luft / KTW / W270 / FDA / NSF61 and more parts, such as O-rings with PTFE content, off er the best pos-

Actuator interface according to DIN EN ISO 5211 sible functionality and operational reliability in applications

with diverse environments and various media.

Standard wafer-style valve Standard lug-style valve Type 578 Butterfl y valve with fi ne Butterfl y valve with manual

Type 567 adjustment reduction gear

4

Page5

At a glance

Unlimited Modularity

for Maximum Flexibility

and Precision

The comprehensive and application-oriented system solutions from GF Piping Systems off er ultimate

modularity and complement on another ideally in terms of functionality. A large selection of standard-

ized, high-quality components and actuating elements provide technical precision with maximum

variability. The targeted combination or, if required, the fast and simple exchange of individual system

components means there are no limits to versatility and fl exibility. With smart solutions for actuation

and control valves, such as positioners and integrated mechanical or electrical position feedback units

for precise process control, the high demands of your industry are met.

Process under control Variable control media

The integrated electrical feedback function in the mounting The variety of system components on off er enables integrat-

fl ange constantly maintains an overview of the system and ing diverse controllers as required by your specifi c

which valves are open or closed. The feedback concept application. From simple open / close valves to precision

includes a choice of fi ve diff erent types of end position fl ow control devices (controlled via PLC or other computer-

switches. In addition, the type of actuator, electric or aided instruments).

pneumatic, gives you a unique level of fl exibility in confi gu-

rating and operating your system.

Standard wafer-style valve Butterfl y valve with pneumatic Butterfl y valve with pneumatic Butterfl y valve with electric

Type 567 actuator – single acting actuator – double acting; optional actuator; optional manual override

manual override and electrical feedback

5

Page6

Technical specifications

More Than the Sum

of Its Details

Taken together, innovative technologies, sophisticated materials processing and specifically implement-

ed functionalities all contribute to the added value, on which our customers rely worldwide. Proven

concepts are just as important as newly developed operating principles and individual components. The

successful interaction of materials and technical elements leads to the high and dependable efficiency

of these valves.

Torque movement (reference value) to open / close

(Standard valve, new condition)

140

100 700 500

Type 567/578 Type 567 / 578

120 90 600 450

80 400

100 500

70 350

80 60 400 300

@ PN 50 @ PN 250

60 @ 1/2 PN 30040 @ 1/2 PN 200

40 30 200 150

20 100

20 100

10 50

0 0 0 0

2" 21/2" 3" 4" 5" 6" 8" 10" 12" 14" 16" 18" 20" 24"

50 65 80 100 125 150 200 250 300 350 400 450 500 600

X (inch / mm) X (inch / mm)

X nominal diameter DN (inch, mm)

Y torque (Nm, lb-ft)

Pressure-temperature diagram Pressure-temperature diagram

ABS, PVC-U, PVC-C PP-H, PVDF

T (°F) T (°F)

-58 -38 -18 2 22 42 62 82 102 122 142 162 182

16 -58 -28 2 32 62 92 122 152 182 212 242 272 302

15 220 16PVC-U

14 15 PP 220Type 567, 578 200

13 14

180 Type 567

200

12 13

12 18011 ABS 160 PP

10 PN 10 1) Type 567, 578 11 160140 10 PN 10 1) Type 567, 5789 140

8 120 9

7 PVC-C 100 8 PN 8

2) Type 567 PVDF 120

6 PN 6 2) Type 567, 578 7 10080

5 6 PN 6

3)

80

4 60 5 PN 5

4)

5) 60

3 4 PN 4 40

2 3 40

20 2 Type 5781

1 200 0

0 0

-50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90

T (°C) -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

T (°C)

1) DN50–DN300 T Temperature in °C, °F

2) DN350–DN400 P Permissible pressure in bar, psi

1) DN50–DN300 T Temperature in °C, °F 1) DN50–DN200 5) DN500–DN600

2) DN350–DN400 P Permissible pressure in bar, psi 2) DN250–DN300 T Temperature in °C, °F

3) DN350–DN400 P Permissible pressure in bar, psi

4) DN450

6

P (bar)

Y (Nm)

Y (lb-ft)

PP ((ppssii))

P (bar)

Y (Nm)

Y (lb-ft)

P (psi)

Page7

Material

A System Environment

of Diversity

The range of butterfl y valves from GF Piping Systems with its modular element structure combines the

aspects of standardization with those of specialization. This allows serving not only classic application

areas, in which universal material and product characteristics are required, but also, highly demanding

applications, e.g. for aggressive environments in the chemical process industry. Our customers benefi t

from the same high level of performance regarding quality and service – whether for standard applica-

tions or for special solutions, i.e. customization.

Safety derived from operational excellence Lightweight champions

The unique combination of the high-performance plastics Enhancing the product range to include the large dimensions

PVDF (polyvinylidene fl uoride) and PTFE (polytetrafl uoroeth- DN350 to DN600 enables the universal use of these butterfl y

ylene) off ers the maximum level of process and operational valves, wherever large amounts of liquid media need to be

reliability that is so often required, especially in the chemical safely transported. These special constructions for applica-

industry. The resistance to aggressive media, such as acids, tions in water treatment or in the chemical industry are

saline solutions and hydrocarbons, derived from the integra- convincing because of their very high operational reliability

tion of the PTFE profi le passage seal is particularly eff ective. and their nearly 50 % lower weight compared to butterfl y

Equally impressive is the temperature resistance in the valves made of metal. Customers profi t from signifi cant sav-

range of -20 ºC to +120 ºC, achieved through the specifi c ings in time and costs for transport, storage and installation.

combination and scope of materials. The PTFE seal is also

available for PP-H and PVC-C butterfl y valves. Professional support worldwide

International teams of experts from GF Piping Systems

Low permeability resolutely carry on the customeroriented approach, so

The PTFE butterfl y valves aff ord a permeability far below successful in the product environment, in providing services

average and thus utmost reliability, even when transporting to our customers. With individual technical advice and

diff using substances. The mandatory 100 % leakproof and support in selecting materials, they are competent and

functional tests performed on the valves are testimony to experienced partners for our customers.

the high quality.

7

Page8

Technical data

Oriented to Your

Individual Needs

The plastic butterfl y valves from GF Piping Systems come in many variations and combine the unique

nature of the material in design, application and performance. Characteristics, such as the much lower

net weight, corrosion resistance and excellent chemical resistance, ensure maximum effi ciency and

reliability as well as a consistently high degree of economic effi ciency over the entire lifetime of the

product or the respective system.

Technical Data

Butterfl y valves

Designation Manual Pneumatic Electric

Type 567 578 240 / 243 / 244 140 / 143 / 144

Basis type 567/ 578 567 / 578

General

Actuator type PA30–70 EA31 / 42

Dimension DN50–DN600 DN50–DN300 DN50–DN600 DN50–DN600

Pressure rating PN4–PN10 PN10 PN4–PN10 PN4–PN10

PVC-U

PVC-C

Materials ABS

PP-H

PVDF

Wafer

Connection Lug

Threaded socket

EPDM

PTFE / FPM

Seal materials

FPM

Other

Manual

Pneumatic

actuation

Drive

Electric

actuation

With manual gear

8

Page9

Technical data

Strength

through Diversity

The metal valves are a valuable complement to the line of plastic

butterfl y valves and they contribute decisively to the versatility of

the overall system. Added value is especially generated by the

permanently high temperature and pressure resistance, the low

pressure loss and long lifetime. The resulting cost and perfor-

mance effi ciency, together with the compact construction for safe

and easy handling, fi rmly establish the metal butterfl y valves in

the modular system world of GF Piping Systems.

Metal valves

Technical features

Dimension

Type 038

Type 039

Pressure rating Type 039 / Type 038 PN16

EN 558 series 20

DN50 - DN500 ISO 5752 series 20

Installation length DN600 - 1200 Own standard

EN1092–1 PN10 / PN16

DIN 2501 PN10 / PN16

Flange connection measurements ANSI B 16.5, Class 150

Mounting fl ange EN ISO 5211

Leakproof test ISO 5208-93 (DIN3230)

Allowable working pressure max. 10 bar / 16 bar

Allowable diff erential pressure max. 10 bar / 16 bar

up to 0.2 bar absolute (higher vacuum depending on medium

Use in vacuum and temperature)

Ductile cast iron ASTM norm:

A395 M:88 DIN / EN NORM EN JS 1020 EN 1563

Material specifi cations of housing Type 038 / Type 039 Coating: DN50 - DN300 Rilsan, from DN 350 Epoxy

Ductile cast iron ASTM norm:

A395 M:88; DIN / EN NORM EN JS 1020 EN 1563 up to DN300

Disk Rilsan-coated, from DN350 Epoxy-coated

Stainless steel ASTM norm:

A351-94 CF8M; DIN / EN NORM 1.4408 EN 10213-4

Aluminum bronze: ASTM norm: B 148-92 C95800 DIN / EN

NORM: EN 1982-99 CC333G

Seal liner EPDM, FPM, other materials available on request

(depending on pressure, medium and material)

Temperature range -10°C to +180° C up to +80 °C with disk with coating

9

Page10

Application areas

Your Processes Determine the System –

Our Products Ensure the Necessary

Safety and Efficiency

The many demanding application areas and media in use today necessitate a consistently high level of

safety, effi ciency, quality and profi tability of systems as well as of the individual components. GF Piping

Systems has successfully developed application-oriented system solutions for discerning customers for

over 50 years. As diff erent as our customers, their process environments and requirements are, as

diverse and individual are our specifi c products. Focused on customer and industry-specifi c circum-

stances, we off er a multitude of systems, and valves as well. These are ideally integrated in the process

structure of complete system and uncompromisingly meet the challenge of high performance and

quality requirements.

Chemical process industry Microelectronics

Because of the aggressive environment of many applications The majority of all processes in microelectronics take place

in the chemical industry, production and transport process- under strictly controlled cleanroom conditions. Particularly

es in this segment pose a particular challenge to piping high demands are placed on the consistent purity of the

systems regarding safety and quality. When dosing, mixing process water as well as the transport of ultrapure water

and batching chemicals good fl ow and linear control charac- within the manufacturing process. The new generation of

teristics are basic requirements for effi cient and safe butterfl y valves is ideally suited for this challenging

processes. Contamination must be prevented in all process environment and also greatly improves hygiene in the

steps, especially surface treatment. Integrating the right application environment thanks to minimal dead space.

system components is therefore crucial. Designed A consistent thermal expansion behavior at the same time

specifi cally for the requirements and stringent regulations increases safety and consequently reduces the need for

in this demanding market, the butterfl y valves from costly maintenance.

GF Piping Systems provide high fl ow performance and

precise process control and regulation.

10

Page11

Applications

A Modern System with

Universal Character

The universal system and material properties of this product range are impressive, making it possible to

realize numerous applications in the chemical process industry, microelectronics and water treatment.

Profi tability is achieved through system benefi ts, i.e. the use of plastics as system material. Not only

the excellent abrasion and corrosion resistance to external infl uences and aggressive media, as

proved in a direct comparison with metal, but also the smooth surface and low weight ensure added

value in terms of system lifetime, maintenance and handling. The „Total Plastic Solutions" from

GF Piping Systems are therefore a guarantee for safety and quality, but also effi ciency and profi tability

in nearly all applications.

Water treatment Energy

Economical and sustainable water treatment is becoming With smart and comprehensive plastic solutions, GF Piping

more and more important, especially in light of the increas- Systems actively contributes to the successful realization of

ing scarcity of resources. Thanks to their technical features complex, highly specialized water and chemical applications

and functionalities, the versatile butterfl y valves from in the energy production of today and tomorrow. Selecting

GF Piping Systems meet this global need. In water treatment ideal components in the right material and implementing

applications they are mainly implemented to transport the them effi ciently are decisive for successful processes as

water. Depending on the chemical composition of the well as the entire system. GF Piping Systems off ers

medium, the use of diff erent types of butterfl y valves is solutions targeted for safety and reliability and feature such

possible. For example, type 567 is generally preferred for its outstanding properties, such as high performance, low

low weight, corrosion resistance and low tightening torque. weight, reduced energy consumption, excellent corrosion

A viable alternative to the plastic valves would be the metal resistance and minimal downtime. The innovative design,

butterfl y valve type 039. This valve has been designed for fl ow effi ciency and control characteristics, for which the

demanding applications with a pressure rating of up to butterfl y valves are known, are especially appreciated in

PN16 and because of its high stability off ers added value in cooling applications in energy production.

terms of resistance and durability.

11

Page12

GF Piping Systems

Worldwide at home

Our sales companies and representatives

ensure local customer support in over 100 countries

www.gfps.com

Argentina / Southern South America France Mexico / Northern Latin America Singapore

Georg Fischer Central Plastics Sudamérica S.R.L. Georg Fischer SAS Georg Fischer S.A. de C.V. George Fischer Pte Ltd

Buenos Aires, Argentina 95932 Roissy Charles de Gaulle Cedex Apodaca, Nuevo Leon 11 Tampines Street 92, #04-01/07

Phone +54 11 4512 02 90 Phone +33 (0) 1 41 84 68 84 CP66636 Mexico 528 872 Singapore

gfcentral.ps.ar@georgfischer.com fr.ps@georgfischer.com Phone +52 (81) 1340 8586 Phone +65 6747 0611

www.gfps.com/ar www.gfps.com/fr Fax +52 (81) 1522 8906 Fax +65 6747 0577

mx.ps@georgfischer.com sgp.ps@georgfischer.com

Australia Germany www.gfps.com/mx www.gfps.com/sg

George Fischer Pty Ltd Georg Fischer GmbH

Riverwood NSW 2210 Australia 73095 Albershausen Middle East Spain / Portugal

Phone +61 (0) 2 9502 8000 Phone +49 (0) 7161 302 0 Georg Fischer Piping Systems (Switzerland) Ltd Georg Fischer S.A.

australia.ps@georgfischer.com info.de.ps@georgfischer.com Dubai, United Arab Emirates 28046 Madrid

www.gfps.com/au www.gfps.com/de Phone +971 4 289 49 60 Phone +34 (0) 91 781 98 90

gcc.ps@georgfischer.com es.ps@georgfischer.com

Austria India www.gfps.com/int www.gfps.com/es

Georg Fischer Rohrleitungssysteme GmbH Georg Fischer Piping Systems Pvt. Ltd

3130 Herzogenburg 400 083 Mumbai Netherlands Sweden

Phone +43 (0) 2782 856 43-0 Phone +91 22 4007 2000 Georg Fischer N.V. Georg Fischer AB

austria.ps@georgfischer.com Fax +91 22 4007 2020 8161 PA Epe 117 43 Stockholm

www.gfps.com/at branchoffice@georgfischer.com Phone +31 (0) 578 678 222 Phone +46 (0) 8 506 775 00

www.gfps.com/in nl.ps@georgfischer.com info.se.ps@georgfischer.com

Belgium / Luxembourg www.gfps.com/nl www.gfps.com/se

Georg Fischer NV/SA Indonesia

1070 Bruxelles/Brüssel George Fischer Pte Ltd Norway Switzerland

Phone +32 (0) 2 556 40 20 41371 Jawa Barat Georg Fischer AS Georg Fischer Rohrleitungssysteme (Schweiz) AG

be.ps@georgfischer.com Phone +62 267 432 044 1351 Rud 8201 Schaffhausen

www.gfps.com/be Fax +62 267 431 857 Phone +47 67 18 29 00 Phone +41 (0) 52 631 3026

indonesia.ps@georgfischer.com no.ps@georgfischer.com ch.ps@georgfischer.com

Brazil www.gfps.com/id www.gfps.com/no www.gfps.com/ch

Georg Fischer Sist. de Tub. Ltda.

04571-020 São Paulo/SP Italy Philippines Taiwan

Phone +55 (0) 11 5525 1311 Georg Fischer S.p.A. George Fischer Pte Ltd Georg Fischer Co. Ltd

br.ps@georgfischer.com 20063 Cernusco S/N (MI) Representative Office San Chung Dist., New Taipei City

www.gfps.com/br Phone +39 02 921 861 Phone +632 571 2365 Phone +886 2 8512 2822

it.ps@georgfischer.com Fax +632 571 2368 Fax +886 2 8512 2823

Canada www.gfps.com/it sgp.ps@georgfischer.com www.gfps.com/tw

Georg Fischer Piping Systems Ltd www.gfps.com/sg

Mississauga, ON L5T 2B2 Japan United Kingdom / Ireland

Phone +1 (905) 670 8005 Georg Fischer Ltd Poland George Fischer Sales Limited

Fax +1 (905) 670 8513 530-0003 Osaka Georg Fischer Sp. z o.o. Coventry, CV2 2ST

ca.ps@georgfischer.com Phone +81 (0) 6 6341 2451 05-090 Sekocin Nowy Phone +44 (0) 2476 535 535

www.gfps.com/ca jp.ps@georgfischer.com Phone +48 (0) 22 31 31 0 50 uk.ps@georgfischer.com

www.gfps.com/jp poland.ps@georgfischer.com www.gfps.com/uk

China www.gfps.com/pl

Georg Fischer Piping Systems Ltd Korea USA / Caribbean

Shanghai 201319 Georg Fischer Korea Co. Ltd Romania Georg Fischer LLC

Phone +86 21 3899 3899 Unit 2501, U-Tower Georg Fischer Piping Systems (Switzerland) Ltd 9271 Jeronimo Road

china.ps@georgfischer.com 120 HeungdeokJungang-ro 020257 Bucharest - Sector 2 92618 Irvine, CA

www.gfps.com/cn (Yeongdeok-dong) Phone +40 (0) 21 230 53 80 Phone +1 714 731 8800

Giheung-gu, Yongin-si, Gyeonggi-do ro.ps@georgfischer.com Fax +1 714 731 6201

Denmark / Iceland Phone +82 31 8017 1450 www.gfps.com/int us.ps@georgfischer.com

Georg Fischer A/S Fax +82 31 217 1454 www.gfps.com/us

2630 Taastrup kor.ps@georgfischer.com Russia

Phone +45 (0) 70 22 19 75 www.gfps.com/kr Georg Fischer Piping Systems (Switzerland) Ltd International

info.dk.ps@georgfischer.com Moscow 125040 Georg Fischer Piping Systems (Switzerland) Ltd

www.gfps.com/dk Malaysia Phone +7 495 748 11 44 8201 Schaffhausen/Switzerland

George Fischer (M) Sdn. Bhd. ru.ps@georgfischer.com Phone +41 (0) 52 631 3003

Finland 40460 Shah Alam, Selangor Darul Ehsan www.gfps.com/ru Fax +41 (0) 52 631 2893

Georg Fischer AB Phone +60 (0) 3 5122 5585 info.export@georgfischer.com

01510 VANTAA Fax +60 (0) 3 5122 5575 www.gfps.com/int

Phone +358 (0) 9 586 58 25 my.ps@georgfischer.com

Fax +358 (0) 9 586 58 29 www.gfps.com/my

info.fi.ps@georgfischer.com

www.gfps.com/fi

The technical data are not binding. They neither constitute expressly

warranted characteristics nor guaranteed properties nor a guaranteed durability.

They are subject to modification. Our General Terms of Sale apply.

GFDO_6285_4a (08.168)

© Georg Fischer Piping Systems Ltd

CH-8201 Schaffhausen/Switzerland, 2016