1/8ページ

ダウンロード(4.3Mb)

Peace of mind in quality of jointing

Pressure piping systems for industrial applications place high demands on mechanical stability,

reproducibility and quality of fusion jointing. The new IR-315 A is part of the automated IR-A family

made by GF. Automation, intuitive handling, system security and the revolutionary cooling system

for big dimensions enable highest reproducibility, quality and efficiency for installers and operators.

このカタログについて

| ドキュメント名 | Automated infrared fusion machine IR-315 A - Product Range |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 4.3Mb |

| 取り扱い企業 | ジョージフィッシャー株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

GF Piping Systems

Product Range

Automated infrared fusion machine

IR-315 A

Page2

IR-315 A

Peace of mind in

quality of jointing

Pressure piping systems for industrial applications place high demands on mechanical stability,

reproducibility and quality of fusion jointing. The new IR-315 A is part of the automated IR-A family

made by GF. Automation, intuitive handling, system security and the revolutionary cooling system

for big dimensions enable highest reproducibility, quality and efficiency for installers and operators.

Automated facer unit

Integrated cooling

system

Automated

heater unit

Safety bar

Ambient

temperature

sensor

Lockable main

switch

Circuit breakers

Protected level adjustment

Page3

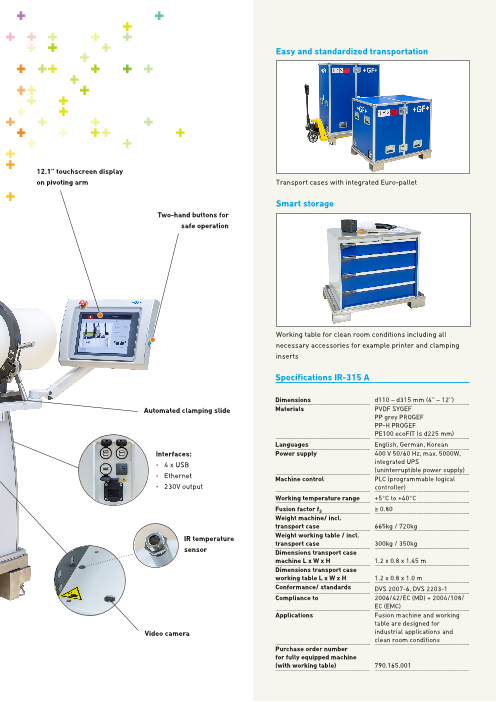

Easy and standardized transportation

12.1’’ touchscreen display

on pivoting arm Transport cases with integrated Euro-pallet

Smart storage

Two-hand buttons for

safe operation

Working table for clean room conditions including all

necessary accessories for example printer and clamping

inserts

Specifications IR-315 A

Dimensions d110 – d315 mm (4’’ – 12’’)

Automated clamping slide Materials PVDF SYGEF

PP grey PROGEF

PP-H PROGEF

PE100 ecoFIT (≤ d225 mm)

Languages English, German, Korean

Interfaces: Power supply 400 V 50/60 Hz, max. 5000W,

• 4 x USB integrated UPS

(uninterruptible power supply)

• Ethernet Machine control PLC (programmable logical

• 230V output controller)

Working temperature range +5°C to +40°C

Fusion factor fs ≥ 0.80

Weight machine/ incl.

transport case 665kg / 720kg

IR temperature Weight working table / incl.

transport case 300kg / 350kg

sensor Dimensions transport case

machine L x W x H 1.2 x 0.8 x 1.45 m

Dimensions transport case

working table L x W x H 1.2 x 0.8 x 1.0 m

Conformance/ standards DVS 2007-6, DVS 2203-1

Compliance to 2006/42/EC (MD) + 2004/108/

EC (EMC)

Applications Fusion machine and working

table are designed for

Video camera industrial applications and

clean room conditions

Purchase order number

for fully equipped machine

(with working table) 790.165.001

Page4

IR-315 A Automated Fusion Machine and Spare Parts

IR-315 A Automated Fusion Machine

Model:

• Fully equipped automated infrared fusion machine and working table designed for industrial

applications and clean room conditions

• Welding of PVDF SYGEF (Standard/Plus), PP PROGEF (Standard/Plus), PE100 ecoFIT

(d≤d225 mm)

• Dimensions d110-315 mm

• Automated facer, clamping slide and heater

• Integrated cooling system

• User friendly touch-screen interface 12.1” with various languages

• 4 USB interfaces, LAN Ethernet interface, 230 V Output

• Integrated video camera and temperature sensors

• Clamping inserts d110-280 mm (8 pcs. per dimension)

• End caps PE d110-315 mm (4 pcs. per dimension)

• Transport cases with integrated Euro-pallet (fusion machine and working table)

• 3-phase AC (50/60 Hz) 400 V L1/L2/L3/N/PE

• Set of facing knives (2 pcs.)

• Torx key (T25) for facing knife

• Hexagon keys (10 mm + 8 mm)

• Fork key (36 mm)

• Cleaning brush

• Label printer (incl. ribbon 24 mm)

• Instruction manual

d-d Code Weight

(mm) (kg)

110 - 315 790 165 001 1070.000

Clamping inserts

• The clamping inserts are different for each dimension. They are used to clamp and position the

pipe components.

d Code Weight Pieces

(mm) (kg)

110 790 165 010 1.500 1

125 790 165 011 1.400 1

140 790 165 012 1.300 1

160 790 165 013 1.300 1

180 790 165 014 1.200 1

200 790 165 015 1.100 1

225 790 165 016 1.000 1

250 790 165 017 0.900 1

280 790 165 018 0.700 1

1

Page5

Set of end caps

• A set includes 4 end caps. The end caps are different for each dimension. The ends of the pipe

must be closed. The caps prevent heat loss due to airflow in the fusion zone and guarantee op-

timum fusion results of the pipe components.

d Code Weight Pieces

(mm) (kg)

110 790 133 038 0.180 4

125 790 133 039 0.150 4

140 790 133 040 0.180 4

160 790 133 041 0.045 4

200 790 133 042 0.080 4

225 790 133 043 0.400 4

250 790 134 151 0.400 4

280 790 134 152 0.400 4

315 790 134 153 0.400 4

Set of facing knives

• A set includes two facing knives and ten screws. Each facing knife has four blades. In case of a

blunt blade the facing knife may be turned three times before it must be replaced.

d-d Code Weight Pieces

(mm) (kg)

110 ‐ 315 790 165 549 0.100 2

Torx key

• For facing knives

Description Code Weight

(kg)

T25 790 133 577 0.009

Cleaning brush

Code Weight

(kg)

790 133 198 0.055

2

Page6

Accessories

Accessories

Tangit KS Cleaner

• Special cleaner for plastic fusion connections in the materialof PP, PE, PVDF and PB

• Suitable for Tangit Rapid. Must not be used for solvent cementing

• DVGW approved

• DW 5290 BR 0464

Size Code Weight

(kg)

1 liter 799 298 023 0.872

Cleaning tissue KO-TON-R

Minimum order quantity 100 pieces

• This cleaning tissue is suitable for the cleaning of the welding zone of piping components, be-

cause it is lint free and clean room checked.

Code Weight

(kg)

790 122 085 0.005

Label Printer

• Label 36 mm included, order Label 24 mm separately

description Code Weight

(kg)

Label Printer Brother PT-P900W 790 131 066 2.740

Ribbon 24 mm Brother TZe-251 790 131 065 0.100

3

Page7

Technology

The pioneer

in IR fusion

GF Piping Systems has been the pioneer

and leader for innovative infrared fusion

technology since 1992. We have been working

closely together with our customers focussing

on their real-life needs. As a result we

developed the automated IR-A family, which

covers the dimension range from d20 up to

d315 mm.

Advantages of IR fusion

• Short welding time

• Minimal defined bead IR (infrared) fusion Conventional butt fusion

• High reproducibility

• High reliability

• Less thermo-stress

• Best for high purity applications

The optimized heating process

Non-contact heating (IR) shortens the heating time by more

than 30% compared to conventional butt fusion. The entire

equalization process is no longer necessary which solves

the problem of varying bead formations”. The tendency for

melted material to stick to the heating element (especially

PVDF) is eliminated.

The one-stop-shop solution

7

Jointing cross- Welding principle

section (PP)

Page8

GF Piping Systems

Worldwide at home

Our sales companies and representatives

ensure local customer support in more than 100 countries

www.gfps.com

Argentina / Southern South America France Mexico / Northern Latin America Singapore

Georg Fischer Central Plastics Sudamérica S.R.L. Georg Fischer SAS Georg Fischer S.A. de C.V. George Fischer Pte Ltd

Buenos Aires, Argentina 95932 Roissy Charles de Gaulle Cedex Apodaca, Nuevo Leon 11 Tampines Street 92, #04-01/07

Phone +54 11 4512 02 90 Phone +33 (0) 1 41 84 68 84 CP66636 Mexico 528 872 Singapore

gfcentral.ps.ar@georgfischer.com fr.ps@georgfischer.com Phone +52 (81) 1340 8586 Phone +65 6747 0611

www.gfps.com/ar www.gfps.com/fr Fax +52 (81) 1522 8906 Fax +65 6747 0577

mx.ps@georgfischer.com sgp.ps@georgfischer.com

Australia Germany www.gfps.com/mx www.gfps.com/sg

George Fischer Pty Ltd Georg Fischer GmbH

Riverwood NSW 2210 Australia 73095 Albershausen Middle East Spain / Portugal

Phone +61 (0) 2 9502 8000 Phone +49 (0) 7161 302 0 Georg Fischer Piping Systems (Switzerland) Ltd Georg Fischer S.A.

australia.ps@georgfischer.com info.de.ps@georgfischer.com Dubai, United Arab Emirates 28046 Madrid

www.gfps.com/au www.gfps.com/de Phone +971 4 289 49 60 Phone +34 (0) 91 781 98 90

gcc.ps@georgfischer.com es.ps@georgfischer.com

Austria India www.gfps.com/int www.gfps.com/es

Georg Fischer Rohrleitungssysteme GmbH Georg Fischer Piping Systems Pvt. Ltd

3130 Herzogenburg 400 083 Mumbai Netherlands Sweden

Phone +43 (0) 2782 856 43-0 Phone +91 22 4007 2000 Georg Fischer N.V. Georg Fischer AB

austria.ps@georgfischer.com Fax +91 22 4007 2020 8161 PA Epe 117 43 Stockholm

www.gfps.com/at branchoffice@georgfischer.com Phone +31 (0) 578 678 222 Phone +46 (0) 8 506 775 00

www.gfps.com/in nl.ps@georgfischer.com info.se.ps@georgfischer.com

Belgium / Luxembourg www.gfps.com/nl www.gfps.com/se

Georg Fischer NV/SA Indonesia

1600 Sint-Pieters-Leeuw / Belgium PT Georg Fischer Indonesia Norway Switzerland

Phone +32 (0) 2 556 40 20 Karawang 41371, Jawa Barat Georg Fischer AS Georg Fischer Rohrleitungssysteme (Schweiz) AG

Fax +32 (0) 2 524 34 26 Phone +62 267 432 044 1351 Rud 8201 Schaffhausen

be.ps@georgfischer.com Fax +62 267 431 857 Phone +47 67 18 29 00 Phone +41 (0) 52 631 3026

www.gfps.com/be indonesia.ps@georgfischer.com no.ps@georgfischer.com ch.ps@georgfischer.com

www.gfps.com/id www.gfps.com/no www.gfps.com/ch

Brazil

Georg Fischer Sist. de Tub. Ltda. Italy Philippines Taiwan

04571-020 São Paulo/SP Georg Fischer S.p.A. George Fischer Pte Ltd Georg Fischer Co. Ltd

Phone +55 (0) 11 5525 1311 20063 Cernusco S/N (MI) Representative Office San Chung Dist., New Taipei City

br.ps@georgfischer.com Phone +39 02 921 861 Phone +632 571 2365 Phone +886 2 8512 2822

www.gfps.com/br it.ps@georgfischer.com Fax +632 571 2368 Fax +886 2 8512 2823

www.gfps.com/it sgp.ps@georgfischer.com www.gfps.com/tw

Canada www.gfps.com/sg

Georg Fischer Piping Systems Ltd Japan United Kingdom / Ireland

Mississauga, ON L5T 2B2 Georg Fischer Ltd Poland George Fischer Sales Limited

Phone +1 (905) 670 8005 530-0003 Osaka Georg Fischer Sp. z o.o. Coventry, CV2 2ST

Fax +1 (905) 670 8513 Phone +81 (0) 6 6341 2451 05-090 Sekocin Nowy Phone +44 (0) 2476 535 535

ca.ps@georgfischer.com jp.ps@georgfischer.com Phone +48 (0) 22 31 31 0 50 uk.ps@georgfischer.com

www.gfps.com/ca www.gfps.com/jp poland.ps@georgfischer.com www.gfps.com/uk

www.gfps.com/pl

China Korea USA / Caribbean

Georg Fischer P iping Systems Ltd Georg Fischer Korea Co. Ltd Romania Georg Fischer LLC

Shanghai 201319 Unit 2501, U-Tower Georg Fischer Piping Systems (Switzerland) Ltd 9271 Jeronimo Road

Phone +86 21 3899 3899 120 HeungdeokJungang-ro 020257 Bucharest - Sector 2 92618 Irvine, CA

china.ps@georgfischer.com (Yeongdeok-dong) Phone +40 (0) 21 230 53 80 Phone +1 714 731 8800

www.gfps.com/cn Giheung-gu, Yongin-si, Gyeonggi-do ro.ps@georgfischer.com Fax +1 714 731 6201

Phone +82 31 8017 1450 www.gfps.com/int us.ps@georgfischer.com

Denmark / Iceland Fax +82 31 217 1454 www.gfps.com/us

Georg Fischer A/S kor.ps@georgfischer.com Russia

2630 Taastrup www.gfps.com/kr Georg Fischer Piping Systems (Switzerland) Ltd International

Phone +45 (0) 70 22 19 75 Moscow 125040 Georg Fischer Piping Systems (Switzerland) Ltd

info.dk.ps@georgfischer.com Malaysia Phone +7 495 748 11 44 8201 Schaffhausen/Switzerland

www.gfps.com/dk George Fischer (M) Sdn. Bhd. ru.ps@georgfischer.com Phone +41 (0) 52 631 3003

40460 Shah Alam, Selangor Darul Ehsan www.gfps.com/ru Fax +41 (0) 52 631 2893

Finland Phone +60 (0) 3 5122 5585 info.export@georgfischer.com

Georg Fischer AB Fax +60 (0) 3 5122 5575 www.gfps.com/int

01510 VANTAA my.ps@georgfischer.com

Phone +358 (0) 9 586 58 25 www.gfps.com/my

Fax +358 (0) 9 586 58 29

info.fi.ps@georgfischer.com

www.gfps.com/fi

„The information and technical data (altogether “Data”) herein are not binding, unless explicitly confirmed in writing.

The Data neither constitutes any expressed, implied or warranted characteristics, nor guaranteed properties or a guaranteed

durability. All Data is subject to modification. The General Terms and Conditions of Sale of Georg Fischer Piping Systems apply.”

© Georg Fischer Piping Systems Ltd

CH-8201 Schaffhausen/Switzerland, 2018