1/5ページ

ダウンロード(1.9Mb)

Peace of mind in quality of jointing

Pressure piping systems for industrial applications place high demands on mechanical stability,

reproducibility and quality of fusion jointing. The IR-110 A is the new generation of infrared fusion

machines by GF. Automation, intuitive handling and system security enable highest efficiency

for installers and operators.

このカタログについて

| ドキュメント名 | Automated infrared fusion machine IR-110 A |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 1.9Mb |

| 取り扱い企業 | ジョージフィッシャー株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

GF Piping Systems

Peace of mind

Automated infrared fusion machine

IR-110 A

Page2

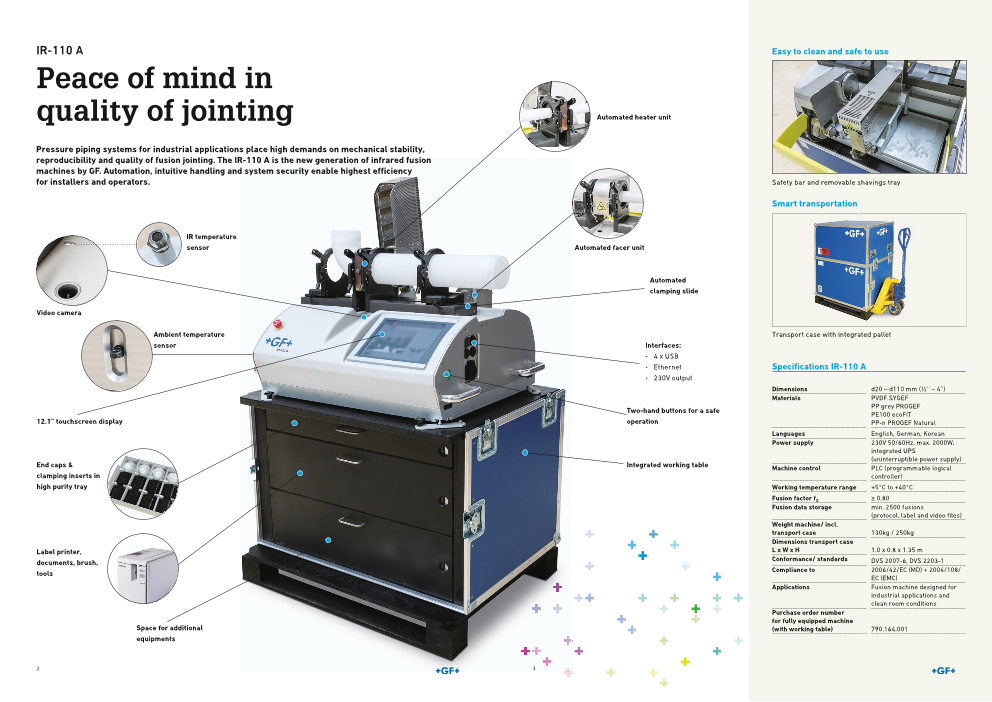

IR-110 A Easy to clean and safe to use

Peace of mind in

quality of jointing Automated heater unit

Pressure piping systems for industrial applications place high demands on mechanical stability,

reproducibility and quality of fusion jointing. The IR-110 A is the new generation of infrared fusion

machines by GF. Automation, intuitive handling and system security enable highest e ciency

for installers and operators. Safety bar and removable shavings tray

Smart transportation

IR temperature

sensor Automated facer unit

Automated

clamping slide

Video camera

Ambient temperature Transport case with integrated pallet

sensor Interfaces:

• 4 x USB

• Ethernet Specifi cations IR-110 A

• 230V output

Dimensions d20 – d110 mm (½’’ – 4’’)

Materials PVDF SYGEF

PP grey PROGEF

Two-hand buttons for a safe PE100 ecoFIT

12.1” touchscreen display operation PP-n PROGEF Natural

Languages English, German, Korean

Power supply 230V 50/60Hz, max. 2000W,

integrated UPS

(uninterruptible power supply)

End caps & Integrated working table Machine control PLC (programmable logical

clamping inserts in controller)

high purity tray Working temperature range +5°C to +40°C

Fusion factor fS ≥ 0.80

Fusion data storage min. 2500 fusions

(protocol, label and video fi les)

Weight machine/ incl.

transport case 130kg / 250kg

Dimensions transport case

Label printer, L x W x H 1.0 x 0.8 x 1.35 m

documents, brush, Conformance/ standards DVS 2007-6, DVS 2203-1

tools Compliance to 2006/42/EC (MD) + 2004/108/

EC (EMC)

Applications Fusion machine designed for

industrial applications and

clean room conditions

Purchase order number

for fully equipped machine

Space for additional (with working table) 790.164.001

equipments

2 3

Page3

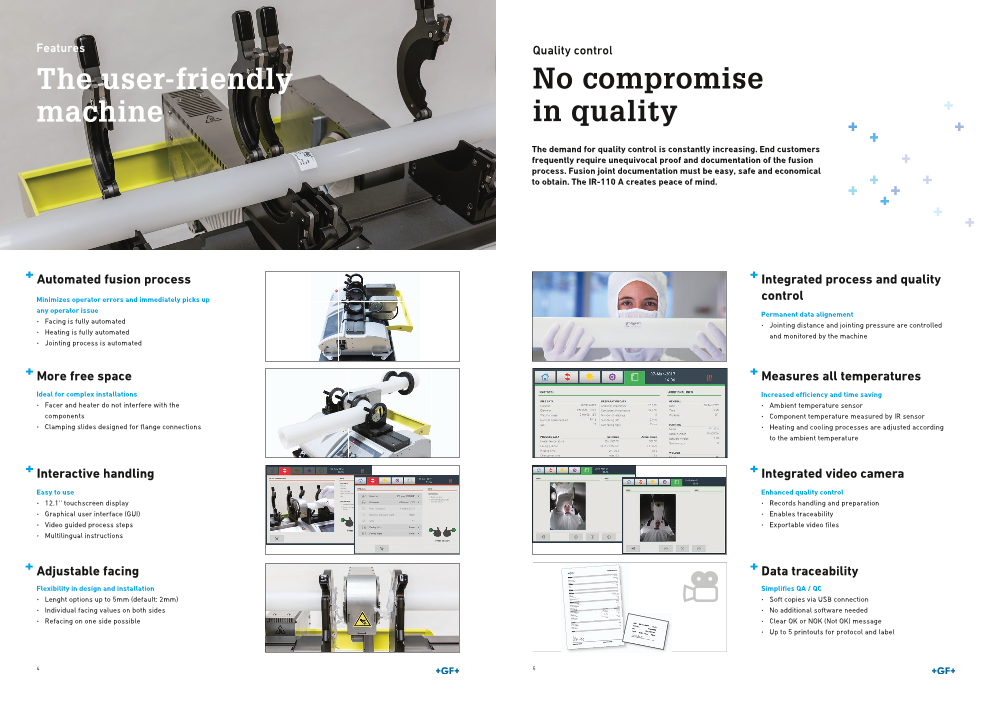

Features Quality control

The user-friendly No compromise

machine in quality

The demand for quality control is constantly increasing. End customers

frequently require unequivocal proof and documentation of the fusion

process. Fusion joint documentation must be easy, safe and economical

to obtain. The IR-110 A creates peace of mind.

Automated fusion process Integrated process and quality

Minimizes operator errors and immediately picks up control

any operator issue Permanent data alignement

• Facing is fully automated

• Jointing distance and jointing pressure are controlled

• Heating is fully automated and monitored by the machine

• Jointing process is automated

More free space Measures all temperatures

Ideal for complex installations Increased e ciency and time saving

• Facer and heater do not interfere with the • Ambient temperature sensor

components • Component temperature measured by IR sensor

• Clamping slides designed for fl ange connections • Heating and cooling processes are adjusted according

to the ambient temperature

Interactive handling Integrated video camera

Easy to use Enhanced quality control

• 12.1‘‘ touchscreen display • Records handling and preparation

• Graphical user interface (GUI) • Enables traceability

• Video guided process steps • Exportable video fi les

• Multilingual instructions

Adjustable facing Data traceability

Flexibility in design and installation Simplifi es QA / QC

• Lenght options up to 5mm (default: 2mm) • Soft copies via USB connection

• Individual facing values on both sides • No additional software needed

• Refacing on one side possible • Clear OK or NOK (Not OK) message

• Up to 5 printouts for protocol and label

4 5

Page4

Technology Complete systems, services and trainings

The pioneer in IR fusion The one-stop-shop solution

In 1992, GF Piping Systems introduced the fi rst IR fusion machines. Since then GF Piping Systems is a solution provider in the piping systems market.

GF Piping Systems became a leader for innovative fusion technology. We have been This includes, in addition to the core products (pipes, fi ttings, valves, and

working strongly together with customers and kept in touch with their needs. As a result fusion machines) service and customer training, such as certifi ed welding

we developed the new automated IR-110 A: user friendly, bigger screen, enhanced QA/QC courses and maintenance courses. The correct installation of our products

and high reproducibility. is just as important as the quality of the products themselves.

1992 2003 2009 2012 2017 2018

IR-63 & IR-225 Plus IR-315 Plus IR-110 Plus IR-450 IR-110 A IR-315 A Total plastic

d20 – d63 mm d225 – d315 mm d20 – d110 mm d315 – d450 mm d20 – d110 mm d110 – d315 mm Sales &

d63 – d225 mm rental pool solution

Over 70’000 products

Sales companies world-

IR (infrared) fusion Conventional butt fusion wide, global and local

Advantages of IR fusion rental pools

• Short welding time

• Minimal defi ned bead Service &

• High reproducibility

• High reliability Training maintenance

• Less thermo-stress Trainings for welders, Worldwide

• Best for high purity applications weld bead inspection and maintenance centers,

special maintenance engineering services,

after sales

The optimized heating process support

Non-contact heating (IR) cuts the heating time by more than

30% compared to conventional butt fusion. The entire

equalization process is no longer necessary, what ends the

problems with varying bead formations. The tendency for

melted material to stick at the heating element (especially

for PVDF) is eliminated.

Applications

Microelectronics Chemical process industry Clean water applications Energy

Ultrapure water (UPW) is the SYGEF is uniquely equipped to Wherever defi ned water quali- For secure processing in water

lifeblood of semiconductor wet provide a broad and versatile ties and controlled processes and chemical applications the

processing. SYGEF Plus system solution for the safe convey- are required PROGEF Plus PROGEF Standard system

manufactured out of PVDF high ance of aggressive chemicals in off ers reliable and economical combines high performance

purity material added with extreme conditions. The excel- system solutions. With PROGEF utilization with outstanding

latest IR fusion technology lent life span for temperatures Plus high purity water specifi - material properties. This leads

off ers an industrial benchmark up to 140°C including UV- cations and quality standards to a benefi cial gain in condi-

solution with excellent leach- resistance even allows outside are dependably met. tions of safety and health.

out values and no rouging. installations.

6 7

Jointing cross- Macro-image Welding principle

section (PP) (PP)

Page5

GF Piping Systems

Worldwide at home

Our sales companies and representatives

ensure local customer support in more than 100 countries

www.gfps.com

Argentina / Southern South America France Mexico / Northern Latin America Singapore

Georg Fischer Central Plastics Sudamérica S.R.L. Georg Fischer SAS Georg Fischer S.A. de C.V. George Fischer Pte Ltd

Buenos Aires, Argentina 95932 Roissy Charles de Gaulle Cedex Apodaca, Nuevo Leon 11 Tampines Street 92, #04-01/07

Phone +54 11 4512 02 90 Phone +33 (0) 1 41 84 68 84 CP66636 Mexico 528 872 Singapore

gfcentral.ps.ar@georgfischer.com fr.ps@georgfischer.com Phone +52 (81) 1340 8586 Phone +65 6747 0611

www.gfps.com/ar www.gfps.com/fr Fax +52 (81) 1522 8906 Fax +65 6747 0577

mx.ps@georgfischer.com sgp.ps@georgfischer.com

Australia Germany www.gfps.com/mx www.gfps.com/sg

George Fischer Pty Ltd Georg Fischer GmbH

Riverwood NSW 2210 Australia 73095 Albershausen Middle East Spain / Portugal

Phone +61 (0) 2 9502 8000 Phone +49 (0) 7161 302 0 Georg Fischer Piping Systems (Switzerland) Ltd Georg Fischer S.A.

australia.ps@georgfischer.com info.de.ps@georgfischer.com Dubai, United Arab Emirates 28046 Madrid

www.gfps.com/au www.gfps.com/de Phone +971 4 289 49 60 Phone +34 (0) 91 781 98 90

gcc.ps@georgfischer.com es.ps@georgfischer.com

Austria India www.gfps.com/int www.gfps.com/es

Georg Fischer Rohrleitungssysteme GmbH Georg Fischer Piping Systems Pvt. Ltd

3130 Herzogenburg 400 083 Mumbai Netherlands Sweden

Phone +43 (0) 2782 856 43-0 Phone +91 22 4007 2000 Georg Fischer N.V. Georg Fischer AB

austria.ps@georgfischer.com Fax +91 22 4007 2020 8161 PA Epe 117 43 Stockholm

www.gfps.com/at branchoffice@georgfischer.com Phone +31 (0) 578 678 222 Phone +46 (0) 8 506 775 00

www.gfps.com/in nl.ps@georgfischer.com info.se.ps@georgfischer.com

Belgium / Luxembourg www.gfps.com/nl www.gfps.com/se

Georg Fischer NV/SA Indonesia

1600 Sint-Pieters-Leeuw / Belgium PT Georg Fischer Indonesia Norway Switzerland

Phone +32 (0) 2 556 40 20 Karawang 41371, Jawa Barat Georg Fischer AS Georg Fischer Rohrleitungssysteme (Schweiz) AG

Fax +32 (0) 2 524 34 26 Phone +62 267 432 044 1351 Rud 8201 Schaffhausen

be.ps@georgfischer.com Fax +62 267 431 857 Phone +47 67 18 29 00 Phone +41 (0) 52 631 3026

www.gfps.com/be indonesia.ps@georgfischer.com no.ps@georgfischer.com ch.ps@georgfischer.com

www.gfps.com/id www.gfps.com/no www.gfps.com/ch

Brazil

Georg Fischer Sist. de Tub. Ltda. Italy Philippines Taiwan

04571-020 São Paulo/SP Georg Fischer S.p.A. George Fischer Pte Ltd Georg Fischer Co. Ltd

Phone +55 (0) 11 5525 1311 20063 Cernusco S/N (MI) Representative Office San Chung Dist., New Taipei City

br.ps@georgfischer.com Phone +39 02 921 861 Phone +632 571 2365 Phone +886 2 8512 2822

www.gfps.com/br it.ps@georgfischer.com Fax +632 571 2368 Fax +886 2 8512 2823

www.gfps.com/it sgp.ps@georgfischer.com www.gfps.com/tw

Canada www.gfps.com/sg

Georg Fischer Piping Systems Ltd Japan United Kingdom / Ireland

Mississauga, ON L5T 2B2 Georg Fischer Ltd Poland George Fischer Sales Limited

Phone +1 (905) 670 8005 530-0003 Osaka Georg Fischer Sp. z o.o. Coventry, CV2 2ST

Fax +1 (905) 670 8513 Phone +81 (0) 6 6341 2451 05-090 Sekocin Nowy Phone +44 (0) 2476 535 535

ca.ps@georgfischer.com jp.ps@georgfischer.com Phone +48 (0) 22 31 31 0 50 uk.ps@georgfischer.com

www.gfps.com/ca www.gfps.com/jp poland.ps@georgfischer.com www.gfps.com/uk

www.gfps.com/pl

China Korea USA / Caribbean

Georg Fischer Piping Systems Ltd Georg Fischer Korea Co. Ltd Romania Georg Fischer LLC

Shanghai 201319 Unit 2501, U-Tower Georg Fischer Piping Systems (Switzerland) Ltd 9271 Jeronimo Road

Phone +86 21 3899 3899 120 HeungdeokJungang-ro 020257 Bucharest - Sector 2 92618 Irvine, CA

china.ps@georgfischer.com (Yeongdeok-dong) Phone +40 (0) 21 230 53 80 Phone +1 714 731 8800

www.gfps.com/cn Giheung-gu, Yongin-si, Gyeonggi-do ro.ps@georgfischer.com Fax +1 714 731 6201

Phone +82 31 8017 1450 www.gfps.com/int us.ps@georgfischer.com

Denmark / Iceland Fax +82 31 217 1454 www.gfps.com/us

Georg Fischer A/S kor.ps@georgfischer.com Russia

2630 Taastrup www.gfps.com/kr Georg Fischer Piping Systems (Switzerland) Ltd International

Phone +45 (0) 70 22 19 75 Moscow 125040 Georg Fischer Piping Systems (Switzerland) Ltd

info.dk.ps@georgfischer.com Malaysia Phone +7 495 748 11 44 8201 Schaffhausen/Switzerland

www.gfps.com/dk George Fischer (M) Sdn. Bhd. ru.ps@georgfischer.com Phone +41 (0) 52 631 3003

40460 Shah Alam, Selangor Darul Ehsan www.gfps.com/ru Fax +41 (0) 52 631 2893

Finland Phone +60 (0) 3 5122 5585 info.export@georgfischer.com

Georg Fischer AB Fax +60 (0) 3 5122 5575 www.gfps.com/int

01510 VANTAA my.ps@georgfischer.com

Phone +358 (0) 9 586 58 25 www.gfps.com/my

Fax +358 (0) 9 586 58 29

info.fi.ps@georgfischer.com

www.gfps.com/fi

„The information and technical data (altogether “Data”) herein are not binding, unless explicitly confirmed in writing.

The Data neither constitutes any expressed, implied or warranted characteristics, nor guaranteed properties or a guaranteed

durability. All Data is subject to modification. The General Terms and Conditions of Sale of Georg Fischer Piping Systems apply.”

700.671.666

GFDO_6461_4 (03.18)

© Georg Fischer Piping Systems Ltd

CH-8201 Schaffhausen/Switzerland, 2018