1/21ページ

ダウンロード(275Kb)

- System Specification - for ABS Metric Piping Systems

This specification covers requirements for the GF Piping System ABS intended for a

wide range of applications including water, wastewater and effluent treatment as well

as applications like process cooling water and secondary refrigeration.

このカタログについて

| ドキュメント名 | ABS (metric) - System specification |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 275Kb |

| 取り扱い企業 | ジョージフィッシャー株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

1. Scope

GF Piping Systems

- System Specification -

for ABS Metric Piping Systems

1. Scope

This specification covers requirements for the GF Piping System ABS intended for a

wide range of applications including water, wastewater and effluent treatment as well

as applications like process cooling water and secondary refrigeration. The

components of the ABS piping systems are in accordance with the following

standards.

2. Basic System Data

2.1 Material Specification for Acrylonitrile Butadiene Styrene (ABS)

ABS pipes, fittings and valves from GF Piping Systems shall be manufactured from

acrylonitrile butadiene styrene (ABS) andare designed for 25 years of operation with

water as medium (20°C). ABS has also an optimal chemical resistance against salt

solutions, dilute acids and bases. The raw material used shall be designed for use

with pressure bearing piping systems with long term hydrostatic properties in

accordance with DIN EN ISO 15493, as supplied by GF Piping Systems.

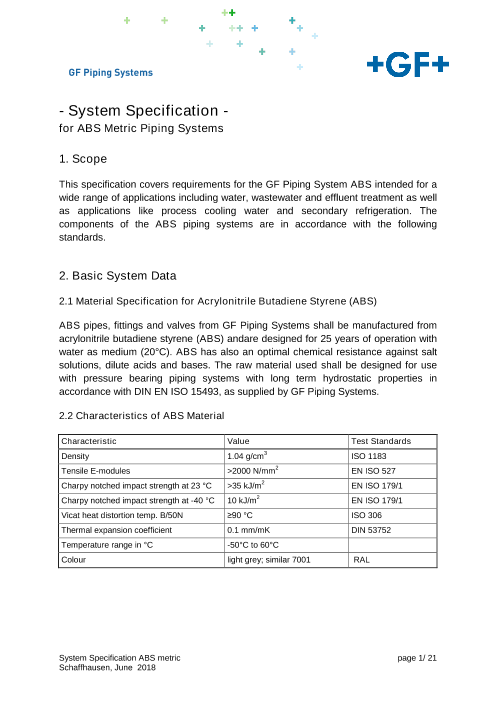

2.2 Characteristics of ABS Material

Characteristic Value Test Standards

Density 1.04 g/cm3 ISO 1183

Tensile E-modules >2000 N/mm2 EN ISO 527

Charpy notched impact strength at 23 °C >35 kJ/m2 EN ISO 179/1

Charpy notched impact strength at -40 °C 10 kJ/m2 EN ISO 179/1

Vicat heat distortion temp. B/50N ≥90 °C ISO 306

Thermal expansion coefficient 0.1 mm/mK DIN 53752

Temperature range in °C -50°C to 60°C

Colour light grey; similar 7001 RAL

System Specification ABS metric page 1/ 21

Schaffhausen, June 2018

Page2

- System Specification -

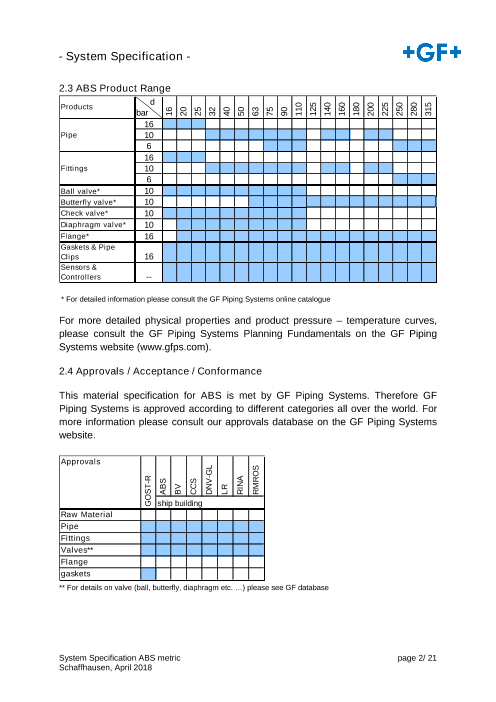

2.3 ABS Product Range

Products d

bar

16

Pipe 10

6

16

Fittings 10

6

Ball valve* 10

Butterfly valve* 10

Check valve* 10

Diaphragm valve* 10

Flange* 16

Gaskets & Pipe

Clips 16

Sensors &

Controllers --

* For detailed information please consult the GF Piping Systems online catalogue

For more detailed physical properties and product pressure – temperature curves,

please consult the GF Piping Systems Planning Fundamentals on the GF Piping

Systems website (www.gfps.com).

2.4 Approvals / Acceptance / Conformance

This material specification for ABS is met by GF Piping Systems. Therefore GF

Piping Systems is approved according to different categories all over the world. For

more information please consult our approvals database on the GF Piping Systems

website.

Approvals

ship building

Raw Material

Pipe

Fittings

Valves**

Flange

gaskets

** For details on valve (ball, butterfly, diaphragm etc. …) please see GF database

System Specification ABS metric page 2/ 21

Schaffhausen, April 2018

GOST-R

ABS

16

BV

20

CCS 25

DNV-GL 32

LR 40

RINA 50

RMROS 63

75

90

110

125

140

160

180

200

225

250

280

315

Page3

3. Pipes、4. Fittings、5. Accessories

- System Specification -

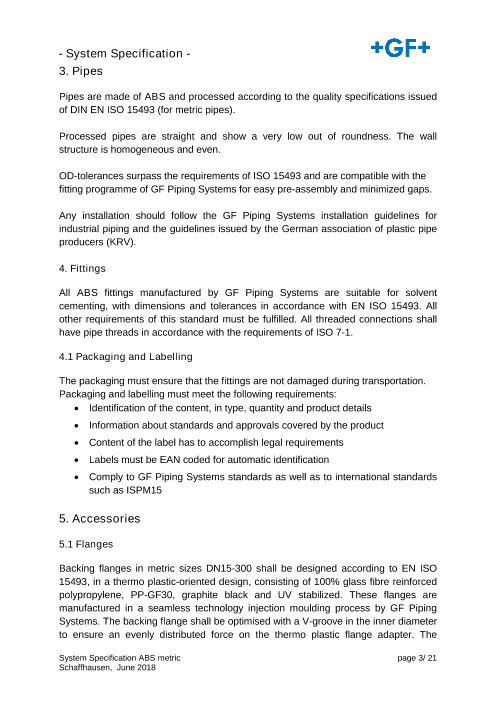

3. Pipes

Pipes are made of ABS and processed according to the quality specifications issued

of DIN EN ISO 15493 (for metric pipes).

Processed pipes are straight and show a very low out of roundness. The wall

structure is homogeneous and even.

OD-tolerances surpass the requirements of ISO 15493 and are compatible with the

fitting programme of GF Piping Systems for easy pre-assembly and minimized gaps.

Any installation should follow the GF Piping Systems installation guidelines for

industrial piping and the guidelines issued by the German association of plastic pipe

producers (KRV).

4. Fittings

All ABS fittings manufactured by GF Piping Systems are suitable for solvent

cementing, with dimensions and tolerances in accordance with EN ISO 15493. All

other requirements of this standard must be fulfilled. All threaded connections shall

have pipe threads in accordance with the requirements of ISO 7-1.

4.1 Packaging and Labelling

The packaging must ensure that the fittings are not damaged during transportation.

Packaging and labelling must meet the following requirements:

• Identification of the content, in type, quantity and product details

• Information about standards and approvals covered by the product

• Content of the label has to accomplish legal requirements

• Labels must be EAN coded for automatic identification

• Comply to GF Piping Systems standards as well as to international standards

such as ISPM15

5. Accessories

5.1 Flanges

Backing flanges in metric sizes DN15-300 shall be designed according to EN ISO

15493, in a thermo plastic-oriented design, consisting of 100% glass fibre reinforced

polypropylene, PP-GF30, graphite black and UV stabilized. These flanges are

manufactured in a seamless technology injection moulding process by GF Piping

Systems. The backing flange shall be optimised with a V-groove in the inner diameter

to ensure an evenly distributed force on the thermo plastic flange adapter. The

System Specification ABS metric page 3/ 21

Schaffhausen, June 2018

Page4

- System Specification -

backing flanges shall be marked with dimension, PN-value, standards, brand and lot

number. Connecting dimensions metric according to ISO 7005, EN 1092; Bolt circle

diameter PN 10; Inch: ANSI B 16.5, BS 1560; class 150.

Alternatively backing flanges in metric sizes DN15-300 shall be designed according

to EN ISO 15493, consisting of unplasticised polyvinyl chloride (PVC-U), in a thermo

plastic-oriented design. The backing flanges shall be marked with dimension, PN-

value, standards, brand and lot number. Connecting dimensions metric according to

ISO 7005, EN 1092; Bolt circle diameter PN 10; Inch: ANSI B 16.5, BS 1560; class

150.

5.2 Gaskets

Gaskets in metric sizes DN10-300 shall consist of elastomeric material according to

EN681, designed with or without metal reinforcement for use with solvent cementable

flange adaptors according to EN ISO 15493. Gaskets with reinforcement shall be

designed to be centred by the outer diameter. Gaskets with reinforcement shall

provide fixation aids to fit on the flange bolts.

5.3 Pipe Support System

Pipe Support System shall be KLIP-IT, sizes d10-400, supplied by GF Piping

Systems. The product range includes two different Types of pipe clamps, Type 060

and Type 061. Type 60 is available for d90-400 and shall be made of PP. Type 061

is available for d10-160 and shall be made of PP or PE. Pipe clamps bigger than d40

shall be equipped with a security bow to secure the pipe.

6. Valves

All ABS valves shall be metric sizes manufactured by GF Piping Systems or equal in

accordance with EN ISO 16135 (ball valves), 16136 (butterfly valves), 16137 (check

valves), 16138 (diaphragm valves), tested according to the same standard.

6.1 Ball Valves

All ABS ball valves, with metric sizes DN15-100, shall be GF Piping Systems Type

546 with true double union design manufactured by GF Piping Systems in

accordance with EN ISO 16135. Incorporated into its design shall be a safety stem

with a predetermined breaking point above the upper O-ring, preventing any media

leaking in the event of damage. The valve nut threads shall be buttress Type to allow

fast and safe radial mounting and dismounting of the valve during installation or

maintenance work. Seats shall be PTFE with backing rings creating self-adjusting

seals and constant operating torque. Backing rings and seals shall be EPDM or FKM.

The handle shall include in its design an integrated tool for removal of the union

System Specification ABS metric page 4/ 21

Schaffhausen, June 2018

Page5

6.1.1 Electric Ball Valves

- System Specification -

bush. Union bush shall have left-hand threads to prevent possible unscrewing when

threaded end connectors are removed from pipe.

Following accessories shall be available:

• A Multi-Functional Model (MFM) in PPGF equipped with internal limit switches

for reliable electrical position feedback, is mounted directly between the valve

body and the valve handle. This MFM is also the necessary interface for later

mounting of actuators.

• Mounting plate in PPGF with integrated inserts for later screw mounting on

any support

• Lockable multi-functional handle

6.1.1 Electric Ball Valves

Electric actuators shall be Types EA15 (metric sizes DN10-50), EA25 (metric sizes

DN10-50), EA45 (metric sizes DN65) and EA120 (metric sizes DN80-100) shall be

available manufactured by GF Piping Systems in accordance with EN 61010-1, EC

directives 89/336/EWG-EMV and 73/23/EWG (LVD). Additionally they need to be CE

marked. Actuator housing shall be made of PPGF (polypropylene glass fibre

reinforced), flame retardant with external stainless steel screws. All electric actuators

shall have an integrated emergency manual override and integrated optical position

indication.

All electric actuator types shall have the following accessories available:

Accessories

EA15 / EA25 / EA45 / EA120 / EA250:

• Failsafe return unit

Battery incorporated into the housing for moving to a safe position in case of

power outage (open or closed).

EA25 / EA45 / EA120 / EA250:

• positioner

For continuous valve control with 4-20mA or 0-10V and 4-20mA feedback

• Monitoring board

• Cycle time extension

• Cycle time monitoring

• Cycle counter

• Motor current monitoring

• Fieldbus connection

• Profibus DP auxiliary card

• AS interface module

System Specification ABS metric page 5/ 21

Schaffhausen, June 2018

Page6

- System Specification -

The system Specifications for electric actuators are as follows:

* at rated torque

Specification

Combinations EA15 2-Way Ball valve type 546 bis DN50

3-Way Ball valve type 543 bis DN50

EA25 2-Way Ball valve type 546 bis DN50

3-Way Ball valve type 543 bis DN50

EA45 2-Way Ball valve type 546 bis DN65

Butterfly valve types 567/578, Type 038/039

EA120 2-Way Ball valve type 546 bis DN100

Butterfly valve types 567/578, Type 038/039

EA250 Butterfly valve types 567/578, Type 038/039

Rated voltage AC 100 – 230 V, 50/60 Hz

AC/DC 24 V, 50/60 Hz

Rated voltage tolerance - 10 % …+ 15 %

Protection class IP67per EN 60529

Contamination level 2 according to EN 61010-1

Overload protection Current/time-dependent (resetting)

Overvoltage category II

Ambient temperature -10 °C to +45 °C

Allowable humidity Max. 90% relative humidity, non-condensing

Housing material PP-GF for very good chemical resistance

EA15 EA25 EA45 EA120 EA250

Power input max. 45 VA 45 VA 65 VA 60 VA 70 VA

Rated torque MDN. 10 (20) 10 (25) 20 (45) 60 (120) 100 (250)

(peak)

Duty cycle at 25 °C / 15 40% 100% 50 % 50 % 35 %

min

Cycle time s/90 at Mdn. 5s 5 s 6s 15 s 20 s

Connection F05 F05 F05 F07 F07

Tested cycles (at 20 °C 150 000 250 000 100 000 100 000 75 000

and Mdn.)

Weight 1.85 kg 2.193 kg 2.193 kg 3.356 kg 4.995 kg

Actuating angle Max. 355°, set to 90 °

System Specification ABS metric page 6/ 21

Schaffhausen, June 2018

Page7

- System Specification -

6.1.2 Pneumatic Ball Valves

6.1.2.1 Pneumatic Ball Valves DN15 to DN50

Pneumatic actuators shall be GF Piping Systems Types PA11 (metric sizes DN15-

25) and PA21 (metric sizes DN32-50). Pneumatic actuators shall be available as fail

safe close, fail safe open and double acting and have an integrated optical position

indicator. Actuator housing shall be made of Polypropylene fibre glass reinforced

(PPGF) and flame retardant. Actuators shall contain a preloaded spring assembly to

ensure safe actuator operation and maintenance. Actuators shall contain integrated

Namur interface for the easy mounting of positioners, limit switches and accessories.

The Valve shall be equipped with a Multi-functional-module for reliable electric

feedback, mounted directly between the valve body and the actuator as

manufactured by GF Piping Systems.

6.1.2.2 Pneumatic Ball Valves DN65 to DN100

• For valve size DN65 pneumatic actuators shall be Type PA 30 (fail safe to

close or open function), Type PA35 (double acting function).

• For valve size DN80 pneumatic actuators shall be Type PA 40 (fail safe to

close or open function), Type PA40 (double acting function).

• For valve size DN100 pneumatic actuators shall be Type PA 45 (fail safe to

close or open function), Type PA45 (double acting function)

Pneumatic actuators shall have an integrated optical position indicator. Actuator

housing shall be made of hardened anodized aluminium. Actuators shall contain

integrated Namur interface for the easy mounting of positioners, limit switches and

accessories.

All pneumatically actuated ball valves shall have the following accessories available:

• Pilot valve remote or direct mounted in voltages 24VDC/AC, 110VAC,

240VAC

• Positioner Type DSR 500-3

• Limit switch kits Ag-Ni, Au, NPN, PNP

• Stroke limiter

• Manual override for all sizes up to DN100

• AS Interface Control module with incorporated position feedback and a

solenoid pilot valve

System Specification ABS metric page 7/ 21

Schaffhausen, June 2018

Page8

6.2 Diaphragm Valves

- System Specification -

6.2 Diaphragm Valves

6.2.1 Manual Diaphragm Valves

6.2.1.1 Manual Diaphragm Valves DN15 to DN50

All ABS diaphragm valves, with metric sizes DN15-50, shall be either:

• Type 514 (true double union design, DN15-50)

• Type 517 (flange design, DN15 to 50)

All diaphragm valves shall be manufactured by GF Piping Systems in accordance

with EN ISO 16138. The upper body shall be PPGF (polypropylene glass fibre

reinforced) connected to the lower body with a central union avoiding exposed

screws. A two coloured position indicator integrated into the hand wheel must be

present to determine diaphragm position. The hand wheel shall have an integrated

locking mechanism. Diaphragms are to be EPDM, FKM, NBR, PTFE with EPDM or

FKM backing diaphragm.

Following options shall be available:

• Electrical feedback unit with either AgNi or AU contacts

• Pressure proof housing

The diaphragm valve shall have following KV values:

d DN KV

[mm] [mm] [l/min @ ΔP=1 bar]

20 15 125

25 20 271

32 25 481

40 32 759

50 40 1263

63 50 1728

6.2.1.2 Manual Diaphragm Valves DN65 to DN100

All ABS diaphragm valves, with metric sizes DN65-100, shall be Type 317 (flanged

design). All diaphragm valves shall be manufactured by GF Piping Systems in

accordance with EN ISO 16138. The upper body shall be PPGF (polypropylene glass

fibre reinforced) connected to the lower body with exposed stainless steel bolts. A

position indicator integrated into the hand wheel must be present to determine

diaphragm position. Diaphragms are to be EPDM, FKM, NBR, or PTFE with EPDM or

FKM backing diaphragm.

System Specification ABS metric page 8/ 21

Schaffhausen, June 2018

Page9

- System Specification -

6.2.2 Pneumatic Diaphragm Valves

6.2.2.1 Pneumatic Diaphragm Valves DN15 to DN50

All ABS diaphragm valves, with metric sizes DN15-50, shall be either:

• true double union design, DN15-50

• flange design, DN15-50

All diaphragm valves shall be manufactured by GF Piping Systems in accordance

with EN ISO 16138. The upper body shall be connected to the lower body with a

central union avoiding exposed screws. Diaphragms are to be EPDM, FKM, NBR,

PTFE with EPDM or FOM backing diaphragm.

The diaphragm valve shall have following KV values:

d DN KV

[mm] [mm] [l/min @ ΔP=1 bar]

20 15 125

25 20 271

32 25 481

40 32 759

50 40 1263 (960*)

63 50 1728 (1181*)

* DIASTAR Six

Pneumatic actuators shall be GF Piping Systems Type DIASTAR or 604/605 and

shall be available as

• DIASTAR Six for PN up to 6bar,

• DIASTAR Ten for PN up to 10bar,

• DIASTAR TenPlus for PN up to 10bar both sides

• DIASTAR Sixteen for PN up to 16bar

The mode of operation shall be fail safe close (FC), fail safe open (FO) and double

acting (DA). The valves shall have an integrated optical position indicator. Actuator

housing shall be made of PPGF (polypropylene glass fibre reinforced). Actuators with

FC mode shall contain a preloaded galvanised steel spring assembly to ensure safe

actuator operation and maintenance.

The actuator DIASTAR Ten, DIASTAR TenPlus and DIASTAR Sixteen shall have

following accessories available:

• Solenoid pilot valve remote or direct mounted in voltages 24VDC/AC,

110VAC, 230VAC

• Positioner Type DSR 500-1

• Feedback with following limit switches Ag-Ni, Au, NPN, PNP, NAMUR

System Specification ABS metric page 9/ 21

Schaffhausen, June 2018

Page10

6.3 Butterfly Valves

- System Specification -

• Stroke limiter & emergency manual override

• ASI controller

6.2.2.2 Pneumatic Diaphragm Valves DN65 to DN100

All ABS diaphragm valves, with metric sized DN65-100, shall be flanged design. All

diaphragm valves shall be manufactured by GF Piping Systems in accordance with

EN ISO 16138. The upper body shall be connected to the lower body with exposed

stainless steel bolts. Diaphragms are to be EPDM, FKM, NBR, or PTFE with EPDM

or FKM backing diaphragm.

Pneumatic diaphragm actuators shall be GF Piping Systems Type DIASTAR Type

025. The mode of operation shall be fail safe close (FC), fail safe open (FO) and

double acting (DA). The valves shall have an integrated optical position indicator.

Actuator housing shall be made of PPGF (polypropylene glass fibre reinforced).

Actuators with FC mode shall contain a preloaded galvanised steel spring assembly

to ensure safe actuator operation and maintenance. The actuator DIASTAR 025 shall

have following accessories available:

• Solenoid pilot valve remote or direct mounted in voltages 24VDC/AC,

110VAC, 230VAC

• Positioner Type DSR 500-2

• Feedback with following limit switches Ag-Ni, Au, NPN, PNP, NAMUR

• Stroke limiter & emergency manual override

• ASI Controller

• Stroke limiter & emergency manual override

• ASI Controller

6.3 Butterfly Valves

All ABS butterfly valves, with metric sizes DN50-300, shall be GF Piping Systems

Type 567 (wafer type) or 578 (lug type) with a double eccentric disc design

manufactured by GF Piping Systems in accordance with EN ISO 16136. Butterfly

valves ≥ DN300 are metal butterfly valves. Seals shall be available in both EPDM

and FKM. The lever handle shall be lockable in increments of 5 degrees. There shall

always be six teeth engaged between the ratchet and the index plate to ensure

accurate and safe positioning of the lever. There shall be the option of fine

adjustment by use of a specific hand lever, allowing the disc to be exposed at any

angle between 0° und 90°. As an option, the hand lever shall be lockable. The hand

lever shall be manufactured of high strength PPGF (polypropylene glass fibre

reinforced). The option of an integrated electric position indicator shall be available.

The electric position indicator shall be integrated into the mounting flange. Butterfly

valves shall have low actuation torque to enable easy operation. All butterfly valves

System Specification ABS metric page 10/ 21

Schaffhausen, June 2018

Page11

6.3.1. Electric Butterfly Valves

- System Specification -

Type 567/578 manufactured by GF Piping Systems are designed for a nominal

pressure rate of 10bar.

6.3.1. Electric Butterfly Valves

Electric actuators shall be GF Piping Systems Types EA45/120/250 dependent on

valve size. For valve size from DN350 – 600 with Valpes VS300, VT600 and VT1000.

They shall be manufactured by GF Piping Systems in accordance with EN 61010-1,

as per the above specifications. Actuator housing shall be made of PPGF

(polypropylene glass fibre reinforced), flame retardant and feature external stainless

steel screws. All electric actuators shall have an integrated emergency manual

override and integrated optical position indication.

All electric actuator types shall have the following accessories available:

• Failsafe return unit

Battery incorporated into the housing for moving to a safe position in case of

power outage (open or closed).

• positioner

For continuous valve control with 4-20mA or 0-10V and 4-20mA feedback

• Monitoring board

• Cycle time extension

• Cycle time monitoring

• Cycle counter

• Motor current monitoring

• Fieldbus connection

• Profibus DP auxiliary card

• AS interface module

6.3.2 Pneumatic Butterfly Valves

Pneumatic actuators shall be GF Piping Systems Types PA 35 (metric sizes DN50-

65), PA40 (metric size DN 80), PA45 (metric sizes DN100-125), PA55 (metric sizes

DN150-200), PA60 (metric size DN 200 FC). For valve size from DN350 – 600 with

Revac types. They shall be supplied by GF Piping Systems. Pneumatic actuators

shall be available as fail safe close, fail safe open and double acting and have an

integrated optical position indication. Actuator housing shall be made of hard

anodized aluminium. Actuators shall contain integrated Namur interfaces for the easy

mounting of positioners, limit switches and accessories.

All pneumatically actuated butterfly valves shall have the following accessories

available:

System Specification ABS metric page 11/ 21

Schaffhausen, June 2018

Page12

- System Specification -

• Solenoid pilot valve remote and direct mounted in voltages 230V, 50-60 Hz;

115V 50-60Hz; 24V 50-60 Hz; 24 VDC

• Positioner Type DSR 500-3

• Feedback with following limit switches Ag-Ni, Au, NPN, PNP, NAMUR

• Stroke limiter & emergency manual override

• ASI controller

6.4 Check Valves

6.4.1 Check Valves

All ABS check valves, according to EN ISO 16137, with metric sizes DN10-300 shall

be Type 561 / 562 true union design. Seals shall be EPDM or FKM, optional FFKM.

Union bushes shall have a left hand thread to prevent possible unscrewing when

threaded end connectors are removed from pipe. This valve shall be suitable for

mounting in a vertical and horizontal position. Type 562 shall be equipped with a

spring made of stainless steel (V2A) or as an option stainless steel HALAR coated or

Nimonic 90 to allow position independent installation. The valves are designed for a

nominal pressure of 16bar. Check Valves Type 561 shall be leakproof from a water

column of 2m (0.2bar). Type 561 shall be leakproof from a water column of 1m

(0.1bar).

6.4.2 Angle Seat Check Valves

All ABS Angle Seat Check Valves Type 303 shall be manufactured by GF Piping

Systems according to EN ISO 16137 and overall length according to EN 558-

1, available in metric sizes DN10-50, EPDM or FKM seals and with solvent cement

spigots. The Angle Seat Check Valves shall be leakproof from a water column of 2 m

for EPDM and 3 m for FKM seals as supplied by GF Piping Systems. The Angle Seat

Check valves manufactured by GF Piping Systems are designed for a nominal

pressure rate of 10bar.

6.5 Ventilating- and Bleed Valves

All ABS Ventilating- and Bleed valves shall be GF Piping System Type 591.

Dimensions DN10-100 are with pressure rating PN16. They shall be equipped with a

PP-H floater with density of 0.91 g/cm³.

6.6 Ventilating Valves

All ABS Ventilating Valves shall be GF Piping System Type 595. Dimensions DN10-

100 are with pressure rating PN10. They shall be equipped with a coated stainless

steel spring with minimal opening pressure (10-80 mbar).

System Specification ABS metric page 12/ 21

Schaffhausen, June 2018

Page13

8. Measurement & Control / Instrumentation

- System Specification -

7. Solvent Cement & Cleaner

For adhesive jointings, ABS cement with gap-filling adhesives must be used for

solvent cementing. GF Piping System recommends the Henkel cement system

TANGIT ABS for all ABS solvent cement joints. All specifications are based on using

TANGIT ABS, including strength and chemical resistance.

ABS TANGIT contains app. 20% ABS, dissolved in a blend of solvents. The solvents

soften and macerate the edges of the surfaces they are applied to. Once the solvents

have evaporated, they leave a homogenous joint with the same mechanical, thermo

and chemical properties as of the ABS pipe system.

The jointing surfaces of pipe and fitting must be clean and free of grease. They must

be cleaned with TANGIT cleaner.

8. Measurement & Control / Instrumentation

The following parameters can be measured (Sensors), indicated and/ or transmitted

(transmitters) to PLC, PC and other Data Acquisition Systems. All products comply

with the CE standard.

Parameter Technology Compatible liquids (*)

Flow Paddlewheel clean liquids

Rotameter clean liquids

Magmeter contaminated liquids

Level Hydrostatic/Ultrasonic/Radar all liquids

pH-ORP Glas electrodes all liquids

Conductivity Contact all liquids

Pressure Piezoresistive all liquids

Temperature Pt1000 all liquids

(*) please check first the sensors limitations in material, pressure and temperature (data sheet) and chemical

resistance list

8.1 Sensors

The sensors listed hereafter will transfer the measured value to a GF Piping Systems

Transmitter, to indicate the measured value and allowing simple calibration and

maintenance of the devices. Alternatively the measured values of the sensors can be

sent directly to a PLC, PC or other local made electronics using either an analogue

signal (4-20mA, open collector or sinusoidal voltage) or a digital signal called S3L

(GF Piping Systems Signet serial signal).

System Specification ABS metric page 13/ 21

Schaffhausen, June 2018

Page14

- System Specification -

8.1.1 Installation Fittings

Installation fittings consist of a body out of PP-H or PVC-U with connection elements

PE. Depending on the sensor type, special installation fittings shall be used for

connection to the pipeline: Installation T-Fitting sizes d20-63 with double true union in

PP, Wafer fitting made out of PP-H in sizes d75–315mm and weld-o-let made out of

PE100 in sizes d75–630mm supplied by GF Piping Systems. Sensor thread

connection shall be 1¼" NPSM.

8.1.2 Flow sensors

8.1.2.1 Paddlewheel sensors

515 and 525 sensors:

All sensors of this family are “sinusoidal” sensors. This sensor from GF Piping

Systems SIGNET requires no external power source to produce a signal. Internal to

the body of the sensor is a wire coil which when excited by the rotor assembly

produces a small sinusoidal signal. The rotor assembly consists of four paddles;

inserted into each of the paddles of the rotor are magnets. As liquid flows past the

rotor assembly it rotates each of the four paddles produces a sine wave signal as it

passes the centre of the body (two paddles of the rotor produces a full AC sine

wave).

The sensors as manufactured by GF Piping Systems SIGNET produce a signal

output which is proportional to the flow rate. A K-factor (number of pulses generated

by the sensor per 1 liter or 1 gallon of fluid the sensor) is used to define the size of

the pipe that the sensor is inserted into.

3-2536 and 3-2537 sensors:

All sensors of this family of sensors are “Hall Effect” sensors. Internal to the GF

Piping Systems SIGNET sensors body is an open collector relay. The sensor is

supplied with a voltage from the 3-8550 transmitters or an external power supply

ranging from 5 to 24 volts. This voltage is switched through the open collector relay

as the paddlewheel (rotor) of the sensor rotates. The sensor’s rotor assembly has

four paddles. Inserted in two of the paddles is a magnet. As the paddles pass the

centre of the sensors body, the magnetic field switches the open collector relay on

and off which generates a square wave pulse as manufactured by GF Piping

Systems SIGNET. Two pulses indicates a complete rotation (on/off cycle) of the open

collector relay. The pulse output is directly proportional to the fluid velocity. A K-factor

(number of pulses generated by the sensor per 1 liter or 1 gallon of fluid passing the

sensor) is used to define the size of the pipe that the sensor is inserted into.

System Specification ABS metric page 14/ 21

Schaffhausen, June 2018

Page15

- System Specification -

8.1.2.2 Rotameters

As supplied by GF Piping Systems are radially installed dismountable meters for flow

rate measuring in industrial piping applications. If needed, minimum or maximum flow

can also be monitored via limit switches. Also, analogue flow measurement with a

4…20mA Signal is possible.

The working principle of the rotameter is based in gravity and equilibrium of forces. If

a medium flows upwards at a sufficient flow rate through the vertically mounted taper

tube, the float is raised to the point at which a state of equilibrium sets in between the

lifting force of the medium and the weight of the float. Since the mean rate of flow is

proportional to the quantity flowing through per unit of time, this state of equilibrium

corresponds to the measurement of the instantaneous flow rate.

Following types and sizes are available:

• Type SK, DN10–65mm

• Type 335, DN25–65mm

• Type 350, DN25–65mm

8.1.2.3 Magmeter

The Magmeter sensor from GF Piping Systems SIGNET consists of two metallic pins

that produce a small magnetic field across the inside of the pipe. The The Magmeter

measures the velocity of a conductive liquid (20 μS or greater) as it moves across the

magnetic field produced by the Magmeter. A voltage occurs on the sensor tips, which

is directly proportional to the flow rate of the fluid. The magnetic signal is conditioned

and translated in to a pulse signal. A K-factor (number of pulses generated by the

sensor per 1 liter or 1 gallon of fluid passing the sensor) is used to define the size of

the pipe that the sensor is inserted into. The Magmeter of GF Piping Systems

SIGNET is offered as a blind frequency, 4-20 mA or digital S3L output, or with

integral display and control relays.

8.1.2.4 Ultrasonic Flowmeter

The U3000/4000 and PF220/330 from GF Piping system are transit time ultrasonic

flow meter designed to work with clamp-on transducers, to provide accurate

measurement of liquid flowing within a closed pipe, without the need for any

mechanical parts to be inserted through the pipe wall or to protrude into the flow

system. It takes just a few minutes to install and there is no need to shut down flow or

drain the system! From process control in industrial applications, to water

management from raw to deionized water, the Ultraflow 3000/4000 for fixed

installation and the PF220/330 for portable flow monitoring cover a wide spectrum of

flow monitoring and process control in many industries.

System Specification ABS metric page 15/ 21

Schaffhausen, June 2018

Page16

- System Specification -

Using ultrasonic transit time techniques enables to be used with pipes having an

outside diameter range from d13 to d2000 as standard and up to d5000 as an option.

The instruments will also operate over a wide range of fluid temperatures. All of the

Ultrasonic Flowmeters have the same basic features.

However, the standard U4000 and PF330 can also perform data logging and allows

site details and flow data to be reordered with a memory, that is able to log more than

150 000 separate readings. The standard U4000 and PF330 is also capable of

downloading the stored data via the USB or RS232 interface to the Portagraph

software supplied with the unit.

8.2 Level Sensor and Level Switches

8.2.1 Hydrostatic Level Sensors

Hydrostatic pressure is the pressure exerted on a column of fluid by the weight of the

fluid above it. Internal to the GF Piping Systems SINGET PVDF sensor body is a

ceramic diaphragm sensor and capillary tube/cable assembly. The ceramic

diaphragm sensor exposed to the fluid senses the hydrostatic pressure of the fluid

and compares the pressure to the atmospheric pressure monitored the capillary

tube/cable assembly. The hydrostatic level sensor from GF Piping Systems SIGNET

only senses the hydrostatic pressure of the fluid. The Level Sensor is offered as a

blind output 4-20 mA or digital S3L output connected to the GF Piping Systems

SIGNET Transmitter unit.

8.2.2 Ultrasonic Level

8.2.2.1 Ultrasonic Level Sensors (Series 2260 / 2270)

Ultrasonic level sensors are non-contact devices, using the travel time of sound and

its reflection, for measuring the distance to a liquid or solid surface. Based on this

information, GF Piping Systems sensors are capable of calculating a liquid level or

volume. Their outstanding narrow 5° beam, allow reliable measurement even at the

presence of disturbing objects or when space is limited. The GF Piping Systems

portfolio contains sensing ranges 4 m, 6 m and 15 m.

Sensors with integrated display or blind sensors are available and provide 4-20 mA,

HART protocol or relay outputs. GF Piping Systems ultrasonic level sensors are

compatible with GF Piping Systems transmitters, indicators, controllers and valve

actuators.

8.3 Radar

8.3.1 Radar 2290

The 25 GHz (K-band) 2290 Pulse Radars are the most progressive non-contact level

transmitters for industrial processes. With an excellent accuracy, compact antennas

and a user-friendly set-up the 2290 is an effective, simple, low cost choice for

demanding level applications. GF’s new K-band radar featuring 3 mm (0.1inch)

System Specification ABS metric page 16/ 21

Schaffhausen, June 2018

Page17

- System Specification -

accuracy and short dead band excels with its robust full plastic housing. Its antenna

range incorporates a stainless steel horn and enclosed plastic tube choices. The

enclosed antenna versions can be replaced without removing the antenna enclosure

from the process. Local programming of type 2290 is aided by a plug-in display

module. The signal processing algorithm of the 2290 is based on years of experience

with non-contact level measurement making it an excellent choice for applications

simple and challenging alike. Process enclosures are available in PTFE, PP & PE

8.3.2 Radar 2291

With its ability to read accurately when other non-contacting or invasive methods fail,

the guided level transmitter type 2291 using GWR (guided wave radar) is the solution

to your level needs.

The radar signal is sent down the probe assembly eliminating the interferences

caused by low dielectric liquids, heavy fuming, slightly conductive foams, internal

tank obstructions, etc. By focusing its energy along the probe, the type 2291 can be

installed in tanks with limited space. The type 2291 is also less sensitive to

turbulence that would normally upset the readings in ultrasonic and unguided radar

technologies. The probes are also available as coated options in FEP & PFA

8.4 Point Level Switches (Series 2280)

The GF Piping Systems portfolio of point level switches contains various different

detection technologies, to provide a solution for various liquids and application

requirements.

• Type 2280

Vibration Forks detect a liquid level with two vibrating stainless steel wings. In

air they vibrate with a specific, calibrated frequency. By the contact with a

liquid the frequency changes which forces an electrical output to switch. GF

Piping Systems vibration forks are equipped with digital PNP/NPN or relay

output. Versions with ATEX or WHG approval are available.

• Type 2281

Conductive Multipoint Switch contains up to 5 stainless steel electrodes, which

allow to detect 4 different liquid levels in a tank. Up to 2 external relay pairs

allow to switch pumps or valves. GF Piping Systems conductive multipoint

switches work with liquids of min. 10µS conductivity.

Their four-in-one design allows fast installation and provides attractive

solutions concerning costs.

• Type 2282

Guided Float Switches are equipped with an air filled float with embedded

magnet. Rising liquid lifts up the float. The magnetic field forces a reed contact

to switch. GF Piping Systems guided float switches are available in PP and

PVDF to provide best chemical compatibility to corrosive liquids.

System Specification ABS metric page 17/ 21

Schaffhausen, June 2018

Page18

- System Specification -

• Type 2284

Ultrasonic Gap Switches are equipped with an ultrasonic transducer and

receiver in their fork tips. Based on the switch design, the sound waves are

damped in air. Thus the output is disabled. In contact with liquid the sound

waves start to travel from transmitter to receiver, which enables the output. GF

Piping Systems ultrasonic gap switches provide an electronic relay output

which allows to control pumps and valves. Thanks to their PPS full-plastic

body they provide a very high resistance against mechanical impacts and

corrosive liquids. They work with no moving parts, so they do not require any

maintenance.

• Type 2285

Float Switches are primarily used in open basins and pump shafts for

detecting liquid level. In an empty tank they hang in vertical position, attached

to the tank wall at their cable. Rising liquid carry them on the liquid surface. At

an angle of approximately 45° an integrated switch is enabled. GF Piping

Systems float switches are double chambered and equipped with a mercury-

fee switch. Hence they may be used for drinking and for waste water

applications.

8.5 Analytic

8.5.1 pH Sensors

All pH sensors from GF Piping Systems SIGNET are constructed commonly called

combination electrodes. The measuring cell is constructed of hydrogen sensitive

glass that can detect the concentration of hydrogen ions (+H) in a solution. The

concentration of +H ions directly determines the pH of the fluid. The reference cell is

used to provide a stable reference signal. The pH signal is measured against the

stable reference signal. The reference junction allows the reference cell to come in

contact with the fluid being measured. The measured signals are then conditioned

and sent as a blind 4-20 mA or as a digital S3L signal to the GF Piping Systems

SIGNET Transmitter unit.

8.5.2 ORP Sensors

All ORP sensors from GF Piping Systems SIGNET are constructed similar to the pH

sensors, except that a noble metal like platinum or gold replaces the silver chloride

element of the measuring and reference cell of the pH electrode. Temperature

compensation is not used in ORP measurements as well. ORP is an abbreviation for

Oxidation-Reduction Potential. Oxidation is a term used to denote the occurrence of

a molecule losing an electron. Reduction occurs as a molecule gains an electron.

The “potential” is simply an indication of a solution’s propensity to contribute or

accept electrons. ORP reactions (sometimes referred to as REDOX) always take

System Specification ABS metric page 18/ 21

Schaffhausen, June 2018

Page19

- System Specification -

place simultaneously. There is never oxidation without reduction, and ORP

electrodes are used to detect electrons exchanged by molecules as these reactions

occur. The measured signals are then conditioned and sent as a blind 4-20 mA or as

a digital S3L signal to the GF Piping Systems SIGNET Transmitter unit.

8.5.3 Conductivity Sensors

All Conductivity sensors from GF Piping Systems SIGNET are manufactured using

two stainless steel electrodes. Alternative materials are available in case of chemical

incompatibility. Conductivity sensors measure the ability of a fluid to conduct an

electrical current between two electrodes. The proper term for this ability of a solution

is electrolytic conductivity, since only ions conduct electric current in solution.

Electrolytic conductivity (or simply conductivity) is therefore an indirect measure of

the ionic concentration of a solution. Generally, conductivity increases and decreases

with the concentration of ions.

Most conductivity electrodes consist of two measuring half-cells. The geometry of the

half-cells can be tailored to provide highly accurate measurements over a specific

conductivity range. Cell constants help to describe electrode geometry for the

purpose of selecting the appropriate electrode for a given application.

A cell constant is defined as the length between the two half cells divided by the area

of the cells. All conductivity sensors have a temperature compensation circuits in

order to increase the sensors accuracy.

The measured signals are then conditioned and sent as a blind 4-20mA or as a

digital S3L signal to the GF Piping Systems SIGNET Transmitter unit.

8.6 Multi Parameter Instruments

8.6.1 Transmitters

The GF Piping Systems Signet 9900 Transmitter provides a single channel interface

for many different parameters including Flow, pH/ORP, Conductivity/Resistivity,

Salinity, Pressure, Temperature, Level and other sensors that output a 4 to 20 mA

signal. The display shows separate lines for units, main and secondary

measurements as well as a dial-type digital bar graph.

The 9900 is offered in both panel or field mount versions. Both configurations can run

on 12 to 32 VDC power (24 VDC nominal). The 9900 can also be loop powered with

compatible sensors.

Designed for complete flexibility, plug-in modules allow the unit to easily adapt to

meet changing customer needs. Optional modules include Relay, Direct

Conductivity/Resistivity, H COMM and a PC COMM configuration tool.

• 1 sensor input (Flow, pH/ORP, Conductivity/Resistivity, Salinity, Pressure,

Temperature, Level and other sensors that output a 4 to 20 mA signal, Signet

8058 i-Go™ Signal Converter required)

System Specification ABS metric page 19/ 21

Schaffhausen, June 2018

Page20

9. Quality

- System Specification -

• 1 analogue output (4-20 mA)

• 1 Open Collector output

• Optional relay module with 2 Dry Contact Relay SPDT

• Power supply 12-32 VDC

The GF Piping Systems Signet 8900 Multi-Parameter Controller takes the concept of

modularity. Each 8900 is field commissioned with the users specified combination of

inputs, outputs, and relays using simple-to-install modular boards into the base unit.

Configure the system by selecting either two, four, or six input channels which

accepts any of the Signet sensors listed below, and/or other manufacturer's sensors

via a 4 to 20 mA signal converter (Signet Model 8058). To complete your unit, choose

a power module with universal AC line voltage or 12 to 24 VDC. Analog output and

relay modules are available and easily installed. Derived measurements include

difference, sum, ratio, percent recovery, percent rejection, percent passage and BTU.

The menu system can be programmed to display in multi-languages including

English, German, French, Spanish, Italian, and Portuguese.

• 2,4 or 6 sensor input (Flow, Level, pH-ORP, Conductivity, Pressure

Temperature)

• 0,2 or 4 analogue output (4-20 mA or 0-10 Volts)

• 0,2,4,6 or 8 relay output

• Power supply 12-30 VDC or 110-230 VAC

8.7 Batch Control

The batch controller manufactured by GF Piping Systems Signet Type 5600 allows

batching a pre-selected quantity of liquid. After selection of the quantity to be dosed,

a start signal (local or remote) will close a batch controller contact to energize or de-

energize a valve and/or switch on a pump. The batch controller count the pulses

coming from any Signet sensor with frequency output and stop the batch process as

the pre-selected quantity is reached. Advanced features include a user-set security

code, an automatic calibration option, and overrun compensation The batch process

is repeatable and is designed for intensive industrial applications.

9. Quality

9.1 Production Conditions

Pipes, fittings, solvent cement, cleaner, valves and accessories shall be

manufactured in an environment operating a Quality Assurance System to ISO 9001

and an Environmental Management System conform to ISO 14001.

System Specification ABS metric page 20/ 21

Schaffhausen, June 2018