1/8ページ

ダウンロード(10Mb)

統合型マシンビジョン

インテリジェントなVISIONカメラ、革新的な照明機器、および高度な画像処理アルゴリズム - B&Rは統合型マシンビジョンソリューションを新たなレベルに引き上げています。既存のアプリケーションをより速く生産的にするだけでなく、マシンメーカがこれまで不可能だったアプリケーションを実現することも可能にします。

B&Rのホームページにて、製品の詳しい内容をご覧いただけます。

製品に関するお問い合わせやご質問等は、弊社営業までご連絡ください。

関連メディア

このカタログについて

| ドキュメント名 | 産業用画像処理システム Vision System |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 10Mb |

| 登録カテゴリ | |

| 取り扱い企業 | B&R株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

Integrated machine vision

エンベデッドからさらに進化へ

MM-FO-CO-VI-JP-02

© 01/2019 by B&R.All rights reserved worldwide.

Page2

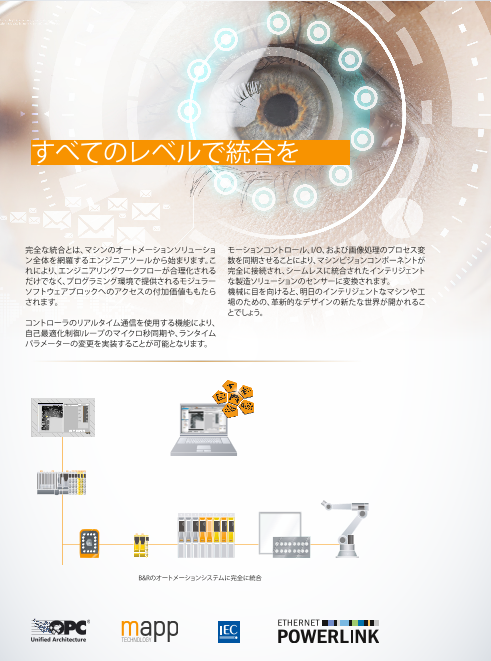

すべてのレベルで統合を

完全な統合とは、マシンのオートメーションソリューショ モーションコントロール、I/O、および画像処理のプロセス変

ン全体を網羅するエンジニアツールから始まります。こ 数を同期させることにより、マシンビジョンコンポーネントが

れにより、エンジニアリングワークフローが合理化される 完全に接続され、シームレスに統合されたインテリジェント

だけでなく、プログラミング環境で提供されるモジュラー な製造ソリューションのセンサーに変換されます。

ソフトウェアブロックへのアクセスの付加価値ももたら 機械に目を向けると、明日のインテリジェントなマシンや工

されます。 場のための、革新的なデザインの新たな世界が開かれるこ

とでしょう。

コントローラのリアルタイム通信を使用する機能により、

自己最適化制御ループのマイクロ秒同期や、ランタイム

パラメーターの変更を実装することが可能となります。

B&Rのオートメーションシステムに完全に統合

ACOPOSmulti

ACOPOSmulti

ACOPOSmulti

ACOPOSmulti

ACOPOSmulti

ACOPOSmulti

Page3

エンベデッドを超えて

マシンビジョンシステムの現在のトレンドと、ユーザーフ マシンへの必要な接続をセットアップすることは、引

レンドリーなエンジニアリングツールの継続的な改善 き続き大きな課題です。コストを上げるか、システム全

は、歓迎すべき開発です。 それはコンピュータを使った 体のパフォーマンスに不必要な妥協を強いるかなど

画像処理をマシンの設計全体に統合することが容易に 山積しています。

なってきています。

革新的なソリューションプロバイダーが直面する課題

自動化コンポーネントは完全に統合されていますが、画像 は、画像処理を表面的なアドオンからマシンコンセプト

処理は依然として孤立した領域です。 の不可欠な部分に変換することです。

unicati men

mm on lop

e t &

tion odevel

Control Safety

& light co & co

mp

g n

ac

d t

Motion

g & dat

HMI

in

a a

マシンビジョンコンポーネントの基礎的な統合

Lightin

eal-

time c

R o

Monitor

pement

Visio

n deve

PC-base

stemssy

isua

lizatio

V n

lysis

na

Automa

trigge& ri ng

roll

er

t

Page4

優れたパフォーマンス

パワフルでエネルギー効率の高いエンベデッドビジョンシステム用プロセッサの可用性により、PCベースのソリューションと

コンパクトなソリューションの境界があいまいになっています。オートメーションへの完全な統合により、同期、視覚化、通信

のためのリソース集約の後処理が不要になります。

高度な照明システム、トリガー、前処理ソリューションにより、さらに多くのリソースを解放できます。複雑な画像処理およびマ

シン制御ソリューションを使用して、より多くの処理能力が利用可能です。

この順応性の高いシステムは、アプリケーションの要件に合わせて効率的に調整できます。統合型マシンビジョンのコンセプ

トは、マシン設計全体に基本的なメリットを提供します。

デザイン オプション 可視領域 ハイスピード

350 texp = 1 µs

300

250

200

150

100

50

0

50

100

150

200

250

300

350

200 400 600 800 1000 texp = 0.1 ms

フレキシブルなレンズ 近赤外線1000nmまでのアプリケーション 高速シャッター

4.6mm

6mm

8mm

12mm

16mm

25mm

Page5

Integrated machine vision:

The vision-enhanced future of automation

ハイライト

< マイクロ秒精度の照明コントロール

< 外部光に対する耐性と高性能LED

< あらゆる状況に自動適応

キャリブレーション 計測 画面方向 OCR読み取り

< 標準化 < 長さ < エッジ < データの有無

< 収差 < エリア < シェイプ ABC < 表面

Page6

Integrated machine vision:

The vision-enhanced future of automation

ハイライト

< 1台で多くの機能

< 電子フォーカス設定

< FPGA による強力な前処理

< 工場でのキャリブレーションによる簡単な

交換

強力なマルチコアプロセッサ

16個のハイパワーLED

高解像度の光学系

設定可能なステータス

インジケータ

リアルタイムのフラッシュ照明

(ジッター<1µs)

電子フォーカス設定

さまざまなフィルター

IP67保護

ハイブリッドケーブル接続 デイジーチェーン用の統合ハブ

OCR読み取り コード読み取り 認識 データ処理 マッチング

< データの有無 < データコード < ポジション < フィルター < 幾何学

< 表面 < テキスト/数字 < ロケーション < 変換 < カラー

Page7

並外れた多能性

従来のビジョンセンサーとは異なり、B&Rのスマートソリューションは単一の機能に限定されません。コードリーダーまたは測

定デバイスとしてセンサーをどのように使用するか - その質問は購入のタイミングではなく、アプリケーションの後半で回答す

ることでしょう。ロジスティクスの合理化に加えて、これは、変化する要件を満たすために歓迎される敏速性をもたらします。

関連するタスクの複雑さに応じて、業界固有のソリューションを作成することもできます。センサーは、はるかに広範なアプリ

ケーションに対応しています。

すべてのセンサーの画像処理機能を処理できるスマートカメラでも、同じ柔軟性が順次提供されます。センサーの機能要件

が変更された場合でも、システムは新たな開発作業を追加せずに、プラットフォームを簡単にアップグレードできます。

フレキシブル 高信頼性 高精細

適応可能な機能 堅牢なアルゴリズム サブピクセル測定

Page8

Integrated automation

Global presence

Solid partnership

B&R 日本法人 神奈川県横浜市西区高島1-1-2 t 045 263 8460 office.jp@br-automation.com 最寄りのご連絡先

B&R株式会社 横浜三井ビル f 045 263 8461 www.br-automation.com/ja/ www.br-automation.com/contact

MM-FO-CO-VI-JP-02

© 01/2019 by B&R.All rights reserved worldwide.