1/8ページ

ダウンロード(2.2Mb)

超高速枚葉式スパッタ装置 SOLARISファミリー

『SOLARISファミリー』は、1枚当たり最速3秒の成膜を可能としたインライン式生産プラットフォームです。

5000台を超える高速光ディスク用システムを納入したノウハウと、

3000台を超える半導体用PVD装置から得られた経験を組み合わせて、

薄膜の大量生産における新しいアプローチを提供。

「完全に自動化された工場」向けに設計されており、スループットを

向上させ、手動処理を排除します。

【特長】

■基板成膜に「インライン」式アーキテクチャを導入

■「完全に自動化された工場」向けに設計

■スループットを向上させ、手動処理を排除

■柔軟性の高いプロセス向けの高速生産ソリューションを提供

※詳しくは関連リンクをご覧いただくか、お気軽にお問い合わせください。

このカタログについて

| ドキュメント名 | SOLARIS |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 2.2Mb |

| 登録カテゴリ | |

| 取り扱い企業 | 日本エバテック株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

SOLARIS

PLATFORMS

Fully automated solutions

for thin film production

Page2

NEW THINKING IN

PVD PRODUCTION

A NEW APPROACH TO MANUFACTURING -

FAST, ACCURATE, RELIABLE

SOLARIS platforms combine the know how from delivering over 5000 high speed

optical disk systems with experience gained from over 3000 semiconductor PVD

tools to deliver a new approach in thin film mass production.

From Touch Panels to Thermoelectric Generators, Power Devices to

Photovoltaics, SOLARIS S151 and S380 platforms deliver flexible high speed

manufacturing solutions for both rigid and flexible substrates up to 15 inch

diagonal.

SOLARIS capabilities in a nutshell

— High speed sputter processing

— Full integration into automated fab

— Dielectrics, metals, metal oxides & TCOs

— Antireflection and Antismudge Coatings

— Small footprint for reduced cleanroom costs

2

Page3

SOLARIS

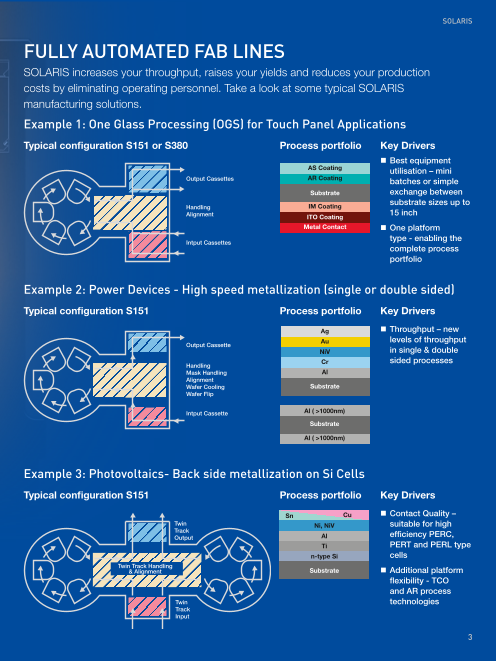

FULLY AUTOMATED FAB LINES

SOLARIS increases your throughput, raises your yields and reduces your production

costs by eliminating operating personnel. Take a look at some typical SOLARIS

manufacturing solutions.

Example 1: One Glass Processing (OGS) for Touch Panel Applications

Typical configuration S151 or S380 Process portfolio Key Drivers

Best equipment

AS Coating utilisatSionn – mini Cu Ag

Output Cassettes AR Coating batches or simNpi, lNei V Au

exchange betweAel n NiV

Substrate

Output Cassettes substrate sizes uTip to Cr Al ( >1000nm)

Handling IM Coating n-type Si Al

Alignment Substrate

ITO Coating 15 inch

Metal Contact Substrate Substrate

One platform Al ( >1000nm)

Handling

Alignment type - enabling the

Intput Cassettes

Output Cassettes complete process

portfolio

Intput Cassettes

Handling

Example 2: Power Devices - HAliiggnmhe nst peed metallization (single or double sided)

Typical configuration S151 Intput Cassettes Process portfolio Key Drivers

Output Cassette

AS Coating Sn Cu Ag Throughput – new

AR Coating NH levels of throughput

Oai,un Ntpdi

uli

V

tn Cg

Au

assette

MaAslk Handling NiV in single & double

Substrate Alignment

WaTfei r Cooling Cr sided proceAsHandling l s( e>1s000nm)

IM Coating nWM-tyaapsfeker HFSaliipndling Al

AS Coating Substrate

Sn ITO CoatingCu AliAggnment

AR Coating MetNail, CNoiVntact SubAsutrate Substrate

IWafer Cooling

WO

nutpatfpeut r t

C

F C

a

lipa

sssseetttete Al ( >1000nm)

Al NiV

Substrate

Ti IHnatCpnurdtl inCgassette Al ( >1000nm)

IM Coating n-type Si MaAslk Handling

Substrate

ITO Coating Alignment

Metal Contact Substrate SuWbasfterra Cteooling

Wafer Flip Al ( >1000nm)

Twin

TrackIn tput Cassette

Output

Example 3: Photovoltaics- BTwain ck side metallization on Si Cells

Track

Typical configuration S151 Output

Twin Track Handling Process portfolio Key Drivers

& Alignment

AS Coating Sn Cu Contact QualityA –g

Twin Track Handling

& Alignment TwAinR Coating Ni, NiV suitable for highA u

TTrwacink

O efficiency PERC,

Truatput Al NiV

Scukb strate

Input Ti PERT and PERLC trype Al ( >1000nm)

TwIMin Coating n-type Si cells Al

Track Substrate

Twin Track Handling ITO Coating

& Alignment Input

Metal Contact Substrate Additional plaSutfbosrtrmat e Al ( >1000nm)

flexibility - TCO

and AR process

Twin technologies

Track

Input

3

Page4

SOLARIS S151

MAIN FEATURES

— Substrates sizes up to 8 inch diagonal or mini batches

— Single substrate / carrier processing at throughputs up

to 1200 pieces / hour**

— Up to 6 process stations for RTP, PVD, Etch or CVD

SOLARIS S151 carrier for flexible substrate sizes: 3.5” to 8” (max. area Ø220mm)

2” carrier 3.5” carrier 8” carrier 8” carrier

** C ycle times according exact process

Carrier Ø 245mm

Page5

SOLARIS S380

MAIN FEATURES

— Substrates sizes up to 15 inch diagonal or mini batches

— Single substrate / carrier processing at throughputs

up to 900 pieces/hour**

— Up to 5 process stations for RTP, PVD, Etch or CVD

SOLARIS S380 carrier for flexible substrate sizes: 3.5” to 15” (max. area Ø380mm)

8” carrier 12” carrier 15” carrier EMI carrier

** C ycle times according exact process

Carrier Ø 430mm

Page6

THE POWER

BEHIND SOLARIS

SOLARIS SUBSTRATE

HANDLING -

SPEED AND FLEXIBILITY

Whether you choose the S151 or S380 platform you

can handle glass, silicon or polymeric substrates

with ease. Parallel carrier transfer around SOLARIS

by synchronous indexer is the perfect solution to

achieve high speed processing and lowest cost of

ownership in mass production applications.

— Carriers for individual substrates or mini

batches without compromise on process

uniformity

— Simple conversion between rigid,

2.5D substrates & foils

— Make multiple passes in front of process

stations for complex stack designs

— Change direction of indexer travel enabling

sputter in reverse order for more process

flexibility

6

Page7

SOLARIS

SOURCE TECHNOLOGY

From EMI shielding applications to Thermoelectric Generators,

SOLARIS brings you advanced source technologies for

deposition of metals, alloys, oxides, dielectrics and TCOs.

SOLARIS SOURCE TECHNOLOGY -

SPEED WITHOUT COMPROMISE

IN FILM QUALITY

Choose from large area single DC, DC Reactive or RF sputter

with cooling, etch and RTP capabilities up to 550ºC , or

Evatec multisource capability for up to 4 sputter cathodes

at a single process station. All process modules run

independently in isolation and are configured according to

your application.

— Dielectrics: SiN-H, SiN, SiO2, Al2O3, SiC

— Metal Oxides: NbO2, TiO2, Ta2O5

— TCOs: ITO, GZO, Zn:AlO

— Metal stacks: Al, NiV, Ag, AuGe

— Alloys with MSQ multisource

— Deposition uniformities <±2% over whole carrier

PENTA PLUS

CATHODE

TECHNOLOGY

Penta Plus cathode technology

delivers perfect step coverage

in deposition of alloys in EMI

shielding and reduces both

consumables costs and target

change times

7

Page8

SOLARIS Platform summary

Fully automated production solutions

From Touch Panels to Thermoelectric Generators, Power

Devices to Photovoltaics, SOLARIS platforms deliver High-throughput on substrates sizes up to 15” diagonal

flexible high speed manufacturing solutions. Flexible configurations

TYPICAL LAYOUTS

SOLARIS S380

SOLARIS S151

ABOUT EVATEC

Evatec offers complete solutions for thin film deposition Our team is ready to offer process advice, sampling

and etch in the semiconductor, optoelectronics and services and custom engineering to meet our customers

photonics markets. individual needs in platforms from R&D to prototyping and

true mass production.

Our technology portfolio includes standard and enhanced

evaporation, a range of advanced sputter technologies as We provide sales and service through our global network

well as plasma deposition & etch. of local offices.

For more information visit us at www.evatecnet.com or contact our head office.

Evatec AG Tel: + 41 81 403 80 00 Product descriptions, photos and data are supplied within the

brochure for general information only and may be superseded

Hauptstrasse 1a Fax: + 41 81 403 80 01 by any data contained within Evatec quotations, manuals or

CH-9477 Trübbach info@evatecnet.com specifications.

Edition 3: Reprinted March 2018, first printed June 2017.

Switzerland www.evatecnet.com (Edition 2 first printed Jan 2016, Edition 1 first printed Sep 2015).

EVA_Brochure_SOLARIS_Edition3_March2018