1/25ページ

ダウンロード(4.8Mb)

FineTek製 電磁流量計 EPD Series の製品カタログです。

FineTek Co., Ltd.は、1978年に設立された上場企業で、レベル,液面計測,ニューマチック振動機器,温度・圧力・回転速度計測関係などを製造するメーカーです。

FineTek Co., Ltd. (桓達科技股份有限公司)

FineTek製品について、ご質問等がございましたら、

「aperza@tobe.jp」へメールにてお問い合わせください。

Electromagnetic Flow Meter

EPD30 Standard type

EPD34 Remote type

関連メディア

このカタログについて

| ドキュメント名 | FineTek 電磁式流量計 カタログ |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 4.8Mb |

| 登録カテゴリ | |

| 取り扱い企業 | トベ電機株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

頁面 1

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

EPD A PPLICATION / ORDER FORM

Company Profile

Company Name: Contact Person: Flow range (m3/h)

Pipe diameter (mm)

E-mail: Phone: Tax: Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/s

40 0.45~4.5 4.5~45.2

Application

50 0.71~7.1 7.1~71

Medium: Temperature: Sanitary Degree Request� Yes NO 65 1.19~11.9 11.9~119

Conductivity: Viscosity: 80 1.81~18.1 18.1~181

Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: 100 2.83~28.3 28.3~283

125 4.42~44.2 44.2~442

(m3 3 3Normal Flow Rate /h): Max. Flow Rate(m /h): Min. Flow Rate(m /h):

150 6.36~63.6 63.6~636

Connection Spec: Connection Material**:

200 11.3~113 113~1130

Pressure(Kg/m3) 3: Max. Static Pressure(Kg/m ): **SUS304, SUS316, SUS316L

250 17.7~177 177~1770

Lining Material*: Electrode Material***: 300 25.4~254 254~2540

* PTFE、NBR、Neoprene

* **SUS316,Hastelloy Alloy,Titanium,Tantalum

P ower: 110Vac 220Vac 24Vdc

Output : 4-20mA /Pulse(ferq) R S-485/Modbus ERROR OF RATE (%)

Grounding : NO YE S

0.2% 0.3% 0.5% www.fine-tek.com

CL II=2%

Installation Directio n: Horizo ntal Vertic al

5.0 ERROR OF RATE (%)

Vibration Inside Tube : NO YES

4.0 0.2% 0.3% 0.5%

Strong Magnetic Near by: NO YES

2.0

Explosion Proof: NO YES 3.0

Explosion Proof Code: 2.0

Electromagnetic Flow Meter 1.5

1.0

1.0

0.0

Q1 Q2 Q3 Q4

0.5

0.0

0 1 2 3 4 5 6 7 8 9 10 11 12

VELOCITY (M/S)

Page2

頁面 2

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

EPD A PPLICATION / ORDER FORM FLOW MEASUREMENT FIELD

Company Profile

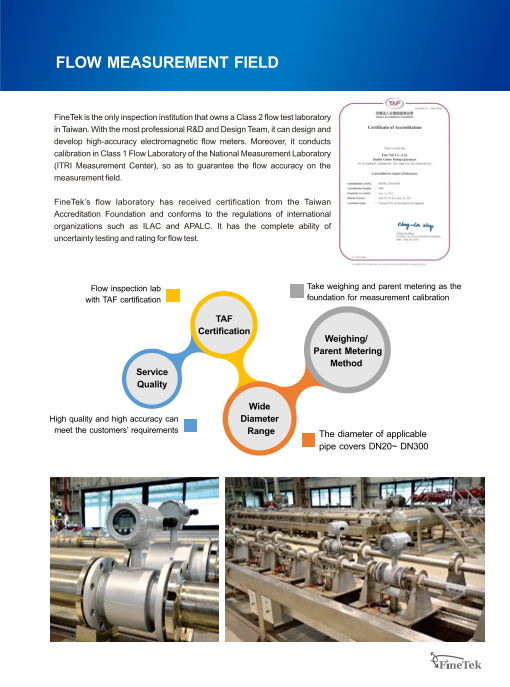

Company Name: Contact Person: FineTek is the only inspection institution that owns a Class 2 flow test laboratory Flow range (m3/h)

in Taiwan. With the most professional R&D and Design Team, it can design and Pipe diameter (mm)

E-mail: Phone: Tax: Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/s

develop high-accuracy electromagnetic flow meters. Moreover, it conducts

calibration in Class 1 Flow Laboratory of the National Measurement Laboratory

40 0.45~4.5 4.5~45.2

(ITRI Measurement Center), so as to guarantee the flow accuracy on the

Application

measurement field.

50 0.71~7.1 7.1~71

Medium: Temperature: Sanitary Degree Request� Yes NO 65 1.19~11.9 11.9~119

FineTek’s flow laboratory has received certification from the Taiwan

Conductivity: Viscosity: Accreditation Foundation and conforms to the regulations of international 80 1.81~18.1 18.1~181

organizations such as ILAC and APALC. It has the complete ability of

Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: 100 2.83~28.3 28.3~283 uncertainty testing and rating for flow test.

125 4.42~44.2 44.2~442

3 3

Normal Flow Rate(m /h): Max. Flow Rate(m /h): Min. Flow Rate(m3/h):

150 6.36~63.6 63.6~636

Connection Spec: Connection Material**:

Flow inspection lab Take weighing and parent metering as the 200 11.3~113 113~1130

Pressure(Kg/m3) 3: Max. Static Pressure(Kg/m ): **SUS304, SUS316, SUS316L with TAF certification foundation for measurement calibration

250 17.7~177 177~1770

Lining Material*: Electrode Material***: TAF 300 25.4~254 254~2540

Certification

* PTFE、NBR、Neoprene Weighing/

* **SUS316,Hastelloy Alloy,Titanium,Tantalum Parent Metering

Method

Service

P ower: 110Vac 220Vac 24Vdc Quality

Output : 4-20mA /Pulse(ferq) R S-485/Modbus ERROR OF RATE (%) Wide

Grounding : NO YE S

0.2% 0.3% 0.5% High quality and high accuracy can Diameter

CL II=2% Installation Direction: Horizontal Vertical

5.0 meet the customers’ requirements Range ERROR OF RATE (%)The diameter of applicable

Vibration Inside Tube : NO YES pipe covers DN20~ DN300

4.0 0.2% 0.3% 0.5%

Strong Magnetic Near by: NO YES

2.0

Explosion Proof: NO YES 3.0

Explosion Proof Code: 2.0

1.5

1.0

1.0

0.0

Q1 Q2 Q3 Q4

0.5

0.0

0 1 2 3 4 5 6 7 8 9 10 11 12

VELOCITY (M/S)

Page3

頁面 3

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

EPD A PPLICATION / ORDER FORM FLOW MEASUREMENT FIELD

Company Profile

Company Name: Contact Person: Flow range (m3/h)

Pipe diameter (mm)

E-mail: Phone: Tax: Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/s

40 0.45~4.5 4.5~45.2

Application

50 0.71~7.1 7.1~71

Medium: Temperature: Sanitary Degree Request� Yes NO 65 1.19~11.9 11.9~119

Conductivity: Viscosity: PUMP equipment Weighing equipment Control room & Graphical HMI 80 1.81~18.1 18.1~181

(The maximum horsepower

Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: 100 2.83~28.3 28.3~283 is 110KW per unit)

125 4.42~44.2 44.2~442

(m3/h) (m3/h) (m3Normal Flow Rate : Max. Flow Rate : Min. Flow Rate /h):

150 6.36~63.6 63.6~636

Connection Spec: Connection Material**:

200 11.3~113 113~1130

(Kg/m3) (Kg/m3Pressure : Max. Static Pressure ): **SUS304, SUS316, SUS316L

250 17.7~177 177~1770

Lining Material*: Electrode Material***: 300 25.4~254 254~2540

* PTFE、NBR、Neoprene

* **SUS316,Hastelloy Alloy,Titanium,Tantalum

P ower: 110Vac 220Vac 24Vdc

Output : 4-20mA /Pulse(ferq) R S-485/Modbus ERROR OF RATE (%)

Grounding : NO YE S

0.2% 0.3% 0.5%

CL II=2%

Installation Directio n: Horizo ntal Vertic al

5.0 ERROR OF RATE (%)

Vibration Inside Tube : NO YES

4.0 0.2% 0.3% 0.5%

Strong Magnetic Near by: NO YES

3.0 2.0Explosion Proof: NO YES

Explosion Proof Code: 2.0

1.5

1.0

1.0

0.0

Q1 Q2 Q3 Q4

0.5

0.0

0 1 2 3 4 5 6 7 8 9 10 11 12

VELOCITY (M/S)

Piping system I Piping system II The exclusive report

(Max capacity for four meters calibration (Maximum diameter is 300mm) (Each flow meter has its

simultaneously in above system.) own calibration report)

Page4

頁面 4

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

EPD A PPLICATION / ORDER FORM ELECTROMAGNETIC FLOW METER

Company Profile

Company Name: Contact Person: EPD electromagnetic flow meter is a high-accuracy flow meter manufactured based on the latest international Flow range (m3/h)

technology. It is widely applied in papermaking, chemical industry, metallurgical industry, drainage, waste Pipe diameter (mm)

E-mail: Phone: Tax: water treatment, liquid high-pressure metering, medical care, food, and environmental protection industries. Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/s

It is used to measure the non-magnetic liquid and plasma in the enclosed pipe.

40 0.45~4.5 4.5~45.2

Application Magnetic coil

50 0.71~7.1 7.1~71

Medium: Temperature: Sanitary Degree Request� Yes NO 65 1.19~11.9 11.9~119

Conductivity: Viscosity: 80 1.81~18.1 18.1~181

Flow speed:V

Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: liquid 100 2.83~28.3 28.3~283 Voltage:E

Measuring pipe

Electrode 125 4.42~44.2 44.2~442

3

Normal Flow Rate(m /h) 3: Max. Flow Rate(m /h): Min. Flow Rate(m3/h): Strength of magnetic:B ID:D

150 6.36~63.6 63.6~636

Connection Spec: Connection Material**:

WORKING PRINCIPLE FEATURES 200 11.3~113 113~1130

Pressure(Kg/m3) 3: Max. Static Pressure(Kg/m ): **SUS304, SUS316, SUS316L The working principle of the electromagnetic flow Low impact on environmental matter

250 17.7~177 177~1770meter is based on the Faraday law of The measurement results are not affected by

Lining Material*: Electrode Material***: electromagnetic induction. When the conducting the change in liquid density, viscosity, 300 25.4~254 254~2540

liquid flows in the orthogonal direction of the temperature, pressure and conductivity.

* PTFE、NBR、Neoprene

magnetic line direction, it will cut the magnetic lines It can be widely applied in the conducting

* **SUS316,Hastelloy Alloy,Titanium,Tantalum and generate induced voltage, which shows linear liquids that may contain fiber, solid granules and

relationship with the flowing speed. Thus, the fluidic suspended matters.

volume flow can be calculated. Enclosure protection rating: IP67/NEMA 4X

P ower: 110Vac 220Vac 24Vdc

Wide measurement range & high efficiency Output: 4-20mA /Pulse(ferq) R S-485/Modbus ERROR OF RATE (%) EPD electromagnetic flow meter is mainly The wide measurement turndown ratio can be

Grounding : NO YE S composed of the sensor and transmitter. The reach 1:100, which can be set randomly and

0.2% 0.3% 0.5%

CL II=2% measuring tube of the sensor is equipped with the achieve high accuracy for small flow Installation Direction: Horizontal Vertical

5.0 excitation coils upward and downward. The ERROR OF RATE (%)measurement.

Vibration Inside Tube : NO YES transmitter supplies the excitation current, which Highly-integrated backlit display of two rows,

4.0 0.2% 0.3% 0.5%

Strong Magnetic Near by: NO YES generates the magnetic field which goes through dual isolation, parameter setting, menu-type

3.0 the measuring tube once it is powered on. A pair of operation, memory function, reliable 2.0Explosion Proof: NO YES

induction electrodes installed on the inner side of programming, password lock and access, small

Explosion Proof Code: 2.0 the measuring tube comes in contact with the liquid

signal elimination, non-linear correction and two- 1.5

to guide the induced voltage to the sensor. way measurement.

1.0 Various outputs: Current output 4~20mA, 1.0

frequency output 2~8KHz and RS485

0.0

Q1 Q2 Q3 Q4 APPLICATIONS communication.

0.5

Waste water treatment Multiple self-diagnosis function

Tapped water purification Power-saving and low fault rate: The measuring

0.0

Sewerage tube is without baffle and movable parts, so it

0 1 2 3 4 5 6 7 8 9 10 11 12

Sea water desalination module won’t cause pressure loss and jam.

Dyeing machines Smart self-detection and self-diagnosis function, VELOCITY (M/S)

Solar energy and PCB wet processing as well as various alarms

Food manufacturing The low installation cost

Pharmaceutical machines It is easy-to-install with low requirements for the

straight tube section (Front 5D and rear 2D)

2-wire analog output

1

Page5

頁面 5

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

EPD A PPLICATION / ORDER FORM SPECIFICATION

Company Profile

Company Name: Contact Person:

EPD30 Standard type EPD34 Remote type Flow range (m

3/h)

Item

Pipe diameter (mm)

E-mail: Phone: Tax: Display LCM 128*64 pixel backlit type Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/s

Buttons Tri-button operation

40 0.45~4.5 4.5~45.2

RS-485 (Modbus)

Application Communication interface

(Optional support for ZigBee Pro wireless transmission) 50 0.71~7.1 7.1~71

Accuracy ±0.5% of reading@1m/s(0.2% optional)

Medium: Temperature: Sanitary Degree Request� Yes NO 65 1.19~11.9 11.9~119

Medium temperature -20 ~ 120 BC(PTFE Lining)

Conductivity: Viscosity: 80 1.81~18.1 18.1~181

Ambient temperature -40 ~ 70 BC*

Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: Fluidic conductivity 100 2.83~28.3 28.3~283 > 5 uS/cm

Measuring scope 0.1m/s ~ 10m/s 125 4.42~44.2 44.2~442

3 3 3

Normal Flow Rate(m /h): Max. Flow Rate(m /h): Min. Flow Rate(m /h):

0.1% of Pulse Output AccuracyCurrent output accuracy

Temperature coefficient (100ppm/BC) 150 6.36~63.6 63.6~636

Connection Spec: Connection Material**:

Operating pressure 10Kg/cm2 200 11.3~113 113~1130

3 3

Pressure(Kg/m ): Max. Static Pressure(Kg/m ): **SUS304, SUS316, SUS316L Current output mode Proactive

250 17.7~177 177~1770

Analog output 4 ~ 20mA

Lining Material*: Electrode Material***: 300 25.4~254 254~2540

Maximum load of current output < 700Ω

* PTFE、NBR、Neoprene

Alarming current 3.6mA or 22 mA

* **SUS316,Hastelloy Alloy,Titanium,Tantalum

Frequency output scope 2 ~ 8 KHz

Pulse width Automatic (pulse width 50%)

P ower: 110Vac 220Vac 24Vdc

Pulse mode NPN transistor output 32vdc/200mA

Output : 4-20mA /Pulse(ferq) R S-485/Modbus ERROR OF RATE (%)

Time constant 1~100 sGrounding: NO YES

0.2% 0.3% 0.5%

CL II=2% Control output (DO) NPN transistor output 32vdc/200mA ;2-CH

Installation Directio n: Horizo ntal Vertic al

5.0 ERROR OF RATE (%)

Dry contact ON< 200Ω ; 1,000Ω< OFF ; Vibration Inside Tube: NO YES Control input (DI) 1-CH(EPD30),2-CH(EPD34)

4.0 0.2% 0.3% 0.5%

Strong Magnetic Near by: NO YES

Baud rate 1200 ~ 57600 bps 2.0

Explosion Proof: NO YES 3.0

Protection rating

IP68**(Transducer)

Explosion Proof Code: IP67 / NEMA 4X2.0 IP67/ NEMA 4X (Transmitter)

1.5

Enclosure material Aluminum alloy

1.0

Input power AC 100~240V or DC 24V 1.0

0.0

Power consumption

Q1 Q2 Q3 Q4 < 10W

0.5

1/2"NPT x 2(Transducer),

Wire inlet specification M20 x 1.5 x 2 M20 x 1.5 x 4(Transmitter)

0.0

Excitation mode Pulse DC

0 1 2 3 4 5 6 7 8 9 10 11 12

Vibration regulation IEC 60068-2-3 VELOCITY (M/S)

EMC regulation IEC/EN 61326-1 Class A table2

*It can’t display when LCM is lower than -20℃.

**Continuous immersion in 6 meters of water for up to 48 hours,IP68 protection,optional function.

2

Page6

頁面 6

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

EPD A PPLICATION / ORDER FORM MATERIAL SELECTION

Company Profile

Company Name: Contact Person: �Electrode material Flow range (m3/h)

Pipe diameter (mm)

E-mail: Phone: Tax: Electrode material Anti-corrosion property Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/s

Stainless steel (316L) It is applied in water, sewage and organic and non-organic corrosive medium. 40 0.45~4.5 4.5~45.2

Application

It is resistant to the corrosion of the medium mixture of oxidizing acid such as Nitric

50 0.71~7.1 7.1~71

acid, mixed acid or Sulfuric acid. Moreover, it is resistant to the corrosion of the

Medium: Temperature: Sanitary Degree Request� Yes NO Hastelloy alloy oxidizing salt such as Fe2+、 Cu2+ or other substances containing oxidants such as 65 1.19~11.9 11.9~119

the salt solution of hypochlorous acid above the ambient temperature and sea water.

Conductivity: Viscosity: 80 1.81~18.1 18.1~181

It is resistant to the corrosion of sea water, various oxides, salt solution of Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: 100 2.83~28.3 28.3~283

hypochlorous acid, oxidating acid (including fuming Nitric acid) and organic

Titanium acid and alkane. It is not resistant to the corrosion of pure reducing acid 125 4.42~44.2 44.2~442

(m3/h) 3 3Normal Flow Rate : Max. Flow Rate(m /h): Min. Flow Rate(m /h): (such as Sulfuric acid and Hydrochloric acid). However, the anti-corrosion

property will be greatly degraded if the acid contains some oxidants. 150 6.36~63.6 63.6~636

Connection Spec: Connection Material**:

200 11.3~113 113~1130

Pressure(Kg/m3) 3: Max. Static Pressure(Kg/m ): **SUS304, SUS316, SUS316L It has excellent corrosion resistance. Its characteristic is similar to glass. In addition

to hydrofluoric acid , nitric acid , alkali, it could resist almost all chemical medium 250 17.7~177 177~1770Tantalum

(including boiling hydrochloric acid, nitric acid and sulfuric acid below 175 BC).

Lining Material*: Electrode Material***: It could not resist corrosion in alkali. 300 25.4~254 254~2540

* PTFE、NBR、Neoprene

* **SUS316,Hastelloy Alloy,Titanium,Tantalum

�Lining material

P ower: 110Vac 220Vac 24Vdc

Lining material Main properties Application scopeOutput: 4-20mA/Pulse(ferq) RS-485/Modbus ERROR OF RATE (%)

Grounding : NO YE S 1. Stable chemical properties, resistant to

0.2% 0.3% 0.5% various acid, alkane, and salt solutions and 1. -20~120BC

CL II=2%

Installation Directio n: Horizo ntal Vertic al

5.0 various organic solvents. It is not tolerant to 2. Strong corrosive medium such ERROR OF RATE (%)PTFE

the corrosion of CIF3, high-temperature OF3 as concentrated acid and Vibration Inside Tube: NO YES

4.0 and high-speed liquid oxygen and ozone. alkane. 0.2% 0.3% 0.5%

Strong Magnetic Near by: NO YES 2. The anti-abrasion property is average.

2.0

Explosion Proof: NO YES 3.0

1. Excellent flexibility, highly tearing force Explosion Proof Code: 1. < 80BC2.0

capability, good wear resistance 2. Neutral-strong wearing mineral 1.5

NBR 2. It is resistant to low concentrations of acid, pulp, coal slurry and mud

1.0 alkali, salt solution;It is not tolerant the slurry

corrosion of oxidizing mediums. 1.0

0.0

Q1 Q2 Q3 Q4

0.5

1. Neutral wearing capability 1. < 80BC

Neoprene 2. It is resistant to low concentrations of acid, 2. Water, Industrial water ,

alkali, acid corrosion. Seawater 0.0

0 1 2 3 4 5 6 7 8 9 10 11 12

VELOCITY (M/S)

3

Page7

頁面 7

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

APPEARANCE AND DIMENSION AND

EPD A PPLICATION / ORDER FORM FLANGE CONNECTION DIMENSION STANDARD TYPE

Company Profile

Company Name: Contact Person: Flow range (m3/h)

Pipe diameter (mm)

E-mail: Phone: Tax: Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/st

t

H2

H2 40 0.45~4.5 4.5~45.2

Application

H1 fD fC 50 0.71~7.1 7.1~71 H1 fD fC

Medium: Temperature: Sanitary Degree Request� Yes NO 65 1.19~11.9 11.9~119

qh

Conductivity: Viscosity: L -q° L N 80 1.81~18.1 18.1~181 f q°

Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: 100 2.83~28.3 28.3~283 DN40~80 DN100~300

125 4.42~44.2 44.2~442

3

Normal Flow Rate(m /h) 3 3: Max. Flow Rate(m /h): Min. Flow Rate(m /h):

Connection specification JIS 10K

150 6.36~63.6 63.6~636

Nominal diameter(mm) 40 50 65 80 100 125 150 200 250 300

Connection Spec: Connection Material**:

Lining material PTFE 200 11.3~113 113~1130

3 3

Pressure(Kg/m ): Max. Static Pressure(Kg/m ): **SUS304, SUS316, SUS316L Length L 200 200 200 200 250 250 300 350 400 500

250 17.7~177 177~1770External diameter fD 140 155 175 185 210 250 280 330 400 445

Lining Material*: Electrode Material***: PCD fC 105 120 140 150 175 210 240 290 355 400 300 25.4~254 254~2540

* PTFE、NBR、Neoprene Flange thickness t 14 14 16 16 16 20 22 22 24 24

* **SUS316,Hastelloy Alloy,Titanium,Tantalum Inclined angle of q° 45 45 45 22.5 22.5 22.5 22.5 15 15 11.25

screw hole

Diameter of screw hole qh 19 19 19 19 19 23 23 23 25 25

P ower: 110Vac 220Vac 24Vdc Quantity of screw holes N 4 4 4 8 8 8 8 12 12 16

Output : 4-20mA /Pulse(ferq) R S-485/Modbus ERROR OF RATE (%) Height of sensor casing H1 125 125 145 145 195 195 270 305 365 406

Grounding : NO YE S Total height H2 314.5 322 342 347 384.5 404.5 467 506 572 616

0.2% 0.3% 0.5%

CL II=2% Installation Direction: Horizontal Vertical Weight (kg) 6.8 7.68 8.98 9.87 12.9 17.5 23.51 33.23 54.03 69.55

5.0 ERROR OF RATE (%)

Vibration Inside Tube : NO YES

Connection specification

4.0 JIS 20K 0.2% 0.3% 0.5%

Strong Magnetic Near by: NO YES Nominal diameter(mm) 40 50 65 80 100 125 150 200 250 300

3.0 Lining material 2.0Explosion Proof: NO YES PTFE

Explosion Proof Code: Length L 200 200 200 200 250 250 300 350 400 5002.0

1.5External diameter fD 140 155 175 200 225 270 305 350 430 480

1.0 PCD fC 105 120 140 160 185 225 260 305 380 430

1.0

Flange thickness

0.0 t 18 18 20 22 24 26 28 30 34 36

Q1 Q2 Q3 Q4 Inclined angle of

q° 45 22.5 22.5 22.5 22.5 22.5 15 15 15 11.25 0.5

screw hole

Diameter of screw hole qh 19 19 23 23 23 25 25 25 27 27

0.0

Quantity of screw holes N 4 8 8 8 8 8 12 12 12 16 0 1 2 3 4 5 6 7 8 9 10 11 12

Height of sensor casing H1 125 125 145 145 195 195 270 305 365 406 VELOCITY (M/S)

Total height H2 314.5 322 342 354.5 392 414.5 478 514 585 632

Weight (kg) 7.08 7.72 8.98 12.25 16.42 23.56 31.03 43.37 74.23 94.15

Remarks: For DN40~DN80, the lining protective ring is 2mm, so the total length of the flow meter shall be increased by L+4mm.

For DN100~DN300, the lining protective ring is 0.5mm, so the total length of the flow meter shall be increased by L+1mm;

total length (L) tolerance is ±3mm, total height (H2) tolerance is ±5mm

4

fN-qh

Page8

頁面 8

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

APPEARANCE AND DIMENSION AND

EPD A PPLICATION / ORDER FORM FLANGE CONNECTION DIMENSION STANDARD TYPE

Company Profile

Company Name: Contact Person: Flow range (m3/h)

Pipe diameter (mm)

E-mail: Phone: Tax: Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/st

t

H2

H2 40 0.45~4.5 4.5~45.2

Application

H1

fD fC 50 0.71~7.1 7.1~71

H1 fD fC

Medium: Temperature: Sanitary Degree Request� Yes NO 65 1.19~11.9 11.9~119

qh

Conductivity: Viscosity: L -q° L N 80 1.81~18.1 18.1~181 f q°

Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: 100 2.83~28.3 28.3~283 DN40~80 DN100~300

125 4.42~44.2 44.2~442

3 3 3

Normal Flow Rate(m /h): Max. Flow Rate(m /h): Min. Flow Rate(m /h):

Connection specification JIS 7.5K

150 6.36~63.6 63.6~636

Nominal diameter(mm) 50 80(75) 100 125 150 200 250 300

Connection Spec: Connection Material**:

Lining material PTFE 200 11.3~113 113~1130

Pressure(Kg/m3): Max. Static Pressure(Kg/m3): **SUS304, SUS316, SUS316L Length L 200 200 250 250 300 350 400 500

250 17.7~177 177~1770External diameter fD 155 211 238 263 290 342 410 464

Lining Material*: Electrode Material***:

PCD

fC 120 168 195 220 247 299 360 414 300 25.4~254 254~2540

* PTFE、NBR、Neoprene Flange thickness t 14 16 16 18 20 20 22 21

* **SUS316,Hastelloy Alloy,Titanium,Tantalum Inclined angle of screw hole q° 45 45 45 30 30 22.5 22.5 18

Diameter of screw hole qh 19 19 19 19 19 19 23 23

P ower: 110Vac 220Vac 24Vdc Quantity of screw holes N 4 4 4 6 6 8 8 10

Output : 4-20mA /Pulse(ferq) R S-485/Modbus Height of sensor casing H1 125 145 195 195 270 305 365 406ERROR OF RATE (%)

Total height H2 322 360 398.5 411 472 511 577 625Grounding: NO YES

0.2% 0.3% 0.5%

CL II=2% Weight (kg) 7.68 12.45 15.82 19.55 25.63 36.83 55.63 74.95

Installation Directio n: Horizo ntal Vertic al

5.0 ERROR OF RATE (%)

Remarks: For DN40~DN80, the lining protective ring is 2mm, so the total length of the flow meter shall be increased by L+4mm. Vibration Inside Tube: NO YES For DN100~DN300, the lining protective ring is 0.5mm, so the total length of the flow meter shall be increased by L+1mm;

4.0

total length (L) tolerance is ±3mm, total height (H2) tolerance is ±5mm

0.2% 0.3% 0.5%

Strong Magnetic Nearby: NO YES

3.0 2.0Explosion Proof: NO YES

Explosion Proof Code: 2.0

1.5

1.0

1.0

0.0

Q1 Q2 Q3 Q4

0.5

0.0

0 1 2 3 4 5 6 7 8 9 10 11 12

VELOCITY (M/S)

5

fN-qh

Page9

頁面 9

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

APPEARANCE AND DIMENSION AND

EPD A PPLICATION / ORDER FORM FLANGE CONNECTION DIMENSION STANDARD TYPE

Company Profile

Company Name: Contact Person: Flow range (m3/h)

Pipe diameter (mm)

E-mail: Phone: Tax: Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/st

t H2

H2 40 0.45~4.5 4.5~45.2

Application

H1 fD fC 50 0.71~7.1 7.1~71 H1 fD fC

Medium: Temperature: Sanitary Degree Request� Yes NO 65 1.19~11.9 11.9~119

qh

Conductivity: Viscosity: L -q° L N 80 1.81~18.1 18.1~181 f q°

Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: 100 2.83~28.3 28.3~283 DN40~80 DN100~300

125 4.42~44.2 44.2~442

(m3/h) (m3Normal Flow Rate : Max. Flow Rate /h): Min. Flow Rate(m3/h): Connection specification

Nominal diameter(mm) 150 6.36~63.6 63.6~636 250 300

Connection Spec: Connection Material**:

Lining material

200 11.3~113 113~1130

Length 400 500

Pressure(Kg/m3) 3: Max. Static Pressure(Kg/m ): **SUS304, SUS316, SUS316L

250 17.7~177 177~1770External diameter 406.4 482.6

Lining Material*: Electrode Material***:

PCD 361.9 431.8 300 25.4~254 254~2540

* PTFE、NBR、Neoprene Flange thickness 16 17 21 22 22 22 27 28.6 30.2

* **SUS316,Hastelloy Alloy,Titanium,Tantalum Inclined angle of screw hole 15 15

Diameter of screw hole 25.4 25.4

P ower: 110Vac 220Vac 24Vdc Quantity of screw holes 12 12

Output : 4-20mA /Pulse(ferq) R S-485/Modbus ERROR OF RATE (%) Height of sensor casing 365 406

Grounding : NO YE S

0.2% 0.3% 0.5% Total height 308 321 344 350 394 407 464 511 575 633

CL II=2%

Installation Directio n: Horizo ntal Vertic al

5.0 Weight (kg) 6.48 8.32 10.78 12.25 17.82 20.96 27.03 44.17 67.23 99.55 ERROR OF RATE (%)

Vibration Inside Tube : NO YES

4.0 Connection specification ANSI 300Lbs 0.2% 0.3% 0.5%

Strong Magnetic Near by: NO YES

Nominal diameter(mm) 250 300 2.0

Explosion Proof: NO YES 3.0

Lining material

Explosion Proof Code: 2.0

Length 200 200 200 200 250 250 300 350 400 500 1.5

1.0 External diameter 156 165 190 210 254 279 317.5 381 444.5 520.7

1.0

PCD 114.3 127 149.2 168.3 200 235 269.9 330.2 387.35 450.9

0.0

Q1 Q2 Q3 Q4 Flange thickness 19 21 24 27 30 33 34.9 39.7 46 49.2 0.5

Inclined angle of screw hole 45 22.5 22.5 22.5 22.5 22.5 15 15 11.3 11.3

Diameter of screw hole 22.2 19 22.2 22.2 22.2 22.2 22.2 25.4 28.6 31.8 0.0

0 1 2 3 4 5 6 7 8 9 10 11 12

Quantity of screw holes 4 8 8 8 8 8 12 12 16 16

VELOCITY (M/S)

Height of sensor casing 125 125 145 145 195 195 265 305 365 406

Total height 323 327 350 360 407 419 481 528 592 650

Weight (kg) 9.08 10.32 12.78 16.45 26.62 32.96 43.83 69.17 100.43 146.6

Remarks: For DN40~DN80, the lining protective ring is 2mm, so the total length of the flow meter shall be increased by L+4mm.

For DN100~DN300, the lining protective ring is 0.5mm, so the total length of the flow meter shall be increased by L+1mm;

total length (L) tolerance is ±3mm, total height (H2) tolerance is ±5mm

6

fN-qh

Page10

頁面 10

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

APPEARANCE AND DIMENSION AND

EPD A PPLICATION / ORDER FORM FLANGE CONNECTION DIMENSION STANDARD TYPE

Company Profile

Company Name: Contact Person: Flow range (m3/h)

Pipe diameter (mm)

E-mail: Phone: Tax: Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/st

t H2

H2 40 0.45~4.5 4.5~45.2

Application

H1 fD fC 50 0.71~7.1 7.1~71 H1 fD fC

Medium: Temperature: Sanitary Degree Request� Yes NO 65 1.19~11.9 11.9~119

qh

Conductivity: Viscosity: L -q° L N 80 1.81~18.1 18.1~181 f q°

Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: 100 2.83~28.3 28.3~283 DN40~80 DN100~300

125 4.42~44.2 44.2~442

Normal Flow Rate(m3/h) 3: Max. Flow Rate(m /h) 3: Min. Flow Rate(m /h):

Connection specification DIN PN40 DIN PN16

150 6.36~63.6 63.6~636

Nominal diameter(mm) 40 50 65 80 65 80 100 125 150 200

Connection Spec: Connection Material**:

Lining material PTFE 200 11.3~113 113~1130

3

Pressure(Kg/m ): Max. Static Pressure(Kg/m3): **SUS304, SUS316, SUS316L Length L 200 200 200 200 200 200 250 250 300 350

250 17.7~177 177~1770External diameter fD 150 165 185 200 185 200 220 250 285 340

Lining Material*: Electrode Material***:

PCD fC 110 125 145 160 145 160 180 210 240 295 300 25.4~254 254~2540

* PTFE、NBR、Neoprene Flange thickness t 18 20 22 24 18 20 20 22 22 24

* **SUS316,Hastelloy Alloy,Titanium,Tantalum Inclined angle of screw hole q° 45 45 22.5 22.5 45 22.5 22.5 22.5 22.5 15

Diameter of screw hole qh 18 18 18 18 18 18 18 18 22 22

P ower: 110Vac 220Vac 24Vdc Quantity of screw holes N 4 4 8 8 4 8 8 8 8 12

Height of sensor casing Output: 4-20mA/Pulse(ferq) RS-485/Modbus H1 125 125 145 145 145 145 195 195 265 305ERROR OF RATE (%)

Total height H2 320 327 347 355 347 355 390 405 470 510Grounding: NO YES

0.2% 0.3% 0.5%

CL II=2% Weight (kg) 7.08 7.72 8.98 12.25 8.58 11.65 15.62 20.96 28.23 39.97Installation Direction: Horizontal Vertical

5.0 ERROR OF RATE (%)

Vibration Inside Tube : NO YES Connection specification DIN PN10

4.0 0.2% 0.3% 0.5%

Strong Magnetic Near by: NO YES Nominal diameter(mm) 200 250 300

3.0 Lining material PTFE 2.0Explosion Proof: NO YES

Length L 350 400 500

Explosion Proof Code: 2.0

External diameter fD 340 395 445 1.5

1.0 PCD fC 295 350 400

1.0

Flange thickness t 24 26 26

0.0

Q1 Q2 Q3 Q4 Inclined angle of screw hole q° 22.5 15 15 0.5

Diameter of screw hole qh 22 22 22

Quantity of screw holes N 8 12 12 0.0

Height of sensor casing H1 305 365 406 0 1 2 3 4 5 6 7 8 9 10 11 12

Total height VELOCITY (M/S)H2 510 568 637

Weight (kg) 33.23 54.03 69.55

Remarks: For DN40~DN80, the lining protective ring is 2mm, so the total length of the flow meter shall be increased by L+4mm.

For DN100~DN300, the lining protective ring is 0.5mm, so the total length of the flow meter shall be increased by L+1mm;

total length (L) tolerance is ±3mm, total height (H2) tolerance is ±5mm

7

fN-qh

Page11

頁面 11

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

APPEARANCE AND DIMENSION AND

EPD A PPLICATION / ORDER FORM FLANGE CONNECTION DIMENSION REMOTE TYPE

Company Profile

Company Name: Contact Person: Flow range (m3/h)

Pipe diameter (mm)

E-mail: Phone: Tax: t Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/s

N-qh

t 40 0.45~4.5 4.5~45.2

H2

N-q H2Application h

50 0.71~7.1 7.1~71 fc H1 D fc H1 D

Medium: Temperature: Sanitary Degree Request� Yes NO 65 1.19~11.9 11.9~119

q° L

Conductivity: Viscosity: 80 1.81~18.1 18.1~181

q° L

Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: 100 2.83~28.3 28.3~283 DN40~80 DN100~300

125 4.42~44.2 44.2~442

3 3

Normal Flow Rate(m /h): Max. Flow Rate(m /h) 3: Min. Flow Rate(m /h):

Connection specification JIS 10K

150 6.36~63.6 63.6~636

Nominal diameter(mm) 40 50 65 80 100 125 150 200 250 300

Connection Spec: Connection Material**:

Lining material PTFE 200 11.3~113 113~1130

Pressure(Kg/m3) 3: Max. Static Pressure(Kg/m ): **SUS304, SUS316, SUS316L Length L 200 200 200 200 250 250 300 350 400 500

250fD 17.7~177 177~1770External diameter 140 155 175 185 210 250 280 330 400 445

Lining Material*: Electrode Material***: PCD fC 105 120 140 150 175 210 240 290 355 400 300 25.4~254 254~2540

* PTFE、NBR、Neoprene Flange thickness t 14 14 16 16 16 20 22 22 24 24

Inclined angle of

* **SUS316,Hastelloy Alloy,Titanium,Tantalum q° 45 45 45 22.5 22.5 22.5 22.5 15 15 11.25screw hole

Diameter of screw hole qh 19 19 19 19 19 23 23 23 25 25

Quantity of screw holes N 4 4 4 8 8 8 8 12 12 16

P ower: 110Vac 220Vac 24Vdc

Height of sensor casing

H1 125 125 145 145 195 195 270 305 365 406Output: 4-20mA/Pulse(ferq) RS-485/Modbus ERROR OF RATE (%) Total height H2 276.4 283.9 303.9 308.9 346.4 366.4 429 468 534 578

Grounding : NO YE S

0.2% 0.3% 0.5% Weight (kg)*2 - 5.25 6.13 7.43 8.32 11.35 15.95 21.96 31.68 52.48 68.00

CL II=2%

Installation Directio n: Horizo ntal Vertic al

5.0 ERROR OF RATE (%)

Vibration Inside Tube : NO YES Connection specification JIS 20K

4.0

Nominal diameter(mm) 40 50 65 80 100 125 150 200 250 300

0.2% 0.3% 0.5%

Strong Magnetic Nearby: NO YES

Lining material PTFE 2.0

Explosion Proof: NO YES 3.0

Length L 200 200 200 200 250 250 300 350 400 500

Explosion Proof Code: 2.0 External diameter fD 140 155 175 200 225 270 305 350 430 480 1.5

PCD fC 105 120 140 160 185 225 260 305 380 430

1.0

Flange thickness t 18 18 20 22 24 26 28 30 34 36 1.0

0.0 Inclined angle of q° 45 22.5 22.5 22.5 22.5 22.5 15 15 15 11.25

Q1 Q2 Q3 Q4 screw hole

0.5

Diameter of screw hole qh 19 19 23 23 23 25 25 25 27 27

Quantity of screw holes N 4 8 8 8 8 8 12 12 12 16

0.0

Height of sensor casing H1 125 125 145 145 195 195 270 305 365 406

0 1 2 3 4 5 6 7 8 9 10 11 12

Total height H2 276.4 283.9 303.9 316.4 353.9 376.4 440 476 547 594 VELOCITY (M/S)

Weight (kg)*2 - 5.53 6.17 7.43 10.7 14.87 22.01 29.48 41.82 72.68 92.60

*1: Remarks: For DN40~DN80, the lining protective ring is 2mm, so the total length of the flow meter shall be increased by L+4mm.

For DN100~DN300, the lining protective ring is 0.5mm, so the total length of the flow meter shall be increased by L+1mm;

total length (L) tolerance is ±3mm, total height (H2) tolerance is ±5mm

*2: To shows the weight of transducer only. Not include the weight of transmitter 2.06kg

8

Page12

頁面 12

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

AAPPPPEEAARARNACNE CAEND A DNIMDE NDSIMIOEN NASNDION AND

EPD A PPLICATION / ORDER FORM FLAANNGGE ECO CNONENCNTEIOCNT DIOIMNEN DSIOMNE RNESMIOTNE TYPE

Company Profile

Company Name: Contact Person: Flow range (m3/h)

Pipe diameter (mm)

E-mail: Phone: Tax: t Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/s

N-qh

t 40 0.45~4.5 4.5~45.2

H2

N H2

Application -qh

50 0.71~7.1 7.1~71 fc H1 D fc H1 D

Medium: Temperature: Sanitary Degree Request� Yes NO 65 1.19~11.9 11.9~119

q° L

Conductivity: Viscosity: 80 1.81~18.1 18.1~181

q° L

Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: 100 2.83~28.3 28.3~283 DN40~80 DN100~300

125 4.42~44.2 44.2~442

3 3 3

Normal Flow Rate(m /h): Max. Flow Rate(m /h): Min. Flow Rate(m /h):

Connection specification ANSI 150 Lbs

150 6.36~63.6 63.6~636

Nominal diameter(mm) 40 50 65 80 100 125 150 200 250 300

Connection Spec: Connection Material**:

Lining material PTFE 200 11.3~113 113~1130

3

Pressure(Kg/m ): Max. Static Pressure(Kg/m3): **SUS304, SUS316, SUS316L Length L 200 200 200 200 250 250 300 350 400 500

250 17.7~177 177~1770External diameter fD 127 152 178 190 229 254 279.4 342.9 406.4 482.6

Lining Material*: Electrode Material***: PCD fC 98.4 120.6 139.7 152.4 190.5 215.9 241.3 298.4 361.9 431.8 300 25.4~254 254~2540

* PTFE、NBR、Neoprene Flange thickness t 15.9 17.4 20.6 22.2 22.2 22.2 23.8 27 28.6 30.2

Inclined angle of

* **SUS316,Hastelloy Alloy,Titanium,Tantalum q° 45 45 45 45 22.5 22.5 22.5 22.5 15 15screw hole

Diameter of screw hole qh 15.9 19 19 19 19 22.2 22.2 22.2 25.4 25.4

Quantity of screw holes N 4 4 4 4 8 8 8 8 12 12

P ower: 110Vac 220Vac 24Vdc

Height of sensor casing

H1 125 125 145 145 195 195 265 305 365 406Output: 4-20mA/Pulse(ferq) RS-485/Modbus ERROR OF RATE (%) Total height H2 270 282 305 311 356 368 426 473 537 595

Grounding : NO YE S

0.2% 0.3% 0.5% Weight (kg)*2 - 4.93 6.77 9.23 10.7 16.27 19.41 25.48 42.62 65.68 98

CL II=2%

Installation Directio n: Horizo ntal Vertic al

5.0 ERROR OF RATE (%)

Connection specification ANSI 300 Lbs

Vibration Inside Tube : NO YES

4.0 Nominal diameter(mm) 40 50 65 80 100 125 150 200 250 300 0.2% 0.3% 0.5%

Strong Magnetic Near by: NO YES Lining material PTFE

2.0

Explosion Proof: NO YES 3.0 Length L 200 200 200 200 250 250 300 350 400 500

Explosion Proof Code: 2.0 External diameter fD 156 165 190 210 254 279 317.5 381 444.5 520.7

1.5

PCD fC 114.3 127 149.2 168.3 200 235 269.9 330.2 387.35 450.85

1.0

Flange thickness t 19 20.6 23.8 27 30.2 33.3 34.9 39.7 46 49.2 1.0

Inclined angle of

0.0 q° 45 22.5 22.5 22.5 22.5 22.5 15 15 11.3 11.3screw hole

Q1 Q2 Q3 Q4

Diameter of screw hole qh 22.2 19 22.2 22.2 22.2 22.2 22.2 25.4 28.6 31.8 0.5

Quantity of screw holes N 4 8 8 8 8 8 12 12 16 16

Height of sensor casing H1 125 125 145 145 195 195 265 305 365 406 0.0

0 1 2 3 4 5 6 7 8 9 10 11 12

Total height H2 284 289 311 321 368 381 443 490 553 612

VELOCITY (M/S)

Weight (kg)*2 - 9.08 10.32 12.78 16.45 26.62 32.96 42.28 67.62 98.88 145

*1: Remarks: For DN40~DN80, the lining protective ring is 2mm, so the total length of the flow meter shall be increased by L+4mm.

For DN100~DN300, the lining protective ring is 0.5mm, so the total length of the flow meter shall be increased by L+1mm;

total length (L) tolerance is ±3mm, total height (H2) tolerance is ±5mm

*2: To shows the weight of transducer only. Not include the weight of transmitter 2.06kg

9

Page13

頁面 13

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

AAPPPPEEAARARNACNE CAEND A DNIMDE NDSIMIOEN NASNDION AND

EPD A PPLICATION / ORDER FORM FLAANNGGE ECO CNONENCNTEIOCNT DIOIMNEN DSIOMNE RNESMIOTNE TYPE

Company Profile

Company Name: Contact Person: Flow range (m3/h)

Pipe diameter (mm)

E-mail: Phone: Tax: t Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/s

N-qh

t 40 0.45~4.5 4.5~45.2

H2

N H2

Application -qh

50 0.71~7.1 7.1~71 fc H1 D fc H1 D

Medium: Temperature: Sanitary Degree Request� Yes NO 65 1.19~11.9 11.9~119

q° L

Conductivity: Viscosity: 80 1.81~18.1 18.1~181

q° L

Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: 100 2.83~28.3 28.3~283 DN40~80 DN100~300

125 4.42~44.2 44.2~442

3

Normal Flow Rate(m /h): Max. Flow Rate(m3/h): Min. Flow Rate(m3/h):

Connection specification DIN PN40 DIN PN16

150 6.36~63.6 63.6~636

Nominal diameter(mm) 40 50 65 80 65 80 100 125 150 200

Connection Spec: Connection Material**:

Lining material PTFE 200 11.3~113 113~1130

3 3

Pressure(Kg/m ): Max. Static Pressure(Kg/m ): **SUS304, SUS316, SUS316L Length L 200 200 200 200 200 200 250 250 300 350

250 17.7~177 177~1770External diameter fD 150 165 185 200 185 200 220 250 285 340

Lining Material*: Electrode Material***:

PCD fC

110 125 145 160 145 160 180 210 240 295

300 25.4~254 254~2540

* PTFE、NBR、Neoprene Flange thickness t 18 20 22 24 18 20 20 22 22 24

* **SUS316,Hastelloy Alloy,Titanium,Tantalum Inclined angle of q° 45 45 22.5 22.5 45 22.5 22.5 22.5 22.5 15screw hole

Diameter of screw hole qh 18 18 18 18 18 18 18 18 22 22

P ower: 110Vac 220Vac 24Vdc Quantity of screw holes N 4 4 8 8 4 8 8 8 8 12

Height of sensor casing Output: 4-20mA/Pulse(ferq) R S-485/Modbus H1 125 125 145 145 145 145 195 195 265 305ERROR OF RATE (%)

Total height H2 281 289 309 316 309 316 351 366 435 476Grounding: NO YES

0.2% 0.3% 0.5%

CL II=2% Weight (kg)*2 5.53 6.17 7.43 10.70 7.03 10.10 14.07 19.41 26.68 38.42Installation Direction: Horizontal Vertical

5.0 ERROR OF RATE (%)

Vibration Inside Tube : NO YES Connection specification DIN PN10 Transmitter Dimension

4.0 0.2% 0.3% 0.5%Nominal diameter(mm)

Strong Magnetic Near by: NO YES 200 250 300

Lining material PTFE 2.0

Explosion Proof: NO YES 3.0

Length 69.2L 350 400 500 f6.5

Explosion Proof Code: 2.0

External diameter fD 340 395 445 1.5

1.0 PCD fC 295 350 400

1.0

Flange thickness t 24 26 26

0.0 Inclined angle of 233.5

Q1 Q2 Q3 Q4 screw hole q° 22.5 15 15

265.6

0.5

Diameter of screw hole qh 22 22 22

Quantity of screw holes N 8 12 12 0.0

Height of sensor casing H1 305 365 406 0 1 2 3 4 5 6 7 8 9 10 11 12

Total height f6.5H2 476 534 603 f6.5 VELOCITY (M/S)70

Weight (kg)*2 16431.68 52.48 68

*1: Remarks: For DN40~DN80, the lining protective ring is 2mm, so the total length of the flow meter shall be increased by L+4mm.

For DN100~DN300, the lining protective ring is 0.5mm, so the total length of the flow meter shall be increased by L+1mm;

total length (L) tolerance is ±3mm, total height (H2) tolerance is ±5mm

*2: To shows the weight of transducer only. Not include the weight of transmitter 2.06kg

10

Page14

頁面 14

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

PIPE DIAMETER, FLOW RANGE AND

EPD A PPLICATION / ORDER FORM ACCURACY SELECTION

Company Profile

Company Name: Contact Person: 3

Pipe 3 Flow range (m /h) Flow range (m /h)

Pipe diameter (mm)

E-mail: Phone: Tax: diameter Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/s(mm) Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/s

40 0.45~4.5 4.5~45.2 40 0.45~4.5 4.5~45.2

Application 50 0.71~7.1 7.1~71

50 0.71~7.1 7.1~71

65 1.19~11.9 11.9~119

Medium: Temperature: Sanitary Degree Request� Yes NO 65 1.19~11.9 11.9~119

80 1.81~18.1 18.1~181

Conductivity: Viscosity: 80 1.81~18.1 18.1~181

100 2.83~28.3 28.3~283

Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: 125 4.42~44.2 44.2~442 100 2.83~28.3 28.3~283

150 6.36~63.6 63.6~636 125 4.42~44.2 44.2~442

3 3 3

Normal Flow Rate(m /h): Max. Flow Rate(m /h): Min. Flow Rate(m /h):

200 11.3~113 113~1130

150 6.36~63.6 63.6~636

Connection Spec: Connection Material**: 250 17.7~177 177~1770

200 11.3~113 113~1130

300 25.4~254 254~2540

Pressure(Kg/m3) 3: Max. Static Pressure(Kg/m ): **SUS304, SUS316, SUS316L

250 17.7~177 177~1770

DN Q4 Q3 Q2 Q1

Lining Material*: Electrode Material***:

(mm) 3 3 3 3 300 25.4~254 254~2540 (m /h) (m /h) (m /h) (m /h)

* PTFE、NBR、Neoprene Ratio 5 1.25 1.6 160

* **SUS316,Hastelloy Alloy,Titanium,Tantalum 40 50 40 0.40 0.25

50 78.75 63 0.63 0.394

65 125 100 1.01 0.63 Power: 110Vac 220Vac 24Vdc

80 200 160 1.60 1.00 Output: 4-20mA /Pulse(ferq) R S-485/Modbus ERROR OF RATE (%) 100 313 250 2.52 1.57

Grounding : NO YE S

0.2% 0.3% 0.5% 125 500 400 4.00 2.50

CL II=2%

Installation Directio n: Horizo ntal Vertic al

5.0 150 788 630 6.31 3.94 ERROR OF RATE (%)

Vibration Inside Tube : NO YES 200 1250 1000 10.00 6.25

4.0 0.2% 0.3% 0.5%

Strong Magnetic Near by: NO YES 250 2000 1600 16.00 10.00

3.0 300 3125 2500 25.01 15.63 2.0Explosion Proof: NO YES

Explosion Proof Code: OIML Accuracy class & tolerance2.0

1.5

1.0 ERROR OF RATE (%) Type EPD 3x

1.0

0.0 0.2% 0.5% Nominal diameter(DN) 50

Q1 Q2 Q3 Q4 (%)

10.0 0.5

Q3/Q1 * 160

8.0

Q /Q 1,6 0.02 1

0 1 2 3 4 5 6 7 8 9 10 11 12

6.0

3

CL II=5% Q1(m /h) 0.394 VELOCITY (M/S)

4.0

Q2(m

3/h) 0.63

CL II=2%

2.0

Q3(m

3/h) 63

0.0

3

Q1 Q2 Q3 Q4 Q4(m /h) 78.75

11

Page15

頁面 15

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

EPD A PPLICATION / ORDER FORM INSTALLATION INSTRUCTIONS

Company Profile

1. The flow meter must be free from strong electromagnetic field. The magnetic intensity of the flow

Company Name: Contact Person: meter installation site must be smaller than 400A/m (It should not be installed near large motors or Flow range (m3/h)

transformers). Pipe diameter (mm)

E-mail: Phone: Tax: Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/s2. It should be installed at the lower point and the vertically upward point of the horizontal pipe. Don’t

install it at the highest point and the vertically downward point of the pipe.

40 0.45~4.5 4.5~45.2

Application

50 0.71~7.1 7.1~71

Medium: Temperature: Sanitary Degree Request� Yes NO 65 1.19~11.9 11.9~119

Conductivity: Viscosity: 80 1.81~18.1 18.1~181

Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: 100 2.83~28.3 28.3~283

125 4.42~44.2 44.2~442

3 3 3

Normal Flow Rate(m /h): Max. Flow Rate(m /h): Min. Flow Rate(m /h):

3. It should be installed at the rising point of the pipe.

150 6.36~63.6 63.6~636

Connection Spec: Connection Material**:

200 11.3~113 113~1130

Pressure(Kg/m3) 3: Max. Static Pressure(Kg/m ): **SUS304, SUS316, SUS316L

250 17.7~177 177~1770

Lining Material*: Electrode Material***: 4. It should be installed at the lower point of the pipe when it is installed on the pipe with opening for 300 25.4~254 254~2540

drainage.

* PTFE、NBR、Neoprene

* **SUS316,Hastelloy Alloy,Titanium,Tantalum

P ower: 110Vac 220Vac 24Vdc 5. If the pipe gap exceeds 5m, the air release valve should be installed at the downstream of the

Output : 4-20mA /Pulse(ferq) R S-485/Modbus ERROR OF RATE (%) sensor. The downstream of the sensor should have some back pressure.

Grounding : NO YE S Air Release Valve

0.2% 0.3% 0.5%

CL II=2%

Installation Directio n: Horizo ntal Vertic al

5.0 ERROR OF RATE (%)

Vibration Inside Tube : NO YES

4.0 0.2% 0.3% 0.5%

Strong Magnetic Near by: NO YES

2.0

Explosion Proof: NO YES 3.0

6. The control valve and cut valve should be installed at the downstream of the sensor rather than the

Explosion Proof Code: 2.0

upstream. 1.5

1.0

1.0

0.0

Q1 Q2 Q3 Q4

0.5

7. The sensor should be installed at the pump outlet rather than the inlet.

0.0

0 1 2 3 4 5 6 7 8 9 10 11 12

VELOCITY (M/S)

8. The fluidic must flow towards the arrow direction of the flow meter.

9. The axial line of the measuring electrode must be approximate to the horizontal direction (The

angle of from the horizontal direction).

10. The measuring pipe must be completely filled with liquid.

12

Page16

頁面 16

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

EPD A PPLICATION / ORDER FORM INSTALLATION INSTRUCTIONS

Company Profile

11. The straight tube section is required to be at least 5D (internal diameter of the flow meter) on the

Company Name: Contact Person: front side, and at least 2D on the rear side. Flow range (m3/h)

Pipe diameter (mm)

E-mail: Phone: Tax: Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/s

40 0.45~4.5 4.5~45.2

Application 12. When measuring the mixture of different media, the distance between the mixing point and the

50 0.71~7.1 7.1~71 flow meter must be 30D at least.

Medium: Temperature: Sanitary Degree Request� Yes NO 13. For convenient cleaning and maintenance of the flow meter, a bypass pipe must be installed. 65 1.19~11.9 11.9~119

Conductivity: Viscosity: 80 1.81~18.1 18.1~181

Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: 100 2.83~28.3 28.3~283

125 4.42~44.2 44.2~442

3 3 3

Normal Flow Rate(m /h): Max. Flow Rate(m /h): Min. Flow Rate(m /h):

14. When installing the sensor, it should ensure that the measuring pipe and the process pipe must be

on the same axial line. For the flow meter with the pipe meter of 50mm or below, the axial line 150 6.36~63.6 63.6~636

Connection Spec: Connection Material**:

deviation should not exceed 2mm. For those of DN65~DN150, the axial line deviation should not 200 11.3~113 113~1130

3 3 exceed 3mm. For those of ≥DN200, the axial line deviation should not exceed 4mm.

Pressure(Kg/m ): Max. Static Pressure(Kg/m ): **SUS304, SUS316, SUS316L

15. The shim installed between the flanges should have excellent anti-corrosion property. The shim 250 17.7~177 177~1770

should not intrude in the pipe, which will affect the fluidic in the pipe.

Lining Material*: Electrode Material***:

16. The sensor and transmitter should be equipped with high-quality independent grounding wire (The

300 25.4~254 254~2540

* PTFE、NBR、Neoprene section area of the copper core is 1.6mm2). The grounding resistance should be <10Ω. If the

* **SUS316,Hastelloy Alloy,Titanium,Tantalum grounding is poor, it won’t work normally. The grounding ring is needed if the pipe connecting with

the sensor is insulating, and the material of the grounding ring should be the same as that of the

electrode. If the test medium is abrasive, the neck grounding ring should be selected.

P ower: 110Vac 220Vac 24Vdc

Output : 4-20mA /Pulse(ferq) R S-485/Modbus ERROR OF RATE (%)

Grounding : NO YE S

0.2% 0.3% 0.5%

CL II=2%

Installation Directio n: Horizo ntal Vertic al

5.0 ERROR OF RATE (%)

Vibration Inside Tube : NO YES 16.1 It is for installing the flow meter on the metal pipe not coated with insulating layer internally.

4.0 0.2% 0.3% 0.5%

Strong Magnetic Near by: NO YES

2.0

Explosion Proof: NO YES 3.0

Explosion Proof Code: 2.0

1.516.2 When installing the flow meter on the protective pipe of the cathode, the pipe with the

1.0 protection of electrolytic corrosion generally has insulating walls and protruding sides. Thus,

1.0

during installation, the grounding ring and the flanges on the pipe should be insulating.

0.0

Q1 Q2 Q3 Q4

0.5

0.0

0 1 2 3 4 5 6 7 8 9 10 11 12

16.3 When installing the flow mater on the plastic pipe or the pipe with insulating coating material, VELOCITY (M/S)

paints or lining, grounding rings on both ends of the sensor should be installed.

13

Page17

頁面 17

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

MODEL NUMBER / ORDER CODE COMPARISON TABLE

EPD A PPLICATION / ORDER FORM ORDERING INFORMATION

Company Profile

Company Name: Contact Person: Flow range (m3/h)

Model Number Order Code Pipe diameter (mm)

E-mail: Phone: Tax: Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/s

EPD30 EPD10000-A

EPD34 EPD10400-A 40 0.45~4.5 4.5~45.2

Application

50 0.71~7.1 7.1~71

Medium: Temperature: Sanitary Degree Request� Yes NO 65 1.19~11.9 11.9~119

Conductivity: Viscosity: 80 1.81~18.1 18.1~181

05 06 10 11 12 13 14 15 16 17 18 19 20 21 23 24 25 26 27 28

Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: EPD1 99 0 0 -A999999999999A999999 100 2.83~28.3 28.3~283

125 4.42~44.2 44.2~442

(m3/h) 3 3Normal Flow Rate : Max. Flow Rate(m /h): Min. Flow Rate(m /h): 05 06

Type

150 6.36~63.6 63.6~636

00: Standard

Connection Spec: Connection Material**:

04: Remote type 200 11.3~113 113~1130

3

Pressure(Kg/m ) 3: Max. Static Pressure(Kg/m ): **SUS304, SUS316, SUS316L

250 17.7~177 177~1770

Lining Material*: Electrode Material***: 10 11 12 Pipe diameter 300 25.4~254 254~2540

040: 40mm 125: 125mm

* PTFE、NBR、Neoprene 050: 50mm 150: 150mm

* **SUS316,Hastelloy Alloy,Titanium,Tantalum 065: 65mm 200: 200mm (Next page)

080: 80mm 250: 250mm

100: 100mm 300: 300mm

P ower: 110Vac 220Vac 24Vdc

Output : 4-20mA /Pulse(ferq) R S-485/Modbus ERROR OF RATE (%)

13 14 15

Grounding : NO YE S Connection specification

0.2% 0.3% 0.5%

CL II=2% C48 : ANSI B16.5 Class 150

Installation Directio n: Horizo ntal Vertic al

5.0 ERROR OF RATE (%)C49 : ANSI B16.5 Class 300

Vibration Inside Tube : NO YES A41: JIS B2220 7.5K

4.0 0.2% 0.3% 0.5%

Strong Magnetic Near by: NO YES A42: JIS B2220 10K

2.0

Explosion Proof: NO YES 3.0 A45: JIS B2220 20K

D57 : DIN 2501 PN10

Explosion Proof Code: 2.0

D58 : DIN 2501 PN16 1.5

D60 : DIN 2501 PN40

1.0

1.0

0.0

Q1 Q2 Q3 Q4 16 17 Casing and flange 0.5

MD: Carbon steel

MA: SUS304 0.0

MC: SUS316L 0 1 2 3 4 5 6 7 8 9 10 11 12

VELOCITY (M/S)

18 19 Lining material

08 : Neoprene

21 : PTFE

37 : NBR

14

Page18

頁面 18

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

EPD A PPLICATION / ORDER FORM ORDERING INFORMATION

Company Profile

Company Name: Contact Person: 3

05 06 10 11 12 13 14 15 16 17 18 19 20 21 23 24 25 26 27 28 Flow range (m /h)

E-mail: Phone: Tax: EPD1 99 0 0 -A999999999999A999999

Pipe diameter (mm)

Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/s

20 21 Electrode material 40 0.45~4.5 4.5~45.2

Application MC: SUS316L

50 0.71~7.1 7.1~71 MF: Titanium

Medium: Temperature: Sanitary Degree Request� Yes NO MK: Tantalum 65 1.19~11.9 11.9~119

MJ : Hastelloy alloy(C-276)

Conductivity: Viscosity: 80 1.81~18.1 18.1~181

Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: 100 2.83~28.3 28.3~283

23 Power supply

A: 100~240Vac, 50/60Hz 125 4.42~44.2 44.2~442 3 3 3

Normal Flow Rate(m /h): Max. Flow Rate(m /h): Min. Flow Rate(m /h):

D: 24Vdc

150 6.36~63.6 63.6~636

Connection Spec: Connection Material**:

200 11.3~113 113~1130

(Kg/m3

24 Accuracy

Pressure ): Max. Static Pressure(Kg/m3): **SUS304, SUS316, SUS316L

F: 0.5% 250 17.7~177 177~1770

Lining Material*: Electrode Material***: G: 0.3% 300 25.4~254 254~2540

H: 0.2%

* PTFE、NBR、Neoprene

* **SUS316,Hastelloy Alloy,Titanium,Tantalum

25 26 Grounding material

00: None

P ower: 110Vac 220Vac 24Vdc MA: SUS304

MC: SUS316LOutput: 4-20mA /Pulse(ferq) R S-485/Modbus ERROR OF RATE (%) MF: Titanium

Grounding : NO YE S

0.2% 0.3% 0.5% MK: Tantalum

CL II=2%

Installation Directio n: Horizo ntal Vertic al MJ: Hastelloy alloy(C-276)

5.0 ERROR OF RATE (%)

Vibration Inside Tube : NO YES

4.0 0.2% 0.3% 0.5%

Strong Magnetic Near by: NO YES 27 28 Cable length

2.0

Explosion Proof: NO YES 3.0 00: None(Only available for standard type)

10: 10 M(Remote type standard)Explosion Proof Code: 2.0

15 : 15 M 1.5

20: 20 M

1.0

1.0

0.0

Q1 Q2 Q3 Q4 95: 95 M 0.5

A0 : 100 M

0.0

0 1 2 3 4 5 6 7 8 9 10 11 12

VELOCITY (M/S)

15

....

Page19

頁面 19

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

EPD A PPLICATION / ORDER FORM SETTING VALUES

Company Profile

Company Name: Contact Person: Flow range (m3/h)

Main Menu Unit Default Setting Range Pipe diameter (mm)Sub Menu

E-mail: Phone: Tax: Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/s

Device Tag Num (1.1)

Zero Adj. (2.1)

40 0.45~4.5 4.5~45.2

Flow Span (1.5)

Application

Flow Unit (1.4) 50 0.71~7.1 7.1~71 Fast Set(0) The paremeter is linking form standard manu

Low cutoff (2.4)

Medium: Temperature: Sanitary Degree Request� Yes NO 65 1.19~11.9 11.9~119

Damping Time (3.1)

Conductivity: Viscosity: Pulse Out Unit (3.3) 80 1.81~18.1 18.1~181

Total Reset (1.9)

Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: 100 2.83~28.3 28.3~283

Main Menu Sub Menu Unit Default Setting Range 125 4.42~44.2 44.2~442

(m3/h) (m3 3Normal Flow Rate : Max. Flow Rate /h): Min. Flow Rate(m /h):

Device Tag Num (1.1) none 00001 00001~65535

150 6.36~63.6 63.6~636

Measure Ty-pe (1.2) - Water Water

Connection Spec: Connection Material**:

10,15,25,32,40,50,65,80,100

Tube Size (1.3) mm actual 200 11.3~113 113~1130

125,150,200,250,300,350,400,450,500

3 3

Pressure(Kg/m ): Max. Static Pressure(Kg/m ): **SUS304, SUS316, SUS316L

3L/(s,min,h), m /(s,min,h), gal/(s,min,h), kg(s,min,h), Ton(s,min,h) 250 17.7~177 177~1770

(Flow rate* Liquid density = weight)

Lining Material*: Electrode Material***: Flow Unit (1.4) -

3

m /h

"L/s", "L/m", "L/h", "m3/s", "m3/m", "m3/h", "gal/s", "gal/m", "gal/h", 300 25.4~254 254~2540

"kg/s", "kg/m", "kg/h", "Ton/s", "Ton/m", "Ton/h", "m3/d"Basic Set (1)

* PTFE、NBR、Neoprene

2

* **SUS316,Hastelloy Alloy,Titanium,Tantalum (5m/s )x (Diameter/2 ) 2Flow Span (1.5) =Flow Rate Unit x pi x Unit of Flow (0.1 ~ 10.0m/s ) x (Diametermm/2) x pi x Unit of Flow Forward

Forward

Direction (1.6) dir Forward Forward,Reverse

P ower: 110Vac 220Vac 24Vdc 3

Total Un-it (1.7) - m

3 Liter,gal,m ,kg,Ton

Output : 4-20mA /Pulse(ferq) R S-485/Modbus ERROR OF RATE (%) Total Mode (1.8) none Forward Forward,Reverse,Bi-direction

Grounding : NO YE S Total Reset (1.9) none Cancel Cancel,Accept

0.2% 0.3% 0.5%

Installation Directio n: Horizo ntal Vertic

CL II=2%

al

5.0 ERROR OF RATE (%)

Main Menu Sub Menu Unit Default Setting Range

Vibration Inside Tube : NO YES

Zero Adj. (2.1) m/s actual -0.5000~+0.50004.0 0.2% 0.3% 0.5%

Strong Magnetic Near by: NO YES K-Factor (2.2) none 1.000 0.000~3.000

3 2.0

Explosion Proof: NO YES 3.0 Density (2.3) g/cm 1.0000 0.0001~9.9999

Explosion Proof Code: 2.0 Low cutoff (2.4) % 0.5 0.00~100.00

1.5Advanced Set (2)

1.0 Fwd. Init. (2.5)

=Total Unit 0 0~9999999999 1.0

0.0

Q1 Q2 Q3 Q4 Rev. Init.(2.6) =Total Unit 0 0~9999999999 0.5

0.0

0 1 2 3 4 5 6 7 8 9 10 11 12

VELOCITY (M/S)

16

Page20

頁面 20

ERROR OF RATE (%)

0.2% 0.3% 0.5%

5.0 CL II=5%

4.0

3.0

CL II=2%

2.0

1.0

0.0

Q1 Q2 Q3 Q4

EPD A PPLICATION / ORDER FORM SETTING VALUES

Company Profile

Company Name: Contact Person: Flow range (m3/h)

Default Setting Range Pipe diameter (mm)Main Menu Sub Menu Unit

E-mail: Phone: Tax: Flowing speed 0.1~1.0m/s Flowing speed 1.0~10m/s

Damping Time (3.1) second (s) 3 0~100

40 0.45~4.5 4.5~45.2

Pulse Out Mode (3.2) Pulse NO, Pulse

Application none Pulse NO

NC, Frequency 50 0.71~7.1 7.1~71

0.001~100(L,gal,m3,g,kg,Ton)

Medium: Temperature: Sanitary Degree Request� Yes NO Pulse Out Unit (3.3) Unit/pulse 30.1 L m /pulse,gal/pulse,m3/pulse 65 1.19~11.9 11.9~119

g/pulse,kg/pulse,Ton/pulse

Conductivity: Viscosity: 80 1.81~18.1 18.1~181

Max. Freq. (3.4) Hz,kHz 2K 1~8K (00.000)

Diameter of Tube (DN) : Accuracy Request(%): Ambient Temp.: 100 2.83~28.3 28.3~283

Curr. Mode (3.5)

I/O Signal Set (3) none 4-20 4-20,0-20

125 4.42~44.2 44.2~442

3

Normal Flow Rate(m /h) 3 3: Max. Flow Rate(m /h): Min. Flow Rate(m /h):

4mA Fine-Tune (3.6) count 0 -5000~5000 150 6.36~63.6 63.6~636

Connection Spec: Connection Material**:

20mA Fine-Tune (3.7) 200 11.3~113 113~1130

count 0 -5000~5000

3

Pressure(Kg/m ): Max. Static Pressure(Kg/m3): **SUS304, SUS316, SUS316L

Input1 Func. (3.8) N/A None None, Total Reset 250 17.7~177 177~1770

Lining Material*: Electrode Material***: Input1 Type (3.9) N/A NO NO,NC 300 25.4~254 254~2540

Filter Variation (3.10) m/s 1 0.000~10.000

* PTFE、NBR、Neoprene

Filter Weight (3.11) % 10 0~100

* **SUS316,Hastelloy Alloy,Titanium,Tantalum

Main Menu Sub Menu Unit Default Setting Range

P ower: 110Vac 220Vac 24Vdc Max. Flow (4.1) Flow Rate Unit Max. Max. Flow Rate

Min. Flow (4.2)

Output : 4-20mA /Pulse(ferq) R S-485/Modbus Flow Rate Unit Min. Min. Flow RateERROR OF RATE (%)

Empty Tube Set (4.3) N/A Disable Enable, Disable

Grounding : NO YE S

0.2% 0.3% 0.5%

CL II=2% Installation Direction: Horizontal Vertical Output 1 Func. (4.4) N/A Max. Flow Rate Max. Flow Rate, Min. Flow Rate, Empty Tube, System Alarm

5.0 ERROR OF RATE (%)

Vibration Inside Tube : NO YES Output 1 Type (4.5) N/A No NO,NC

4.0 Alarm Set (4) 0.2% 0.3% 0.5%

Strong Magnetic Near by: NO YES

Output 2 Func. (4.6) N/A Min. Flow Rate Max. Flow Rate, Min. Flow Rate, Empty Tube, System Alarm

Explosion Proof: NO YES 3.0

2.0

Output 2 Type (4.7) N/A No NO,NCExplosion Proof Code: 2.0

Curr. Func. (4.8) N/A None Empty Tube, System Alarm 1.5

1.0 Alarm Curr. (4.9) mA 3.6 3.6,3.8,20.5,22

Temp. Alarm. (4.10) N/A 1 0:OFF, 1:ON 1.0

0.0

Q1 Q2 Q3 Q4

0.5

0.0

0 1 2 3 4 5 6 7 8 9 10 11 12

VELOCITY (M/S)

17