1/212ページ

ダウンロード(70.7Mb)

世界最高を自負するドイツのプーラー専門メーカー

1919年の創設当時より、産業用、自動車用の各種プーラー専門メーカーとして歴史を歩んできました。製品はドイツ国内と、世界100ヶ国以上に輸出されています。高い技術力と幅広い製品群を持ち、プーラーに関する特許は400に及びます。欧州トップシステムサプライヤーとして、引き抜き工具において世界をリードしています。

このカタログについて

| ドキュメント名 | KUKKO(クッコ)英語版 |

|---|---|

| ドキュメント種別 | 製品カタログ |

| ファイルサイズ | 70.7Mb |

| 取り扱い企業 | 喜一工具株式会社 (この企業の取り扱いカタログ一覧) |

この企業の関連カタログ

このカタログの内容

Page1

Cover-EN-KUKKO

KUKKO A world in motion

Tool factory since 1919!

Specialized in extractors

General catalogue EN

2018/2019

KUKKO tool program

Page2

KUKKO tool factory

A world in motion since 1919!

KUKKO tool factory

a world in motion since 1919!

KUKKO Werkzeugfabrik Kleinbongartz & Kaiser oHG is the manufacturer of extractor tools for

users in trade and industry.

In 1919, Kleinbongartz & Kaiser oHG, the core To this day, the product lines, extractor tools and

company of today‘s KUKKO Group, was founded dismounting tools are the core business of the

by Alfred Kleinbongartz and his brother-in-law KUKKO Group.

Emil Kaiser in Remscheid, the centre of the Ger-

man tool industry. Numerous German and foreign patents,

registered designs, and utility models bear wit-

As of October 2013, the company location is in ness to the intensive, continuous and successful

Hilden. KUKKO has been an independent, ow- development work.

ner-run family company for four generations and

is one of the world‘s leading producers of extrac-

tor tools of all kinds.

From the very beginning, KUKKO specialized in

the development and manufacturing of extrac-

tor tools for the non-destructive dismounting of

gears, bearings, ball bearings and similar compo-

nents in all areas of technology.

2 A world in motion

since 1919!

Page3

KUKKO_Katalog_17_18_EN、Katalog_2017_Teil_01_EN

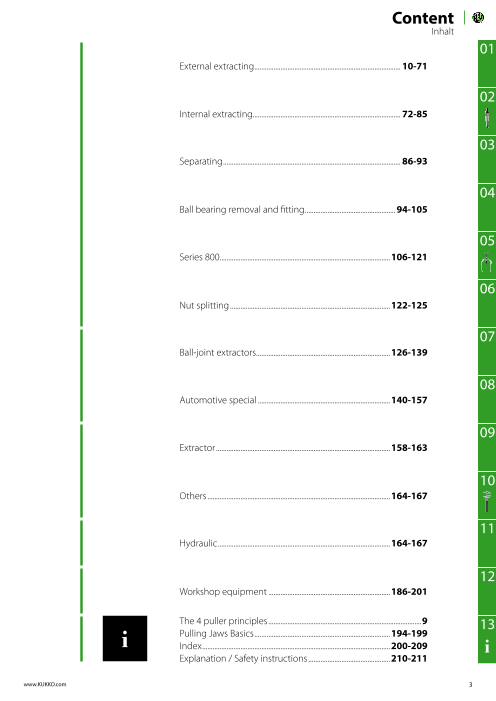

Content

Inhalt

01

External extracting .................................................................................... 10-71

02

Internal extracting..................................................................................... 72-85

03

Separating ...................................................................................................... 86-93

04

Ball bearing removal and fitting .................................................... 94-105

05

Series 800..................................................................................................106-121

06

Nut splitting ............................................................................................122-125

07

Ball-joint extractors .............................................................................126-139

08

Automotive special ............................................................................140-157

09

Extractor ....................................................................................................158-163

10

Others .........................................................................................................164-167

11

Hydraulic ...................................................................................................164-167

12

Workshop equipment ......................................................................186-201

The 4 puller principles ........................................................................................9 13

i Pulling Jaws Basics ..............................................................................194-199

Index ............................................................................................................200-209 i

Explanation / Safety instructions ...............................................210-211

www.KUKKO.com 3

Page4

KUKKO tool factory

Hilden Logistics Center

KUKKO worldwide

Greg Genevro Christian Knoche Katrin Theiner Dragan Pejovic Maike Hölscheid

United States Europe France Belgium Italy

Asia Poland Netherlands Spain

Russia Luxembourg

Hilden Logistics Center

State-of-the-art storage technology - Global distribution - Supply capability as a success factor

An optimized organization, state-of-the-

art data technology and the new, automa-

ted small parts warehouse at the Hilden

location guarantee that 95 per cent of

customer orders received at the factory are

shipped within 24 hours. In the tool indust-

ry, this warehouse is the most modern

of its kind. In addition to shipping, it also

supplies our company‘s production.

4 A world in motion

since 1919!

Page5

KUKKO tool factory

Innovation, design

Innovation, competence, quality,

service and customer proximity

have for decades been the foundation of the company‘s success in the world‘s markets. More

than 60% of production is exported and sold worldwide in more than 100 countries.

The success with more than 150 extractor types Strict adherence to the requirements of the

in more than 500 different implementation sizes customer benefit – as well its modernity, high

has, over time, resulted in the KUKKO brand name technical competence, significant financial power,

becoming synonymous with extractor tools. and timely customer service – has made KUKKO

an esteemed partner of the retail trade and one of

the top European system suppliers in the work-

shop area of the automotive industry.

Design and modeling

3D printing technology in the early design phase

The tradition of technical drawing on paper was

digitalized a long time ago. Today, an engineer

can use professional CAD applications for the de-

sign and construction of technical solutions. They

can be used to create a virtual model of three-di-

mensional objects using a computer. Meanwhile, it is also possible to quickly create the

One great advantage here is the spatial represen- previously produced 3D model with cutting-edge

tation of the object as needed. printing technology early on in the design phase.

www.KUKKO.com 5

Page6

KUKKO tool factory

Knowledge management

Knowledge management

Shorter distances, faster design

With the integration of Confluence into The schedule for the development of a

the operation, the current design status new tool is designed and established from

of any product can be viewed at any time. the start through to completion. The clear

Using defined data on deadlines and allocation of tasks and their due dates help

allocation to teams and people, what is prevent unnecessary down times. The de-

missing, who is responsible, and when the velopment phase is significantly optimized

task must be completed can all be seen at with Confluence.

a glance.

The customer can also see the trans-

parency of the product development.

Project status and Specific customer projects can always be

monitored and, if necessary, immediately

deadlines globally corrected.

visualized.

6 A world in motion

since 1919!

Page7

KUKKO tool factory

Puller guide and TURNUS catalogue

Puller guide

Use our guide to pullers to help quickly and safely select the right puller.

Not sure which puller is the right one for you? The guide also serves as a textbook for pulling

Our guide will ensure that you find the puller applications and is available in seven languages.

best suited for your application. Whether external

pulling, interior extraction, separating pulling, or You can find it under the download section in

the fitting and removal of ball bearings, you can the service area of our website.

find the right tool for every application.

Un mondo in movimento En värld i rörelse

Мы приводим в движение мирEen wereld ron

ilman liikkeessä Un mundo en movimiento

n i bevægelse En verden i bevægelse

Eine Welt in Bewegung

ие мир Świat w ruchu Un mondo in moviment

o en movimiento Мы приводим в движение

aailman liikkeessäEn verden i bevæg

world in motion E n verden i bevegelse

让世界转动起来

ine Welt in Bewegung

onde en mouvement Мы приводим в движение м

orld in motion En verden i bevegelse

rondom bewegingUn mondo in movimento

Un mondo in movimento En värld i rörelse

Мы приводим в движение мир

ilman liikkeessä 让世界转动起

n i bevægelse Un mundo en movimiento

undo em movimento En verden i bevægel

En verden i bevegelse Een wereld rondom bewegin

年以来の伝統と最新技術の融合 Um mundo em movimen

Świat w ruchu

Eine Welt iEn ine Welt in

让世界转动起来Un monde en mouv

Puller guide –

how to choose the right tool

KUKKO AA wwoorrlldd iinn mmoottiioonn

ssiinnccee11991199!! TTooooll ffaaccttoorryy

TURNUS catalogue

Our TURNUS line of products is specially designed for bolting, tensio-

ning, clamping, striking, and marking jobs.

Any time you need to clamp something in place or mark something, the

TURNUS catalogue has the solution for your application. Hand vises, screw

clamps, door clamps, vises, screwdrivers, pin wrenches, punching and cutting,

signing and marking as well as arc-free tools are part of the product range.

You can download the current catalogue under downloads in the service area

of www.KUKKO.com. Our website also offers you fast access to all TURNUS Generall catallogue EENN

22001177//22001188

products via the TURNUS products tab. TTUURRNNUUSS ttooooll pprrooggrraamm

TGURNUeS toonl progeramral catalogue

2017/2018

EN

www.KUKKO.com 7

KTooUl facKtoryKO since1919!

A world in motion

Page8

KUKKO tool factory

Information

Information about

the KUKKO product range

You can find this on our homepage www.kukko.com

We have made plenty of information available for

you in the download area. You will also find detailed

information and application videos concerning the

product.

Would you like to order spare parts? You can do this

quickly and easily, because almost all the compo-

nents are available and numbered as spare parts. In

the service area of our homepage, you will find the

spare parts list for downloading.

Ersatzteil-Liste

Spare part list

Videos

The videos will help you with any questions you may have about the application of our tools.

What is the proper way to use the tool? The application video is a quick illustration of the safe and correct use of our tools.

Almost all our tools have a QR code that you can scan with your smartphone to directly access the corresponding video.

All videos are provided directly on your YouTube channel www.youtube.com/kukkotools.

www.youtube.com/kukkotools

SCAN YOUR

TOOL

SCAN

08:18 / 19:19

8 A world in motion

since 1919!

Page9

The 4 puller principles KUKKO tool factory

The 4 puller principles

EXTERNAL INTERNAL

The part to be removed is on a shaft and The part to be removed is in a recess!

is freely accessible from the outside!

pull pull pressure pressure

pressure

pull pull

Use an EXTERNAL puller Use an INTERNAL puller

SEPARATING BALL BEARING

A B

The part to be removed is level. It is not The ball bearing is in a The ball bearing

possible to use standard puller jaws! housing and on a shaft is inside a casing,

at the same time. but has no shaft

for support.

pull pull

pressure pull pull pull pull

pressure

Non-contact

extraction.

Use an SEPARATING device Use an BALL BEARING extractor

www.KUKKO.com 9

Page10

KUKKO tool factory

External extracting

PULLERS -

these original KUKKO designs have

been known for decades and have

proven themselves in a wide range

of application areas worldwide.

KUKKO has a very large range of

various types of pullers.

Pullers with sliding, parallel jaws

· Parallel pulling hooks in every position, even

with full load.

· Turning the pulling hooks enables them to be

used both internally and externally.

Pullers with swivelling jaws

· The larger the pulling force, the stronger

the puller hook’s grip on the workpiece to

be removed.

Pullers with self-centering jaws

· Automatic self-tensioning and self-centering

pulling hooks auto grip.

Pullers with reversible jaws

· The pulling hooks are reversible and can

be used on both sides with various different

types of hooks.

Pullers with side clamp

· Clamps increase the pressure of the hooks

significantly and prevent the puller from slipping.

· When the tension clamp is tightened, the pulling

jaws grip below the part to be removed and

loosen it before the actual removal process.

Pullers with adjustable jaws

· The Alligator conversions ensure that the

pulling hooks can only be opened and closed

by operating the adjustment spanner.

The grip of the conversions is therefore as

strong as an alligator’s bite.

10 A world in motion

since 1919!

Page11

01

External extracting

Außen-Abziehen

01

Selection of the right external puller....................12

Auswahl des richtigen Außen-Abziehers

Pullers with sliding, parallel jaws.............................16

Abzieher mit gleitenden,

immer parallelen Abzughaken

Puller, high performance is guaranteed.............33

Abzieher, extra kräftige Ausführung

Jaws and accessories external pulling ................36

Abzughaken und Zubehör für Aussen-Abzieher

Spindle basics......................................................................42

Übersicht: Spindel

Pullers with swivelling jaws........................................50

Abzieher mit schwenkbaren Abzughaken

Pullers with self-centering jaws...............................56

Abzieher mit

selbstzentrierenden Abzughaken

Pullers with Auto-Snap..................................................60

Abzieher mit Auto-Snap

Puller with cone-driven spread adjuster............61

Abzieher mit konischer Selbstspannung

Pullers with reversible jaws.........................................62

Abzieher mit umkehrbaren Haken

Pullers with side clamp..................................................64

Abzieher mit seitlicher Spannzwinge

Pullers with adjustable jaws.......................................66

Abzieher mit voreinstellbaren Abzughaken

Small part puller.................................................................67

Kleinteilabzieher

Puller Economy...................................................................68

Abzieher Economy

www.KUKKO.com 11

Page12

KUKKO tool factory

External extracting

Selection of the right external puller

The part to be remo- pull pull

pressure

ved is on a shaft and

is freely accessible

from the outside!

1st step: Measuring the space available

diameter defines the spreads

depth defines max. reach

available space defines the size of the puller jaw

194-199

2nd step: Selection of the puller type

Requirement: Requirement: Requirement: Requirement:

· The puller is used for · The same removal · The same removal · The bearing is flush.

various applications. application is always used. application is always used. · It is especially important

· The puller must be able to · Same application at that the puller arms do

change characteristics e.g. different depths. not slip off.

increase the reach etc.

Recommendation of Recommendation of Recommendation of Recommendation of

KUKKO KUKKO KUKKO KUKKO

Puller with sliding, Puller with self-centering Puller with Puller with

parallel puller jaws puller jaws (autogrip) swivel puller jaws side tension clamps.

The puller jaws can be moved The two puller jaws are The jaws and the cross-beam To remove fitting parts the

continuously (even asymme- connected to each other. The are connected by movable puller jaws grab beneath the

trically) on the cross-beam, pullers therefore ensure au- brackets. As the spindle pulls, part to be removed when pul-

and can be fixed to the cross- tomatic self-tensioning and the jaws tense and tighten ling on the side clamps and

beam using a bolt connecti- self-centering of the jaws. firmly. loosen the part even before

on or knurled knob. An additional option is swi- the actual pulling process. The

vel-jaws pullers. Reversing clamp presses the puller jaws

the puller jaws expands or securely onto the part to be

reduces the reach. removed. This ensures that

the puller jaws do not slip off.

Series Series Series Series

available available available available

11 ; 20; 20+; 20-S; 20+S; 20-S-T 43; 44; 45; 482; 483; 844; 845 41; 42; 46; 47; 201; 203; 205 204; 210

20-S+T; 30; 30+; 30-S; 30+S 206; 207; 208; 209

30-S-T; 30-S+T; 110; 120; 130

12 A world in motion

since 1919!

Page13

KUKKO tool factory

External extracting

3rd step: How much force is required? 01

A normal amount of pressure is required. High pressure is required because the part to be removed

is particularly secure, or rusted.

Puller with Puller with

mechanical pressure spindle long hydraulic spindle

4th step: Select model

The selected pulling tool normally states the necessary power and pulling force. However, in order to be absolutely sure,

you should always choose the largest possible model for dimension ranges which cross over.

Detailed dimension and performance details for all models can be found at www.KUKKO.com

For example:

1st step: Measuring the space available

Diameter: 142 mm / 120 mm / 135 mm

Depth: 135 mm / 120 mm / 220 mm

Available space: unlimited

2nd step: Selection of puller type

Specification: There must be pulled various bearings at different depths.

Target: We are looking for a puller which can be individually adapted.

According to the puller guide should be used pullers with sliding puller arms that are always parallel.

3rd step: How much force is needed?

The bearings are on the shaft.

According to the puller guide should be used a puller with a mechanical spindle.

4th step: Select model

According to the KUKKO website choose the pullers from series 20 and 30 in size 2.

The decision falls to : 30-2+

Advantage:

• with the 3-jaw model, you have the best possible load distribution and a particularly secure hold.

• You can adjust your puller to the relevant reach by buying the extensions.

• The quick adjusting capability allows the reach to be changed quickly.

www.KUKKO.com 13

Page14

KUKKO tool factory

External extracting

You should always give a 3-jaw puller preference if the access conditions

permit. The uniform load distribution guarantees a particularly secure

hold on the to be extracted part.

Mode of operation

STANDARD as INTERNAL extractor

External pulling is the most common type of pul- The external pullers can also be used as internal

ling. The part to be extracted such as a gear wheel, extractors by turning the jaws.

pulley or ball bearing, is gripped from the outside. Important: When used as internal extractors, a

The part is loosened from the shaft by the pull of fixed center point is required to brace the pres-

the pressure screw. sure screw of the products in these series.

Accessories: Modular extensions

For the 20 and 30 series, we offer

modular extensions. If the part

to be removed sits deep on a

shaft, jaw extensions will be

needed.

3x

Accessories: Side clamp

The side clamp is available separately (No. 219-1). It is attached to the puller

jaw after the puller has been fitted and prevents slippage of the puller jaw

under very high forces.

Accessories: Grease hydraulic pressure spindle

The hydraulic spindle ensures controlled and secure operating of 7-20 t. It

uses the entire capability of the puller, over and above what can be achie-

ved with a mechanical spindle. When replacing a mechanical spindle with a

hydraulic one, there is also a considerable reduction in the drive force which

needs to be used.

14 A world in motion

since 1919!

Page15

KUKKO tool factory

External extracting

Sliding-arm pullers with constantly parallel jaws 01

Accessories: auxiliary grease hydraulic rams

For use with mechanical KUKKO pullers from size 3.

The auxiliary grease hydraulic rams are a good tool for significantly increasing the

pressure when removing very secure parts. The hydraulic rams are simply secured

between the spindle and shaft with the mechanical spindle.

No conversion of the puller is needed!

Accessories: Puller jaws

Pullers in series 20 and 30 can easily be adjusted using different puller jaws

lengths and types.

Which puller jaws are right for which puller?

The puller jaws that start with -1 fit all pullers of size -1 and -10

The puller jaws that start with -2 fit all pullers of size -2 and -20

The puller jaws that start with -3 fit all pullers of size -3 and -30

The puller jaws that start with -3 can also use by the pullers of size -4 and -40

Example:

20-2 has the puller jaws 2-150-P

can also use: 2-151-P; 2-152-P; 2-153-P

can also use long puller jaws such as: 2-300-P; 2-301-P; 2-302-P; 2-303-P

Safety instructions

The puller must be centrally If there are several parts to be Jaws must always be positioned

positioned for center shafts. If pulled, always remove them directly below the part to be re-

the shaft is not centered, pul- one-by-one. Never remove se- moved.

ling with parallel jaws may re- veral parts simultaneously.

sult asymmetrical pulling.

If there is adequate free space A 2-jaw puller is always used in

around the part, we recom- situations where there is insuffi-

The jaws must be set firmly mend a 3-jaw puller for optimal cient space for a 3-jaw puller.

and completely against the force distribution.

cross-beam.

www.KUKKO.com 15

Page16

KUKKO tool factory

External extracting

Pullers with sliding, parallel jaws

2-jaw pullers ST

For removing bearings, gears, discs, etc.

20 Description

• Standard pulling hook.

• Parallel pulling hooks in every position, even with full load.

• Pulling hooks with infinitely variable adjustment on the cross-beam.

• Optimal adjustment of the spindle to the shaft with 2-sided spindle tip.

• Mechanical pressure spindle

20-1 Advantage

20-10 • Can be installed on various pulling hooks and variable reach thanks to jaw extensions.

20-2 • Turning the pulling hooks enables them to be used both internally and externally.

20-20 • Suitable for pulling asymmetric workpieces.

20-3 • Spindle head band prevents the wrench from slipping off.

20-30 • Cross-beam, up to size -30, includes hexagonal profile for holding.

20-4

20-40

Art.- max. max.

No.

mm mm mm t Nm

20-1 -009433 90 100 17 4,5 80

20-10 -009921 120 100 17 4,5 80

20-2 -009501 160 150 22 6,0 150

20-20 -010088 200 150 22 6,0 150

20-3 -009686 250 200 27 8,5 300

20-5 20-30 -010163 350 200 27 8,5 300

20-4 -009761 520 200 36 12 400

20-40 -411861 650 300 36 12 400

20-5 -009846 750 400-700 41 15 650

Universal 2-jaw puller with long hydraulic spindle(including mechanical pressure screw) ST

For pulling particularly tight bearings, gears, discs, etc.

20-B Description

• Grease hydraulics.

• Standard pulling hook.

• Parallel pulling hooks in every position, even with full load.

• Pulling hooks with infinitely variable adjustment on the cross-beam.

• Hydraulic and mechanical pressure screw.

Advantage

• Easy and even pulling for particularly tight parts.

• Variable reach thanks to jaw extensions, available up to a puller size of -30.

• Optional conversion to various jaw types for mechanical use.

• Turning the pulling hooks enables them to be used both internally and externally.

• Suitable for pulling asymmetric workpieces.

Art.- mit

No. with

mm mm mm t

20-2-B -885815 160 150 12; 22 7 8-01

20-20-B -885846 200 150 12; 22 7 8-01

20-3-B -885891 250 200 12; 27 10 8-02

20-30-B -885945 350 200 12; 27 10 8-02

20-4-B -885983 520 200 36 15 8-1-B

20-40-B -886010 650 300 36 15 8-1-B

16 A world in motion

since 1919!

Page17

KUKKO tool factory

External extracting

Universal 2-jaw puller with extended jaws ST

For removing bearings, gears, discs, etc. 01

20 Description

• Extended standard puller hook.

• Parallel pulling hooks in every position, even with full load.

• Pulling hooks with infinitely variable adjustment on the cross-beam.

• Optimal adjustment of the spindle to the shaft with 2-sided spindle tip.

• Mechanical pressure screw.

Advantage

• Can be installed on various pulling hooks and variable reach thanks to jaw extensions.

• Turning the pulling hooks enables them to be used both internally and externally.

• Suitable for pulling asymmetric workpieces.

• Spindle head band prevents the wrench from slipping off.

• Cross-beam, up to size -30, includes hexagonal profile for holding.

Art.- max.

No.

mm mm mm t

20-1-2 -466311 90 200 17 4,5

20-1-25 -914362 90 250 17 4,5

20-1-4 -989643 90 400 17 4,5

20-10-2 -466496 120 200 17 4,5

20-10-25 -908682 120 250 17 4,5

20-10-4 -989650 120 400 17 4,5

20-2-3 -466564 160 300 22 6,0

20-20-3 -466649 200 300 22 6,0

20-3-25 -901188 250 250 27 8,5

20-3-3 -466724 250 300 27 8,5

20-3-4 -467066 250 400 27 8,5

20-3-5 -467301 250 500 27 8,5

20-30-3 -466809 350 300 27 8,5

20-30-4 -467141 350 400 27 8,5

20-30-5 -467486 350 500 27 8,5

20-4-3 -466984 520 300 36 12,0

20-4-4 -467226 520 400 36 12,0

20-4-5 -467554 520 500 36 12,0

20-40-4 -730641 650 400 36 12,0

20-40-5 -731976 650 500 36 12,0

Sales display for 2-jaw pullers ST

For removing bearings, gears, discs, etc.

20-ST Description

• The sales and workshop stands enable 2-jaw pullers to be stored and presented safely.

• Standard pulling hook.

• Parallel pulling hooks in every position, even with full load.

• Pulling hooks with infinitely variable adjustment on the cross-beam.

• Optimal adjustment of the spindle to the shaft with 2-sided spindle tip.

Advantage

• Can be installed on various pulling hooks and variable reach thanks to jaw extensions.

• Turning the pulling hooks enables them to be used both internally and externally.

• Suitable for pulling asymmetric workpieces.

• Spindle head band prevents the wrench from slipping off.

• Cross-beam with hexagonal profile for good grip.

Art.- max. Stück

No. pieces

mm mm mm t

20-1, 20-10,

20-ST -010248 90 - 250 100 - 200 17-27 4,5 - 8,5 20-2, 20-20, 5

20-3, 20-STL

www.KUKKO.com 17

Page18

KUKKO tool factory

External extracting

Universal 2-jaw puller with long hydraulic spindle and extended jaws(including mechanical pressure screw) ST

For pulling particularly tight bearings, gears, discs, etc.

20-B Description

• Grease hydraulics.

• Extended standard puller hook.

• Parallel pulling hooks in every position, even with full load.

• Pulling hooks with infinitely variable adjustment on the cross-beam.

• Hydraulic and mechanical pressure screw.

Advantage

• Easy and even pulling for particularly tight parts.

• Optional conversion to various jaw types for mechanical use.

• Variable reach thanks to jaw extensions, available up to a puller size of -30.

• Turning the pulling hooks enables them to be used both internally and externally.

• Suitable for pulling asymmetric workpieces.

Art.- mit

No. with

mm mm mm t

20-2-3-B -885808 160 300 12; 22 7 8-01

20-20-3-B -885839 200 300 12; 22 7 8-01

20-3-3-B -885860 250 300 12; 27 10 8-02

20-3-4-B -885877 250 400 12; 27 10 8-02

20-3-5-B -885884 250 500 12; 27 10 8-02

20-30-3-B -885914 350 300 12; 27 10 8-02

20-30-4-B -885921 350 400 12; 27 10 8-02

20-30-5-B -885938 350 500 12; 27 10 8-02

20-4-3-B -885952 520 300 36 15 8-1-B

20-4-4-B -885969 520 400 36 15 8-1-B

20-4-5-B -885976 520 500 36 15 8-1-B

20-40-4-B -885990 650 400 36 15 8-1-B

20-40-5-B -886003 650 500 36 15 8-1-B

Universal 2-jaw puller, in set ST

For removing bearings, gears, discs, etc.

20-P Description

• Standard pulling hooks in various lengths.

• Parallel pulling hooks in every position, even with full load.

• Pulling hooks with infinitely variable adjustment on the cross-beam.

• Optimal adjustment of the spindle to the shaft with 2-sided spindle tip.

• Mechanical pressure screw.

Advantage

• Variable reach thanks to optional jaw extensions.

• Can be installed on various pulling hooks.

• Turning the pulling hooks enables them to be used both internally and externally.

• Suitable for pulling asymmetric workpieces.

• Spindle head band prevents the wrench from slipping off.

Art.- max. mit

No. with

mm mm mm t

1-90-P,

20-10-P3 -267611 120 100/200/250/350 17 4,5 1-190-P,

1-250-P

20-20-P2 -003004 200 150/300 17 6 2-150-P,

2-300-P

3-200-P,

20-30-P3 -003011 350 200/300/400 19 8,5 3-300-P,

3-400-P

18 A world in motion

since 1919!

Page19

KUKKO tool factory

External extracting

Set of universal 2- and 3-jaw pullers ST

For removing bearings, gears, discs, etc. 01

K-2030-10 Description

• 8 in 1 kit in the tried-and-tested KUKKO-L-Boxx-System.

• The set facilitates the assembly of eight different pulling device models through the combination of

pulling jaws and extensions.

• Flexibility assured thanks to two-arm or three-arm design.

• Standard pulling hook.

• Jaw extensions.

Advantage

• Practical package for universal use.

• Variable reach thanks to optional jaw extensions.

• Can be installed on various pulling hooks.

• Turning the pulling hooks enables them to be used both internally and externally.

• Suitable for pulling asymmetric workpieces.

Art.- max.

No.

mm mm mm t

K-2030-10 -974748 120 - 130 100 - 350 17 4,5 - 6,0 L-Boxx

Set of universal 2- and 3-jaw pullers ST

For removing large bearings, gears, discs, etc.

K-2030-20 Description

• 7 in 1" kit in the tried-and-tested KUKKO-L-Boxx system.

• The set facilitates the assembly of seven pulling device models through the combination of pulling

jaws and extensions.

• The rugged construction is particularly suitable for large and heavy applications in industrial and

commercial vehicles.

• Flexibility assured thanks to two-arm or three-arm design.

• Standard pulling hook.

Advantage

• Practical package for universal use.

• Variable reach thanks to optional jaw extensions.

• Can be installed on various pulling hooks.

• Turning the pulling hooks enables them to be used both internally and externally.

• Suitable for pulling asymmetric workpieces.

Art.- max.

No.

mm mm mm t

K-2030-20 -161360 150 - 600 200 24 6 L-Boxx

Universal hydraulic 2-jaw and 3-jaw puller set ST

For hydraulic removal of large bearings, gears, discs, etc.

Description

K-2030-20-B • 14 in 1" kit in the tried-and-tested KUKKO-L-Boxx system.

• The set facilitates the assembly of 14 pulling device models through the combination of hydraulics,

pulling jaws and extensions.

• The rugged construction is particularly suitable for large and heavy applications in industrial and

commercial vehicles.

• Flexibility assured thanks to two-arm or three-arm design.

• Standard pulling hook.

Advantage

• Practical package for universal use.

incl. • Variable reach thanks to optional jaw extensions.

• Optional conversion to various jaw types for mechanical use.

• Turning the pulling hooks enables them to be used both internally and externally.

• Suitable for pulling asymmetric workpieces.

Art.- mit

No. with

mm mm mm t

K-2030-20-B -123269 150 - 600 200 24 8-01 7 L-Boxx

www.KUKKO.com 19

Page20

KUKKO AND SYSTEM

Save keeping of the tools in special foam

Instructions in the cover always remain visible with:

• Statement of contents

• Usage diagrams

• Safety notes

If you register online, the manufacturer‘s guarantee

increased to 5 years.

KUKKO special sliding grease for pressure spindle included.

Completeness - easy to check at a glance

Connectable with the systems of other well known

manufacturers

ONE SYSTEM. A LOT OF POSSIBILITIES.

With the KUKKO-i and L-BOXX-System you get all oppor-

tunities. You can equip it with insert-boxes, thermo formed

parts, foam inlets and different applications for the lid. Your

tools, small parts or spare parts will be kept and transported

safely and well arranged. The KUKKO-i and L-BOXX-System

is the perfect mobile solution and can be integrated easily

into most vehicles. SECURE MOBILE The new front handle for easy

carrying the proven L-Boxx.

TOOLS InSErT-BOxES LOCKaBLE OFFICE Max. LOad 100 KG Car HOLdEr +

CRASHSAFE