1/38ページ

Download(23.3Mb)

Stainless steel container unit catalog

Product Catalog

Industrial stainless steel container and peripheral equipment

[contents]

1.Agitation and temperature control unit

2.Agitators

3.Pressurized container units

4.Custom-made purpose-built units

5.Stainless steel container accessories

6.Auxiliary products for transport and installation

Document Information

| Document Title | Stainless steel container unit catalog |

|---|---|

| Document Type | Product Catalog |

| File size | 23.3Mb |

| Category | |

| Company | NITTO KINZOKU KOGYO CO.,LTD (Documents List) |

Documents related to this company

Document Contents

Page2

NITTO KINZOKU KOGYO CO., LTD.

Sales Division 358 Nichome Yashio-shi, Saitama Prefecture 340-0811, Japan

TEL +81-48-996-4221

URL: https://www.nitto-kinzoku.co.jp/

E-mail: sales@nitto-kinzoku.co.jp

2019.1

Page3

Unit catalog index P21–28 Custom-made purpose-built units

We offer a range of unit products with a variety

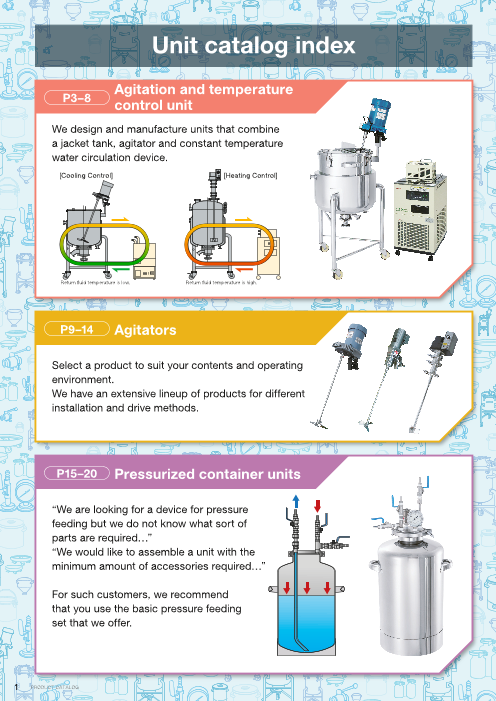

Agitation and temperature

P3–8 of functions such as storage, transport, heating, control unit discharge, etc.

We design and manufacture units that combine We can also produce custom-made products to match

a jacket tank, agitator and constant temperature your application.

water circulation device. Leave the selection of the agitator and pump to us.

[Cooling Control] [Heating Control]

Stainless steel container

P29–32 accessories

Useful functions can be added to the stainless

steel container with optional accessories.

Return fluid temperature is low. Return fluid temperature is high.

We offer a variety of sight glasses that allow

you to check the inside of the container and

P9–14 Agitators valves for both powder and fluids to suit

different applications.

Select a product to suit your contents and operating

environment. Auxiliary products for

We have an extensive lineup of products for different P33, 34 transport and installation

installation and drive methods.

Stainless steel containers that are filled with contents

and large valves are heavy, and thus transport and valve

installation work often leads to injuries and wounds.

P15–20 Pressurized container units We offer auxiliary products that help to simplify such work.

“We are looking for a device for pressure

feeding but we do not know what sort of

parts are required…” We offer new and custom-made

“We would like to assemble a unit with the

minimum amount of accessories required…” product design and manufacturing.

The number of designs for custom-made products that we have

For such customers, we recommend created so far is more than 80,000.

We take care of the entire process from design to drafting and

that you use the basic pressure feeding production while maintaining close communications with the customer.

set that we offer. One of our strengths is the fact that many of our sales representatives

have a manufacturing background.

With our extensive knowledge of raw materials and manufacturing

techniques, we will supply what the customer wants.

1 PRODUCT CATALOG

Page4

Unit catalog index P21–28 Custom-made purpose-built units

We offer a range of unit products with a variety

Agitation and temperature

P3–8 of functions such as storage, transport, heating, control unit discharge, etc.

We design and manufacture units that combine We can also produce custom-made products to match

a jacket tank, agitator and constant temperature your application.

water circulation device. Leave the selection of the agitator and pump to us.

[Cooling Control] [Heating Control]

Stainless steel container

P29–32 accessories

Useful functions can be added to the stainless

steel container with optional accessories.

Return fluid temperature is low. Return fluid temperature is high.

We offer a variety of sight glasses that allow

you to check the inside of the container and

P9–14 Agitators valves for both powder and fluids to suit

different applications.

Select a product to suit your contents and operating

environment. Auxiliary products for

We have an extensive lineup of products for different P33, 34 transport and installation

installation and drive methods.

Stainless steel containers that are filled with contents

and large valves are heavy, and thus transport and valve

installation work often leads to injuries and wounds.

P15–20 Pressurized container units We offer auxiliary products that help to simplify such work.

“We are looking for a device for pressure

feeding but we do not know what sort of

parts are required…” We offer new and custom-made

“We would like to assemble a unit with the

minimum amount of accessories required…” product design and manufacturing.

The number of designs for custom-made products that we have

For such customers, we recommend created so far is more than 80,000.

We take care of the entire process from design to drafting and

that you use the basic pressure feeding production while maintaining close communications with the customer.

set that we offer. One of our strengths is the fact that many of our sales representatives

have a manufacturing background.

With our extensive knowledge of raw materials and manufacturing

techniques, we will supply what the customer wants.

NITTO KINZOKU KOGYO CO., LTD. 2

Page5

Agitation and temperature control unit

Agitation and temperature control unit

We design and manufacture units that combine a jacket tank, agitator

and temperature-controlled water circulation device.

Heating and cooling capability

Freezer works throughout the entire operating temperature

range, allowing cooling to be controlled even in high

temperature ranges.

[Cooling Control] [Heating Control]

Return fluid temperature is low. Return fluid temperature is high.

We manufacture these units with

pressurized containers as well.

3 PRODUCT CATALOG

Page6

Bowl type jacket container with agitator mount

Jacket container with agitator which features

temperature regulation

■ Range of agitator mount

PO (portable type) (P9, 10) SD (standing type) (P11, 12, 13) BO (bottom type) (P14)

Specifications

■ Inlet

Container, jacket, legs: SUS304

Cover: SUS304

Castor: SUS + urethane wheels

(of which 2 are attached with a stopper)

Gasket: Silicone rubber

(compliant with the Japanese Food

Hygiene Law)

Jacket nozzle: 1S ferrule

■ Outlet (ferrule) ● Surface treatment: Inner and outer surface buffing

● Operating condition: Atmospheric pressure

(no pressurization adjustment)

φD1 t1

φD1 t1 φD1 t1

φD2 t2 φD2 φD2t2 t2

[DTK-J-36-PO]

[PO type] [SD type] [BO type]

Bowl type jacket container with agitator mount (ferrule discharge) [DTK-J]

Internal Internal Internal

Model Capacity diameter diameter height Height Plate thickness Drain size

L D1 D2 H1 H2 t1 t2 PO model SD model BO model

DTK-J-36 35 360 430 430 830 1.2 1.2 1S

DTK-J-39 45 387 430 470 870 1.2 1.2 1S

DTK-J-43 60 430 470 505 905 1.2 1.5 2S

DTK-J-47 80 470 565 555 955 1.5 1.5 2S

DTK-J-47H 100 470 565 670 1070 1.5 1.5 2S

DTK-J-565 150 565 635 695 1095 1.5 1.5 2S

DTK-J-635 200 635 700 755 1155 1.5 2.0 2S

● Order can be custom-made. Leg length, nozzle size, etc. can be changed.

● Price of agitator shall be quoted separately. We can also design to match the agitator that you have on hand.

Order Tank model - Size - Agitator mount model

Ordering example DTK-J - 39 - PO

NITTO KINZOKU KOGYO CO., LTD. 4

H1

H2

H1

H2

H1

H2

Page7

Jacket container with agitator mount

Container with jacket that supports temperature-

controlled agitation

■ Improved discharge and agitation!

[No accumulation] ■ Container without jacket

There is almost no accumulation of the

contents because of the flange connection.

[Efficient discharge]

Contents inside the tank can be Bowl container

Problem: with agitator discharged efficiently.

Contents mount

accumulate inside [Agitation efficiency] [DTM]

the ferrule and valve. Agitation efficiency improves as there is [DTK]

[DTK-J] [DTM-J] no dead space.

Bowl type jacket container with agitator mount (tank bottom valve) [DTM-J]

Specifications

■ Inlet Container, jacket, legs: SUS304

φD1 t1 Cover: SUS304

φD2 t2 Castor: S US + urethane wheels

(of which 2 are attached with

a stopper)

Gasket: Silicone rubber

[DTK-J] [DTK-J] [DTM-J] [DTM-J] (compliant with the Japanese

Food Hygiene Law)

■ Tank bottom valve Jacket nozzle: 1S ferrule

⃝ Surface treatment: Inner and outer

surface buffing

● Operating condition: A tmospheric pressure

(no pressurization adjustment)

* Price of the agitator shall be quoted separately. * C onsult us if you want to apply pressure on the jacket.

Model Capacity Internal diameter Internal Drain Plate height height thickness Valve

L D1 D2 H1 H2 t1 Size

DTM-J-36 35 360 430 426 404 1.2 1S

DTM-J-39 45 387 430 467 403 1.2 1S

DTM-J-43 60 430 470 494 411 1.2 2S

DTM-J-47 80 470 565 546 409 1.5 2S

DTM-J-47H 100 470 565 661 409 1.5 2S

DTM-J-565 150 565 635 688 407 1.5 2S

DTM-J-635 200 635 700 749 406 1.5 2S

Unit of length is mm.

■ Optional parts

Insulation cover [ECK]

Insulation jacket for stainless steel tanks which can be used repeatedly.

・ Excellent insulation improves the warming and cooling effect of the jacket tank.

・ Prevents burns and condensation.

・ Custom-made to suit the tank.

Specifications

Material (Outer material): Glass cloth, silicone coat

(Insulation material): Glass wool, needle mat

(Thickness): t15

Model Weight External External diameter height Model Weight

External External

diameter height

kg φD H kg φD H

ECK-DTK-J-36 4 470 300 ECK-DTM-J-36 4 470 310

ECK-DTK-J-39 4 470 340 ECK-DTM-J-39 4 470 350

ECK-DTK-J-43 5 510 370 ECK-DTM-J-43 5 510 380

ECK-DTK-J-47 6 610 420 ECK-DTM-J-47 6 610 430

ECK-DTK-J-47H 7 610 540 ECK-DTM-J-47H 7 610 550

ECK-DTK-J-565 8 680 560 ECK-DTM-J-565 8 680 570

ECK-DTK-J-635 10 740 630 ECK-DTM-J-635 10 740 640

Unit of length is mm.

5 PRODUCT CATALOG

H2 H1

H3

Page8

■ Range of agitator mount

PO (portable type) (P9, 10) SD (standing type) (P11, 12, 13) BO (bottom type) (P14)

● Comes with a stand for mounting the agitator (clamp lock), allowing the container and agitator to be moved.

● Fitted with a heating and cooling jacket, with temperature-controlled agitation and discharge capabilities.

Features ● DTK-J is for ferrule discharge while DTM-J is for tank valve discharge.

● KTTK-J has a bottom that is slanted at an angle to the discharge direction for lateral discharge, allowing the contents

to be discharged smoothly.

● Comes with a split cover for easy filling and checking, allowing the agitator to be removed easily with the cover.

■ Manual 2-way ball valve

■ Smooth lateral discharge is possible

tion As the bottom of the container is slanted at an angle to the Flow direc direction of the discharge drain, the agitated liquid flows in

the discharge direction and is discharged smoothly.

Slanted bottom Since the discharge drain is fitted without any difference

in the elevation, residual liquids can be eliminated while

Jacket discharging the contents laterally.

Slant bottom type jacket container with agitator mount and legs [KTTK-J-L]

■ Inlet

Specifications

Container, jacket, legs: SUS304

Cover: SUS304

φD1 t1 Castor: S US + urethane wheels

φD2 t2 (of which 2 are attached with ■ Ferrule a stopper)

R Gasket: Silicone rubber

(compliant with the Japanese

Food Hygiene Law)

Jacket nozzle: 15A ferrule

⃝ Surface treatment: Inner and outer

surface buffing

● Operating condition:

Atmospheric pressure

(no pressurization adjustment)

* P rice of the agitator shall be quoted separately.

* C onsult us if you want to apply pressure on

the jacket.

Model Capacity Internal diameter Internal Drain Plate

■ height height thickness

Drain

Discharge outlet can be selected L D1 D2 H1 H2 t1 Size

・ T ype and size of the discharge outlet can be KTTK-J-L-36 35 360 430 380 400 1.2 1S

selected to suit the pipe and contents.

KTTK-J-L-39 45 387 430 420 400 1.2 1S

KTTK-J-L-43 65 430 470 480 400 1.2 1S

KTTK-J-L-47 80 470 565 500 400 1.5 1S

KTTK-J-L-47H 100 470 565 620 400 1.5 1S

KTTK-J-L-565 150 565 635 650 400 1.5 2S

KTTK-J-L-565H 200 565 635 930 400 1.5 2S

Ferrule (standard) Nipple Flange

KTTK-J-L-635 300 635 700 1030 400 1.5 2S

Unit of length is mm.

NITTO KINZOKU KOGYO CO., LTD. 6

H2 H1

H3

H4

Page9

Cooling pump, temperature-controlled water circulation device

Combine with a jacket tank to control temperature

Cooling pump Temperature-controlled water circulation device

CH-402B, CH-602B T-55, T-55W

Temperature-controlled water circulation device which

can circulate hot water up to temperatures of +80ºC to

sealed system circuit. Of course, it can also be used as

a temperature-controlled water tank.

[T-55]

[CH-402B/CH-602B]

Model name CH-402B CH-602B

Operating temperature range*1 -10ºC - +80ºC

Temperature control accuracy*2 Heater PID control, ±0.5ºC

Cooling capacity (50Hz)*3 Approx. 0.7kW Approx. 1.0kW

Freezer (air cooled) output 400W 600W

Heater output 1.8kW 2.25kW [T-55W]

Temperature setting, display Digital type (switches between the temperature ■ T-55 specifications

setting and tank internal temperature display)

Short circuit/over-current breaker, freezer error External dimensions W290×D370×H (water tank 460 + circulation port 40) mm

alarm, high/low temperature, pump motor error

Safety devices/Safety functions alarm, temperature sensor error diagnosis circuit, Tank internal dimensions W220×D300×H200mm

liquid replenishing alarm, prevention of boiling Capacity 10L

without water, phase reversal relay

Temperature range Room temperature +15ºC - +80ºC

temperature check monitor, remote temperature

Other functions setting, External sensor temperature

*4 connection, Temperature stability ±0.2ºC (when circulation pump is not in use)

safety device operating signal output, temperature

monitor signal output Temperature control Digital temperature indicator and control device PID control method

Water tank capacity (80% water level)*5 Approx. 26L Heater Sheath wire type 1.3kW

Magnet pump 45W (for agitation at the same time)

Applicable pump unit P-320 Circulation pump Maximum lifting height 5m

External dimensions (excluding the pump) 407×565×766Hmm Maximum flow rate 9L/min

Dry weight (excluding the pump) Approx. 66kg Approx. 68kg Circulation IN-OUT Outer shape φ12 hose connection (Rp 3/8)

Tank overheating prevention device, device to prevent

Required power supply 3-phase AC200V 50/60Hz Safety devices heating without any contents,

(excluding the pump) 10A 15A short circuit breaker, overflow

Operating current (excluding the pump) 8A 10A Material Inner tank: Made of stainless steel (SUS-304)

Exterior: Steel plate with baked finish

Standard accessories Power supply cord, waste water rubber hose,

signal connector Accessories Stainless steel lid (SUS-304)

Power supply AC100V 14A 50/60Hz

*1 When using at a temperature of +7ºC or less, be sure to use an anti-freezing

agent (type to be discussed with us). Weight 18 kg

*2 T hermal regulation may be affected by the heat transfer medium used, the operating

environmental temperature, thermal load, circulation piping length, etc.

*3 C apacity of the individual device using pure water at a circulation liquid ■ T-55W

temperature of +10ºC. Cooling capacity varies depending on the pump unit

installed. Cooling capacity drops when the environmental temperature reaches

+30ºC or higher. Increased heat capacity over the T-55 to 2.6kW with

*4 External temperature sensor is sold separately. single phase 200V power supply. Equipped with an

*5 A s it is not a sealed structure, the liquid used may evaporate and lose volume

depending on the temperature setting and the type of heat transfer medium used. indicator for the inside temperature of the tank and a Pt

● Operating environmental temperature range of this device is +5ºC to +35ºC.

100 ohm temperature sensor.

7 PRODUCT CATALOG

Page10

Cover with cleaning nozzle / container ferrule baffle

Guide to optional parts compatible with container units

Cover with cleaning nozzle [MF-CN/CF-CN]

Cleaning nozzle and cover comes as a set, allowing the inner ■ Sprays detergent 360° to clean the inside of

surfaces of the container to be sprayed and cleaned. the container.

Ideal for rinsing and removing stains prior to cleaning.

[MF-CN]

For clip type

Specifications Spray nozzle

Cover: SUS304

Spray nozzle: SUS316L

Ferrule gasket: Silicone rubber

Clamp band: SCS13 Low speed rotation of 5 - 10 rpm (at 0.3 MPa) ensures

Ball valve: SCS14 that the detergent is fully in contact with the inner

Coupler: SUS + Nitrile rubber surfaces of the container.

● Heat-resistant temperature: 150ºC

● Operating conditions: * Gasket between the container and cover is not enclosed.

[CF-CN] Atmospheric pressure (no pressurization * Compatible with the clip-type and band-type stainless steel container with

For band type adjustment) discharge outlet made by Nitto (internal diameter φ360mm - φ1000mm).

* Be sure to open the discharge outlet and use the agitator with the

container depressurized and no water remaining inside the container.

Cleaning nozzle Screw Injection pattern RPM* Mist flow rate (L/min) 〃 〃 〃 〃

Size rpm 0.15 MPa 0.3 MPa 0.5 MPa 0.7 MPa 1.0 MPa

Common specifications 1/8F Fan shape, up down 360° 5 - 10 9.19 13.0 16.8 19.9 23.7

Quick reference

table for models Size

Applicable containers Size 36 Size 39/39H Size 43/43H Size 47/47H Size 565/565H Size 635 Size 77/77H Size 100/100H

Clip type MF-CN-36 MF-CN-39 MF-CN-43 MF-CN-47

MF-CN-565 MF-CN-635 MF-CN-77 MF-CN-100

Band type CF-CN-36 CF-CN-39 CF-CN-43 CF-CN-47

Ferrule baffle [BP]

Can be attached to a ferrule. ■ Improves agitation efficiency

All stainless steel baffle plate.

Sanitary and easy to clean. Without With

Specifications Liquid flow by the agitator turns turbulent when it hits

⃝ Material: SUS304 the baffle plate, improving the agitation efficiency. Ideal

● Surface treatment: Buffing when you want to mix and stir contents uniformly.

* Gasket and clamp band required for connecting to a ferrule are

sold separately. φD

■ * Use of SUS316L, electrolytic polishing and fluoropolymer coating Model selection is available.

Choose a model that suits your preferred size.

Plate Plate

Ferrule Length width thickness

BP-1.5S - 300 D A W t W

1.5S 300, 350, 400, 450, 30

Ferrule Length 2S 500, 600, 700, 800, 40 4.0

3S 900, 1000 50

Unit of length is mm.

NITTO KINZOKU KOGYO CO., LTD. 8

A

H

Page11

Agitator PO (portable type)

Portable agitator with easily detachable clamp

Agitator PO [portable type] ■ Range of agitator mount

・ Agitator with clamp that can be attached and

detached easily

・ Mounting angle and attitude angle of the

agitation shaft (blades) can be adjusted.

・ An "electric motor agitator" or "air motor

agitator" can be selected.

PO (portable type)

Electric motor agitator

Model A720 Portable mixer

Compact, lightweight and easy-to-handle design with an integrated clamp and body.

Material: Shaft, vanes Stainless steel (SUS304)

Motor Impeller Shaft Weight

Model Power Number of poles Phase, voltage Frequency RPM Diameter Number of levels Overall length approx.

kW P V Hz rpm mm stage mm kg

Single 50 300

A720-0.065A 0.065 4 150 1 600 10

phase, 100 60 360

Single 50 300

A720-0.1A 0.1 4 220 1 800 11

phase, 100 60 360

3-phase, 50 300

A720-0.1B 0.1 4

200 220 1 800 1160 360

■ Model A720 options

■ Anodizing ■ One-touch coupling

Patented PAT. No.5637587

Gear case unit is made of anodized aluminum. Connecting parts can be removed with a

Unlike a plated coating, it resists peeling, thereby single touch for easy cleaning, e.g. in food and

reducing the risk of contamination. pharmaceutical factories.

9 PRODUCT CATALOG

Page12

Electric motor agitator

KPS-400 model Stainless steel portable mixer

Made of stainless steel, ideal for food and pharmaceutical plants.

Motor Rotation speed Shaft 3-blade propeller Maximum agitation capacity Weight

Model

No. Output Horsepower Voltage 50Hz 60Hz

Standard length Diameter Diameter Dilution Medium With

L φd φD liquid viscosity motor

kW HP V rpm rpm mm mm mm ℓ ℓ (Approx.) kg

A 100 11

KPS-4040 40W 1/18 250 300 600 16

120×2

stacks 100 50B 200 11

A 100 12

KPS-4060 60W 1/12 250 300 600 16

160×1

stack 250 100B 200 11

A 100 160×2 19

KPS-4001 0.1 1/8 300 360 800 16 600 200

B 200 stacks 17

◎ Motor and reduction gear are standard options of the manufacturer (made of aluminium).

◎ Standard motor is a 3-phase 200/220V4P fully sealed outside fan outdoor type.

Model KCP-670 Step-less variable speed portable mixer

Rotation speed can be adjusted according to changes in liquid viscosity.

Material: Shaft, blades - stainless steel (SUS304)

Motor (outdoor type) Rotation speed Agitation shaft 2-level, 3-blade propeller Maximum agitation capacity Weight

Model

Power Horsepower Voltage 50Hz 60Hz Standard length Diameter Diameter Dilution Medium With No. L φd φD liquid viscosity motor

kW HP V rpm rpm mm mm mm ℓ ℓ (Approx.) kg

KCP-6700-NRX 0.06 1/12 100 0 - 500 0 - 600 600 19 100 250 100 16

KCP-6701-NRX 0.09 1/8 100 0 - 500 0 - 600 800 19 120 500 150 17

Air motor agitator

LZB22-CB5 Oil-less air motor agitator

Material: Shaft (SUS304), blade (SUS316)

MAX MAX MAX air Agitation shaft 3-blade propellerModel Maximum output Weight

LZB22 Torque RPM consumption Shaft length Diameter Diameter approx.

-CB5

kW hp N・m rpm ℓ/min mm mm mm kg

A 0.34 3 825

0.25

B 0.34 4.8 520 320 600 10 140 5.5

C 0.24 0.32 8.6 270

LZB33-B2.5 Oil-less air motor agitator

Material: Shaft (SUS304), blade (SUS316)

MAX MAX MAX air Agitation shaft 3-blade propellerModel Maximum output Weight

LZB33 Torque RPM consumption Shaft length Diameter Diameter approx.

-B2.5

kW hp N・m rpm ℓ/min mm mm mm kg

A 6.5 580

0.39 0.52

B 8 470

500 1000 15 200 10

C 15.75 230

0.38 0.51

D 35 103

NITTO KINZOKU KOGYO CO., LTD. 10

Page13

Agitator SD (standing type)

Agitation capability for sealed containers

Agitator SD [standing type] ■ Range of agitator mount

・ Agitation can be carried out in a sealed or

pressurized container.

・ Ferrule connection can be attached and detached

easily.

SD (standing type)

Magnet agitator

MAG-NEO® Seal mixer RC type

Equipped with a drive unit at the top of the tank, agitation can be carried out with the tank fully sealed.

Ideal for agitation which requires a high level of sanitation and cleanliness e.g. pharmaceutical, cosmetics, bio,

semiconductor, food-related and other industries.

■ Clean and stable agitation with magnetic coupling

The seal of the container is maintained without any penetrating shaft, so agitation can be

carried out without being affected by the external environment. The environment inside the

container will also never leak outside. As a result, the sanitation level inside the container

can be maintained without any leaks in both pressurized and vacuum environments.

It can also be used for highly corrosive contents and in an explosion-proof environment

based on the Fire Services Act. Agitators with PFA coating on areas in contact with

liquids and gases and agitators that use explosion-proof motors and air motors are

also available.

Electrical parts

Drive motor As the magnetic coupling uses a powerful magnet, extra

care is required while handling.

⃝ Be sure to read the instructions on the handling of the device to use it correctly.

⃝R efer to the following together with the instruction manual for precautions to be

taken when using magnets.

"Precautions/Guidelines on the Use of Permanent Magnets"

EMAJ-R005 Japan Electronics and Information Technology Industries

Sealing area (partition)

Magnetic Association

coupling

Bearing

Examples of warning and precaution

Bearing

housing ● Seek medical advice if you are wearing any electronic medical devices

Warning such as a pacemaker etc. before using this unit.

Ferrule

Foreign matter

receptacle Details of the port for detergent,

(can be disassembled for

manual washing) steam sterilization ● Do not place floppy disks, magnetic cards, prepaid cards,

Cautions

Sealing area (partition) tickets, etc. near permanent magnets.

8A port ● When the magnetic actuation unit and parts for storing

Detergent the magnet are removed, the magnet will fly out with great

Sterilization steam

momentum like a bullet depending on the combination of

No cover magnets used. Never disassemble the magnetic parts as it is

Bearing very dangerous.

Separation of liquid ● Be careful not to crush your fingers etc. between the actuating

Clockwise

rotation viewed and steam magnet and actuated magnet during handling.

from the top 10A port

● Do not bring the actuating magnet and actuated magnet near

iron objects as you may get injured by tools etc.

Foreign matter receptacle

Agitator shaft, blades (auto rinse type)

Sterilization steam passage *MAG-NEO is a registered trademark of MAG-NEO. (Registration No. 4265849)

*The MAG-NEO seal mixer uses a patented magnetic coupling.

*Unauthorized production, copying and duplication of this catalog is prohibited.

*The information listed here has been reproduced with the consent of MAG-NEO.

11 PRODUCT CATALOG

Page14

Electric motor agitator

KX-125 KX-145 KX-395P KX-399R

Model KX-125 KX-145 KX-395P KX-399R

Shaft φ12 φ12 φ12 φ12

Output power 25W 40W 90W 90W

Torque (N∙m) 0.18 - 0.65 0.22 - 1.10 2.84 - 12.25 3.30 (constant)

Maximum rotation speed (rpm) 280 280 173 222

Minimum rotation speed (rpm) 18 18 0 11

Speed control Included

Standard agitation blades Two 2-bladed units or one 4-bladed unit L=90,100,120,150mm

Power supply AC100V (50Hz/60Hz)

・Coupling section is protected by a safety cover in all models.

・Models shown in the photos are all Type E (optional) with a shaft that can be removed from below the cover.

*Maximum torque of KX125, KX145 is at 240rpm while the minimum torque is at 18rpm.

*Maximum torque of KX-395P is at approx. 0rpm while the minimum torque is at 173rpm.

*Torque of KX399R is constant regardless of the rpm.

*Maximum and minimum rotation speeds are motor specifications. Actual speed differs depending on the viscosity of the material etc.

Air motor agitator

Safe, explosion-proof structure because it is run by an air motor.

Rotation speed and torque are controlled by adjusting the air pressure and opening/closing the valve.

KY-110 KY-215 KY-330

Model KY-110 KY-215 KY-330

Maximum operating air pressure 0.6 MPa 0.6 MPa 0.6 MPa

Maximum power 73.5W 125W 228W

Maximum torque (N∙m) 0.637 1.37 2.94

Maximum rotation speed (rpm) 1,100rpm (variable) 900rpm (variable) 750rpm (variable)

Minimum working speed (rpm) About 220rpm About 180rpm About 150rpm

Air consumption (at maximum torque) 200 liters/min 260 liters/min 400 liters/min

Shaft φ12×300mm or less φ12×400mm or less φ12×500mm or less

Blades Two 2-bladed units or one 4-bladed unit L=90,100,120,150mm

・Coupling section is protected by a safety cover in all models.

・KY-110 shown in the photo is a standard type while the KY-215 and KY-330 are Type E (optional) in which the shaft can be removed from below the cover.

* Be sure to use a lubricator if you are using an air motor unit.

* Maximum torque is the value at the maximum rpm.

*Maximum and minimum rotation speeds are motor specifications. Actual speed differs depending on the viscosity of the material etc.

NITTO KINZOKU KOGYO CO., LTD. 12

Page15

Agitator SD (standing type)

Agitation capability for sealed containers

■ Centrifugal agitating bar E-REVO φ99 ■ Agitation unit (P27)

Stirs the liquid using blade-free centrifugal force.

Allows the liquid to be stirred without drawing in air.

Precise and uniform agitation can be achieved.

Excellent drainage and cleaning functions.

(Patent No. 6169207)

Electric motor agitator

Agitation capabilty for sealed containers.

Can be mounted with a ferrule.

Can also be used under pressurized or depressurized conditions.

Capable of stirring low- to high-viscosity liquids.

Controller is a standard feature and the rotation speed can be adjusted.

Model Shaft Power Torque Maximum Minimum rotation speed rotation speed Standard agitation bar Power supply

φ W N・m rpm rpm

NTME-E99 15 200 2.2 - 2.9 800 16 E-REVO φ99 AC100V

Operating pressure (room temperature): F.V - 0.18MPa

Air motor agitator

Agitation capability for sealed containers.

Can be used in explosion-proof areas.

All stainless steel and sanitary.

No splashing of oil as it can be run without oiling

Can also be used under pressurized or depressurized conditions.

Capable of stirring low- to high-viscosity liquids.

Model Shaft Supply Maximum Maximum Air Standard pressure torque rotation speed consumption agitation bar

φ MPa N・m rpm L / min

NTMA-E99 15 0.6 2.7 700 378 E-REVO φ99

Operating pressure (room temperature): F.V - 0.18MPa

13 PRODUCT CATALOG

Page16

Agitator BO (bottom type)

Stirs sealed tanks to prevent sedimentation

BO [bottom type] ■ Range of agitator mount

・ Equipped with a drive unit below the container, agitation

can be carried out in sealed containers.

・ Ideal for agitation to prevent sedimentation.

BO (bottom type)

Magnet agitator

MAG-NEO® seal mixer RBnt type

Ideal for agitation which

requires a high level of Rotor blade

sanitation and cleanliness

e.g. pharmaceutical, Magnetic coupling

cosmetics, bio,

semiconductor, food-related Ferrule connection

and other industries.

Simple structure with no

complex sealing structures

or penetrating shaft in the Detachable drive unit

sealing areas between the

tank and agitator shaft.

Motor cover

■Installation example As the magnetic coupling uses a powerful magnet, extra

care is required while handling.

● B e sure to read the instructions on the handling of the device to use it correctly.

● Refer to the following together with the instruction manual for precautions to be

taken when using magnets.

"Precautions/Guidelines on the Use of Permanent Magnets"

EMAJ-R005 Japan Electronics and Information Technology Industries

Association

Examples of warning and precaution

● Seek medical advice if you are wearing any electronic medical devices

Warning

such as a pacemaker etc. before using this unit.

Cautions ● Do not place floppy disks, magnetic cards, prepaid cards, tickets, etc.

near permanent magnets.

● When the magnetic actuation unit and parts for storing the magnet

are removed, the magnet will fly out with great momentum like a bullet

depending on the combination of magnets used. Never disassemble

the magnetic parts as it is very dangerous.

● Be careful not to crush your fingers etc. between the actuating magnet

and actuated magnet during handling.

● Do not bring the actuating magnet and actuated magnet near iron

objects as you may get injured by tools etc.

*MAG-NEO is a registered trademark of MAG-NEO. (Registration No. 4265849)

*The MAG-NEO seal mixer uses a patented magnetic coupling.

*Unauthorized production, copying and duplication of this catalog is prohibited.

*The information listed here has been reproduced with the consent of MAG-NEO.

NITTO KINZOKU KOGYO CO., LTD. 14

Page17

Pressurized container units

Pressurized container unit

“We have been looking for a device for pressure feeding but we do not know what parts are required…”

“We would like to assemble a unit with the minimum amount of accessories required…”

A basic pressure feeding set recommended by Nitto Kinzoku is available for such customers.

What is pressure feeding?

A method to transfer and push out a

liquid in a container by pumping a gas

into it.

It is useful in the following cases:

• When handling highly viscous liquids

• W hen handling liquids which you do not

want to expose to the air.

■ Set contents

Pressurized container body Parts required for pressure feeding

Details are given from Page 16 onwards. Details are given from Page 19 onwards.

15 PRODUCT CATALOG

Page18

Pressurized containers with pump and pressure units

Featuring a lightweight cover and clamp band

compared to other pressurized containers

● Pressurized container required for liquid feeding is offered as a set together with the accessories.

● Compared to other pressurized containers, the cover and clamp band are easier to handle as they ■ Accessories

are smaller and lighter.

Features ● PCN-UT/PCN-J-UT are for discharge from the top while PCN-L-UT/PCN-J-L-UT are for discharge

from the bottom and both are capable of pressure feeding.

● PCN-J-UT/PCN-J-L-UT are equipped with a jacket for heating or cooling the contents.

● Can be custom-made to suit the application and changes in dimensions and material.

Pressurized container with pump unit Jacket type pressurized container with

[PCN-UT] pump unit [PCN-J-UT]

Attached accessories Attached accessories

・Liquid feeding port ・Liquid feeding port

・Pressurization port ・Pressurization port

・Pressure gauge ・Pressure gauge

・Safety valve ・Safety valve

Material: SUS304 Material: SUS304

Clamp band: SCS13 Clamp band: SCS13

Gasket: Silicone rubber Gasket: Silicone rubber

(Alternative option: Fluororubber) (Alternative option: Fluororubber)

Opening: 4S ferrule Jacket nozzle: 1S ferrule

● Surface treatment: Opening: 4S ferrule

Inner and outer surface buffing 1L 3L - ● Surface treatment:

Inner and outer surface buffing

Capacity: 1L, 3L, 5L, 10L, 20L, 30L, 40L, 50L Capacity: 5L, 10L, 20L, 30L, 40L, 50L

Operating pressure (room temperature) Operating pressure (room temperature)

1L - 30L: 0 - 0.4MPa 40L, 50L: 0 - 0.18MPa Body 5L - 30L: 0 - 0.4MPa 40L, 50L: 0 - 0.18MPa

Jacket 0 - 0.18MPa

Pressurized container with legs and Jacket type pressurized container with

pressure unit [PCN-L-UT] legs and pressure unit [PCN-J-L-UT]

Attached accessories Attached accessories

・Pressurization port ・Pressurization port

・Pressure gauge ・Pressure gauge

・Safety valve ・Safety valve

・Manual 2-way ball valve ・Manual 2-way ball valve

Material: SUS304

Material: SUS304 Clamp band: SCS13

Clamp band: SCS13 Gasket: Silicone rubber

Gasket: Silicone rubber (Alternative option: Fluororubber)

(Alternative option: Fluororubber) Castor: SUS + urethane wheels

Castor: SUS + urethane wheels (of which 2 are attached with a stopper)

(of which 2 are attached with a stopper) Jacket nozzle: 1S ferrule

Opening: 4S ferrule Opening: 4S ferrule

● Surface treatment: Inner and outer ● Surface treatment: Inner and outer

surface buffing surface buffing

Capacity: 10L, 20L, 30L, 40L, 50L Capacity: 5L, 10L, 20L, 30L, 40L, 50L

Operating pressure (room temperature) Operating pressure (room temperature)

10L - 30L: 0 - 0.4MPa 40L, 50L: 0 - 0.18MPa Body 5L - 30L: 0 - 0.4MPa 40L, 50L: 0 - 0.18MPa

Jacket 0 - 0.18MPa

NITTO KINZOKU KOGYO CO., LTD. 16

Page19

Flange open type pressurized containers with pump and pressure units

Swing bolt type keeps bolts secure when opening or

closing the cover.

● Pressurized container required for liquid feeding is offered as a set together with the accessories. ■ Optional parts

● Swing bolt type in which the container internal diameter is the same as the opening, makes A hinge with spring can also

cleaning easy and ensures that parts do not fall off when opening and closing the cover. be attached

Features ● PCN-O-UT/PCN-O-J-UT are for discharge from the top while PCN-O-L-UT/PCN-O-J-L-UT which enables

are for discharge from the bottom and both are capable of pressure feeding. easy operation

● PCN-O-J-UT/PCN-O-J-L-UT are equipped with a jacket for heating or cooling the contents. of the cover.

● Can be custom-made to suit the application and changes in dimensions and material.

Flange open type pressurized container Jacket type, flange open type pressurized

with pump unit [PCN-O-UT] container with pump unit [PCN-O-J-UT]

Attached accessories Attached accessories

・Liquid feeding port ・Liquid feeding port

・Pressurization port ・Pressurization port

・Pressure gauge ・Pressure gauge

・Safety valve ・Safety valve

・Sight glass ・Sight glass

Material: SUS304 Material: SUS304

Clamp band: SCS13 Clamp band: SCS13

O-ring, gasket: Silicone rubber O-ring, gasket: Silicone rubber

(Alternative option: Fluororubber) (Alternative option: Fluororubber)

● S urface treatment: Inner and outer Jacket nozzle: 1S ferrule

surface buffing ● Surface treatment: Inner and outer

surface buffing

Capacity: 20L, 30L, 40L, 50L, 80L, 100L, 150L, 200L

Operating pressure (room temperature) Body 0 - 0.18MPa

Capacity: 10L, 20L, 30L, 40L, 50L, 80L, 100L, 150L, 200L Jacket 20L - 100L: 0 - 0.18MPa

Operating pressure (room temperature) 0 - 0.18MPa 150L: 0 - 0.12MPa

200L: 0 - 0.09MPa

Flange open type pressurized container Jacket type, flange open type pressurized

with legs and pressure unit [PCN-O-L-UT] container with legs and pressure unit

[PCN-O-J-L-UT]

Attached accessories

・Pressurization port

・Pressure gauge Attached accessories

・Safety valve ・Pressurization port

・Manual 2-way ball valve ・Pressure gauge

・Sight glass ・Safety valve

・Manual 2-way ball valve

・Sight glass

Material: SUS304 Material: SUS304

Clamp band: SCS13 Clamp band: SCS13

O-ring, gasket: Silicone rubber O-ring, gasket: Silicone rubber

(Alternative option: Fluororubber) (Alternative option: Fluororubber)

Castor: SUS + urethane wheels Castor: SUS + urethane wheels

(of which 2 are attached with a stopper) (of which 2 are attached with a stopper)

● Surface treatment: Inner and outer Jacket nozzle: 1S ferrule

surface buffing ● Surface treatment: Inner and outer

surface buffing

Capacity: 20L, 30L, 40L, 50L, 80L, 100L, 150L, 200L Capacity: 20L, 30L, 40L, 50L, 80L, 100L, 150L, 200L

Operating pressure (room temperature) 0 - 0.18MPa Operating pressure (room temperature) Body 0 - 0.18MPa

Jacket 20L - 100L: 0 - 0.18MPa

150L: 0 - 0.12MPa

200L: 0 - 0.09MPa

17 PRODUCT CATALOG

Page20

Ferrule open type pressurized containers with pump and pressure units

Sanitary and easy to clean

● Pressurized container required for liquid feeding is offered as a set together with the accessories.

● Container internal diameter is the same as the opening, and container is easy to clean ■ Round bar handle (sanitary type)

and sanitary due to the all round welding of the handle as well. Full circumference welding

Features ● PCN-F-UT/PCN-F-J-UT are for discharge from the top while PCN-F-L-UT/PCN-F-J-L-UT are

for discharge from the bottom and both are capable of pressure feeding.

● PCN-F-J-UT/PCN-F-J-L-UT are equipped with a jacket for heating or cooling the contents.

● Can be custom-made to suit the application and changes in dimensions and material.

Ferrule open type pressurized container Jacket type, ferrule open type pressurized

with pump unit [PCN-F-UT] container with pump unit [PCN-F-J-UT]

Attached accessories Attached accessories

・Liquid feeding port ・Liquid feeding port

・Pressurization port ・Pressurization port

・Pressure gauge ・Pressure gauge

・Safety valve ・Safety valve

・Sight glass (30L or more) ・Sight glass (30L or more)

Material: SUS304 Material: SUS304

Clamp band: SCS13 Clamp band: SCS13

O-ring, gasket: Silicone rubber O-ring, gasket: Silicone rubber

(Alternative option: Fluororubber) (Alternative option: Fluororubber)

● S urface treatment: Inner and outer Jacket nozzle: 1S ferrule

surface buffing ● S urface treatment: Inner and outer

surface buffing

Capacity: 10L, 20L, 30L, 40L, 50L, 80L Capacity: 10L, 20L, 30L, 40L, 50L, 80L

Operating pressure (room temperature) 0 - 0.18MPa Operating pressure (room temperature) Body 0 - 0.18MPa

Jacket 0 - 0.18MPa

Ferrule open type pressurized container Jacket type, ferrule open type pressurized

with legs and pressure unit [PCN-F-L-UT] container with legs and pressure unit

[PCN-F-J-L-UT]

Attached accessories

・Pressurization port Attached accessories

・Pressure gauge ・Pressurization port

・Safety valve ・Pressure gauge

・Manual 2-way ball valve ・Safety valve

・Sight glass (30L or more) ・Manual 2-way ball valve

・Sight glass (30L or more)

Material: SUS304

Material: SUS304 Clamp band: SCS13

Clamp band: SCS13 O-ring, gasket: Silicone rubber

O-ring, gasket: Silicone rubber (Alternative option: Fluororubber)

(Alternative option: Fluororubber) Castor: SUS + urethane wheels

Castor: SUS + urethane (of which 2 are attached with a stopper)

● S urface treatment: Inner and outer Jacket nozzle: 1S ferrule

surface buffing ● S urface treatment: Inner and outer

surface buffing

Capacity: 10L, 20L, 30L, 40L, 50L, 80L Capacity: 10L, 20L, 30L, 40L, 50L, 80L

Operating pressure (room temperature) 0 - 0.18MPa Operating pressure (room temperature) Body 0 - 0.18MPa

Jacket 0 - 0.18MPa

NITTO KINZOKU KOGYO CO., LTD. 18