1/52ページ

Download(6.7Mb)

SmartMotors

Document Information

| Document Title | MoogAnimatics 2016 ProductCatalog |

|---|---|

| Document Type | Product Catalog |

| File size | 6.7Mb |

| Category | |

| Company | トーアメック株式会社 (Documents List) |

Document Contents

Page1

When Performance Really Matters®

Page2

Welcome to Moog Animatics

Thank you for your interest in our innovative automation solutions. Since its founding in 1987, Moog Animatics has delivered upon a

unique approach to motion and machine control that enables you to leapfrog your global competition. Moog Animatics is the world leader

in fully integrated servo technology and is part of Moog Inc., a worldwide designer, manufacturer, and integrator of precision motion control

products and systems. Moog’s high-performance systems control military and commercial aircraft, satellites and space vehicles, launch

vehicles, missiles, industrial machinery, wind energy, marine applications, and medical equipment.

Moog Animatics offers the most advanced highly integrated automation solutions in the industry. Starting with the SmartMotor™, the

world’s first fully integrated servo system, and extending through a large variety of I/O, machine control, software, and integrated actuator

products, Moog Animatics offers total solutions with a much smaller footprint, a lower total cost and a simplicity that reduces your machine

development and build time – getting you to market faster.

With offices in Tokyo, California, New York, Pennsylvania and Continental Europe, the sun never sets on Moog Animatics while we directly

support key customers along with a global network of factory trained Automation Solution Providers; independent companies in your

backyard ready to supply and support your Moog Animatics products through the long haul.

This catalog contains all Class 5 and Class 6 SmartMotor products, software, and Moog Animatics’ actuator line (Linear Integrated

Systems). All of the SmartMotor servos in this catalog have the latest feature set and are recommended for new designs.

Many new products are highlighted in this catalog, including our Class 6 EtherNet/IP™ SmartMotor that is available in both standard servo

and hybrid versions. The new product represents the next step in the evolution of the Class 6 integrated motor design, which includes

PROFINET® and EtherCAT® versions, and extends the robust, dual-port industrial Ethernet SmartMotor with EtherNet/IP™ Position

Controller capability.

Our expanded linear actuator offerings include low-backlash, high-precision, belt-driven rotary stage units, true belt-driven linear systems,

and combination H-Bot and T-Bot units for high-precision, two-axis motion. All units come integrated with your choice of SmartMotor.

Our exciting firmware advances include I/O device CAN Bus Master capability, sophisticated custom spooling pattern capabilities for

traverse and take-up winding applications, and DMX Protocol for a wide variety of entertainment automation applications.

In need of a custom solution for your motion control challenge? Please contact us and let us show you innovative, compact, and highly

effective ideas that are optimally engineered to help you gain competitive advantage and win in your market.

Thank you again and welcome to Moog Animatics, When Performance Really Matters®.

We define the future of motion control by innovation, invention, We invite our customers and users to join with us in the joint

and a dedication to the highest standards of professionalism and development of custom products and systems using our

quality in everything we do and in every product that we make. technology.

We invite quality firms to ally with us and to participate in our We commit to providing a fair workplace for our employees.

inventions and innovations for the benefit of the companies that We subscribe to the principle of being a good corporate citizen,

need and use our advanced technology and products. a good neighbor, and a protector of our environment.

When Performance Really Matters®

REVISED 01/17

2 Moog Animatics • www.animatics.com

Power Supplies Gearheads Actuators Cables, Etc. C6 Low Cost C6 M-Style C5 M-Style C5 D-Style Software Overview

Page3

Contents

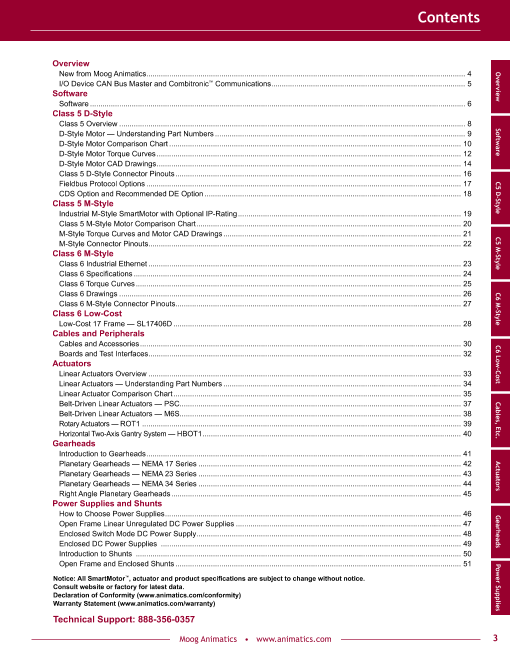

Overview

New from Moog Animatics......................................................................................................................................................... 4

I/O Device CAN Bus Master and Combitronic™ Communications ............................................................................................. 5

Software

Software .................................................................................................................................................................................... 6

Class 5 D-Style

Class 5 Overview ...................................................................................................................................................................... 8

D-Style Motor — Understanding Part Numbers ........................................................................................................................ 9

D-Style Motor Comparison Chart ............................................................................................................................................ 10

D-Style Motor Torque Curves .................................................................................................................................................. 12

D-Style Motor CAD Drawings .................................................................................................................................................. 14

Class 5 D-Style Connector Pinouts ......................................................................................................................................... 16

Fieldbus Protocol Options ....................................................................................................................................................... 17

CDS Option and Recommended DE Option ........................................................................................................................... 18

Class 5 M-Style

Industrial M-Style SmartMotor with Optional IP-Rating ........................................................................................................... 19

Class 5 M-Style Motor Comparison Chart ............................................................................................................................... 20

M-Style Torque Curves and Motor CAD Drawings .................................................................................................................. 21

M-Style Connector Pinouts...................................................................................................................................................... 22

Class 6 M-Style

Class 6 Industrial Ethernet ...................................................................................................................................................... 23

Class 6 Specifications ............................................................................................................................................................. 24

Class 6 Torque Curves ............................................................................................................................................................ 25

Class 6 Drawings .................................................................................................................................................................... 26

Class 6 M-Style Connector Pinouts......................................................................................................................................... 27

Class 6 Low-Cost

Low-Cost 17 Frame — SL17406D .......................................................................................................................................... 28

Cables and Peripherals

Cables and Accessories .......................................................................................................................................................... 30

Boards and Test Interfaces ...................................................................................................................................................... 32

Actuators

Linear Actuators Overview ...................................................................................................................................................... 33

Linear Actuators — Understanding Part Numbers .................................................................................................................. 34

Linear Actuator Comparison Chart .......................................................................................................................................... 35

Belt-Driven Linear Actuators — PSC....................................................................................................................................... 37

Belt-Driven Linear Actuators — M6S....................................................................................................................................... 38

Rotary Actuators — ROT1 ......................................................................................................................................................... 39

Horizontal Two-Axis Gantry System — HBOT1 ............................................................................................................................ 40

Gearheads

Introduction to Gearheads ....................................................................................................................................................... 41

Planetary Gearheads — NEMA 17 Series .............................................................................................................................. 42

Planetary Gearheads — NEMA 23 Series .............................................................................................................................. 43

Planetary Gearheads — NEMA 34 Series .............................................................................................................................. 44

Right Angle Planetary Gearheads ........................................................................................................................................... 45

Power Supplies and Shunts

How to Choose Power Supplies .............................................................................................................................................. 46

Open Frame Linear Unregulated DC Power Supplies ............................................................................................................ 47

Enclosed Switch Mode DC Power Supply............................................................................................................................... 48

Enclosed DC Power Supplies ................................................................................................................................................ 49

Introduction to Shunts ............................................................................................................................................................ 50

Open Frame and Enclosed Shunts ......................................................................................................................................... 51

Notice: All SmartMotor™, actuator and product specifications are subject to change without notice.

Consult website or factory for latest data.

Declaration of Conformity (www.animatics.com/conformity)

Warranty Statement (www.animatics.com/warranty)

Technical Support: 888-356-0357

Moog Animatics • www.animatics.com 3

Overview Software C5 D-Style C5 M-Style C6 M-Style C6 Low-Cost Cables, Etc. Actuators Gearheads Power Supplies

Page4

Overview、New from Moog Animatics

NENWe!w from Moog Animatics

Class 6 Industrial Ethernet SmartMotors

Support EtherNet/IP™, PROFINET® and EtherCAT® protocols

• NEMA 23 frame in standard (MT) and high pole count (MH) versions

• High-end, high-speed processor for exceptional performance

• Compact, feature-rich controls allow for rapid solution development

See page 23 for details.

Low-Cost 17 Frame SmartMotor

SmartMotor features in a low-cost 17 frame package

• RS-232 and CANopen interfaces are standard

• Includes high-speed processor and Combitronic support

• Integrated drive and controller simplifies installation and reduced cost

See page 28 for details.

M6S/PSC Linear and ROT1 Rotary Actuators

SmartMotor-powered belt-driven actuators

• Delivered as a turnkey solution

• Low backlash, high positional accuracy and long service life

• Motor mounting options for maximum design and mounting flexibility

See pages 37-39 for details.

T-Bot and H-Bot Systems

SmartMotor-powered turnkey gantry systems

• Low backlash belt actuators with stationary SmartMotors

• Shipped preassembled with the SmartMotors of your choice

• Precise and accurate horizontal or vertical positioning for low to medium loads

See page 40 for details.

I/O Device CAN Bus Master ® Motor to I/O TM Motor to Motor Without data collision!

Interfaces with standard CiA 301 CANopen devices

• Multiple SmartMotors and multiple I/O devices on the same CAN bus

• Support for both PDO and SDO protocols (some limitations apply)

• SmartMotor achieves FULL machine control -- no other HMI or bus master required!

CANopen Valve Block

See page 5 for details. CANopenREMOTE I/O

CANopen

ABS Encoder

Expanded Traverse and Takeup Be sure to follow proper guidelines for CAN bus cabling and termination.

Now supports complex winding patterns

• Overlay camming profiles onto traversing profiles for complex patterns

• Prevent material from becoming tangled or trapped when unwinding

• Auto Reverse and Electronic Gearing profiles for the perfect spool every time

See website Case Studies and SmartMotor Developer’s Guide for details.

REVISED 01/17

4 Moog Animatics • www.animatics.com

Power Supplies Gearheads Actuators Cables, Etc. C6 Low-Cost C6 M-Style C5 M-Style C5 D-Style Software OOvveerrvviieeww

Page5

I/O Device CAN Bus Master and Combitronic™ Communications

I/O Device CAN Bus Master and Combitronic™ Communications

!

NEW

Motor to I/O TM® Motor to Motor Without data collision!

CANopen Valve Block

CANopen

REMOTE I/O

CANopen

ABS Encoder

Be sure to follow proper guidelines for CAN bus cabling and termination.

Be sure to follow proper guidelines for CAN bus cabling and termination.

I/O Device CAN Bus Master - SmartMotors can now interface with standard CiA 301 CANopen devices including but not

limited to:

• Remote digital/analog/mixed signal I/O • Temperature controllers

• CAN bus absolute or relative encoders • Pneumatic valve blocks

• Inclinometers • And more

• Load cells

Basic control allows 8, 16, or 32-bit sized data objects with support for both PDO and SDO protocols. The supported profiles include but

are not limited to I/O profile, encoder profile, and DS4xx profile. This provides the ability to:

• Dynamically map SmartMotor PDOs, map another device’s PDOs, start the NMT state

• A SmartMotor can send/receive up to 5 PDOs each for RX (Receive) and TX (Transmit)

• Read/write SDOs in expedited mode only; which works up to 32-bit data

Multiple SmartMotors and multiple I/O devices may be on the same CAN bus. This combined with Combitronic motor-to-motor

communications allows for complex, multi-axis, multi-I/O-device network control. Now you can achieve full machine control with just

the SmartMotors -- no other HMI or bus master is required!

TM High-Speed Communications is a protocol that operates over a standard “CAN” (Controller Area Network) interface.

It may simultaneously coexist with either CANopen or DeviceNet protocols. Unlike these common protocols however, Combitronic™

requires no single dedicated master to operate. Each integrated servo connected to the same network communicates on an equal

footing, sharing all information, and therefore, sharing all processing resources.

Combitronic protocol features:

• 120 axis node count

• 1 MHz bandwidth

• No master required

• No scan list or node list set up required

• All nodes have full read/write access to all other nodes

Combitronic™ technology allows any motor’s program to read from, write to, or control any other motor simply by tagging a local variable

or command with the other motor’s CAN address. All SmartMotors become one multi-tasking, data-sharing system without writing a single

line of communications code or requiring detailed knowledge of the CAN protocol. The only prerequisite is to have matched baud rates

and unique addresses.

For more details, see animatics.com/combi

Combitronic technology enables standalone multi-axis linear interpolation:

a=1 b=2 c=3 ' Motor addresses, x, y and z

x=123000 'X Axis Target Position

y=20000 'Y Axis Target Position

z=8000 'Z Axis Target Position

PTS(x;a,y;b,z;c) 'Set 3-axis synchronized target position

GS 'Go, 3-axis linear interpolation

TSWAIT 'Wait until 3 axis move is complete

Moog Animatics • www.animatics.com 5

OOvveerrvviieeww Software C5 D-Style C5 M-Style C6 M-Style C6 Low-Cost Cables, Etc. Actuators Gearheads Power Supplies

Page6

Software、Software

Software

SmartMotor Interface (SMI)

Moog Animatics’ SMI™ Version 3 software provides an easy-to-use Microsoft Windows compatible interface to

your Moog Animatics SmartMotor™. Using SMI, you can define multi-axis motion control for 1 to 120 SmartMotors.

SMI includes a terminal program, program editor, and source level debugger. Standard SMI features include SMI

a Tools menu to set PID tuning parameters and plot the step response, motor info and dynamic status tracking,

and online help and documentation. The SMI software can also open multiple windows for program editing,

instantly address multiple motors, and upload programs.

Free Download from

Key Features in Version 3 Website: www.animatics.com/smi

• New Program Editor includes undo/redo commands and group tabbing for more efficient programming

• SmartMotor fieldbus network view and extended CANopen support for smoother fieldbus integration

• Context Sensitive Help for instant access to full keyword descriptions

• Revised help system provides documentation access when working online or offline

• Preprocessor Extension for specifying include files, defining macros, and more, to speed application development

• And much more...refer to the website/factory for details

SMIEngine

Moog Animatics’ SMIEngine™ is a source code module library created as a software tool for the Windows operating system environment.

It comes free with the installation of SMI software (see above). The installation includes source code examples. SMIEngine is based on

the Windows Component Object Model (COM) and works with:

• Microsoft C++, Visual Basic, .NET environment

• Borland C++ and Delphi

• VBA (Visual Basic for Applications)

• Pascal

• Python

• LabVIEW (when installed as an ActiveX component)

Using SMIEngine, you can perform tasks such as:

• Detecting motors on the desired port

• Addressing a SmartMotor™ daisy chain

• Sending commands to the motors and getting the motor responses

• Downloading/uploading compiled user programs (“.smx” files) to/from the motors

• Controlling the motors using coordinated motion (contouring or host mode)

• Creating circular and linear path coordinates used for coordinated motion

• Scanning user program source files (“.sms”) for errors

• Creating a list of errors in a user program and providing an interface for

navigating through errors

• And much more...refer to the website/factory for details

Free download from website!

6 Moog Animatics • www.animatics.com

Power Supplies Gearheads Actuators Cables, Etc. C6 Low-Cost C6 M-Style C5 M-Style C5 D-Style SSooffttwwaarree Overview

Page7

Software

Smart Sizer

Moog Animatics SmartSizer™ is a load sizing software tool to aid in SmartMotor selection for any given load. In a simple single-page

format, the tool allows the user to fill in values to calculate load

torque imposed on a given motor. All input data has a unit selector

that allows you to easily mix and match standard and

metric units.

! WARNING

SmartSizer™ is a software tool to aid in determining

load torque that would be imposed onto a given motor

shaft. It is up to the user to ensure proper servo motor

sizing and power supply sizing to prevent over loading

damage. Moog Animatics is not responsible for motor

sizing.

SMNC Included in free SMI download from website!

SMNC™, Moog Animatics’ G-code based servo motion control

software, uses numeric control to deliver multi-axis contouring

for your Moog Animatics SmartMotor™ applications. SMNC

provides a set of features that are comparable to any CNC

system, including a user interface that is similar in appearance

to a traditional CNC system.

SMNC features include:

• Linear and circular motion control of multiple axes

• Configures SmartMotors across multiple serial ports

• Converts CAD (DXF) files into motion control G and M codes

• Duplication of axis motion for gantry systems

• Smooth control of acceleration and deceleration for sensitive

curvilinear motion

• And much more...refer to the website/factory for details

AniCNC

AniCNC™ is Moog Animatics’ newest CNC application software exclusively for use with the Class 5 SmartMotor™. When coupled

with the Class 5 SmartMotor, the AniCNC product provides a graphical Human-Machine Interface (HMI), G-code editing and runtime

environment and other built-in features to help you quickly tackle your milling, routing, machining, shaping and related projects.There’s

even an offline mode that lets you preview and refine your G-code tool paths without being attached to the SmartMotor.

AniCNC features include:

• A simple, intuitive user interface, optimized for touchscreen use

• Advanced Code Writer and Shape Writer for creating complex patterns

• DXF file import to produce scalable G-code for quick

resizing and/or arraying of your design

• G-code export to DXF format for efficient use in CAD

or illustration software

• G-code editing and runtime environment with real-time

viewing of the tool path

• TrueType font to G-code converter allows you to

scale/frame text as desired

• Built-in functions for point-and-click programming of

common metalwork shapes

• Nested-array code building for easy duplication of parts

in sheet material

• Dynamic jog and teach to rapidly record points to the G-code program

• In-path jog correction allows temporary move adjustment and then

resets and continues

REVISED 08/17

Moog Animatics • www.animatics.com 7

Overview SSooffttwwaarree C5 D-Style C5 M-Style C6 M-Style C6 Low-Cost Cables, Etc. Actuators Gearheads Power Supplies

Page8

Class 5 D-Style、Class 5 Overview

Class 5 Overview

Class 5 Control Overview Enhanced Trap Mode and Sine Mode Commutation

• Faster processor, over five times faster than previous generation motors The motors can be operated with encoder-based commutation that allows

• Faster RS-232/RS-485 communications speeds, up to 115.2 KBaud for for a more precise alignment and association of rotor to stator magnetic

unparalleled connectivity phases. The result is a smooth, quiet rotation with very low cogging. As a

• Multi-port simultaneous communications, RS-232/RS-485/CAN bus result, much slower commanded speeds may be achieved with little speed

• Enhanced Trap Mode Commutation fluctuation.

• Expanded Math Function capability with floating point math and

trigonometric functions Higher Frequency PID Update Rate

• Modulo Encoder Count capability User selectable PID update rate defaults to 125 microseconds. Optionally,

• Eight priority-stacked, user-definable interrupts it may be decreased or increased. The faster 62.5 microsecond update rate

• Four user-definable, independent timers allows for smoother high-speed operation and faster accel/decel correction

• DE/Dt: Following error limit rate of change under varying load conditions.

• Increased I/O interrupt assignments

• Software programmable limits can be set to trigger interrupts Expanded Math Function Capability

without fault Class 5 SmartMotor

™ includes:

• Enhanced parameter and function-based syntax • Boolean operators such as exclusive OR and modulo • Trigonometry functions: SIN, COS, TAN, ASIN, ACOS, ATAN

• Increased system status bit registers for advanced diagnostics • Absolute value

• Optional onboard expanded I/O: 10 channels, 24 VDC isolated, • IEEE-754 single-precision floats

assignable as inputs or outputs • Commutative and associative math operations with up to 128

• Optional 10 additional points of isolated 24V I/O; source up to 300 mA, characters on the right side of an equal sign

and read both digital and analog signals

• Four times faster PID update rate (down to 62.5 μsec) enables Advantages Over Conventional Systems

ultra-precise motion • High noise immunity

• Optional CANopen communications with high-speed contouring • Low electrical noise emissions

to sub-millisecond synchronization • Very high tuning bandwidth (very stable)

• New Sinusoidal Commutation capability delivers smooth and quiet • Very compact motion system (shortest axial length closed-loop

motion, even at low speeds servo available)

• Commutative, associative, and distributive math syntax

• Software programmable limits can be used as programmable electronic DMX Protocol is Standard on Class 5• Easily program the SmartMotor through DMX protocol

cam switch triggers • Simple/advanced motion control triggered from DMX input

• Optionally communicate with the motor through the serial port, • No control cabinet = smaller machine footprint

which provides access as a Modbus Remote Terminal Unit (RTU) Slave • And much more...refer to the website/factory for details

Power and Encoder

Drive Power +20–48 VDC

Control Power +20–48 VDC (Must be supplied separately when DE option is ordered)

Expanded I/O Option +24 VDC Isolated (Must be supplied)

Commutation Trapezoidal (Default)

Enhanced Trapezoidal Based on Encoder Position

Sinusoidal

Encoder Resolution 23 Frame: 4000 Counts per Revolution (Class 5)

34 Frame: 8000 Counts per Revolution (Class 5)

Processor/Clocks

Processor Clock Speed 32 MHz

PWM Switching Frequency 16 KHz

CPU Regulator Frequency 140 KHz +/-10% Load Dependent

Drive Stage Regulator 100 MHz

PID Update Rates

PID1 16 kHz 62.5 µsec update rate

PID2 (Default) 8 kHz 125 µsec update rate

PID4 4 kHz 250 µsec update rate

PID8 2 kHz 500 µsec update rate

Programming

Code Command Interpretive Text Based

Program 32K Program/32K Data Storage

Subroutines Up to 1000

Stack Pointers 10 Nested GOSUB( ) and/or Interrupt Calls

Communications

RS-232 2400 to 115200 Baud 9600 Default

RS-485 2400 to 115200 Baud 9600 Default

(Optional) CAN Bus 20K to 1 MBaud 125000 Default

8 Moog Animatics • www.animatics.com

Power Supplies Gearheads Actuators Cables, Etc. C6 Low-Cost C6 M-Style C5 M-Style CC55 DD--SSttyyllee Software Overview

Page9

D-Style Motor — Understanding Part Numbers

D-Style Motor — Understanding Part Numbers

Moog Animatics Class 5 D-Style SmartMotor™ Part Numbering Guidelines

Step 1: Basic Part Numbering

NEMA 17 NEMA 23 NEMA 34

The Brake option cannot be All three options (Brake, 24V I/O, CAN bus) are All three options (Brake, 24V I/O, CAN bus) are

used with any other option. available in various combinations for the following available in various combinations for the following

24V I/O can be used alone part numbers. part numbers.

or in combination with other

options. See part numbers SM23375D SM23205D SM34165D** SM34205D

below. SM23375DT SM23305D SM34165DT** SM34305D

SM17205D-BRK SM23105D SM23405D SM34105D SM34405D

SM17205D-C

SM17205D-DN The Brake option cannot be used with any other **SM34165D & SM34165DT are the only models that can have an option. 24V I/O can be used alone or in combination internal shunt.

SM17205D-AD1 with other options. See part numbers below.

SM17205D-C-AD1

SM17205D-DN-AD1 SM23165D-C SM23165DT-C

SM23165D-DN SM23165DT-DN

SM23165D-AD1 SM23165DT-AD1

SM23165D-C-AD1 SM23165DT-C-AD1

SM23165D-DN-AD1 SM23165DT-DN-AD1

SM23165D-BRK SM23165DT-BRK

To see all possible option combinations for each motor and get the exact part number, use the Part Number Generator available on the website at:

http://www.animatics.com/pngenerator.

For the CDS option, see page 18.

Step 2: Advanced Part Numbering

23 16

Frame Size Motor Connector Options Options

Class 5 Style Drive enable*

20 CANopen option17

D Internal brake -CDS CANopen on D-sub

NEMA Frame D-Sub SH Internal shunt(select models only)** DeviceNet

10 30 -PB PROFIBUS ®^

23 16 37 DT 24V Expansion I/O

NEMA Frame 20 40 D-Sub 1 Flat on shaft

High Torque

2 Flats on shaft

10 30

34 -K Machined keyway16 40 on motor shaft

NEMA Frame 20 50 -SL Reduced shaftlength

* Separate drive and control power

** SM34165D and SM34165DT are the only models that can have an internal shunt

^ PROFIBUS option only available on SM23165D and SM23165DT product with no additional options

NOTE: DMX protocol is standard on all Class 5 SmartMotors.

REVISED 02/17

Moog Animatics • www.animatics.com 9

Overview Software CC55 DD--SSttyylele C5 M-Style C6 M-Style C6 Low-Cost Cables, Etc. Actuators Gearheads Power Supplies

Page10

D-Style Motor Comparison Chart

D-Style Motor Comparison Chart

BEST VALUE

• All D-style SmartMotors have a primary RS-232 communications port Relative Torque Comparison

• All D-style SmartMotors have 7 channels 5V TTL non-isolated I/O

• Optional 10 channels expanded 24 VDC isolated I/O NOTE: All torque curves based on 25°C ambient. For ambient

• Dedicated encoder out temperatures above 25°C, continuous torque must be linearly

derated to 0% at 85°C.

Peak Torque

Continuous Torque

SM17205D SM23165D SM23165DT SM23375D SM23375DT SM23205D SM23305D

in-lb 2.08 2.50 4.61 2.86 5.18 2.96 3.98

Continuous Torque oz-in 33 40 74 46 83 47 64

N-m 0.24 0.28 0.52 0.32 0.59 0.33 0.45

in-lb 3.82 4.00 7.40 5.00 9.80 5.03 6.86

Peak Torque oz-in 61 64 118 80 157 80 110

N-m 0.43 0.45 0.84 0.57 1.11 0.57 0.77

Nominal Continuous Power Watts 145 181 204 191 186 226 220

No Load Speed RPM 7,900 10,400 5,200 8,000 4,000 8,100 5,600

RPM 6,000 6,500 3,800 6,000 3,250 6,900 4,750

Max. Continuous Current

Amps 3.81 4.70 5.074 5.072 4.52 6.02 5.57

RPM 4,200 6,100 3,400 4,750 2,450 5,995 4,100

Peak Power

Watts 185 183 210 220 235 335 325

Voltage Constant V/krpm 6.506 4.45 9.08 5.62 10.95 6.137 8.873

Inductance mH 1.4 0.829 1.31 0.770 0.906 0.40 0.61

Encoder Resolution Counts/Rev 4,000 4,000 4,000 4,000 4,000 4,000 4,000

oz-in-sec2 0.00217 0.00099 0.001 0.0019 0.0019 0.00224 0.00332

Rotor Inertia

10-5 kg-m2 1.5325 0.6991 0.706 1.342 1.342 1.582 2.344

lb 1.2 1.0 1.3 2.1 2.2 1.7 2.3

Weight

kg 0.55 0.45 0.59 0.95 0.98 0.79 1.03

in 0.197 0.250 0.250 0.250 0.250 0.250 0.250

Shaft Diameter

mm 5.00 6.35 6.35 6.35 6.35 6.35 6.35

lb 7 7 7 7 7 7 7

Shaft, Radial Load

kg 3.18 3.18 3.18 3.18 3.18 3.18 3.18

lb 3 3 3 3 3 3 3

Shaft, Axial Thrust Load

kg 1.36 1.36 1.36 1.36 1.36 1.36 1.36

DeviceNet Option Yes Yes Yes Yes Yes Yes Yes

PROFIBUS Option Yes Yes

CANopen Option Yes Yes Yes Yes Yes Yes Yes

Due to the variety of operating conditions and applications for Moog Animatics' products, the end user is solely responsible for making the final selection

of the Moog Animatics products and systems based on their own analysis and testing, and ensuring that all performance, safety and warning requirements

for the application and product are met. Please consult factory for any supporting hardware and cables needed, full details and latest information.

REVISED 02/17

10 Moog Animatics • www.animatics.com

Power Supplies Gearheads Actuators Cables, Etc. C6 Low-Cost C6 M-Style C5 M-Style CC55 DD--SSttyyllee Software Overview

Page11

D-Style Motor Comparison Chart

TM

TM

RoHS TM

COMPLIANT ODVA

SM23405D SM34165D SM34165DT SM34205D SM34305D SM34405D SM34505D

4.88 9.67 12.83 7.91 10.87 12.94 16.34 in-lb

78 155 205 126 174 207 261 oz-in Continuous Torque

0.55 1.09 1.45 0.89 1.23 1.46 1.85 N-m

8.04 14.12 30.00 24.91 34.75 40.38 48.19 in-lb

129 226 480 399 556 646 771 oz-in Peak Torque

0.91 1.60 3.39 2.81 3.93 4.56 5.44 N-m

253 235 615 324 400 438 527 Watts Nominal Continuous Power

5,300 3,100 5,100 4,500 4,100 3,800 3,300 RPM No Load Speed

4,500 2,400 4,500 3,750 3,600 3,300 3,100 RPM

Max. Continuous Current

6.76 6.02 16.93 8.28 10.31 11.69 14.37 Amps

4,000 1,900 3,400 2,250 2,500 2,350 2,250 RPM

Peak Power

345 265 930 455 725 820 925 Watts

9.612 14.98 8.9 10.8 12.1 12.9 14.049 V/krpm Voltage Constant

0.49 1.72 0.32 0.596 0.490 0.913 0.871 mH Inductance

4,000 8,000 8,000 8,000 8,000 8,000 8,000 Counts/Rev Encoder Resolution

0.00439 0.014 0.0142 0.012 0.018 0.024 0.03 oz-in-sec2

Rotor Inertia

3.100 9.890 10.031 8.448 12.56 17.02 20.92 10-5 kg-m2

2.8 5.0 5.5 3.5 4.5 5.5 6.5 lb

Weight

1.27 2.27 2.49 1.59 2.04 2.49 2.95 kg

0.250 0.375 0.500 0.375 0.375 0.375 0.375 in

Shaft Diameter

6.35 9.53 12.70 9.53 9.53 9.53 9.53 mm

7 15 30 15 15 15 15 lb

Shaft, Radial Load

3.18 6.80 13.61 6.80 6.80 6.80 6.80 kg

3 3 3 3 3 3 3 lb

Shaft, Axial Thrust Load

1.36 1.36 1.36 1.36 1.36 1.36 1.36 kg

Yes Yes Yes Yes Yes Yes Yes DeviceNet Option

Yes Yes PROFIBUS Option

Yes Yes Yes Yes Yes Yes Yes CANopen Option

Due to the variety of operating conditions and applications for Moog Animatics' products, the end user is solely responsible for making the final selection

of the Moog Animatics products and systems based on their own analysis and testing, and ensuring that all performance, safety and warning requirements

for the application and product are met. Please consult factory for any supporting hardware and cables needed, full details and latest information.

REVISED 02/17

Moog Animatics • www.animatics.com 11

Overview Software CC55 DD--SSttyylele C5 M-Style C6 M-Style C6 Low-Cost Cables, Etc. Actuators Gearheads Power Supplies

Page12

D-Style Motor Torque Curves

D-Style Motor Torque Curves

SM17205D SM23165D

70 (0.494) 200 70 (0.494) 210

Peak Power Peak Torque

Peak Torque Peak Power

60 (0.424) 180

56 (0.395) 160

Continuous Power

50 (0.353) 150

42 (0.297) 120 40 (0.282) 120

Continuous Torque Continuous Torque

30 (0.212) 90

28 (0.198) er 80w

us

Po

20 (0.141) 60

ntin

uo

o

14 (0.099) C 40

10 (0.071) 30

0

0 0 0

0 1 2 3 4 5 6 7 8 0 1 2 3 4 5 6 7 8 9 10 11

kRPM

kRPM

SM23165DT SM23375D

120 (0.847) 240 85 (0.600) Peak Power 225

Peak Torque Peak TorquePeak Power

100 (0.706) 200

68 (0.480) 180

80 (0.565) Continuous Torque 160

51 (0.360) 135

Continuous Torque

60 (0.424) 120

we

r

Po 34 (0.240) 90

40 (0.282) sou 80

ntin

u

o erC 17 (0.120) w

20 (0.141) 40 us

Po 45

uo

on

tin

C

0 0 0 0

0 1 2 3 4 5 6 0 1 2 3 4 5 6 7 8 9

kRPM kRPM

SM23375DT SM23205D

160 (1.130) Peak Torque

90 (0.636) 360

240 Peak Power

Peak Torque

75 (0.530) 300

128 (0.904) 192

60 (0.424) 240

96 (0.678) 144 Continuous Torque

45 (0.318) 180

Continuous Torque

64 (0.452) 96

er 30 (0.212) 120

Po

w

us ruo ow

e

32 (0.226) ntin 48 15 (0.106) us

P

uo 60Co tin

Con

0 0

0 0 0 1 2 3 4 5 6 7 8 9

0 1 2 3 4 5

kRPM

kRPM

SM23305D SM23405D

Peak Power 130 (0.918) Peak Torque Peak Power 350120 (0.847) 330

Peak Torque

100 (0.706) 275 104 (0.734) 280

80 (0.565) 220 Continuous Torque

78 (0.551) 210

Continuous Torque

60 (0.424) 165

52 (0.367) 140

40 (0.282) r er

s Po

we 110 ow

uou

P

in o

us

ont 26 (0.184) n

u

onti 70

20 (0.141) C 55 C

0 0 0 0

0 1 2 3 4 5 6 0 1 2 3 4 5 6

kRPM kRPM

12 Moog Animatics • www.animatics.com

Power Supplies Gearheads Actuators Cables, Etc. C6 Low-Cost C6 M-Style C5 M-Style CC55 DD--SSttyyllee Software Overview

Torque oz-in (Nm) Torque oz-in (Nm) Torque oz-in (Nm) Torque oz-in (Nm)

Peak Power

Power (Watts) Power (Watts) Power (Watts) Power (Watts)

Torque oz-in (Nm) Torque oz-in (Nm) Torque oz-in (Nm) Torqueo z-in (Nm)

Power ( Watts)

Power (Watts) Power (Watts) Power (Watts)

Page13

D-Style Motor Torque Curves

SM34165D SM34165DT

250 (1.765) Peak Power 270 500 (3.531) 1000

Peak Torque Peak Torque Peak Power

200 (1.412) 216 400 (2.825) 800

Continuous Torque

150 (1.059) 162 300 (2.118) 600

we

r Continuous Torque

100 (0.706) o 108

s P 200 (1.412) 400

uo

u

ntin

Co wer

50 (0.353) 54 100 (0.706) us P

o

200

onti

nuo

C

0 0 0 0

0 0.5 1 1.5 2 2.5 3 3.5 0 1 2 3 4 5 6

kRPM kRPM

SM34205D SM34305D

400 (2.860) Peak Torque 500 600 (4.237) Peak Power 750

Peak Power Peak Torque

500 (3.531) 625

320 (2.260) 400

400 (2.824) 500

240 (1.695) 300

er 300 (2.118) 375

Pow

160 (1.130) us

onti

nuo 200

C 200 (1.412) 250

Continuous Torque

r Continuouse Torque80 (0.565) 100 100 (0.706) Pow 125

ntinu

ous

Co

0 0 0 0

0 1 2 3 4 5 0 1 2 3 4 5

kRPM kRPM

SM34405D SM34505D

750 (5.296) Peak Power 840 780 (5.508) Peak Torque 990Peak Power

Peak Torque

625 (4.413) 700 650 (4.590) 825

500 (3.531) 560 520 (3.672) 660

375 (2.648) 420 390 (2.754) 495

250 (1.765) 280 260 (1.836) 330

Continuous Torque Continuous Torque

r were o

125 (0.883) wus P

o 140 130 (0.918) us Puo 165

tinuo ontinCon C

0 0 0 0

0 1 2 3 4 0 1 2 3 4

kRPM kRPM

All torque curves based on 48 VDC at 25°C ambient with rise to 85°C.

Motors were operated using MDT (Trapezoidal Drive Mode) Commutation.

For ambient temperatures above 25°C, continuous torque must be linearly derated to 0% at 85°C.

Operating temperature range: 0°C – 85 °C.

Storage temperature range: -10°C – 85°C, noncondensing.

Moog Animatics • www.animatics.com 13

Torque oz-in (Nm) Torque oz-in (Nm) Torque oz-in (Nm)

Torque (oz-in)

Power (Watts) Power (Watts) Power (Watts)

Torque oz-in (Nm) Torque oz-in (Nm) Torque oz-in (Nm)

Power (Watts) Power (Watts)Power (Watts)

Overview Software CC55 DD--SSttyyllee C5 M-Style C6 M-Style C6 Low-Cost Cables, Etc. Actuators Gearheads Power Supplies

Page14

D-Style Motor CAD Drawings

D-Style Motor CAD Drawings

SM17205D (No Options) CAD Drawing

4X 4-40 x .30 [7.6]

ON Ø1.725 [Ø43.82] BOLT

CIRCLE EQUALLY SPACED

.93 [23.7]

.06 [1.6]

2.29 [58.2] .80 [20.3]

1.65 [41.9]

.1969+.0000 +0.000-.0005 [5.000-0.013 ]

in [mm]

1.65 [41.9] 3.74 [95.1]

Ø.865 +.000-.003 [Ø21.97 +0.00-0.08 ]

SM23165D/DT (No Options) CAD Drawing0.810

[20.57]

2.250 0.062 2.30

[57.15] [1.57] [58.42]

0.205 [5.21] DIA THRU (4X)

ON 2.625 [66.675] DIA B.C.

EQUALLY SPACED

3.050

[77.47]

2.250

[57.15]

0.2498 ±0.0002

[ 6.34 ±0.0051 ]

1.498±0.001 0.250

[38.05±0.03] [6.35] in [mm]

SM232x5D-SM234x5D (No Options) CAD Drawing

2.25 .81 L

[57.2] [20.6]

.06

Ø 1.497± .002 [1.6]

[38.02±0.05]

2.25

[57.2]

Ø .2498 +/- .0002

[ 6.345 +/-0.005 ]

.19

FRONT VIEW 4x R.20 [5.0] [4.8] SIDE VIEW

Ø .21 [5.2] DIA THRU (4X) in [mm]

ON 2.625 [66.68] DIA B.C.

EQUALLY SPACED

14 Moog Animatics • www.animatics.com

Power Supplies Gearheads Actuators Cables, Etc. C6 Low-Cost C6 M-Style C5 M-Style CC55 DD--SSttyyllee Software Overview

Page15

D-Style Motor CAD Drawings

SM34165D (No Options) CAD Drawing

0.21 3.54

[5.37] [90.01]

Ø0.375 +0.0000 -0.0005 4.15

[73.025 ±0.051] [9.525 +0.000 -0.127] [105.40]4.00

3.40 [101.60]

[86.36]

0.223 [5.66] DIA THRU (4X)

ON 3.876 [98.45] DIA B.C. 3.75 3.40

EQUALLY SPACED [95.12] [86.36]

in [mm]

SM34165DT (No Options) CAD Drawing

0.21 3.54

[5.37] [90.01]

Ø0.4998 +0.0000 -0.0005 4.15

[73.025 ±0.051] [12.694 +0.000 -0.127] [105.40]

4.00

3.40 [101.60]

[86.36]

0.223 [5.66] DIA THRU (4X)

ON 3.876 [98.45] DIA B.C. 3.75 3.40

EQUALLY SPACED [95.12] [86.36] in [mm]

SM34205D-SM34505D (No Options) CAD Drawing

3.25 .06 L

[82.6] [1.6]

Ø .3747 ± .0003

Ø2.875 ± .002 [9.517 ± 0.008]

[73.03 ± 0.05]

1.19

[30.2]

Ø .22 [5.7] DIA THRU (4X) R.26 [6.5] .25

ON 3.876 [98.45] DIA B.C. [6.4]

EQUALLY SPACED

in [mm]

Moog Animatics • www.animatics.com 15

Overview Software CC55 DD--SSttyyllee C5 M-Style C6 M-Style C6 Low-Cost Cables, Etc. Actuators Gearheads Power Supplies

Page16

Class 5 D-Style Connector Pinouts

Class 5 D-Style Connector Pinouts

PIN Main Power Specifications Notes P1

1 I/O – 6 GP, Index Input or “G” Command 25 mAmp Sink or Source Redundant Connection 8 7 6 5 4 3 2 1

10 Bit 0-5 VDC A/D on I/O Connector

2 +5 VDC Out 50 mAmps Max. (Total) 15

7 14W 123 1C2 o11 m 10b 9o

D-Sub Connector

3 RS-232 Transmit Com ch. 0 115.2 KBaud Max.

9

4 RS-232 Receive Com ch. 0 115.2 KBaud Max. 11 10 1 2

5 Common Ground (Typ. SIG Ground) A1 A23 4 5

A1 Main Power: +20-48 VDC

A2 Common Ground (Req’d POWER Ground) Must be Main Power Ground

PIN I/O Connector (5VTTL I/O) Specifications Notes P2

1 I/O – 0 GP or Encoder A or Step Input 25 mAmp Sink or Source 1.5 MHz Max. as Encoder

10 Bit 0-5 VDC A/D or Step Input

2 I/O – 1 GP or Encoder B or Direction Input 25 mAmp Sink or Source 1.5 MHz Max. as Encoder

10 Bit 0-5 VDC A/D or Direction Input P2 DB-15 D-Sub Connector

3 I/O – 2 Positive Over Travel or GP 25 mAmp Sink or Source

10 Bit 0-5 VDC A/D 8 7 6 5 4 3 2 1

4 I/O – 3 Negative Over Travel or GP 25 mAmp Sink or Source

10 Bit 0-5 VDC A/D 15 14 13 12 11 10 9

5 I/O – 4 GP, IIC or RS-485 A (Com ch. 1) 25 mAmp Sink or Source 115.2 KBaud Max.

10 Bit 0-5 VDC A/D 9 11 10

6 I/O – 5 GP, IIC or RS-485 B (Com ch. 1) 25 mAmp Sink or Source 115.2 KBaud Max. A1 1 2 A2

10 Bit 0-5 VDC A/D 3 4 5

7 I/O – 6 GP, Index Input or “G” Command 25 mAmp Sink or Source Redundant Connection

10 Bit 0-5 VDC A/D on Main Power Connector

8 Phase A Encoder Output

9 Phase B Encoder Output

10 RS-232 Transmit; For -CDS, CAN-L Only Com ch. 0 115.2 KBaud Max.

11 RS-232 Receive; For -CDS, CAN-H Only Com ch. 0 115.2 KBaud Max.

12 +5 VDC Out 50 mAmp Max. (Total)

13 Common Ground (Typ. SIG Ground)

14 Common Ground

15 Main Power: +20-48 VDC If DE Option, Control Power

Separate from Main Power

Note: I/O ports input impedance = 5 kohm (5 kohm pull-up resistor)

PIN CAN bus Connection Notes P3

1 NC NC M12 5-PIN FEMALE END VIEW

2 +V NC Except DeviceNet Input Current < 10 mA

3 -V (Ground, Not Common) CAN Ground Isolated

4 CAN-H 1 MBaud Max.

5 CAN-L 1 MBaud Max.

PIN Isolated 24 VDC I/O Connector Max. Load (Sourcing) Notes P4

1 I/O – 16 GP 150 mAmps

2 I/O – 17 GP 150 mAmps

3 I/O – 18 GP 150 mAmps

M12 12-PIN FEMALE END VIEW

4 I/O – 19 GP 150 mAmps

5 I/O – 20 GP 300 mAmps These I/O ports also

6 I/O – 21 GP 300 mAmps support analog input

7 I/O – 22 GP 300 mAmps

8 I/O – 23 GP 300 mAmps

9 I/O – 24 GP 300 mAmps

10 I/O – 25 GP 300 mAmps

11 +24 Volts Input 18-32 VDC

12 Ground-I/O (Not Common) Isolated

P2 15-Pin P4 12-Pin Expanded

D-Sub I/O I/O Connector

P1 7-Pin Combo CAUTION: P2 DB-15 D-Sub Connector pins 14 and 15 are

D-Sub Power intended for use with DE series motors for control power

& I/O only. Attempting to supply main servo-drive power to a

non-DE motor through those pins will result in immediate

P3 5-Pin CAN damage to the electronics and void the warranty.

(female is standard)

REVISED 08/17

16 Moog Animatics • www.animatics.com

Power Supplies Gearheads Actuators Cables, Etc. C6 Low-Cost C6 M-Style C5 M-Style CC55 DD--SSttyyllee Software Overview

Page17

Fieldbus Protocol Options

Fieldbus Protocol Options

Moog Animatics CANopen SmartMotor™

Features include:

• All basic motion commands available via CiA V4.02 specification

• Ability to read/write all SmartMotor variables

• Use of onboard I/O via CANopen gateway, SmartMotor program,

or RS-232 commands

• Ability to run 1000 SmartMotor subroutines via CANopen

• Online diagnostics of the SmartMotor™ via SMI software and

RS-232 connection

• Up to 127 nodes

• 250 microsecond interrupt-driven subroutine

• Baud rates: 20K, 50K, 125K, 250K, 500K, 1 Mbps default 125 Kbps

NOTE: This option DOES NOT apply to all models, refer to website or factory.

Moog Animatics DeviceNet SmartMotor™

Features include:

• Polled I/O and Explicit Messages from your PLC to control all

SmartMotor™ operation

• Read/Write control over all ODVA Position Controller parameters

• Use of onboard I/O via DeviceNet, SmartMotor™ program or RS-232

commands

• Ability to run 1000 SmartMotor subroutines via DeviceNet and read/write

four 32-bit user variables

• Online diagnostics of the SmartMotors via SMI software and RS-232

connection

• Up to 64 DeviceNet nodes

• 250 microsecond interrupt-driven subroutine

• Baud rates: 125K, 250K, 500K, 1 Mbps default 125 Kbps

Not Connected

NOTE: This option DOES NOT apply to all models, refer to website or factory.

Common

ODVATM

Moog Animatics PROFIBUS SmartMotor™

Features include:

• Command/Response Codes for all Class 5 SmartMotor commands

• Use of onboard I/O via PROFIBUS, SmartMotor program, or RS-232

commands

• Ability to run 1000 SmartMotor™ subroutines via PROFIBUS

• Ability to read/write all SmartMotor variables

• Online diagnostics of the SmartMotors via SMI software and RS-232

connection

• Up to 127 PROFIBUS nodes

• 250 microsecond interrupt-driven subroutine

• Baud rates: default 1.5 Mbps

- 9.6, 19.2, 31.25, 45.45, 93.75, 187.5, 500 Kbps, 1.5, 3, 6, 12 Mbps

ProfiBus Pinout:

1 NC 6 +5V NOTE: PROFIBUS baud rates are achievable only with proper cable length and termination connectors.

2 NC 7 NC

3 BUS-B 8 BUS-A The minimum cable length when operating >=1 MBaud is 1 meter (3 feet). If the cable is too short,

4 NC 9 NC reflected impedance can cause loss of communications data packets and spurious node errors.

5 ground

Moog Animatics • www.animatics.com 17

Overview Software CC55 DD--SSttyyllee C5 M-Style C6 M-Style C6 Low-Cost Cables, Etc. Actuators Gearheads Power Supplies

Page18

CDS Option and Recommended DE Option

CDS Option and Recommended DE Option

Now with CAN Bus through D-sub Connector

• Get your SmartMotor with CAN and brake

• More compact design decreases required space in machine

• Lower OEM cost applications

The CDS option SmartMotor upgrade provides users the option of employing CAN communications through the D-sub connector on

the top of the motor instead of through the 5-pin connector on the back of the motor. Through a small change to the circuitry, this new

option decreases the space required when integrating the motor into industrial machinery. The CDS option

opens the door to numerous vertical axis applications that would benefit from SmartMotor technology by

allowing for an integrated brake while using CAN.

Example SmartMotor Part Numbers Compatible with –CDS Option*

• SM23165D-CDS • SM23165D-DE-CDS • SM34165D-CDS

• SM23165DT-CDS • SM23165DT-DE-CDS • SM34165D-DE-CDS

• SM23165D-BRK-CDS • SM23165D-DEBRK-CDS • SM34165D-BRK-CDS

• SM23165DT-BRK-CDS • SM23165DT-DEBRK-CDS • SM34165D-DEBRK-CDS

• SM23165D-CDS-AD1 • SM23165D-DE-CDS-AD1 • SM34165D-DE-CDS-AD1

• SM23165DT-CDS-AD1 • SM23165DT-DE-CDS-AD1 • SM34165DT-DE-CDS-AD1

*Consult the factory for the complete list.

! WARNING: Proper bus biasing and termination must be incorporated into system wiring to ensure quality

communications over any industrial bus. Failure to do so could result in loss of communications. Please consult the

associated bus standard organizations for details.

Recommended “DE” Option

The DE option allows the controller and drive-amplifier to be powered from separate 24-48 VDC power supplies.

• Controller can be powered from a standard 24 VDC supply • Load surges will not cause power surge on controller

• Position will not be lost if drive power is lost • Standard battery options are made simpler

• No need to re-home

CONTROL POWER

8 7 6 5 4 3 2 1

15 14 13 12 11 10 9 DRIVE POWER

9

11 10

A1 1 2 A2

3 4 5

Please see the SmartMotor Installation & Startup Guide for the schematic diagram and installation details.

Please see the SmartMotor Installation & Startup Guide for the schematic

NOTE:

• The same podwiear gsurpapmly m ayn bde uisneds ftoar lcloantriol nan d deritvae iplosw.er, but maximum protection is provided with separate power supplies.

• Only DE option SmartMotors can be wired in this manner. Attempting to power a non-DE motor in this way will damage the motor and void

the warranty.

• To suppress back EMF, shunts should be placed between the E-stop switch and motor Drive Power input.

• All M-style SmartMotors are designed to always have separate drive and control power. As a result, no DE designation is available for those

motors.

18 Moog Animatics • www.animatics.com

Power Supplies Gearheads Actuators Cables, Etc. C6 Low-Cost C6 M-Style C5 M-Style CC55 DD--SSttyyllee Software Overview

Page19

Class 5 M-Style、Industrial M-Style SmartMotor with Optional IP-Rating

Industrial M-Style SmartMotor with Optional IP-Rating

Moog Animatics’ Class 5 SmartMotor™ with M-style connectors offers optional IP65 and IP67 ratings for NEMA 23 and 34 frame sizes.

This series of harsh-environment rated M-style SmartMotor combines the quality and advanced motion control capabilities of the

integrated servo in combination with an IP rating.

SmartMotors with the IP65 rating are both completely dust tight and protected from ingress of liquid that may occur from any angle,

rendering no harmful effects on the electrical enclosure. SmartMotors with the IP67 rating can be submersed in water or other non-

hazardous liquids to a depth of one meter for a maximum time of 30 minutes. Therefore, conditions with high levels of humidity and

condensation are no longer a problem. The IP-rated models provide the perfect integrated servo for food and beverage manufacturing

and packaging, rugged outdoor conditions, as well as any wet environment.

Class 5 M-Style SmartMotor Features

• Complete barrier against dust and other harmful particles

IP65 • Splash and submersion protected for wet environments

IP67 with the IP options*

• Industrial style connectors for ensured communication

• New industry capabilities such as food and beverage

manufacturing and packaging, demanding outdoor conditions,

and nautical machinery

*IP rating depends on motor options.

For more information about the M-style SmartMotor, applications or to

read the white paper “Integrated Solutions for Harsh Environments”, visit

www.animatics.com.

Understanding M-Style SmartMotor Part Numbers

Options

23 16 MT BRK IP DN FB01

Frame Size Motor IP Compliance Information: Multiturn

Class 5 • Standard IP-Option Models are IP67 Compliant CAN CAbsAoluNte• IP-Option Models with BRK option are IP65 Compliant

23 Standard Standard16 Encoder Option

NEMA Frame DeviceNet

Oopttiionall

34 16

NEMA Frame

Standard on all M-Style SmartMotors: - C, - AD1 and - DE

Though the above items are "options" on the D-Style SmartMotor, they have been incorporated as standard for the M-Style SmartMotors.

For options such as - F1, - F2, - K, - SL and - SH, please contact Moog Animatics at (650) 960-4216 or email animatics_sales@moog.com.

NOTE: DMX protocol is standard on all Class 5 SmartMotors.

Moog Animatics • www.animatics.com 19

Overview Software C5 D-Style CC55 MM--SSttyyllee C6 M-Style C6 Low-Cost Cables, Etc. Actuators Gearheads Power Supplies

Page20

Class 5 M-Style Motor Comparison Chart

Class 5 M-Style Motor Comparison Chart

Back View Back View

• All M-style SmartMotors have a primary RS-485

communications port

IP65

IP67 • All M-style SmartMotors have 11 channels general

purpose 24V isolated I/O

• Dedicated Drive Enable In and NOT-FAULT Out

• Dedicated encoder bus

• IP65/IP67 available (depends on other options)

IP rating may affect performance - consult factory for details.

SM23165MT SM34165MT

in-lb 4.25 12.58

Continuous Torque @48V oz-in 68 201

N-m 0.48 1.42

in-lb 9.45 34.88

Peak Torque oz-in 151 558

N-m 1.07 3.94

Nominal Continuous Power Watts 189 472

No Load Speed RPM 5,000 4,900

Max. Continuous Current RPM 3,700 4,500

Amps 6.4 13

Peak Power RPM 2,800 3,300

Watts 255 1120

Voltage Constant V/krpm 9.6 9.8

Inductance mH 2.01 0.315

Encoder Resolution Counts/Rev 4,000 8,000

Rotor Inertia oz-in-sec2 0.001 0.0142

10-5 kg-m2 0.706 10.031

Weight lb 1.5 6.0

kg 0.68 2.72

Shaft Diameter in 0.375 0.500

mm 9.53 12.70

Shaft, Radial Load lb 15 30

kg 6.80 13.61

Shaft, Axial Thrust Load lb 3 3

kg 1.36 1.36

DeviceNet Option Firmware Option Firmware Option

PROFIBUS Option

CANopen Option Standard Standard

Due to the variety of operating conditions and applications for Moog Animatics' products, the end user is solely responsible for making the final selection

of the Moog Animatics products and systems based on their own analysis and testing, and ensuring that all performance, safety and warning requirements

for the application and product are met. Please consult factory for any supporting hardware and cables needed, full details and latest information.

REVISED 02/17

20 Moog Animatics • www.animatics.com

Power Supplies Gearheads Actuators Cables, Etc. C6 Low-Cost C6 M-Style CC55 MM--SSttyyllee C5 D-Style Software Overview