1/321ページ

Download(13.1Mb)

Document Information

| Document Title | Circular Connectors |

|---|---|

| Document Type | Product Catalog |

| File size | 13.1Mb |

| Category | |

| Company | HARTING K.K. (Documents List) |

Documents related to this company

Document Contents

Page1

Anfang_en

HARTING

Circular Connectors

Page2

Circular connectors

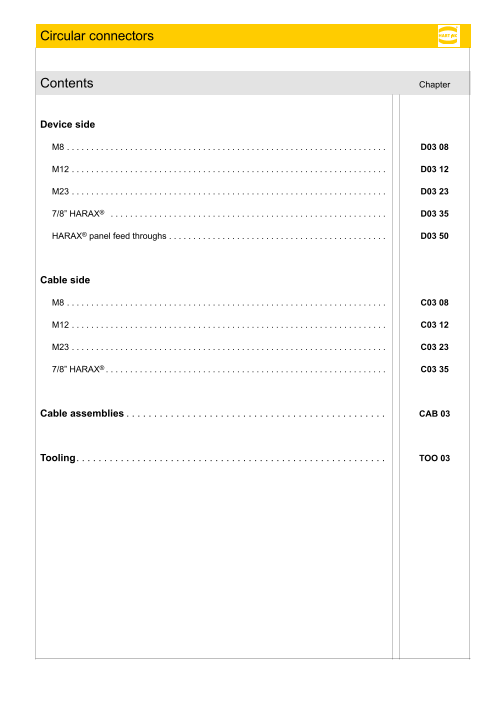

Contents Chapter

Device side

M8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D03 08

M12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D03 12

M23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D03 23

7/8” HARAX® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D03 35

HARAX® panel feed throughs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D03 50

Cable side

M8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C03 08

M12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C03 12

M23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C03 23

7/8” HARAX® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C03 35

Cable assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CAB 03

Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TOO 03

Page3

2_Einleitungsseiten_en_web

HARTING Worldwide

Transforming customer wishes

into concrete solutions

The HARTING Technology Group is skilled in the fields of electrical, electronic and optical connection, transmission and

networking technology, as well as in manufacturing, mechatronics and software creation. The Group uses these skills to develop

customized solutions and products such as connectors for energy and data-transmission/data-networking applications, including,

for example, mechanical engineering, rail technology, wind energy plants, factory automation and the telecommunications sector.

In addition, HARTING also produces electro-magnetic components for the automobile industry and offers solutions in the field of

housing technology and shop systems.

The HARTING Group currently comprises 58 sales companies and production plants worldwide employing a total of about 5,000

staff.

HARTING Worldwide

Page4

HARTING Subsidiary HARTING Representation

We aspire to top performance. Our on-site staff form the interface to the centrally coordinated

Connectors ensure functionality. As core elements of electrical development and production departments. In this way, our

and optical termination, connection and infrastructure customers can rely on consistently high, superior product quality

technologies, they are essential in enabling the modular – worldwide.

construction of devices, machines and systems across an

extremely wide range of industrial applications. Their reliability Our claim: Pushing Performance.

is a crucial factor guaranteeing smooth functioning in the HARTING provides more than optimally attuned components.

manufacturing area, telecommunications, applications in medical In order to offer our customers the best possible solutions, on

technology – in short, connectors are at work in virtually every request HARTING contributes a great deal more and is tightly

conceivable application area. Thanks to the ongoing development integrated into the value-creation process.

of our technologies, our customers enjoy investment security and From ready-assembled cables through to control racks or ready-

benefit from durable, long-term functionality. to-go control desks. Our aim is to generate maximum benefit for

our customers – with no compromises!

Wherever our customers are, we’re there.

Increasing industrialization is creating growing markets Quality creates reliability – and warrants trust.

that are characterized by widely diverging demands and The HARTING brand stands for superior quality and reliability –

requirements. What these markets all share in common is the worldwide. The standards we set are the result of consistent,

quest for perfection, increasingly efficient processes and reliable stringent quality management that is subject to regular

technologies. HARTING is providing these technologies – in certifications and audits.

Europe, the Americas and Asia. In order to implement customer EN ISO 9001, the EU Eco-Audit and ISO 14001:2004 are

requirements in the best possible manner, the HARTING key elements here. We take a proactive stance towards new

professionals at our international subsidiaries engage in up-close, requirements, which is why HARTING is the first company

partnership-based interaction with our customers, right from the worldwide to have obtained the new IRIS quality certificate for

very early product development phase. rail vehicles.

Page5

HARTING Worldwide

HARTING technology creates added value for customers. gy, high-temperature and ultrahigh-frequency applications that

Technologies by HARTING are at work worldwide. HARTING’s are finding use in telecommunications and automation networks,

presence stands for smoothly functioning systems powered by in the automotive industry, or in industrial sensor and actuator

intelligent connectors, smart infrastructure solutions and sophis- applications, RFID and wireless technologies, in addition to pack-

ticated network systems. Over the course of many years of close, aging and housing made of plastics, aluminum and stainless steel.

trust-based cooperation with its customers, the HARTING Technol-

ogy Group has become one of the leading specialists globally for HARTING overcomes technological limitations.

connector technology. We offer individual customers specific and Drawing on the comprehensive resources of the group’s technol-

innovative solutions that go beyond the basic standard function- ogy pool, HARTING devises practical solutions for its customers.

alities. These tailored solutions deliver sustained results, ensure Whether this involves industrial networks for manufacturing

investment security and enable customers to achieve significant automation, or hybrid interface solutions for wireless telecom-

added value. munication infrastructures, 3D circuit carriers with microstruc-

tures, or cable assemblies for high-temperature applications in

Opting for HARTING opens up an innovative, complex the automotive industry – HARTING technologies offer not only

world of concepts and ideas. components, but comprehensive solutions attuned to individual

In order to develop and produce connectivity and network solu- customer requirements and preferences. The range of cost-effec-

tions serving an exceptionally wide range of connector applica- tive solutions covers ready-to-use cable configurations, completely

tions in a professional and cost-effective manner, HARTING not assembled backplanes and board system carriers, as well as fully

only commands the full array of conventional tools and basic tech- wired and tested control panels.

nologies. Above and beyond these capabilities, HARTING is con- In order to ensure the future-proof design of RF and EMC-compat-

stantly harnessing and refining its broad base of knowledge and ible interface solutions, the central HARTING laboratory (certified

experience to create new solutions that also ensure continuity. To to EN 45001) employs simulation tools, as well as experimental,

secure its lead in know-how, HARTING draws on a wealth of sourc- testing and diagnostics facilities all the way to scanning electron

es from its in-house research and applications. microscopes. In addition to product and process suitability con-

Salient examples of these sources of innovative knowledge include siderations, lifecycle and environmental aspects play a key role in

microstructure technologies, 3D design and connection technolo- the selection of materials and processes.

HARTING Worldwide

Page6

HARTING’s knowledge is practical know-how that conversant with the specific application areas in all of these tech-

generates synergy effects. nology fields. In every solution approach, the key focus is on the

HARTING commands decades of experience with regard to the application. In this context, uncompromising, superior quality

applications conditions involved in connections in telecommuni- is our hallmark. Every new solution found invariably flows back

cations, computer, network and medical technologies, as well as into the HARTING technology pool, thereby enriching our resourc-

industrial automation technologies, e.g. in the mechanical engi- es. And every new solution we go on to create will draw on this

neering and plant engineering areas, in addition to the power gen- wealth of resources in order to optimize each and every individual

eration industry and the transportation sector. HARTING is highly solution. HARTING is synergy in action.

Page7

3_HARTING eCatalogue_en_web

HARTING eCatalogue

The HARTING eCatalogue / eShop can be found

on our homepage at www.HARTING.com or at the

direct link www.eCatalogue.HARTING.com.

The HARTING e-Catalogue is your platform for

conveniently selecting individual products as well as

configuring complete solutions. Our comprehensive

product pages provide you with all necessary

technical information and CAD files in various

formats for downloading. You may also contact our

technical sales department directly.

Find out about product innovations and news on

the start page of the HARTING e-Catalogue or go

directly to www.product-news.HARTING.com.

Registered users can take advantage of

MyHARTING to check on availability or prices, and

to place or track their orders. Here, your customized

„HARTING history“ provides you with a list of your

inquiries, quotations and more.

Sign up now for your free e-Catalogue account at

HARTING!

www.eShop.HARTING.com

Page8

D03_08_M8_en

M8

Contents Page

PCB connectors....................................................................................... D03 08.2 M8

Panel feed through .................................................................................. D03 08.9

Accessories ............................................................................................. D03 08.11

D03

08

·

1

Page9

PCB connectors D-coding

Number of contacts

M8 4

Wave soldering termination

Shielded

Technical characteristics Technical characteristics

Number of contacts 4 Material (contacts) Copper alloy

Rated current 4 A Surface (contacts) Gold plated

Rated voltage 60 V RoHS compliant with exemption

Rated impulse voltage 1.5 kV

Pollution degree 3

Insulation resistance >108 Ω Specifications and approvals

Contact resistance ≤10 mΩ

Mating cycles ≥100 IEC 61076-2-114

Degree of protection acc. to IEC IP67, when mated

60529

Transmission characteristics Cat. 5, Class D up to 100 MHz

Tightening torque 1 Nm Lock nut

Part number Drawing

Identification Female (dimensions in mm)

Circular connectors M8, 21 42 000 0006

PCB connector,

Straight,

Wave soldering termination,

Shielded

Order housings separately PCB layout

Circular connectors M8, 21 41 000 0016

Housing,

for front mounting,

9 mm

Circular connectors M8, 21 41 000 0017

Housing,

for front mounting,

13 mm

D03

08

·

2

Page10

PCB connectors D-coding

Part number Drawing

Identification Female (dimensions in mm)

Circular connectors M8, 21 41 000 0018 M8

hexagonal nut,

M10 x 1

D03

08

·

3

Page11

PCB connectors D-coding

Number of contacts

M8 4

Wave soldering termination

Shielded

Technical characteristics Technical characteristics

Number of contacts 4 Transmission characteristics Cat. 5, Class D up to 100 MHz

Rated current 4 A Tightening torque 1 Nm Lock nut

Rated voltage 60 V Material (contacts) Copper alloy

Rated impulse voltage 1.5 kV Surface (contacts) Gold plated

Pollution degree 3 RoHS compliant with exemption

Insulation resistance >108 Ω

Contact resistance ≤10 mΩ

Mating cycles ≥100 Specifications and approvals

Degree of protection acc. to IEC IP67, when mated

60529 IEC 61076-2-114

Part number Drawing

Identification Female (dimensions in mm)

Circular connectors M8, 21 42 010 0003 401

PCB connector,

Angled,

Wave soldering termination,

Shielded

Order housings separately

PCB layout

Circular connectors M8, 21 42 010 0004 401

Housing,

for rear mounting,

7 mm

Circular connectors M8, 21 42 010 0002 401

Housing,

for rear mounting,

11 mm

D03

08

·

4

Page12

PCB connectors D-coding

Part number Drawing

Identification Female (dimensions in mm)

Circular connectors M8, 21 42 010 0001 401 M8

hexagonal nut,

M12 x 1

D03

08

·

5

Page13

PCB connectors D-coding

Number of contacts

M8 4

Wave soldering termination

Shielded

Technical characteristics Technical characteristics

Number of contacts 4 Transmission characteristics Cat. 5, Class D up to 100 MHz

Rated current 4 A Tightening torque 1 Nm Lock nut

Rated voltage 60 V Material (contacts) Copper alloy

Rated impulse voltage 1.5 kV Surface (contacts) Gold plated

Pollution degree 3 RoHS compliant with exemption

Insulation resistance >108 Ω

Contact resistance ≤10 mΩ

Mating cycles ≥100 Specifications and approvals

Degree of protection acc. to IEC IP67

60529 IEC 61076-2-114

Part number Drawing

Identification Female (dimensions in mm)

Circular connectors M8, 21 42 000 0014

9 mm,

PCB connector,

Straight,

for front mounting,

Wave soldering termination,

Shielded

Panel cut out

PCB layout

D03

08

·

6

Page14

PCB connectors D-coding

Part number Drawing

Identification Female (dimensions in mm)

Circular connectors M8, 21 42 000 0005 M8

13 mm,

PCB connector,

Straight,

for front mounting,

Wave soldering termination,

Shielded

Panel cut out

PCB layout

Circular connectors M8, 21 42 000 0020

7 mm,

PCB connector,

Angled,

for rear mounting,

Wave soldering termination,

Shielded

Panel cut out

PCB layout

D03

08

·

7

Page15

PCB connectors D-coding

Part number Drawing

Identification Female (dimensions in mm)

M8 Circular connectors M8, 21 42 000 0019

11 mm,

PCB connector,

Angled,

for rear mounting,

Wave soldering termination,

Shielded

Panel cut out

PCB layout

D03

08

·

8

Page16

Panel feed through A-coding

Number of contacts

3 M8

Unshielded

Technical characteristics Technical characteristics

Number of contacts 3 Material (insert) Thermoplastic polyurethane

Rated current 3 A (TPU)

Rated voltage 50 V Material (hood/housing) Copper-zinc alloy

Rated impulse voltage 1.5 kV Material (contacts) Brass

Pollution degree 3 Surface (contacts) Gold plated

Insulation resistance >108 Ω RoHS compliant with exemption,

Contact resistance ≤10 mΩ compliant

Mating cycles ≥100

Locking type Screw locking Specifications and approvals

Conductor length 50 cm

Degree of protection acc. to IEC IP67 IEC 61076-2-104

60529

Conductor cross-section 0.25 mm²

Conductor cross-section AWG 24

Tightening torque 0.8 Nm Lock nut

Conductor cross-sec- Part number Drawing

Identification tion (mm²) Female (dimensions in mm)

Circular connectors M8, 0.25 21 02 357 6305

Panel feed through,

With conductors,

for front mounting,

Unshielded

Panel cut out

Circular connectors M8, 21 01 000 0048

hexagonal nut,

M8 x 0.5

D03

08

·

9

Page17

Panel feed through A-coding

Number of contacts

M8 4

Unshielded

Technical characteristics Technical characteristics

Number of contacts 4 Material (insert) Thermoplastic polyurethane

Rated current 3 A (TPU)

Rated voltage 50 V Material (hood/housing) Copper-zinc alloy

Rated impulse voltage 1.5 kV Material (contacts) Brass

Pollution degree 3 Surface (contacts) Gold plated

Insulation resistance >108 Ω RoHS compliant with exemption,

Contact resistance ≤10 mΩ compliant

Mating cycles ≥100

Locking type Screw locking Specifications and approvals

Conductor length 5 0 cm

Degree of protection acc. to IEC IP67 IEC 61076-2-104

60529

Conductor cross-section 0.25 mm²

Conductor cross-section AWG 24

Tightening torque 0.8 Nm Lock nut

Conductor cross-sec- Part number Drawing

Identification tion (mm²) Female (dimensions in mm)

Circular connectors M8, 0.25 21 02 357 6405

Panel feed through,

With conductors,

for front mounting,

Unshielded

Panel cut out

Circular connectors M8, 21 01 000 0048

hexagonal nut,

M8 x 0.5

D03

08

·

10

Page18

Accessories

M8

Technical characteristics Technical characteristics

Material (accessories) Thermoplastic Colour (accessories) Black

RoHS compliant

Drawing

Identification Part number (dimensions in mm)

Circular connectors M8, 21 41 000 0003

Cap,

for male inserts,

with cord

Circular connectors M8, 21 41 000 0004

Cap,

for female inserts,

with cord

D03

08

·

11

Page19

M12

Contents Page

PCB connectors....................................................................................... D03 12.2 M12

PCB connectors with transformer ............................................................ D03 12.64

Panel feed through .................................................................................. D03 12.76

Accessories ............................................................................................. D03 12.90

D03

12

·

1

Page20

PCB connectors A-coding

Number of contacts

M12 4

Reflow soldering termination (THR)

Shielded

Technical characteristics Technical characteristics

Number of contacts 4 Material (insert) Liquid crystal polymer (LCP)

Rated current 4 A Material (contacts) Copper alloy

Rated voltage 250 V Surface (contacts) Gold plated

Rated impulse voltage 1.5 kV RoHS compliant with exemption,

Pollution degree 3 compliant

Insulation resistance >108 Ω

Contact resistance ≤10 mΩ

Mating cycles ≥100 Specifications and approvals

Locking type Screw locking, PushPull IEC 61076-2-101

Degree of protection acc. to IEC IP65 / IP67, when mated UL 1977 ECBT2.E102079

60529 CSA-C22.2 No. 182.3 ECBT8.E102079

Tightening torque 2 Nm Lock nut

Part number Drawing

Identification Male Female (dimensions in mm)

Circular connectors M12, 21 03 321 1418 21 03 321 2418

PCB adapter,

Straight,

Reflow soldering termination (THR),

Shielded,

Pack contents:

60 pieces in a tray

Order housings separately

D03

12

·

2