1/6ページ

Download(3.1Mb)

Automatic Leak Inspection System - Helium Leak Tester

Product Catalog

Japan's top class leak tester! This is an automatic inspection system that detects minute leaks at high speed and with high accuracy.

More Details

https://www.yamahafinetech.co.jp/en/fa_products/he_leaktester/

Document Information

| Document Title | Automatic Leak Inspection System - Helium Leak Tester |

|---|---|

| Document Type | Product Catalog |

| File size | 3.1Mb |

| Category | |

| Company | YAMAHA FINE TECHNOLOGIES CO., LTD. (Documents List) |

Documents related to this company

Document Contents

Page1

THE LEAK TESTERS

Product catalog

FA Division

283, Aoya-cho, Minami-ku, Hamamatsu, 435-8568, Japan

TEL +81-53-467-3601 FAX +81-53-467-3613

Website Inquiry

URL https://www.yamahafinetech.co.jp/en/ The contents of this catalog are subject to change without notice.

Page2

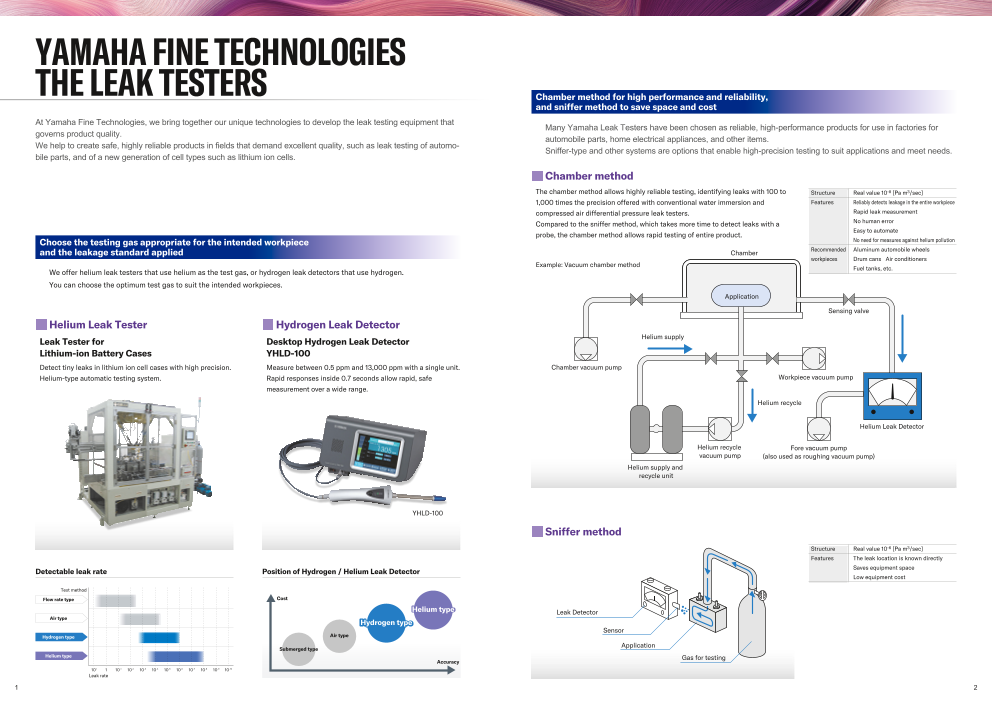

YAMAHA FINE TECHNOLOGIES

THE LEAK TESTERS Chamber method for high performance and reliability,

and sniffer method to save space and cost

At Yamaha Fine Technologies, we bring together our unique technologies to develop the leak testing equipment that Many Yamaha Leak Testers have been chosen as reliable, high-performance products for use in factories for

governs product quality. automobile parts, home electrical appliances, and other items.

We help to create safe, highly reliable products in fields that demand excellent quality, such as leak testing of automo- Sniffer-type and other systems are options that enable high-precision testing to suit applications and meet needs.

bile parts, and of a new generation of cell types such as lithium ion cells.

Chamber method

The chamber method allows highly reliable testing, identifying leaks with 100 to Structure Real value 10-8 [Pa m3/sec]

1,000 times the precision offered with conventional water immersion and Features Reliably detects leakage in the entire workpiece

compressed air differential pressure leak testers. Rapid leak measurement

Compared to the sniffer method, which takes more time to detect leaks with a No human error

Easy to automate

probe, the chamber method allows rapid testing of entire product.

Choose the testing gas appropriate for the intended workpiece No need for measures against helium pollution

and the leakage standard applied Chamber Recommended Aluminum automobile wheels

workpieces Drum cans Air conditioners

Example: Vacuum chamber method Fuel tanks, etc.

We offer helium leak testers that use helium as the test gas, or hydrogen leak detectors that use hydrogen.

You can choose the optimum test gas to suit the intended workpieces.

Application

Sensing valve

Helium Leak Tester Hydrogen Leak Detector

Helium supply

Leak Tester for Desktop Hydrogen Leak Detector

Lithium-ion Battery Cases YHLD-100

Detect tiny leaks in lithium ion cell cases with high precision. Measure between 0.5 ppm and 13,000 ppm with a single unit. Chamber vacuum pump

Helium-type automatic testing system. Rapid responses inside 0.7 seconds allow rapid, safe Workpiece vacuum pump

measurement over a wide range.

Helium recycle

Helium Leak Detector

Helium recycle Fore vacuum pump

vacuum pump (also used as roughing vacuum pump)

Helium supply and

recycle unit

YHLD-100

Sniffer method

Structure Real value 10-6 [Pa m3/sec]

Features The leak location is known directly

Detectable leak rate Position of Hydrogen / Helium Leak Detector Saves equipment space

Low equipment cost

Test method

Flow rate type Cost

Helium type Leak Detector

Air type

Hydrogen type

Sensor

Hydrogen type Air type

Application

Submerged type

Helium type Gas for testing

Accuracy

101 1 10-1 10-2 10-3 10-4 10-5 10-6 10-7 10-8 10-9 10-10

Leak rate

1 2

Page3

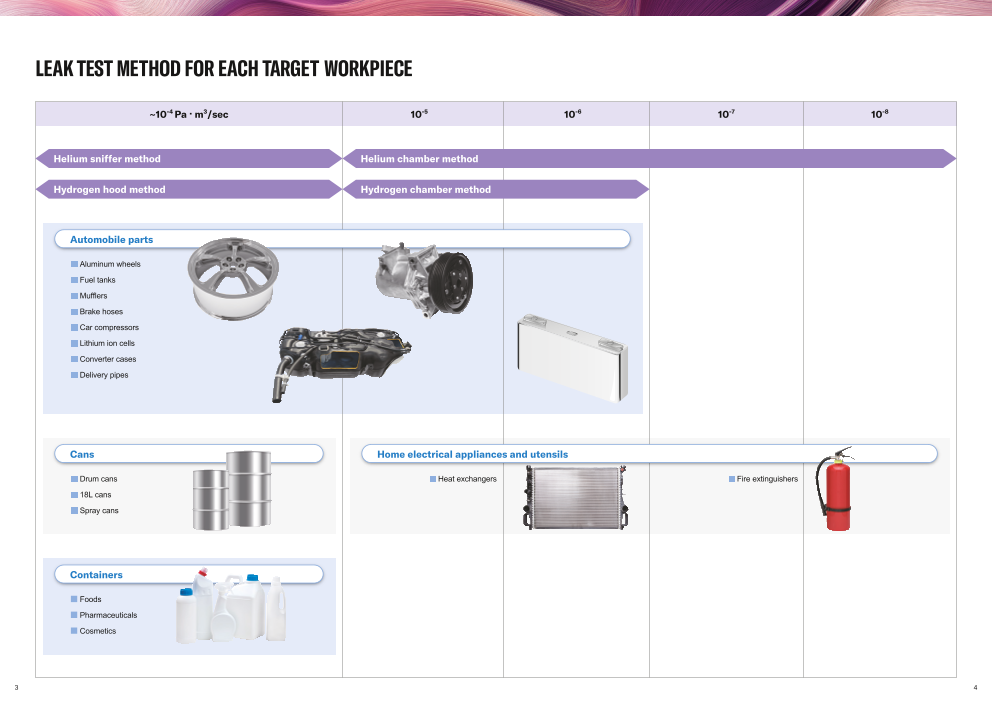

LEAK TEST METHOD FOR EACH TARGET WORKPIECE

~10-4 Pa . m3/sec 10-5 10-6 10-7 10-8

Helium sniffer method Helium chamber method

Hydrogen hood method Hydrogen chamber method

Automobile parts

Aluminum wheels

Fuel tanks

Mufflers

Brake hoses

Car compressors

Lithium ion cells

Converter cases

Delivery pipes

Cans Home electrical appliances and utensils

Drum cans Heat exchangers Fire extinguishers

18L cans

Spray cans

Containers

■ Foods

■ Pharmaceuticals

■ Cosmetics

3 4

Page4

Helium Leak Tester

HELIUM LEAK TEST SYSTEM

Lineup

Yamaha Finetech utilizes a unique low-vacuum chamber and helium gas detector to provide highly reliable testing.

Comprehensive fail-safing and advanced control systems make operation and maintenance easy. YHS-630 Specifications

Leak detector YHS-630

We design products to suit our customers' production environments and workpieces. Leak detector Judgment leak rate 1 x 10-8 to 1 x 10-2 Pa . m3/sec

From proposals right through to delivery—we invite you to leave everything up to us! Minimum detection leak rate 1 x 10-8 Pa . m3/sec

Sniffer Method Startup time 3 minutes

Number of analysis tube filaments Double Filaments (2)

Analysis tube seal Flat Gasket

Calibration External

Temperature 10 to 40°C

Humidity 90% or less

Power supply AC 100V±10% Single phase 50 / 60Hz 10A

Dimensions W546mm x D378mm x H470mm

Features of Helium Leak Tester Weight 46kg

Tiny leaks detected accurately

Yamaha's proprietary low vacuum chamber system judges tiny leaks with an accuracy 100 to 1000 times as high as the accuracy of

a submerged type or differential pressure air leak detection method.

YLD-510 Specifications

Leak detector YLD-510

Construction of a system directly connected to your production line possible Leak detector Judgment leak rate 1 x 10-9 to 1 x 10-2 Pa . m3/sec

Minimum detection leak rate 1 x 10-9 Pa . m3/sec

It is possible to construct a system directly connected to your production line and a robot-based transfer system when it is combined

Startup time 3 minutes

with Yamaha's factory automation technology. Productivity can be increased by manpower saving or unmanned operation. Number of analysis tube filaments Double Filaments (2)

Analysis tube seal Flat Gasket

Calibration Choose between external and internal

Operational errors are reduced with a fail-safe system calibration leaks for calibration work

Temperature 10 to 40°C

A system is designed with safety in mind so as to reduce the operator load and prevent mistakes, Humidity 90% or less

such as adopting automatic sorting of conforming/non-conforming items, marking, processing check, and interlocking. Power supply AC 200V±10%, 3 phase, 800 VA

Dimensions W456mm x D291mm x H578mm

Weight 35kg

Easy operation and easy maintenance

A sophisticated control system is adopted to make operation and maintenance easy.

In case of an operational error or problem, messages in Japanese help you navigate and find a quick and appropriate recovery method.

YLT-1100 Specification example

Comprehensive support provided from design to assembly and adjustment Applications Engine cover AbsorberPackage-type leak tester Detection Detection method 180 degree magnetic deflection type mass spectrometercapability Detection capability 1.0 x 10-9 to 9.0 x 10-3 Pa m3/sec

Comprehensive systems can be offered to customers by carrying out design and manufacturing all in-house, Cycle time Leak cube system Depend on chamber size and Leak rate(excluding work replacement)

from an inspection workpiece handling machine up to control design and assembly & adjustment. Helium charging pressure max 0.9 MPa (G)

Workpiece volume 400 [cc] ((Workpiece=1000) - (core (600)) 115 [cc] ((Workpiece=400) - (core (285))

Selected Chamber size W380mm x D285mm x H120mm Approx. 13L W120mm x D100mm x H345mm Approx. 4.2L

unit Demo system dimensions W900mm x D1100mm x H1500mm

One of the best track records in Japan Chamber vacuum pump 100 [m3/h]

Workpiece vacuum pump 21 [m3/h]

Detector vacuum pump 25 [m3/h]

For Yamaha's leak testers, more than 500 systems have been supplied to a wide range of industries, Usage Temperature 10 to 40°C

having the top share in each of the fuel tank, aluminum wheel, and drum inspections in Japan. environment Power supply 3φAC200V±10% 50/60Hz 300VA

Helium 0.4 [MPa] Rc 3/8 inch

Air 0.4 [MPa] Rc 3/8 inch

Nitrogen 0.2 [MPa] Rc 3/8 inch

Display Display 5 inch LCD touch panel

Language Selectable between Japanese and English

Inspection mode Helium test, master check (inspection based on reference leak)

Calibration External / Internal

Setting Threshold value, master check upper limit, lower limit, calibration leak rate, and others

Records Test result / Error records / Maintenance records / Accumulation counter

I / O I / O signals are 20 (External start / stop, Mode selection, Error signal etc.)

System example Data USB port (type A) USB Ver1.1 compliant

A commercially available USB memory stick or CF I/F is connected to store the settings, test histories, and error histories in it.

* This specification was envisaged by Yamaha Fine Technologies as a demo system, and the leak volume, seal pressure, and other parameters are not actual requirement specification values from customers.

* Products in this catalog are subject to change without notice, for the purpose of improvement to functionality and performance.

5 6

Page5

Helium Leak Tester

SOLUTION CASES

for Lithium-ion Battery Cases

We design and develop systems to suit the size of the intended workpiece, the leakage standards applied, and the Specifications

production facilities of the customer. We offer proposals for optimal testers to meet customer requirements. Application examples Lithium-ion Battery

We also develop systems capable of performing automatic inspection, by combining testing equipment with supply Workpiece size Design customized to suit the size of the

robots and other equipment. workpiece required by the customer.

Detectable leak rate 1.0 x 10-9Pa to 9.0 x 10-3Pa . m3/s

Detection method Vacuum chamber method

for Aluminum Wheels

Specifications

Application examples Aluminum wheels

Detection method Vacuum chamber method

Cycle time 20 to 30 seconds* (Per chamber)

* The time varies depending on the specifications, program,

and chamber section.

Workpiece size Up to 13” to 20” in diameter / up to 10” in width

Detectable leak rate 1.0 x 10-5Pa . m3/s

Helium charging pressure 0.4 to 0.2MPa (G)

Chamber internal pressure -0.1MPa (G)

Helium concentration 10% or less*

* As an option, a helium recycling unit can be installed.

for Car compressor Rotary indexing table type

An all-in-one automatic inspection system that carries out opera- Specifications

tions from vacuuming to helium charging, inspection, and helium Application examples Car compressor

recycling with one unit. Overwhelming cycle time is realized. Workpiece size W5400 mm x D3000 mm

for Fuel Tanks Detection method Vacuum chamber method

Cycle time 24 seconds/workpiece

Specifications Helium charging pressure 2.0MPa (G)

Helium concentration 100%

Application examples Fuel Tanks

Detection method Vacuum chamber method

Cycle time 30 seconds* (Standard specifications 2-chamber type)

* The time varies depending on the specifications, program,

and chamber section.

Workpiece size Max. 1200 x 800 x 250mm

Detectable leak rate 1.0 x 10-5Pa . m3/s

Helium charging pressure -0.09MPa (G)

Chamber internal pressure -0.1MPa (G)

Helium concentration 100%*

* As an option, a helium recycling unit can be installed.

for Car compressor Pallet feed type

An automatic inspection system that carries out operations from vacuuming to helium Specifications

for Drums charging, inspection, and helium recycling, each on a unit basis. This system is easy to Application examples Car compressor

Workpiece size W8200 x D3700 mm

Specifications be combined into an existing production line, which makes process management easy. Detection method Vacuum chamber method

Application examples Drums Cycle time 18 seconds/unit

Detection method Vacuum chamber method Helium charging pressure 1.7MPa (G)

Cycle time 4.7 seconds* (2-chamber type) Helium concentration 80%

* The time varies depending on the specifications, program,

and the number chambers.

Workpiece size JIS Z 1601 and International Standard type B

Volume: 200L

Detectable leak rate Leakage from a hole with a diameter of

0.03 mm or more

Helium charging pressure 0MPa (G)

Chamber internal pressure -0.1MPa (G)

Helium concentration 0.15% or less

7 8

Page6

Hydrogen Leak Detector

HYDROGEN LEAK DETECTION SYSTEM

Lineup

Yamaha Fine Tech's proprietary MEMS hydrogen sensor equipped, and a wide range of concentrations, from low to

high concentrations, detectable just with one unit. YHLD-100 Leak detected without fail and the

leak location identified just with one unit

A high resolution hydrogen leak detector that can detect low to high concentrations in the range from 0.5 ppm to Desktop Hydrogen

13,000 ppm with a single unit. Leak Detector With its wide dynamic range, concentrations of 0.5 ppm to 13,000 ppm are Quick measurement is realized by high-speed response and real measurement. A desktop type and a handy type are measured just with one unit. For a concentration of 13,000 ppm or more, a

available. warning is generated to stop the measurement process. The response speed

is 0.7 seconds or less. Measurement is performed quickly, safely, and widely.

Specifications

Detected concentration 0.5 to 13,000ppm

Detection method Sniffer method

Feature Inline support possible

Features of Hydrogen Leak Detector

Application examples

Yamaha's proprietary MEMS hydrogen Startup and return each in one second

sensor adopted. or less realized

Food and cosmetic Air intake Engine Air conditioner

High resolution detection is possible with Yamaha's propri- High throughput inspection realizes return after measure- product containers

etary MEMS sensor. Low (0.5 ppm) to high (13,000 ppm) ment quickly, making it possible to move to the next

concentrations are supported detection quickly.

YHLD-300 A portable and handy, small lightweight type,

Cordless Hydrogen detecting any location freely

Leak Detector This detector is a cordless version inheriting as-is the function of YHLD-100

MEMS hydrogen sensor element Rapid response (hydrogen 1,000 ppm) that detects concentrations in the range 0.5 ppm to 13,000 ppm. You can

perform detection freely while checking with the display at hand. The energy

Danger detected quickly to generate a warning Real measurement saving function using the acceleration sensor is provided.

Specifications

When the hydrogen concentration exceeds 13,000 ppm Even in an atmosphere with the

Detected concentration 0.5 to 13,000ppm

(=1.3%), a "DANGER" message is displayed, and a warning is same hydrogen concentration,

Detection method Sniffer method

generated to stop the measurement process. as far as hydrogen is present,

the detected value is displayed. Application examples

At high hydrogen concentra-

tions, neither linearity degrada-

tion nor output saturation

Food and cosmetic Air intake Engine Air conditioner

occurs. product containers

Wide dynamic range

YMHN-50 Solve gas supply instability in leak tests

What is Hydrogen Leak Detector? Hydrogen trace This equipment can generate a hydrogen-nitrogen mixed gas just by

gas generator supplying purified water. Capable of generating trace gases that comply with international standards in a safe and affordable manner.

A low-cost leak test using hydrogen Advantages of using hydrogen

Specifications

The hydrogen leak detector is a leak testing device for ●A leak test realized safety and at low cost because Producible hydrogen concentration Max. 3.5vol%

identifying the leak location by injecting hydrogen into the hydrogen is cheaper and safer than helium Trace gas discharge flow rate Max. 50NL/min

workpiece and holding the sensor to ● Safe when using a gas mixture of 5% H2 and 95% N2 Trace gas discharge pressure Max. 390kPa

the workpiece. Yamaha Fine Tech. because it is inflammable Water supply Purified water (electrical conductivity of 0.2 μS/cm or below)

introduces the sniffer method. ●Generation possible by using a hydrogen generating unit Application examples

●Cost reduction possible by properly using helium and

Leak Detector

hydrogen according to the workpiece because the

Sensor

Application hydrogen's detectable leak rate is a value between the

Gas for testing value for helium and the value for air Food and cosmetic Fuel tanks Aluminum wheels Battery cases

product containers

9 10