1/24ページ

Download

Different Thermocouple Types

The materials are made according to internationally accepted standards

as laid down in IEC 584 1,2 which is based on the international Practical

Temperature scale ITS 90. Operating temperature maxima are dependent

on the conductor thickness of the thermoelements. The thermocouple

types can be subdivided in 2 groups, base metal and rare (noble) metal:

Document Information

| Document Title | Thermocouple Selection Guide |

|---|---|

| Document Type | Handbook |

| Company | アールエスコンポーネンツ株式会社 (Documents List) |

Document Contents

Page1

Thermocouple

Selection Guide

uk.rs-online.com (UK)

www.rs-components.com (International)

Page2

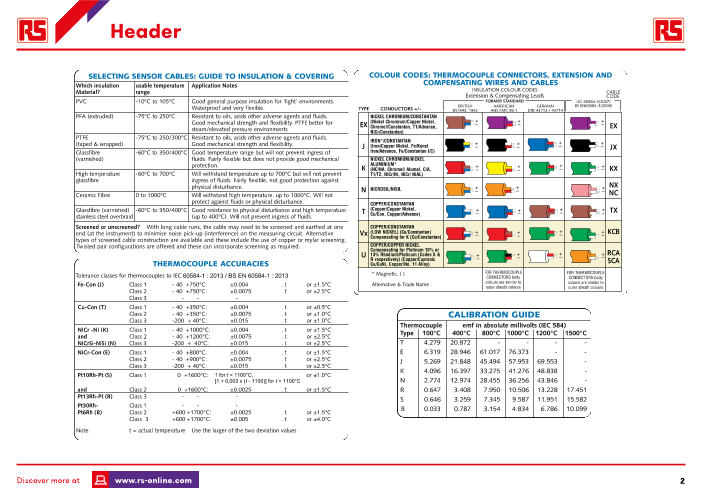

Header Thermocouple Thermometry - At a Glance

60584-1 : 2013 / BS EN 60584-1 : 2013

1 f o r t < 1 1 0 0 ° C ,

[1 + 0,003 x (t - 1100)] for t > 1100°C

Discover more at www.rs-online.com 2

Page3

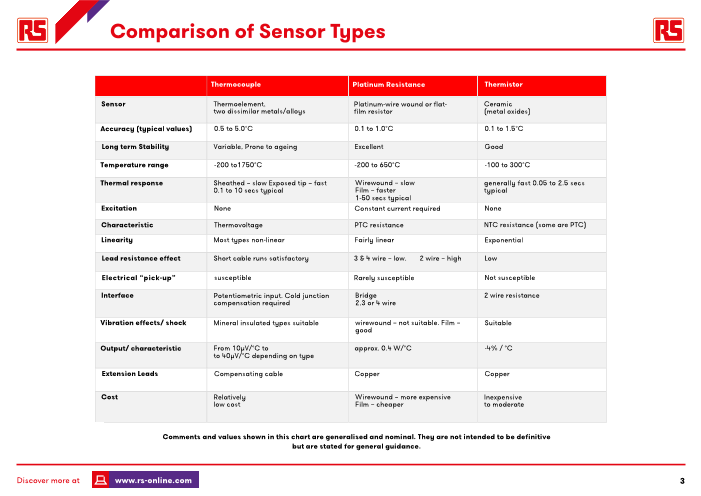

Comparison of Sensor Types

Thermocouple Platinum Resistance Thermistor

Sensor Thermoelement, Platinum-wire wound or flat- Ceramic

two dissimilar metals/alloys Tfhilmer mreosimsteotre r (metal oxides)

Accuracy (typical values) 0.5 to 5.0°C 0.1 to 1.0°C 0.1 to 1.5°C

Long term Stability Variable, Prone to ageing Excellent Good

Temperature range -200 to1750°C -200 to 650°C -100 to 300°C

Thermal response Sheathed – slow Exposed tip – fast Wirewound – slow generally fast 0.05 to 2.5 secs

0.1 to 10 secs typical Film – faster typical

1-50 secs typical

Excitation None Constant current required None

Characteristic Thermovoltage PTC resistance NTC resistance (some are PTC)

Linearity Most types non-linear Fairly linear Exponential

Lead resistance effect Short cable runs satisfactory 3 & 4 wire – low. 2 wire – high Low

Electrical “pick-up” susceptible Rarely susceptible Not susceptible

Interface Potentiometric input. Cold junction Bridge 2 wire resistance

compensation required 2,3 or 4 wire

Vibration effects/ shock Mineral insulated types suitable wirewound – not suitable. Film – Suitable

good

Output/ characteristic From 10µV/°C to approx. 0.4 W/°C -4% / °C

to 40µV/°C depending on type

Extension Leads Compensating cable Copper Copper

Cost Relatively Wirewound – more expensive Inexpensive

low cost Film – cheaper to moderate

Comments and values shown in this chart are generalised and nominal. They are not intended to be definitive

but are stated for general guidance.

Discover more at www.rs-online.com 3

Page4

Different Thermocouple Junctions

Sheathed Thermocouples – Measuring Junctions

Many alternative sheath materials are used to protect thermoelements, three alternative tip configurations are usually offered:

An exposed (measuring) junction is recommended for the measurement of flowing or static

non-corrosive gas temperature when the greatest sensitivity and quickest response is required.

An insulated junction is more suitable for corrosive media although the thermal response is

slower. In some applications where more than one thermocouple connects to the associated

instrumentation, insulation may be essential to avoid spurious signals occurring in the measuring

circuits.

An earthed (grounded) junction is also suitable for corrosive media and for high pressure

applications. It provides faster response than the insulated junction and protection not afforded by

the exposed junction.

Discover more at www.rs-online.com 4

Page5

Different Thermocouple Types

The materials are made according to internationally accepted standards Type T – Copper-Constantan: This thermocouple is used less frequently.

as laid down in IEC 584 1,2 which is based on the international Practical Its temperature range is limited to -200°C up to +350°C. It is however very

Temperature scale ITS 90. Operating temperature maxima are dependent useful in food, environmental and refrigeration applications. Tolerance

on the conductor thickness of the thermoelements. The thermocouple class is superior to other base metal types and close tolerance versions

types can be subdivided in 2 groups, base metal and rare (noble) metal: are readily obtainable. The e.m.f/temperature curve is quite non-linear

especially around 0°C and sensitivity is 42µV/°C.

-200°C up to 1200°C – These thermocouples use base metals

0°C up to +1600°C – Platinum-Rhodium (Noble metal)

Type K – Chromel-Alumel: The best known and dominant thermocouple Thermocouples

belonging to the group chromium-nickel aluminium is type K. Its

temperature range is extended (-200 up to 1100°C). Its e.m.f./ Type S – Platinum rhodium 10% Rh-Platinum: They are normally used

temperature curve is reasonably linear and its sensitivity is 41µV/°C in oxidising atmosphere up to 1600°C. Their sensitivity is between 6 and

12 µV/°C.

Type J – Iron-Constantan: Though in thermometry the conventional

type J is still popular it has less importance in Mineral Insulated form Type R – Platinum rhodium 13% Rh-Platinum: Similar version to type S

because of its limited temperature range, - 200C to +750°C. Type J is with a sensitivity between 6 and 14µV/°C.

mainly still in use based on the widespread applications of old

instruments calibrated for this type. Their sensitivity rises to 55µV/°C. Type B – Platinum rhodium 30% Rh-Platinum rhodium 6% Rh: It

allows measurements up to 1700°C. Very stable thermocouple but less

Type E – Chromel-Constantan: Due to its high sensitivity (68µV/°C) sensitive in the lower range. (Output is negligible at room temperature).

Chromel-Constantan is mainly used in the cryogenic low temperature

range (-200 up to +900°C). The fact that it is non magnetic could be a Historically these thermocouples have been the basis of high temperature

further advantage in some special applications. in spite of their high cost and their low thermoelectric power. Until the

launching of the Nicrosil-Nisil thermocouples, type N, they remained the

Type N – Nicrosil-Nisil: This thermocouple has very good thermoelectric sole option for good thermoelectric stability.

stability, which is superior to other base metal thermocouples and has

excellent resistance to high temperature oxidation.

The Nicrosil-Nisil thermocouple is ideally suited for accurate

measurements in air up to 1200°C. In vacuum or controlled atmosphere,

it can withstand temperatures in excess of 1200°C. Its sensitivity of

39µV/°C at 900°C is slightly lower than type K (41µV/°C).

Interchangeability tolerances are the same as for type K.

Discover more at www.rs-online.com 5

Page6

Immersion or Surface Temperature Measurement

Immersion Surface Temperature Measurement

Thermocouple assemblies are “tip” sensing devices which lends Although thermocouple assemblies are primarily tip sensing

them to both surface and immersion applications depending on devices, the use of protection tubes (sheaths) renders surface

their construction. However, immersion types must be used sensing impractical. Physically, the probe does not lend itself to

carefully to avoid errors due to stem conduction; this is heat flow to surface presentation and stem conduction would cause reading

or from the sheath and into or away from the process which can errors. If a thermocouple is to be used reliably for surface sensing,

result in a high or low reading respectively. A general rule is to it must be in either exposed, welded junction form with very small

immerse into the medium to a minimum of 4 times the outside thermal mass or be housed in a construction which permits true

diameter of the sheath; no quantitative data applies but care must surface contact whilst attaching to the surface.

be exercised in order to obtain meaningful results (e.g. have regard

for furnace wall thickness and such like).

The ideal immersion depth can be achieved in practice by moving

the probe into or out of the process medium incrementally; with Locating a thermocouple on a surface can be achieved in various

each adjustment, note any apparent change in indicated ways including the use of an adhesive patch, a washer and stud, a

temperature. The correct depth will result in no change in indicated magnet for ferrous metals and pipe clips. Examples of surface

temperature. sensing thermocouples are shown below:

Discover more at www.rs-online.com 6

Page7

Comparison of Sheath Materials

Sheath Material Max Continuous Notes Applications

Refractory Oxide 1750°C Good choice for rare metal thermocouples. Good resistance to Forging iron & steel. Incinerators carburizing and

recrystallised, e.g. chemical attack. Mechanically strong but severe thermal shock hardening in heat treatment. Continuous furnaces. Glass

Alumina Impervious should be avoided. Lehrs.

Silicon Carbide 1500°C Good level of protection even in severe conditions. Good resistance Forging iron & steel. Incinerators Billet heating, slab

(Porous) to reasonable levels of thermal shock. Mechanically strong when heating, butt welding. Soaking pits ceramic dryers.

thick wall is specified but becomes brittle when aged. Unsuitable for

oxidising atmospheres but resists fluxes.

Impervious 1600°C Good choice for rare metal thermocouples under severe conditions. Forging iron & steel. Incinerators. Heat treatment. Glass

Mullite Resists Sulphurous and carbonaceous atmospheres. Good resistance to flues. Continuous furnaces.

thermal shock should be avoided.

Mild Steel (cold drawn 600°C Good physical protection but prone to rapid corrosion. Annealing up to 500°C. Hardening pre-heaters. Baking

seamless) ovens.

Stainless steel 25/20 1150°C Resists corrosion even at elevated temperature. Can be used in Heat treatment annealing, flues, many chemical processes.

Sulphurous atmospheres. Vitreous enamelling. Corrosion resistant alternative to mild

steel.

Inconel 600/800* 1200°C Nickel-Chromium-Iron alloy which extends the properties of stainless Annealing, carburizing, hardening. Iron and steel hot blast.

steel 25/20 to higher operating temperatures. Excellent in Sulphur Open hearth flue & stack. Waste heat boilers. Billet

free atmospheres; superior corrosion resistance at higher heating, slab heating. Continuous furnaces. Soaking pits.

temperatures. Good mechanical strength. Cement exit flues & kilns. Vitreous enamelling. Glass flues

and checkers. Gas superheaters. Incinerators up to

1000°C. Highly sulphurous atmospheres should be avoided

above 800°C.

Chrome Iron 1100°C Suitable for very adverse environments. Good mechanical strength. Annealing, carburizing, hardening. Iron & steel hot blast.

Resists severely corrosive and sulphurous atmospheres. Open hearth flue and stack. Waste heat boilers. Billet

heating, slab heating. Continuous furnaces. Soaking pits.

Cement exit flues & kilns. Vitreous enamelling. Glass flues

and checkers. Gas superheaters. Incinerators up to 1000°C.

Nicrobell* 1300°C Highly stable in vacuum and oxidising atmospheres. Corrosion As Inconel plus excellent choice for vacuum furnaces and

resistance generally superior to stainless steels. Can be used in flues.

Sulphurous atmospheres at reduced temperatures. High operating

temperature.

* Tradenames

Sheath materials range from mild and stainless steels to refractory oxides (ceramics, so called) and a variety of exotic materials including rare

metals. The choice of sheath must take account of operating temperature, media characteristics, durability and other considerations including

the material relationship to the type of sensor.

Discover more at www.rs-online.com 7

Page8

Thermocouple or RTD Sensor

Choosing between a Thermocouple and RTD Sensor

Thermocouples comprise a thermoelement which is a junction of two specifield, dissimilar alloys and a suitable two wire extension lead. The junction is a

short circuit only, the EMF is generated in the temperature gradient between the hot junction and the ‘cold’ or reference junction. This characteristic is

reasonably stable and repeatable and allows for a family of alternative thermocouple types (e.g. J,K,T,N) to be used.

The alternative types are defined by the nature of the alloys used in the thermoelements and each type displays a different thermal EMF characteristic.

Resistance Thermometers utilise a high precision sensing resistor, usually platinum, the resistance value of which increases with temperature. The

dominant standard adopted internationally is the Pt100 which has a resistance value of 100.0 Ohms at 0°C and a change of 38.50 Ohms between 0 and

100°C (the fundamental interval).

The platinum sensing resistor is highly stable and allows high accuracy temperature sensing. Resistance thermometer sensing resistors are 2 wire devices

but the 2 wires will usually be extended in a 3 or 4 wire configuration according to the application, the associated instrumentation and accuracy

requirements.

Thermocouples are, generally: RTD’s are, generally:

• Relatively inexpensive • More expensive

• More rugged • More accurate

• Less accurate • Highly stable (if used carefully)

• More prone to drift • Capable of better resolution

• More sensitive • Restricted in their range of temperature

• Tip sensing • Stem, not tip sensitive

• Available in smaller diameters • Rarely available in small diameters (below 3mm)

• Available with a wider temperature range

• More versatile

In both cases, the choice of thermocouple or RTD must be made to

match the instrumentation and to suit the application.

Discover more at www.rs-online.com 8

Page9

Advantages of Mineral Insulated Thermocouples

M.I. (Mineral Insulated) cable is used to insulate thermocouple wires from

one another and from the metal sheath that surrounds them. MI Cable

has two (or four when duplex) thermocouple wires running down the

middle of the tube. The tube is then filled with magnesium oxide powder

and compacted to ensure the wires are properly insulated and

separated. MI cable helps to protect the thermocouple wire from

corrosion and electrical interference.

* Long stable life

* Small size

* Rapid response

* Great mechanical strength

* Water, oil & gas tight

* Ease of installation

* Adaptability

* High insulation resistance

* Low cost

Discover more at www.rs-online.com 9

Page10

Mineral Insulated Thermocouples

A Plug Termination B Plain Pot with Tails Termination C Threaded Pot with Tails Termination

Image Type Probe Dia. Probe Sheath Junction Termination Temperature RS Order Allied Code

(mm) Length(mm) Range Code

A K 0.5 150 310SS Insulated Miniature Plug -40°C to +750°C 444-1275 70644212

A K 1.0 250 310SS Insulated Miniature Plug -40°C to +750°C 787-7765 70653223

A K 3.0 500 310SS Insulated Miniature Plug -40°C to +1100°C 787-7784 70653229

Image Type Probe Dia. Probe Sheath Cable Type Cable Cable Temperature RS Order Allied Code

(mm) Length(mm) Length Colour Range Code

B K 1.5 250 310SS PFA 7/0.2mm 1 metre Green -40°C to +1100°C 397-1258 70643844

B K 3.0 500 310SS PFA 7/0.2mm 1 metre Green -40°C to +1100°C 787-7734 70653214

B K 6.0 1000 310SS PFA 7/0.2mm 1 metre Green -40°C to +1100°C 787-7753 70653219

B J 1.5 150 321SS PFA 7/0.2mm 1 metre Black -40°C to +1100°C 455-4270 70644364

B J 3.0 250 321SS PFA 7/0.2mm 1 metre Black -40°C to +1100°C 455-4309 70644367

B J 6.0 250 321SS PFA 7/0.2mm 1 metre Black -40°C to +1100°C 455-4321 70644369

Image Type Probe Dia. Probe Sheath Cable Type Cable Cable Colour Temperature RS Order Allied

(mm) Length(mm) Length Range Code Code

C K 1.5 150 310SS PFA T/T 7/0.2mm 100mm Green/White -40°C to +1100°C 228-7445 70641663

C K 3.0 250 310SS PFA T/T 7/0.2mm 100mm Green/White -40°C to +1100°C 228-7489 70641666

C K 4.5 500 310SS PFA T/T 7/0.2mm 100mm Green/White -40°C to +1100°C 787-7854 70653314

C K 6.0 1000 310SS PFA T/T 7/0.2mm 100mm Green/White -40°C to +1100°C 219-4422 70641617

This is just a small selection of Mineral Insulated Thermocouples offered by RS / Allied

Discover more at www.rs-online.com 10

Page11

Mineral Insulated Thermocouples

A Thermocouples with Compact KNS Terminal Head B Thermocouple with Ceramic Plug Termination

Image Type Probe Length Sheath Head Block Gland Temperature RS Order Allied

Dia. (mm) Type Range Code Code

(mm)

A K 6.0 100 310SS KNS 2-way ceramic M16 x 1.5mm Plated brass -40°C to +1100°C 787-7804 70653235

A K 6.0 150 310SS KNS 2-way ceramic M16 x 1.5mm Plated brass -40°C to +1100°C 787-7813 70653302

A K 6.0 200 310SS KNS 2-way ceramic M16 x 1.5mm Plated brass -40°C to +1100°C 787-7816 70653303

A K 6.0 250 310SS KNS 2-way ceramic M16 x 1.5mm Plated brass -40°C to +1100°C 787-7810 70653301

A K 6.0 300 310SS KNS 2-way ceramic M16 x 1.5mm Plated brass -40°C to +1100°C 787-7829 70653306

Image Type Probe Length Sheath Head Termination Probe Plug RS Order Allied

Dia. (mm) Type Temperature Temperatu Code Code

(mm) Range re Range

B K 1.0 150 310SS KNS Miniature ceramic plug + Socket -40°C to +1100°C 650°C 872-2654 -

B K 1.5 300 310SS KNS Miniature ceramic plug + Socket -40°C to +1100°C 650°C 872-2660 -

B K 3.0 150 310SS KNS Miniature ceramic plug + Socket -40°C to +1100°C 650°C 872-2679 -

B K 3.0 300 310SS KNS Miniature ceramic plug + Socket -40°C to +1100°C 650°C 872-2672 -

This is just a small selection of Mineral Insulated Thermocouples offered by RS / Allied

Discover more at www.rs-online.com 11

Page12

Fabricated and Specialist Thermocouples

A Magnet Thermocouple B Button Magnet C Magnetic Strip

Image Type Length Cable Termination Temperature RS Order Allied Code

Range Code

A K 1 Metre PFA Teflon® insulated with stainless steel over-braid Miniature Plug -50°C to + 250°C 131-4735 -

A K 2 Metre PFA Teflon® insulated with stainless steel over-braid Miniature Plug -50°C to + 250°C 762-1115 70651739

Image Type Length Cable Termination Temperature RS Order Allied Code

Range Code

B K 1 Metre PFA Teflon® insulated twin twisted Miniature Plug -50°C to + 250°C 236-4255 70641755

B K 2 Metre PFA Teflon® insulated twin twisted Miniature Plug -50°C to + 250°C 131-4736 -

Image Type Length Cable Termination Temperature RS Order Allied Code

Range Code

C K 1 Metre PFA Teflon® insulated twin twisted Miniature Plug -50°C to +100°C 131-4737 -

C K 2 Metre PFA Teflon® insulated twin twisted Miniature Plug -50°C to +100°C 219-4545 70641628

This is just a small selection of Fabricated and Specialist Thermocouples offered by RS / Allied

Discover more at www.rs-online.com 12

Page13

Fabricated and Specialist Thermocouples

A Washer Thermocouple B Nozzle Thermocouple C Leaf Thermocouple

Image Type Length Cable Termination Temperature RS Order Allied Code

Range Code

A K 2 Metre Glassfibre insulated, stainless steel over braid Standard Plug -60°C to 350°C 131-4761 -

A J 2 Metre Glassfibre insulated, stainless steel over braid Standard Plug -60°C to 350°C 131-4744 -

Image Type Length Cable Termination Temperature RS Order Allied Code

Range Code

B K 2 Metre Glassfibre insulated, stainless steel over braid Standard Plug -60°C to 350°C 131-4745 -

Image Type Length Cable Termination Temperature RS Order Allied Code

Range Code

C K 2 Metre Glassfibre insulated, stainless steel over braid Standard Plug -60°C to 350°C 131-4746 -

This is just a small selection of Fabricated and Specialist Thermocouples offered by RS / Allied

Discover more at www.rs-online.com 13

Page14

Fabricated and Specialist Thermocouples

A Bolt Thermocouple B Bayonet Thermocouple C Silicone Rubber Patch

Thermocouple

Image Type Thread Thread Cable Cable Termination Temperature RS Order Allied

Pitch Length Length Range Code Code

A K M8 x 1mm 13mm 2 Metre Glassfibre stainless steel over braided Tails Up to +250°C 872-2581 -

A K M10 x 1mm 25mm 2 Metre Glassfibre stainless steel over braided Tails Up to +250°C 872-2597 -

A K M12 x 1mm 13mm 2 Metre Glassfibre stainless steel over braided Tails Up to +250°C 872-2607 -

A J M8 x 1mm 13mm 2 Metre Glassfibre stainless steel over braided Tails Up to +250°C 872-2569 -

A J M10 x 1mm 25mm 2 Metre Glassfibre stainless steel over braided Tails Up to +250°C 872-2575 -

A J M12 x 1mm 13mm 2 Metre Glassfibre stainless steel over braided Tails Up to +250°C 872-2584 -

Image Type Length Cable Spring Termination Temperature RS Order Allied

Range Code Code

B K 2 Metre Glassfibre insulated, stainless steel 170mm spring, Standard Plug -60°C to 350°C 131-4743 -

over braid adjustable cap

B J 3 Metre Glassfibre insulated, stainless steel 170mm spring, Standard Plug -60°C to 350°C 131-4764 -

over braid adjustable cap

Image Type Length Cable Patch (mm) Termination Temperature RS Order Allied

Range Code Code

C K 1 Metre Teflon® insulated, twin twist 40x13x5 (LxWxH) Tails -50°C to +150°C 290-5036 70642886

This is just a small selection of Fabricated and Specialist Thermocouples offered by RS / Allied

Discover more at www.rs-online.com 14

Page15

Thermocouple Extension Leads with Miniature or Standard Thermocouple Connectors

A PVC Extension Lead with Miniature B PVC Extension Lead with C Glassfibre Extension Lead with Connectors Standard Connectors Miniature Connectors

Image Type Length Cable Termination Cable RS Order Allied Code

Temperature Code

Range

A K 2 Metre PVC Insulated, 7/0.2mm Miniature Plug + Socket -10°C to 105°C 768-6581 70652090

A K 5 Metre PVC Insulated, 7/0.2mm Miniature Plug + Socket -10°C to 105°C 768-6585 70652091

Image Type Length Cable Termination Cable RS Order Allied Code

Temperature Code

Range

B K 2 Metre PVC Insulated, 7/0.2mm Standard Plug + Socket -10°C to 105°C 768-6626 70652103

B K 5 Metre PVC Insulated, 7/0.2mm Standard Plug + Socket -10°C to 105°C 768-6620 70652101

Image Type Length Cable Termination Cable RS Order Allied Code

Temperature Code

Range

C K 2 Metre Glassfibre Insulated with SSOB, 7/0.2mm Miniature Plug + Socket -60°C to 350°C 779-9678 70652776

C K 5 Metre Glassfibre Insulated with SSOB, 7/0.2mm Miniature Plug + Socket -60°C to 350°C 779-9671 70652774

This is just a small selection of Extension Leads offered by RS / Allied

Discover more at www.rs-online.com 15

Page16

Melt Bolt Thermocouple

A 1/2"UNF-20 Melt Bolt Thermocouple with B Twist Melt Bolt Thermocouple with Type ‘J’ Thermocouple Plug Standard Thermocouple Plug

Image Type Thread Bolt Length Tip Immersion Length Temperature Termination RS Order Code Allied

Range Code

A J 1/2"UNF-20 76mm (3” inch) 5.0mm (3.0mm diameter) Up to +500°C Standard plug 219-4731 70641639

A J 1/2"UNF-20 152mm (6” inch) 5.0mm (3.0mm diameter) Up to +500°C Standard plug 353-4578 70642070

Image Type Thread Bolt Length Tip Immersion Length Temperature Termination RS Order Code Allied

Range Code

B J 1/2"UNF-20 152mm (6” inch) 20.0mm Up to +400°C Standard plug 872-2783 -

B K 1/2"UNF-20 152mm (6” inch) 20.0mm Up to +400°C Standard plug 872-2792 -

Discover more at www.rs-online.com 16

Page17

PFA Exposed Junction Thermocouples

A Type K PFA Exposed Junction with B Type J PFA Exposed Junction with Type T PFA Exposed Junction

Miniature Plug Miniature Plug C with Miniature Plug

Image Type Conductors RS Code Allied Code RS Code Allied RS Code Allied Code RS Code Allied Code

Code

1 Metre 2 Metre 5 Metre 10 Metre

A K 1/0.315mm 123-6318 - 123-6319 - 762-1118 70651740 804-7886 70654802

A K 7/0.2mm 123-6320 - 123-6321 - 762-1112 70651738 804-7880 70654800

A K 1/0.2mm 123-6322 - 123-6323 - 804-7899 70654805 123-6324 -

Image Type Conductors RS Code Allied Code RS Code Allied RS Code Allied Code RS Code Allied Code

Code

1 Metre 2 Metre 5 Metre 10 Metre

B J 1/0.2mm 123-6325 - 123-6326 - 804-7883 70654801 123-6327 -

Image Type Conductors RS Code Allied Code RS Code Allied RS Code Allied Code RS Code Allied Code

Code

1 Metre 2 Metre 5 Metre 10 Metre

C T 1/0.315mm 123-6328 - 123-6329 - 762-1121 70651741 804-7892 70654803

C T 7/0.2mm 123-6330 - 123-6331 - 762-1124 70651742 804-7896 70654804

C T 1/0.2mm 123-6332 - 123-6333 - 804-7906 70654807 123-6334 -

This is just a small selection of Exposed Junctions offered by RS / Allied

Discover more at www.rs-online.com 17

Page18

PTFE Exposed Junction Thermocouples

Type K PTFE Exposed Junction with B Type J PTFE Exposed Junction Type T PTFE Exposed Junction A C

Miniature Plug with Miniature Plug with Miniature Plug

Image Type Conductors RS Code Allied Code RS Code Allied RS Code Allied Code RS Code Allied Code

Code

1 Metre 2 Metre 5 Metre 10 Metre

A K 1/0.2mm 363-0250 70643600 110-4482 - 123-6306 - 123-6307 -

Image Type Conductors RS Code Allied Code RS Code Allied RS Code Allied Code RS Code Allied Code

Code

1 Metre 2 Metre 5 Metre 10 Metre

B J 1/0.2mm 363-0244 70643599 123-6308 - 123-6309 - 123-6310 -

Image Type Conductors RS Code Allied Code RS Code Allied RS Code Allied Code RS Code Allied Code

Code

1 Metre 2 Metre 5 Metre 10 Metre

C T 1/0.2mm 363-0266 70643601 123-6311 - 123-6312 - 123-6313 -

This is just a small selection of Exposed Junctions offered by RS / Allied

Discover more at www.rs-online.com 18

Page19

Fine Gauge PFA Exposed Junction Thermocouples

A Type K PFA Fine Gauge Exposed B Type T PFA Fine Gauge Exposed

Junction with Miniature Plug Junction with Miniature Plug

Image Type Conductors RS Code Allied Code RS Code Allied Code RS Code Allied Code

0.5 Metre 1 Metre 2 Metre

A K 1/0.076mm 804-7987 70654832 804-7981 70654830 804-7990 70654833

Image Type Conductors RS Code Allied Code RS Code Allied Code RS Code Allied Code

0.5 Metre 1 Metre 2 Metre

B T 1/0.076mm 804-7993 70654834 804-7997 70654835 804-8000 70654836

This is just a small selection of Exposed Junctions offered by RS / Allied

Discover more at www.rs-online.com 19

Page20

PFA Exposed Junction Thermocouples with a Fitted Cable Tidy

PFA Twin Twist Exposed Junction with PFA Flat Pair Exposed Junction with

A

Miniature Plug + Cable Tidy

B Miniature Plug + Cable Tidy

Image Type Cable RS Code Allied Code RS Code Allied Code

1 Metre 2 Metre

A K PFA Twin Twist 110-4463 - 110-4467 -

A T PFA Twin Twist 110-4465 - 110-4469 -

Image Type Cable RS Code Allied Code RS Code Allied Code

1 Metre 2 Metre

B K PFA Flat Pair 110-4464 - 110-4468 -

B T PFA Flat Pair 110-4466 - 110-4470 -

This is just a small selection of Exposed Junctions offered by RS / Allied

Discover more at www.rs-online.com 20